Device and method for stretching steel wire rope net

A technology of wire rope mesh and installation method, which is applied in the direction of building maintenance, construction, building construction, etc., can solve problems such as different tensioning methods, unspecified tension values, false tensioning, etc., to improve the quality of specifications and perfect reinforcement way effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

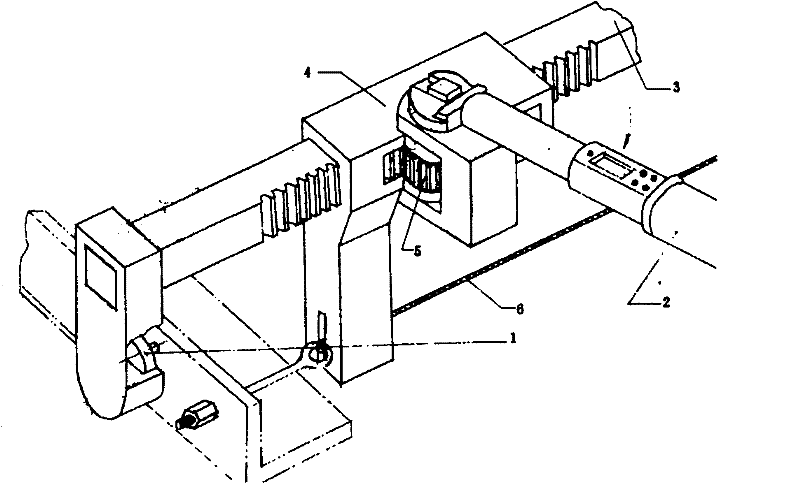

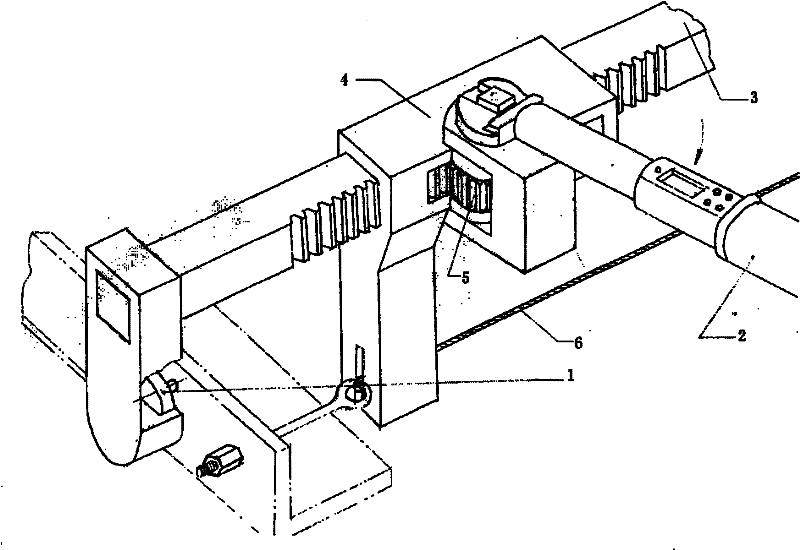

[0018] Example: such as figure 1 Shown, is a kind of tensioning steel wire rope mesh 6 device, comprises steel wire rope mesh 6, the first end of steel wire rope mesh 6, and the other end is fixed on the steel plate after stretching by tensioner. Wire rope mesh sheet 6 can adopt commonly used mesh sheet, and wire rope mesh sheet 6 among the present invention fixes after making, and wherein fixes the first end of wire rope mesh sheet 6 earlier, and the other end is fixed on the steel plate after being stretched by a tensioner. The first end can be welded and hinged on the angle iron, and the other end is fixed after being stretched by the tensioner, so as to achieve the tension of the wire rope mesh sheet 6 .

[0019] In order to measure the bearing force on the steel plate, a pressure sensor 1 is pressed on the steel plate. When the steel plate bears pressure, the pressure sensor 1 can display the pressure value.

[0020] After the other end of the wire rope mesh 6 is fixed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com