Intelligent airless spray gun for spraying semi-enclosed space

An airless spray gun, semi-closed technology, applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of poor spraying quality, poor applicability, inconvenient disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

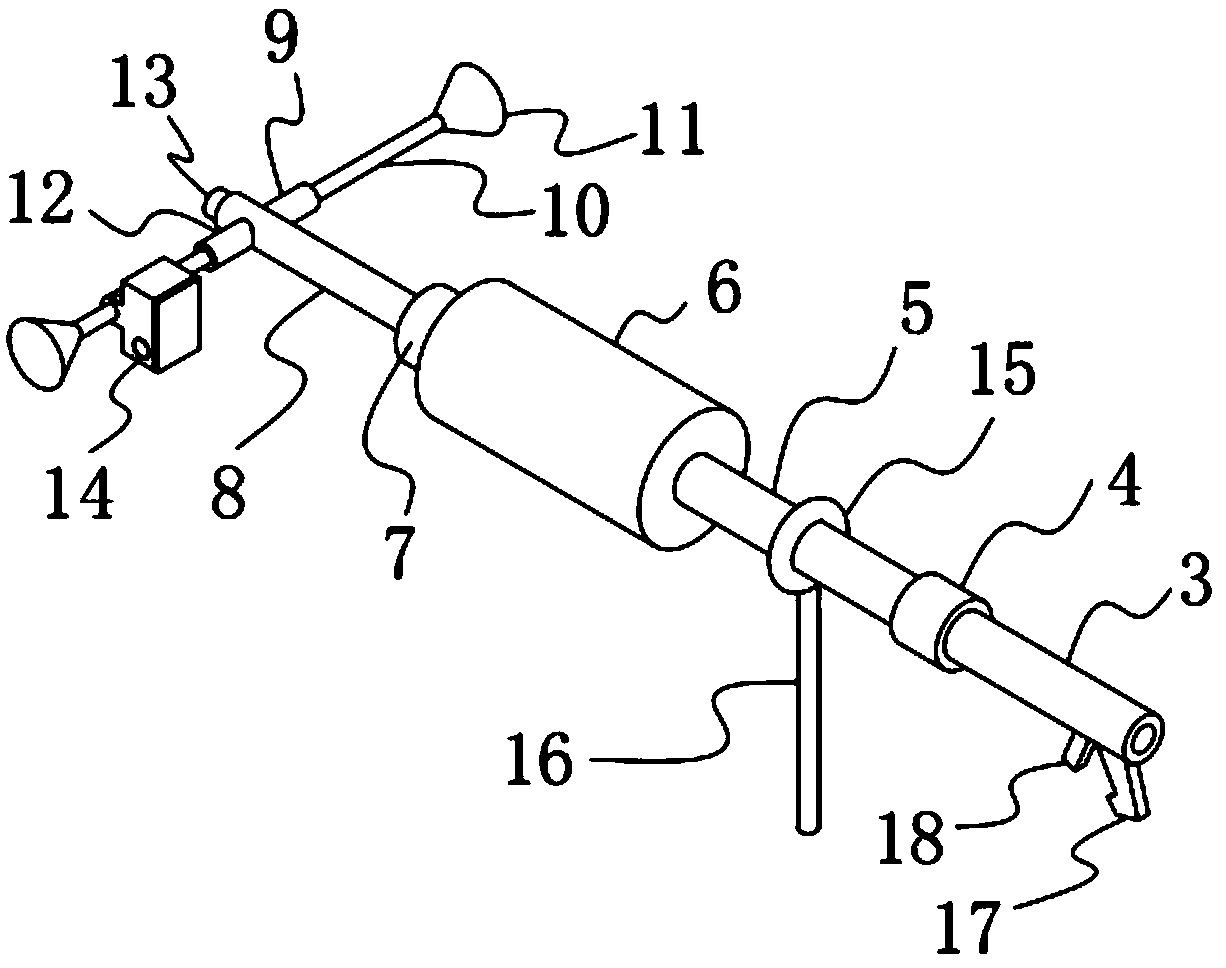

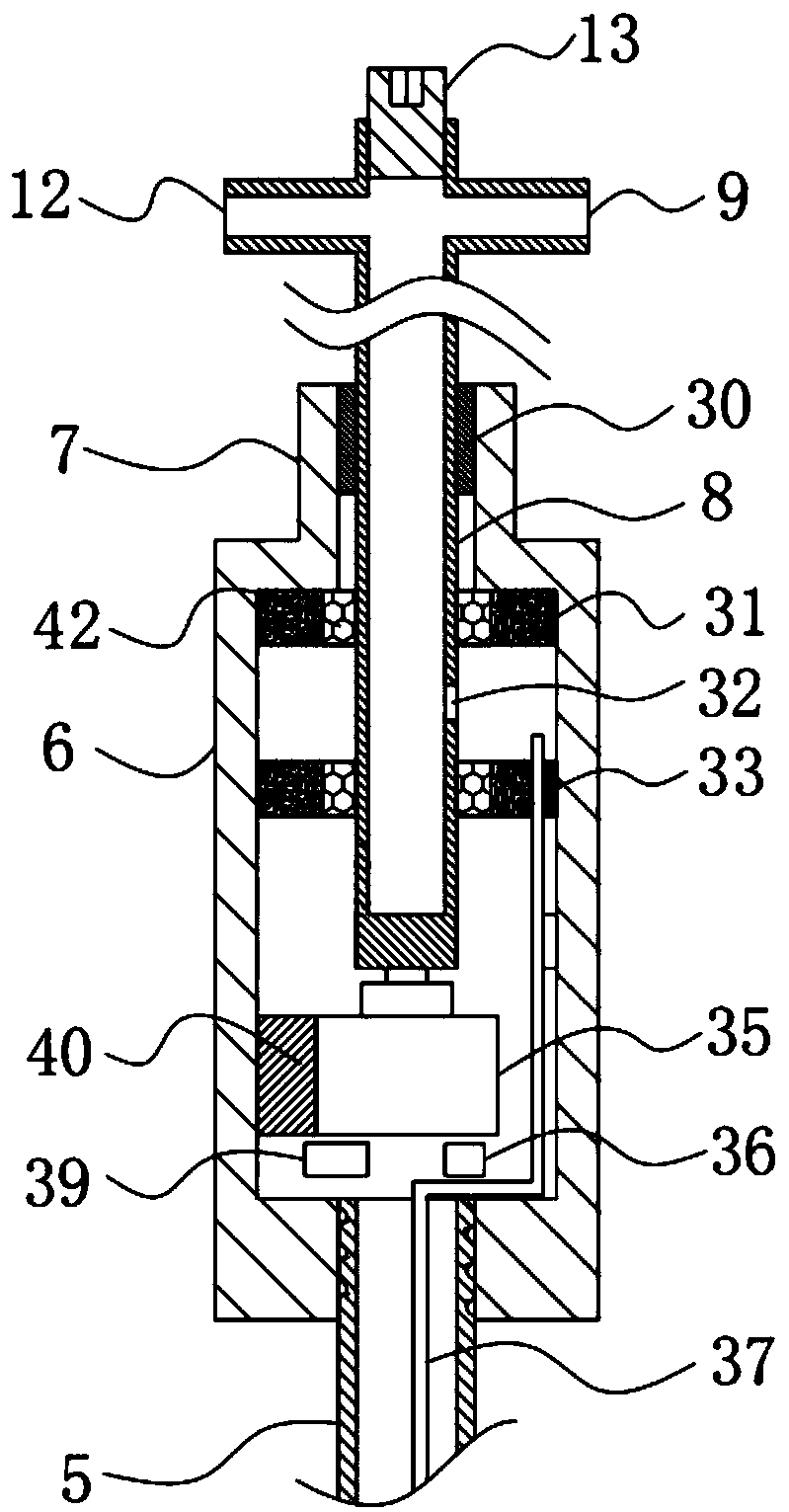

[0059] A smart airless spray gun for semi-enclosed space spraying, such as figure 1 and 5 As shown, it includes a spraying part 1, and the spraying part 1 includes a gun barrel 3, a connecting pipe 5, a cylindrical housing 6 and a hollow rotating shaft 8, and one end of the gun barrel 3 is integrally provided with a cylindrical connector 4, One end of the connecting pipe 5 is screwed inside the cylindrical connector 4, and the other end of the connecting pipe 5 is screwed inside one end of the cylindrical housing 6. The other end of the housing 6 is welded with a fixed sleeve 7, the hollow rotating shaft 8 is fixedly installed inside the fixed sleeve 7 through a rolling bearing 30, and one end of the hollow rotating shaft 8 extends to the fixed sleeve 7, and the other end of the hollow rotating shaft 8 extends to the inside of the cylindrical housing 6, and one end of the hollow rotating shaft 8 outside the fixed sleeve 7 is welded with a first sleeve in a symmetrical manner....

