Connector for optical sensor and substrate, method for manufacturing optical sensor

A technology of a light sensor and a manufacturing method, which are applied in the input/output process of instruments, data processing, electrical digital data processing, etc., can solve difficult control, the light sensor cannot detect the indicator, and the cost of the optical touch system is rising. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

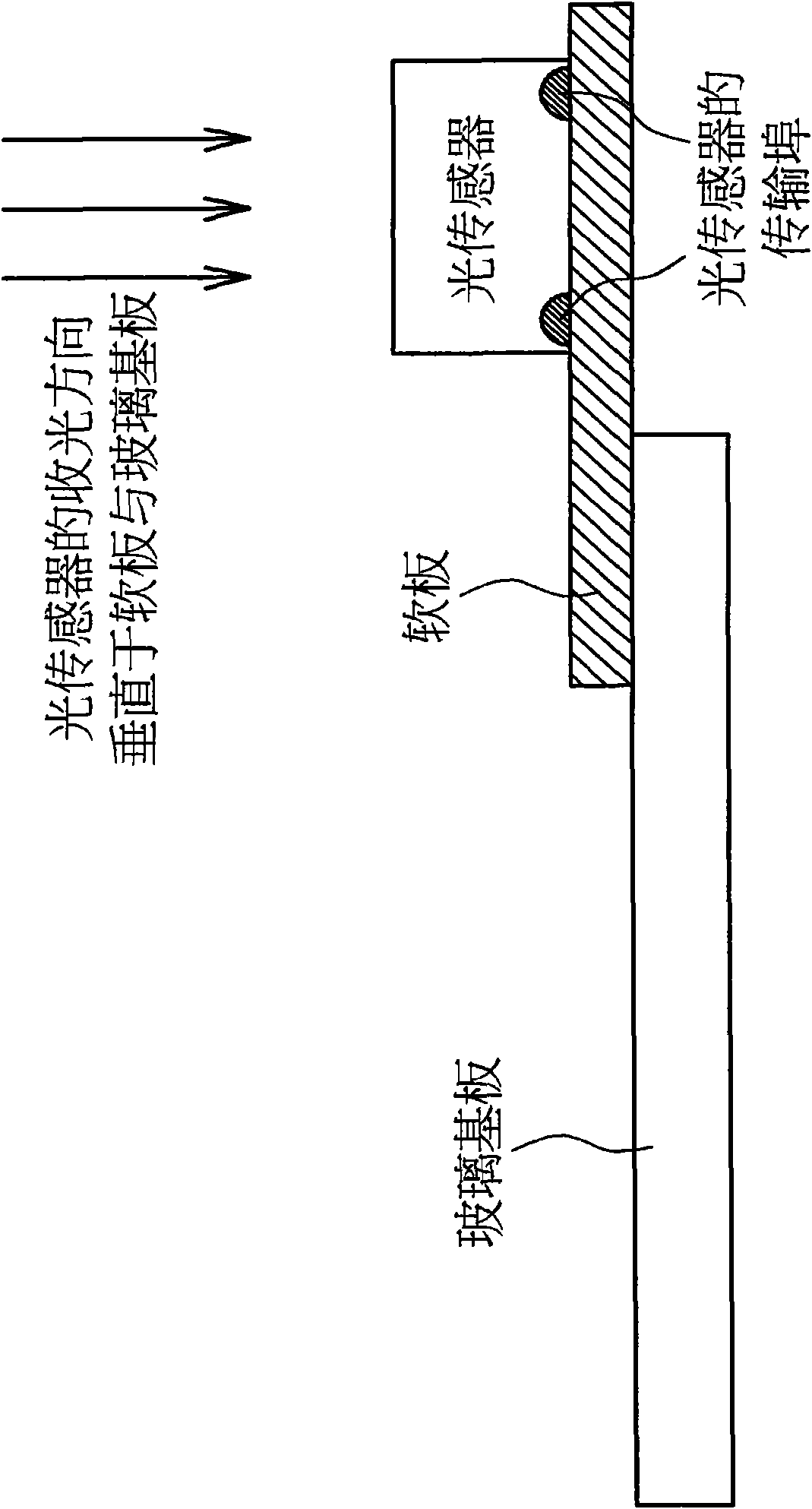

[0037] The invention provides a connector capable of connecting an optical sensor and a substrate. The connector provided by the invention can transpose the light sensor so that the light receiving direction of the light sensor is parallel to the substrate. In this way, by using the connector provided by the present invention, the light sensor can be disposed on the substrate, and the light receiving direction of the light sensor can be kept parallel to the substrate.

