Wiring circuit base plate

A technology for wiring circuit substrates and conductive substrates, which is applied in the field of wiring circuit substrates, can solve problems such as differential signal transmission errors, and achieve the effect of preventing transmission errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

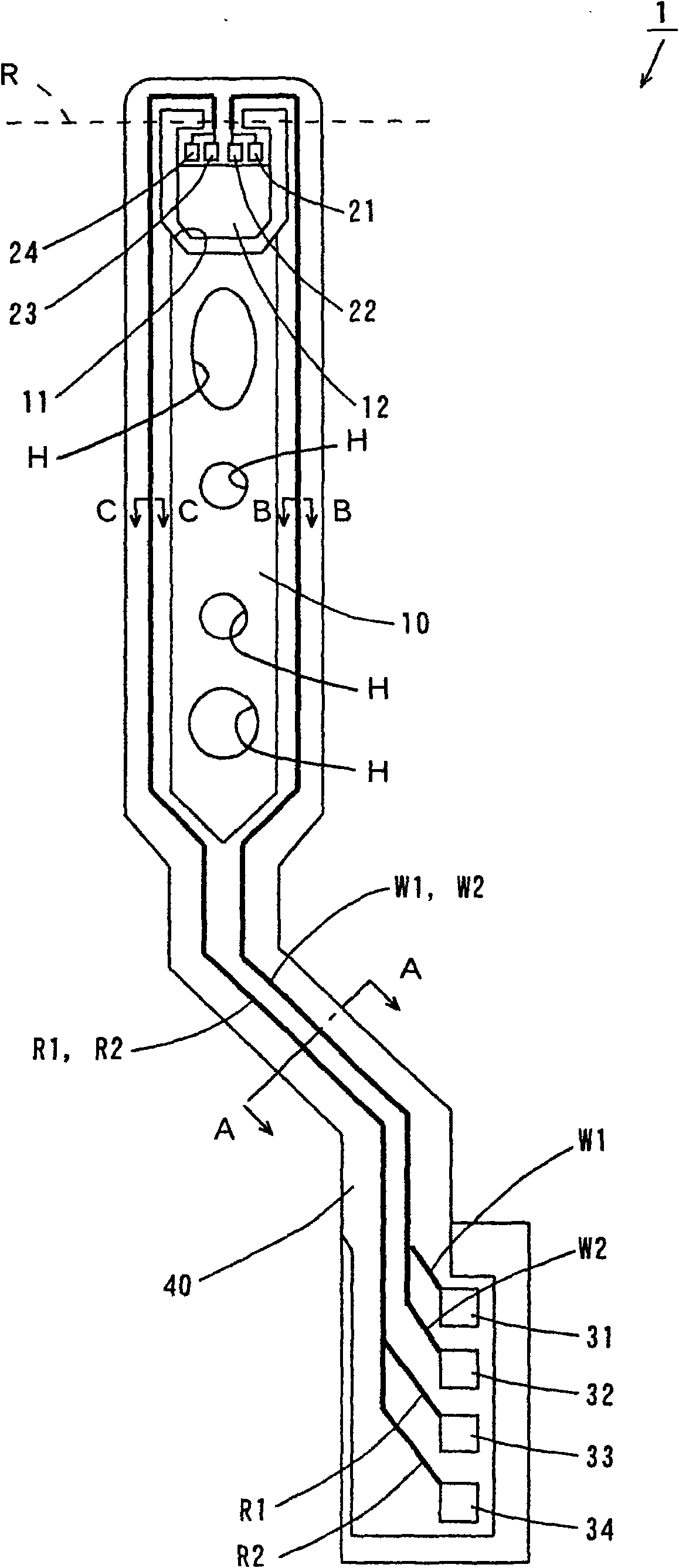

[0050] (1-1) Structure of the suspension board

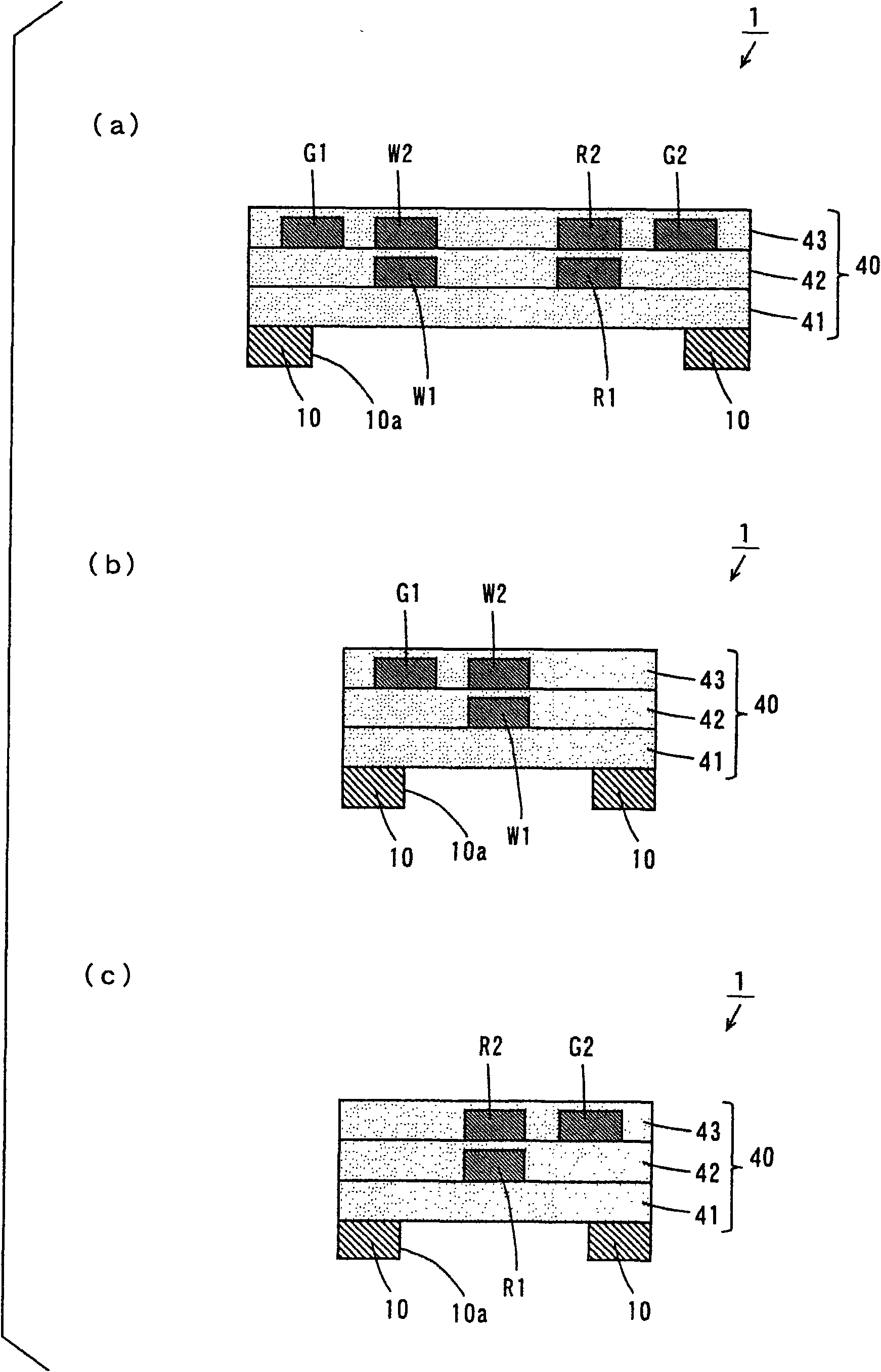

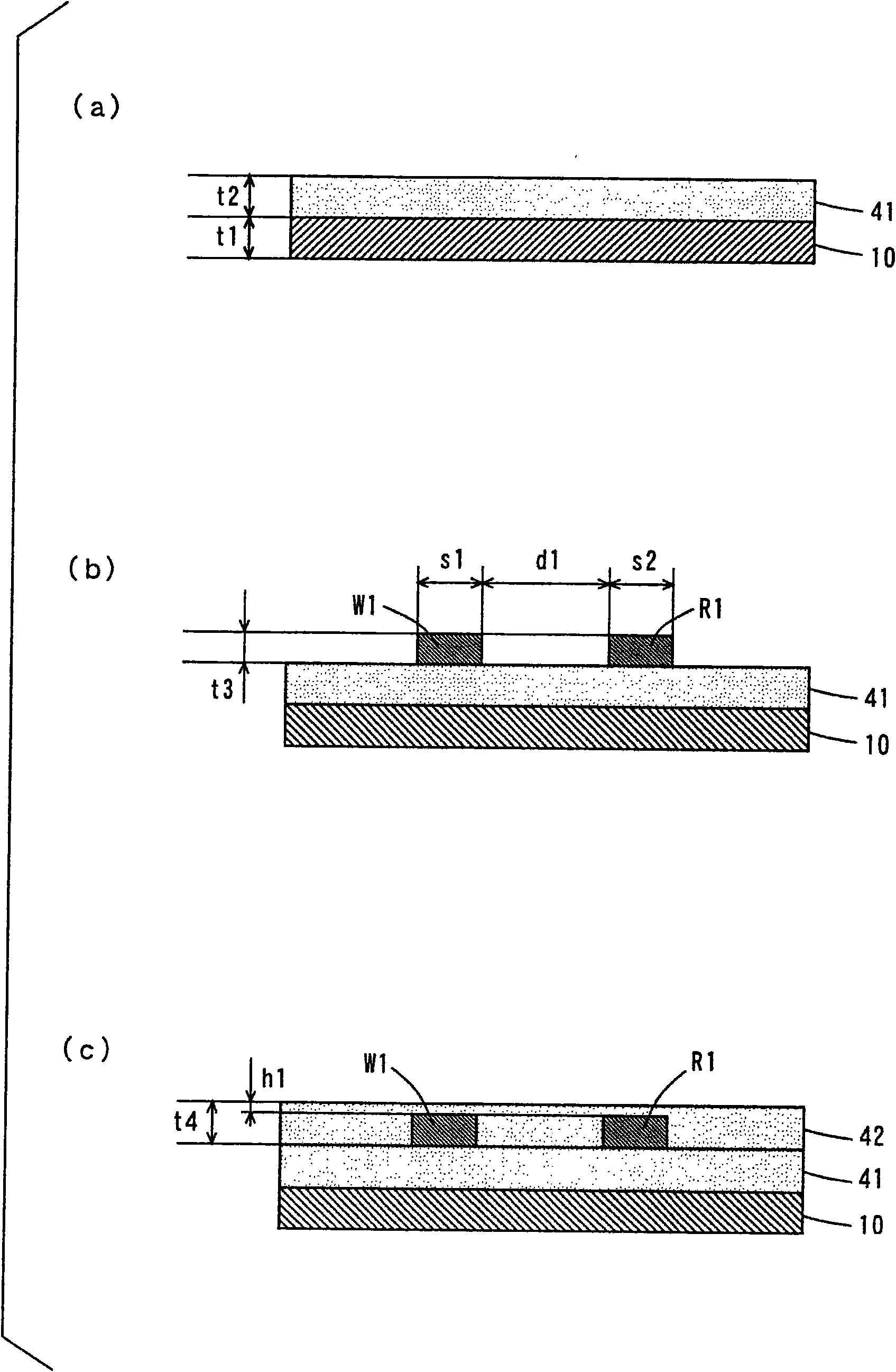

[0051] figure 1 is a plan view of the suspension board in the first embodiment of the present invention, figure 2 yes figure 1 A vertical cross-sectional view of the suspension board 1 of FIG. In addition, in figure 2 Among them, (a) means figure 1 The A-A line view cross-sectional view, (b) represents the B-B line view cross-sectional view, (c) represents the C-C line view cross-sectional view.