Embodiment 2

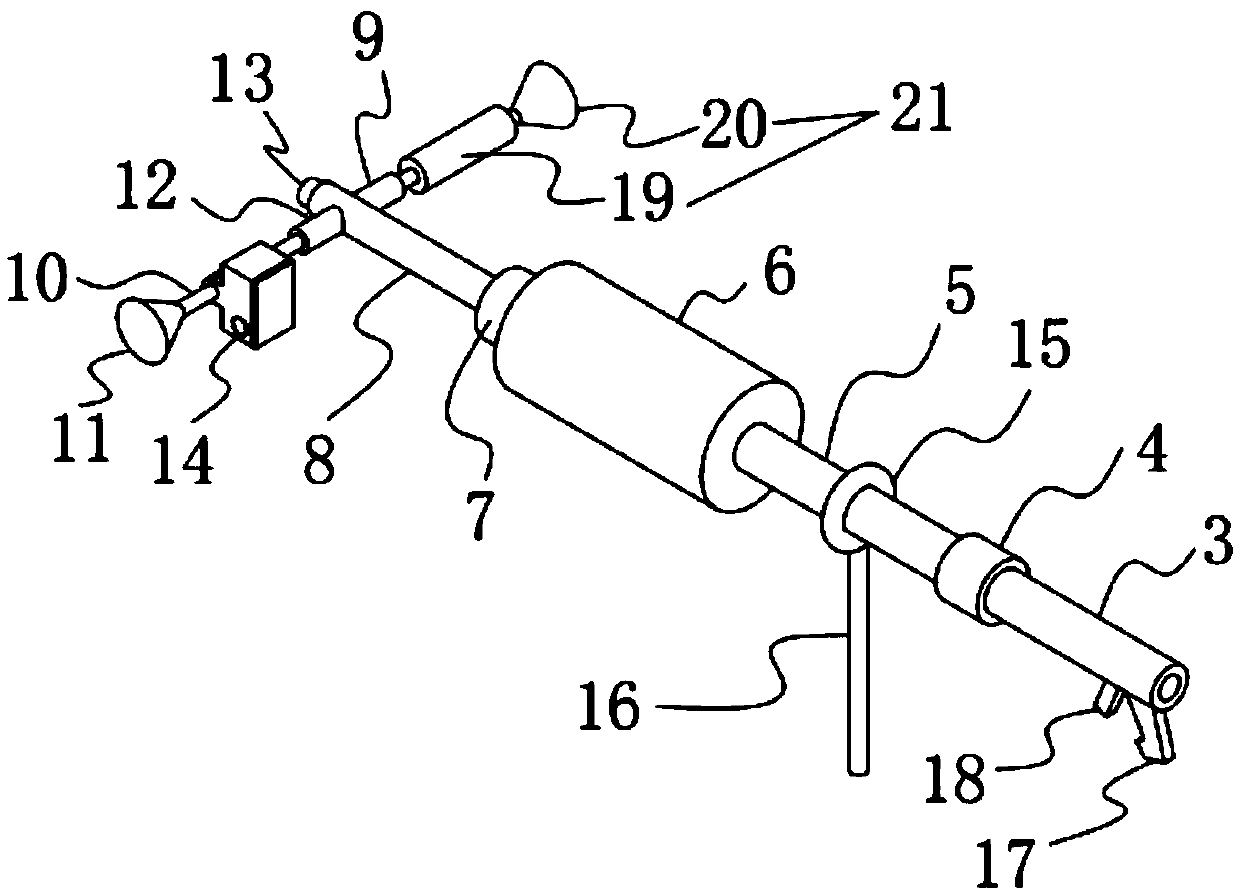

[0074] A smart airless spray gun for semi-enclosed space spraying, such as image 3 and 5 As shown, it includes a spraying part 1, and the spraying part 1 includes a gun barrel 3, a connecting pipe 5, a cylindrical housing 6 and a hollow rotating shaft 8, and one end of the gun barrel 3 is integrally provided with a cylindrical connector 4, One end of the connecting pipe 5 is screwed inside the cylindrical connector 4, and the other end of the connecting pipe 5 is screwed inside one end of the cylindrical housing 6. The other end of the housing 6 is welded with a fixed sleeve 7, the hollow rotating shaft 8 is fixedly installed inside the fixed sleeve 7 through a rolling bearing 30, and one end of the hollow rotating shaft 8 extends to the fixed sleeve 7, and the other end of the hollow rotating shaft 8 extends to the inside of the cylindrical housing 6, and one end of the hollow rotating shaft 8 outside the fixed sleeve 7 is welded with a first sleeve in a symmetrical manner....

Embodiment 3

[0091] A smart airless spray gun for semi-enclosed space spraying, such as Figure 5 , 6 As shown in and 7, it includes a spraying part 1, and the spraying part 1 includes a gun barrel 3, a connecting pipe 5, a cylindrical housing 6 and a hollow rotating shaft 8, and one end of the gun barrel 3 is integrally provided with a cylindrical connector 4. One end of the connecting pipe 5 is screwed inside the cylindrical connector 4, and the other end of the connecting pipe 5 is screwed inside one end of the cylindrical housing 6. The circular The other end of the cylindrical housing 6 is welded with a fixed sleeve 7, the hollow rotating shaft 8 is fixedly installed inside the fixed sleeve 7 through a rolling bearing 30, and one end of the hollow rotating shaft 8 extends to the fixed sleeve 7. The outside of the sleeve 7, and the other end of the hollow rotating shaft 8 extends to the inside of the cylindrical housing 6, and one end of the hollow rotating shaft 8 located outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com