Intelligent alternated long steel rail push-pull continuous conveying system and method thereof

A conveying system and long rail technology, applied in the field of machinery manufacturing and processing, to achieve great application value, considerable social benefits and economic value, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

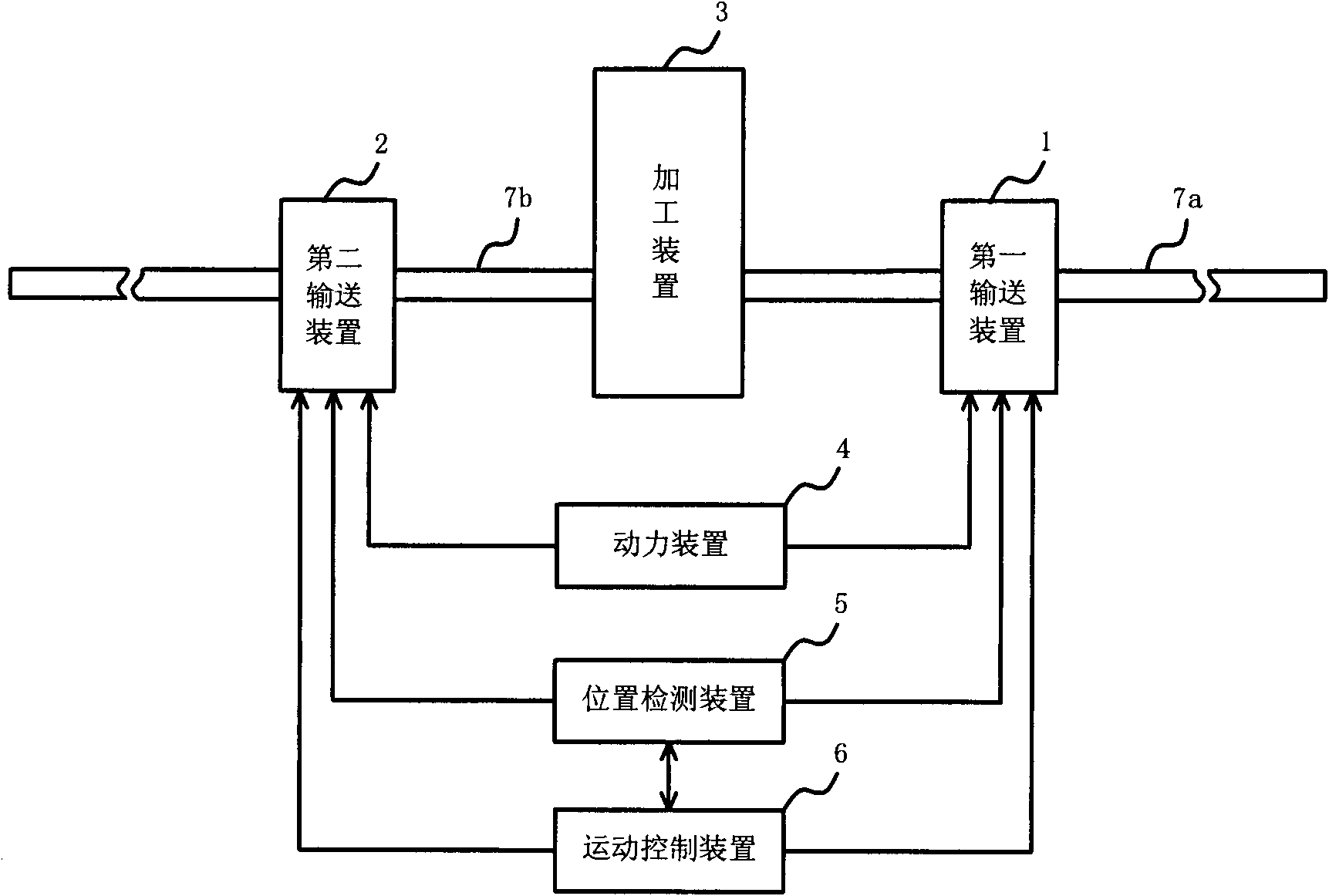

[0049] see figure 1 , which generally shows the overall composition of the intelligent alternating long rail push-pull continuous conveying system of the present invention. Such as figure 1 As shown, the system mainly includes a first conveying device 1, a second conveying device 2, a power device 4, a position detection device 5 and a motion control device 6, and each component will be described in detail below.

[0050] The first conveying device 1 is arranged on the input side of the processing device 3, and clamps the long rail section 7a to be processed by its first clamp (not shown for the sake of simplification of the drawing) and Push into processing device 3. As for the processing device 3, milling equipment is usually used to remove the aging fatigue layer on the surface and / or side of the old long rails removed from the railway line. Of course, other suitable processing equipment in the prior art can also be used according to actual needs to process the rails acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com