[0052] Such as figure 1 As shown, the suspension board 1 has a suspension main body 10 formed of a metal elongated board. As indicated by thick solid lines, the write wiring traces W1 and W2 and the read wiring traces R1 and R2 are formed on the suspension main body 10 .

[0053] At the front end of the suspension body 10 , a U-shaped opening 11 is formed to form a magnetic head mounting portion (hereinafter referred to as a tongue) 12 . The tongue portion 12 is bent at the position of the dotted line R so as to form a pr...

no. 2 approach

[0107] Figure 5 It is a longitudinal sectional view showing the suspension board in the second embodiment of the present invention. Moreover, in Figure 5 Among them, (a) means figure 1 The A-A line sectional view of , (b) represents the B-B line sectional view, and (c) represents the C-C line sectional view.

[0108] The suspension board 2 of this embodiment and figure 2 The suspension board 1 differs in the following points.

[0109] Such as Figure 5 As shown in (a), in the present embodiment, the ground pattern G3 is formed between the write wiring trace W2 and the read wiring trace R2 on the third insulating layer 43 in the cross section viewed along the line A-A.

[0110] In this case, the ground trace G3 can sufficiently prevent crosstalk from occurring between the write wiring traces W1 , W2 and the read wiring traces R1 , R2 .

[0111] In addition, if Figure 5 As shown in (b), the ground pattern G3 is formed on the other side of the write wiring pattern W2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com