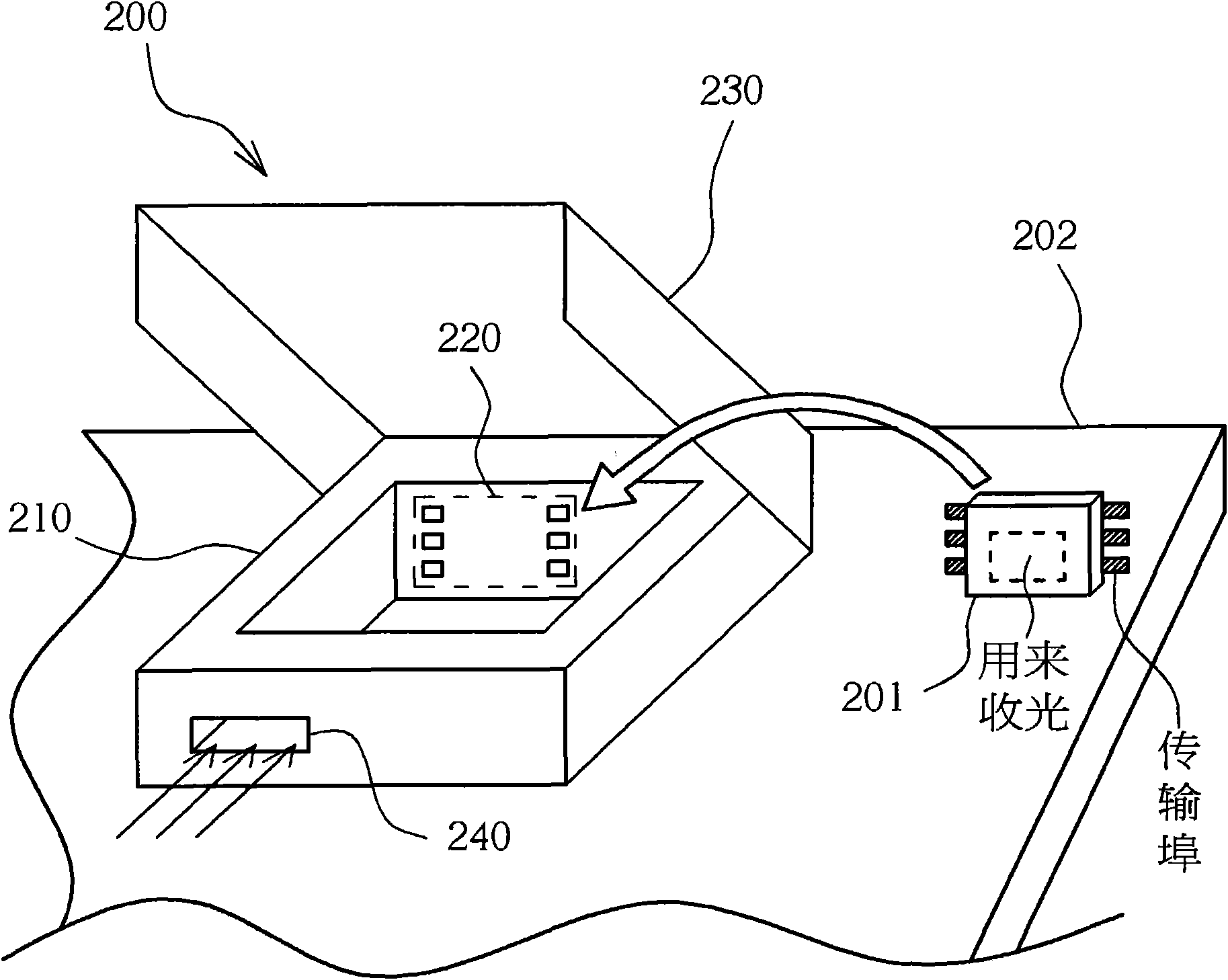

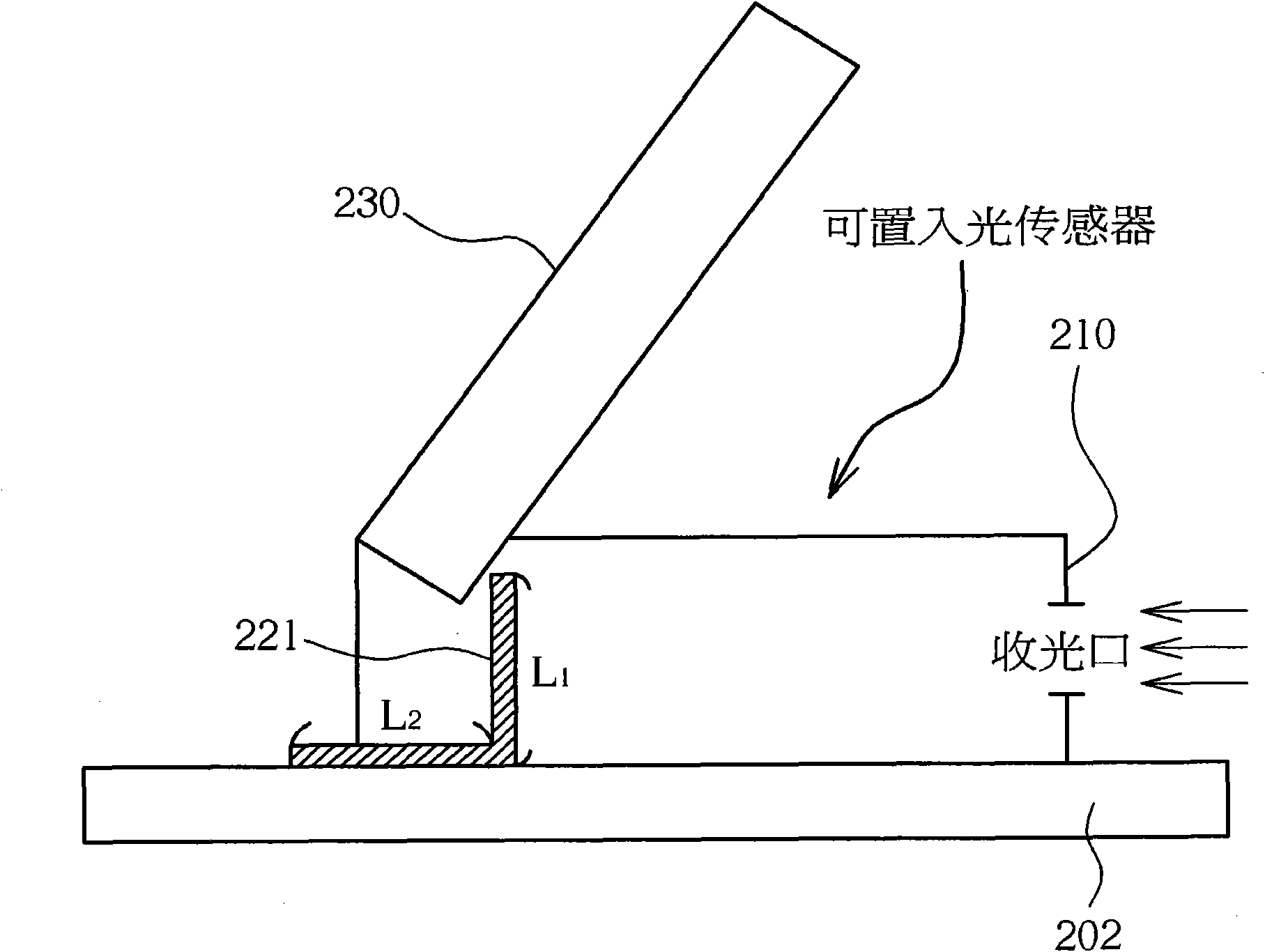

[0038] Please refer to figure 2 . figure 2 It is a schematic diagram illustrating the connector 200 according to the first embodiment of the present invention. exist figure 2 Among them, the connector 200 is disposed on the substrate 202 . The substrate 202 is a transparent substrate (such as a glass substrate or ITO glass). The connector 200 includes a body 210 , a connection port 220 , an upper cover 230 , and a light receiving port 240 . There is enough space in the body 210 for accommodating a light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com