Encoder zero-crossing detecting device and detecting method

A zero-point detection and encoder technology, applied in the direction of the instrument, can solve the problems of loose coupling, no zero-point detection device, angular phase deviation or running, etc., achieve automatic zero point position, convenient installation and debugging, and work phase Control the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

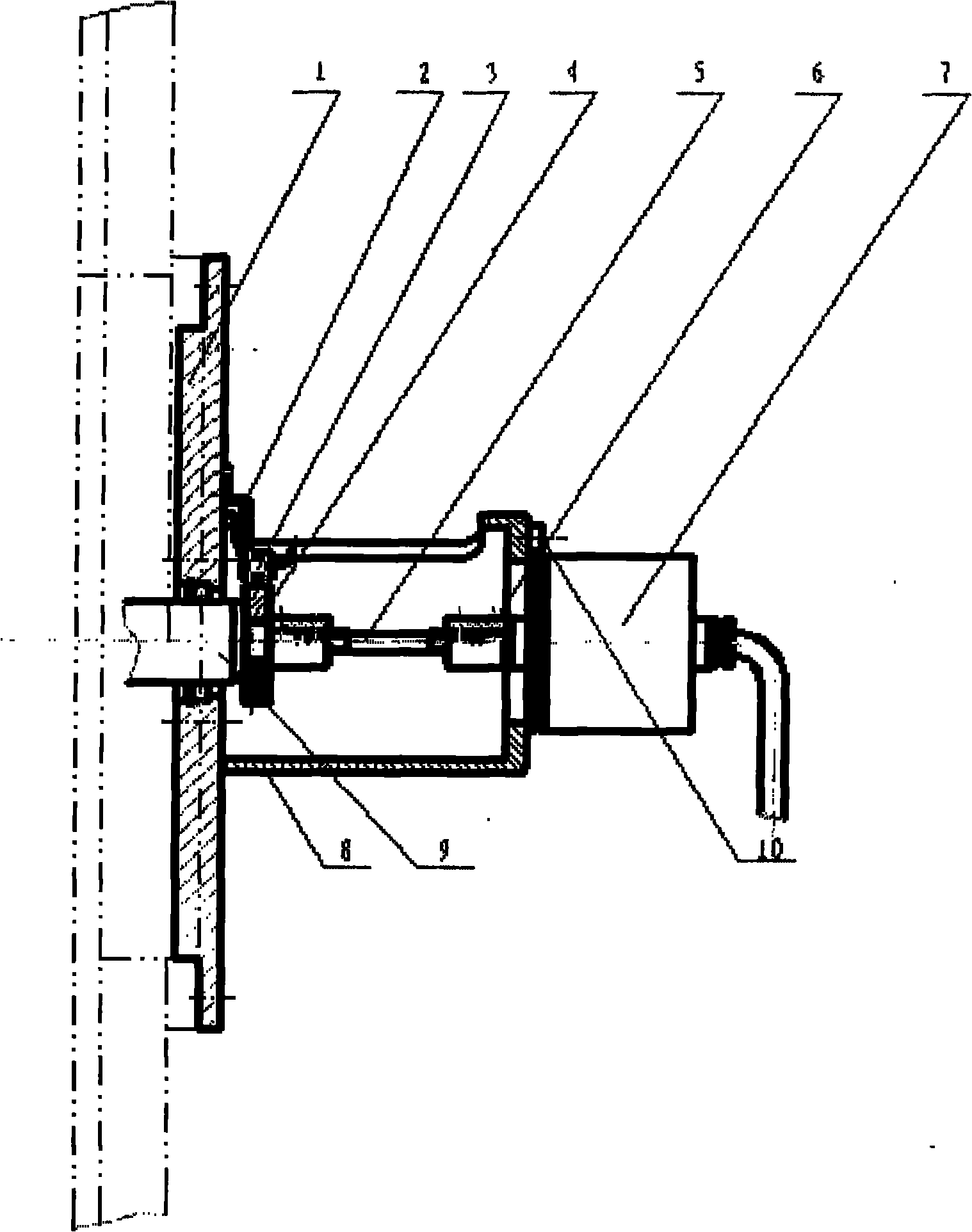

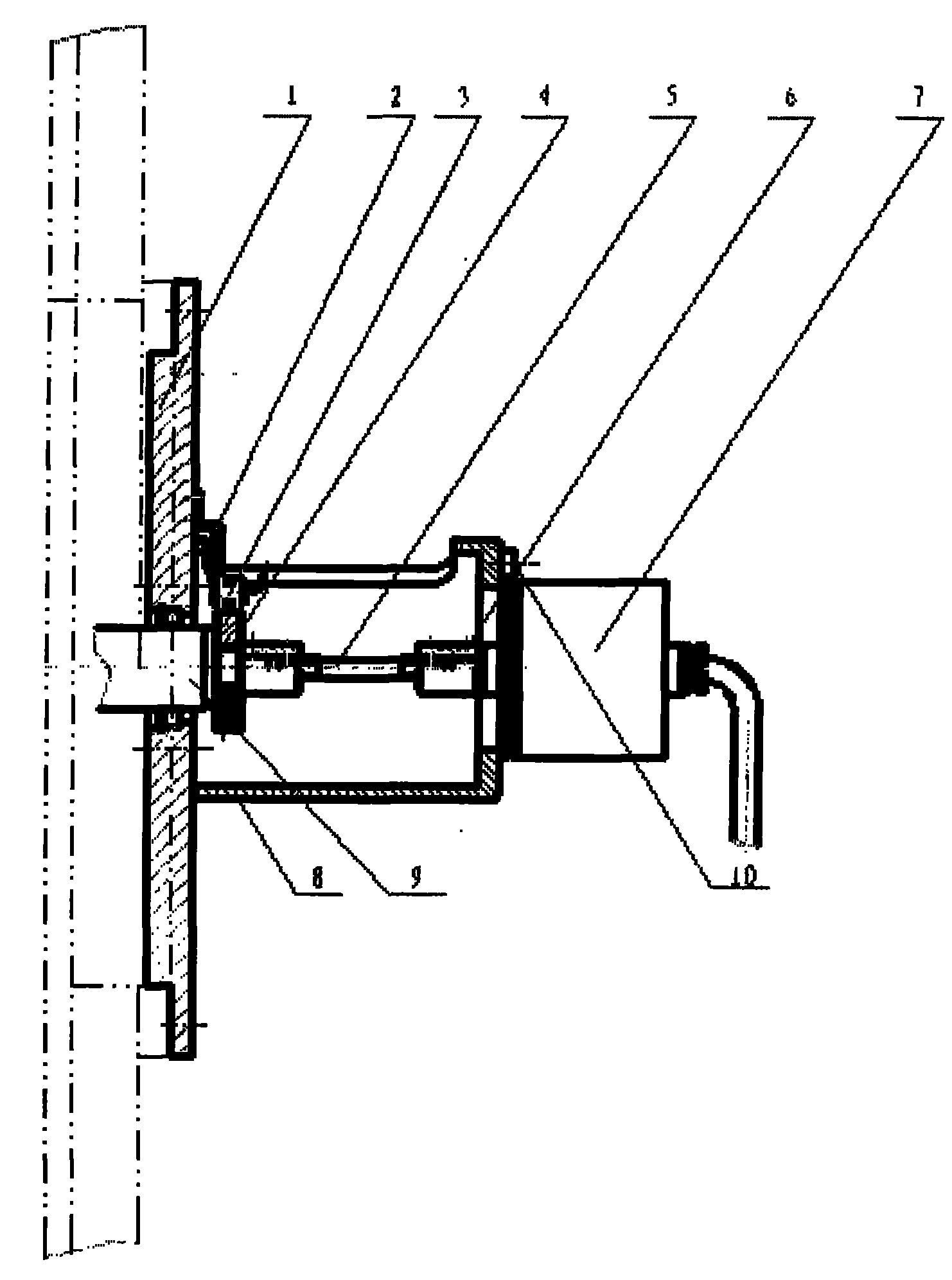

[0013] 1, an encoder zero point detection device of the present invention includes an encoder connecting flange 1, a sensor bracket 2, a detection sensor 3, a detection cam 4, a connecting shaft 5, a shaft coupling 6, a rotary encoder 7, an encoder Device connection seat 8, output shaft 9, fixed pressure plate 10; one end of the detection cam 4 is connected with the output shaft 9, and the detection sensor 3 used to detect the cam phase is arranged on the outside of the detection cam 4, and the sensor passes through the sensor bracket 2 and The encoder connection flange 1 is fixed on the machine body, the other end of the detection cam 4 is connected with the rotary encoder 7 through the connecting shaft 5 and the coupling 6, and the encoder is fixed on the encoder through the fixed pressure plate 10 and the encoder connection seat 8. The device is connected to flange 1.

[0014] A kind of detection method based on encoder zero detection device of the present invention compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com