Actuating unit for a dog transmission and dog transmission comprising such an actuating unit

A technology of operating unit and transmission, applied in the direction of elements with teeth, belt/chain/gear, transmission control, etc., can solve the problems of complex shift fork control, high cost of structure and control cost, etc., and achieve reliable design , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

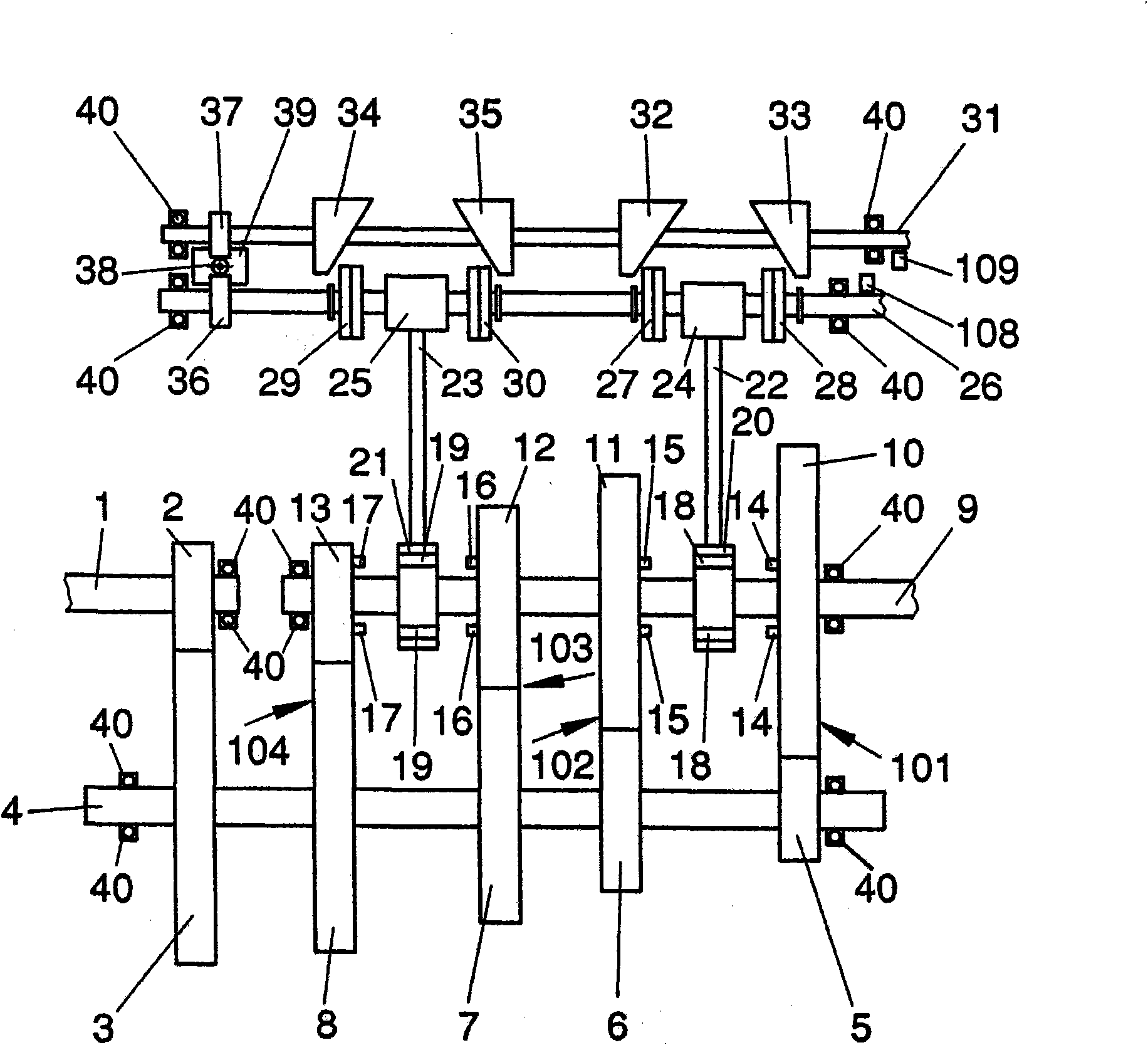

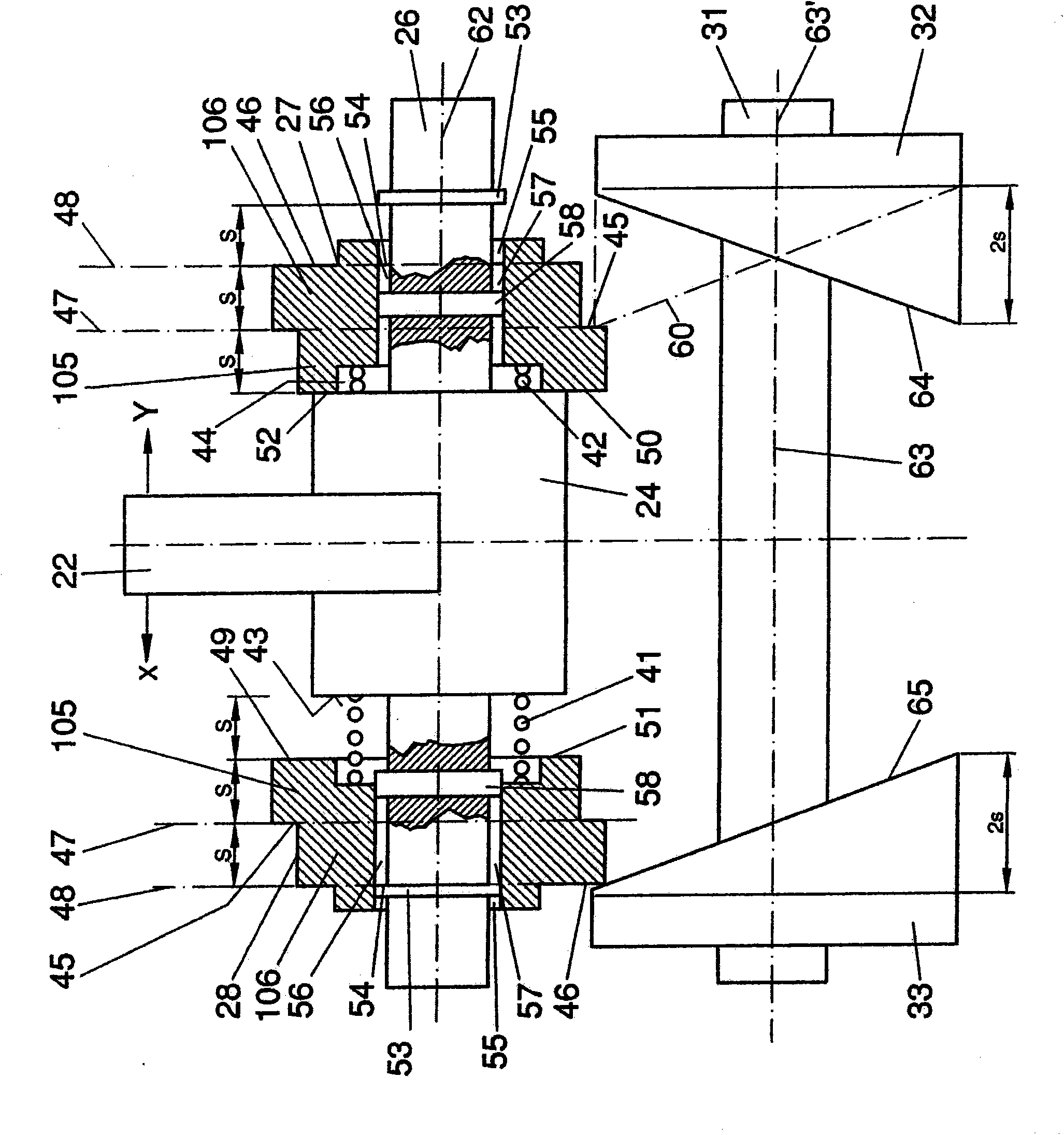

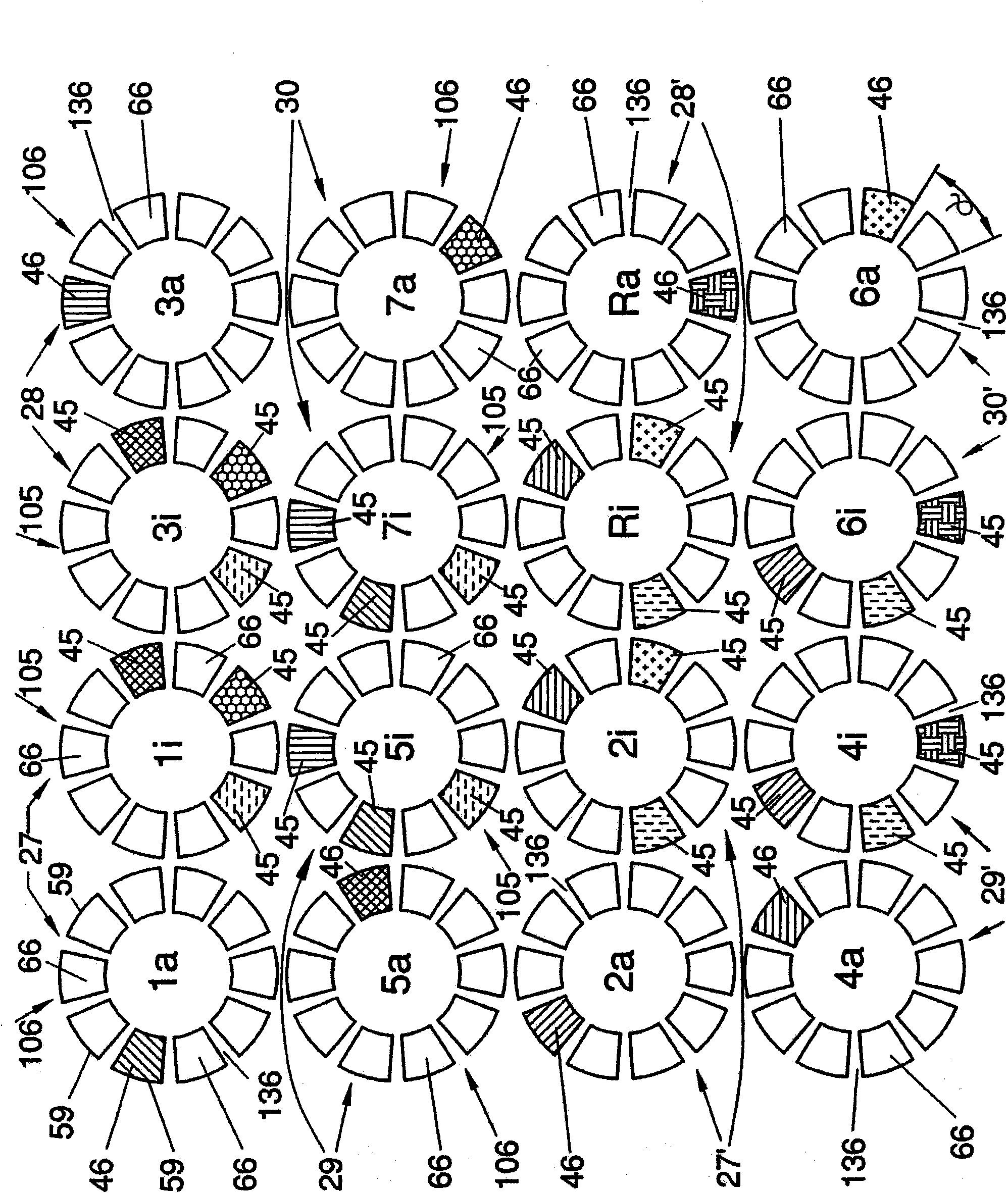

[0052] figure 1 Designates a part of the claw clutch which is provided with the actuating unit designed according to the invention and otherwise designed in a known manner.

[0053] The input shaft 1 is connected via an input gear 2 to a transmission gear 3 , which is connected rotatably and axially immovably to a transmission shaft 4 . On the transmission shaft 4, other transmission gears 5, 6, 7, 8 are fixed in a non-rotational and axially immovable manner, and they are respectively connected with the shifting gear 10, 11, 12, 13 are meshed and together form gear sets 101, 102, 103, 104 for forming the first, third, fifth and sixth gears.

[0054] On the inner sides of the shifting gears 10, 11, 12, 13, claw-toothed appendages 14, 15, 16, 17 are respectively arranged, which are designed to be inserted into bores 18, 19 which extend parallel to the output shaft 9 through Claw rings 20 , 21 mounted on the output shaft in a rotationally fixed but axially displaceable manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com