Industrial control network redundancy fault-tolerant system

An industrial control network, redundant fault-tolerant technology, applied in the direction of comprehensive factory control, comprehensive factory control, transmission system, etc., can solve problems such as inability to solve equipment failure, opaque superstructure, and no redundant system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

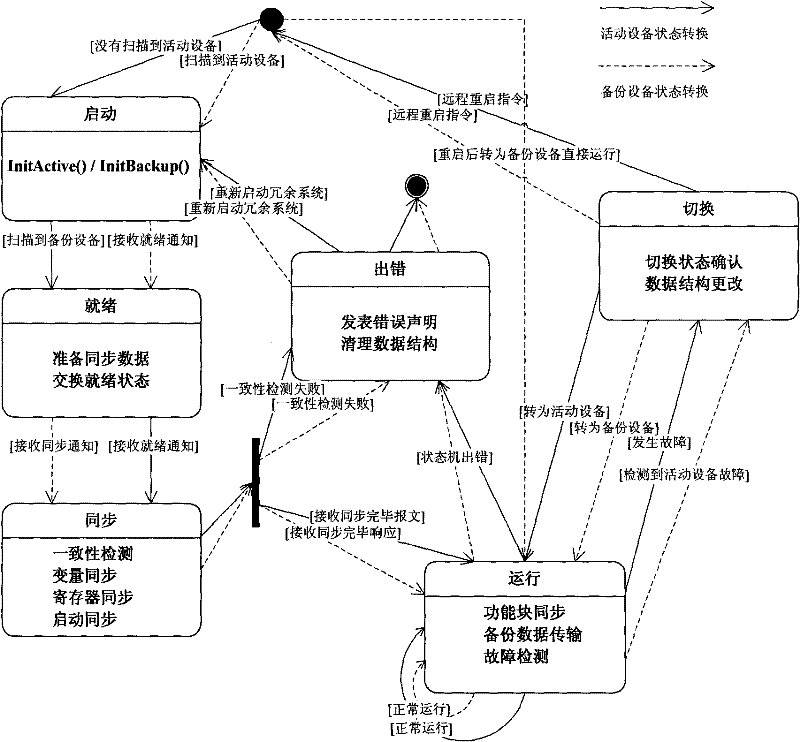

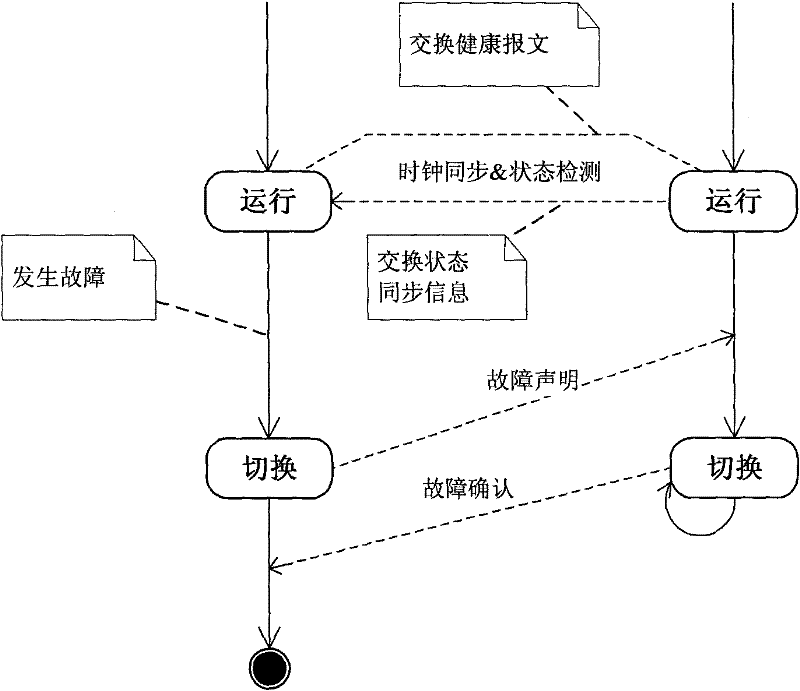

[0029] (1) Master equipment redundancy system

[0030] In the main equipment redundancy system, there are two pieces of equipment with exactly the same IP and MAC, one is the active equipment and the other is the backup equipment.

[0031] The invention designs a connection method for connecting two redundant main control devices with identical addresses to the upper-level Ethernet network through the HUB, and solves the problem caused by the device address conflict in the Ethernet. figure 1 An example is given to describe the network access mode of the main equipment redundancy system.

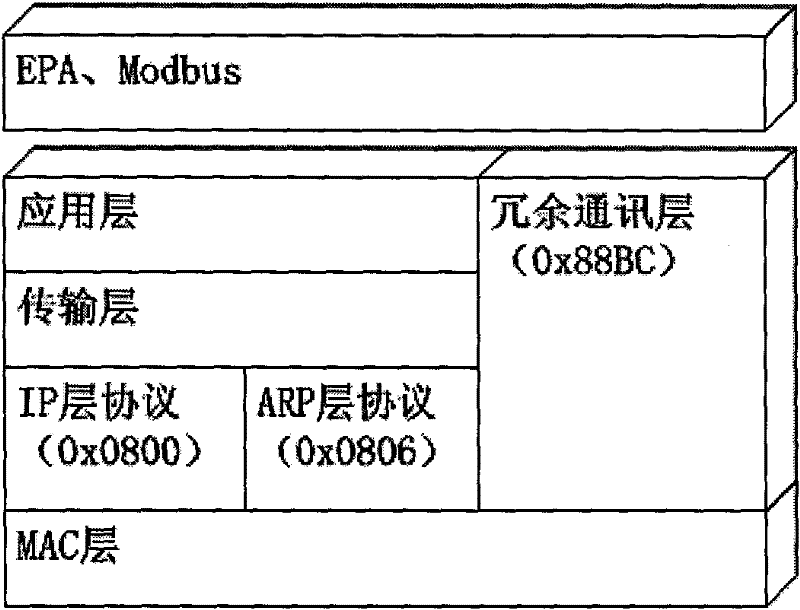

[0032] In the main control equipment redundancy system, two pieces of equipment communicate through the redundant communication layer of the present invention. In a master device redundant system, all communications between two redundant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com