Heating and upsetting cooling device of drill rod pipe end

A technology of cooling device and drill pipe, applied in heating/cooling equipment, forging/pressing/hammer device, metal processing equipment, etc., can solve the problems of reduced production efficiency, length of drill pipe, easy deformation of molds, etc., saving manpower and material resources, improve the service life, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

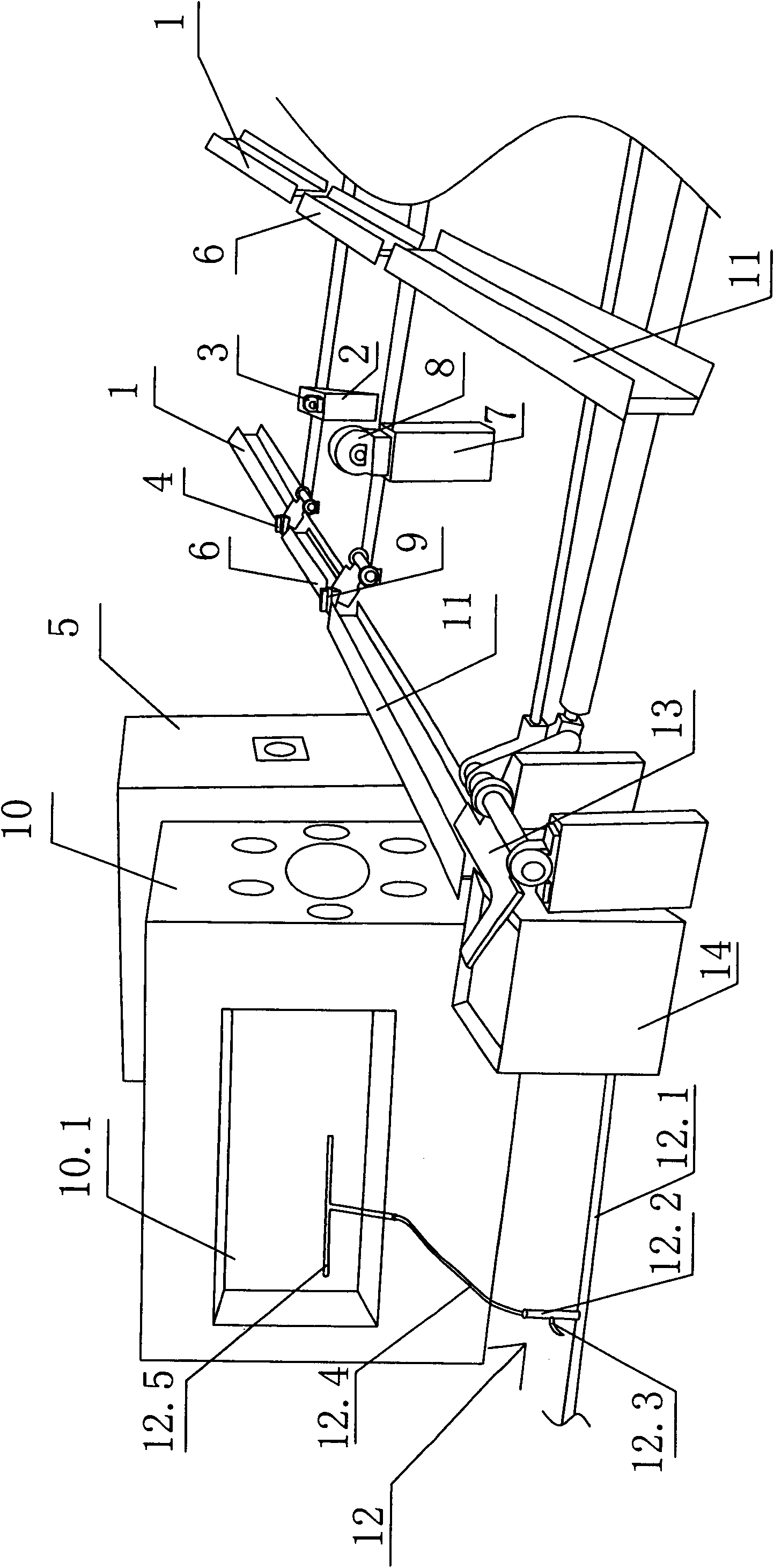

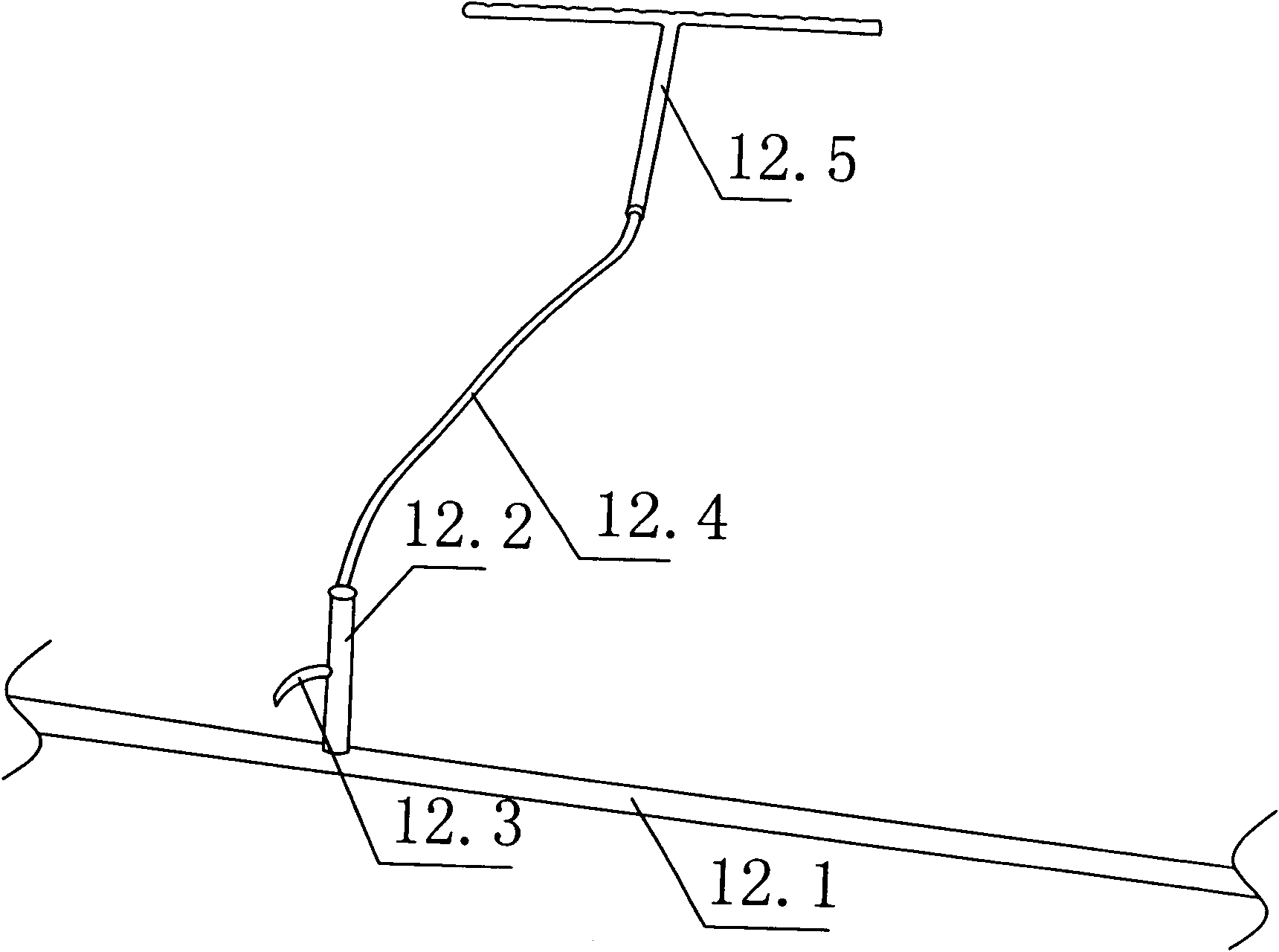

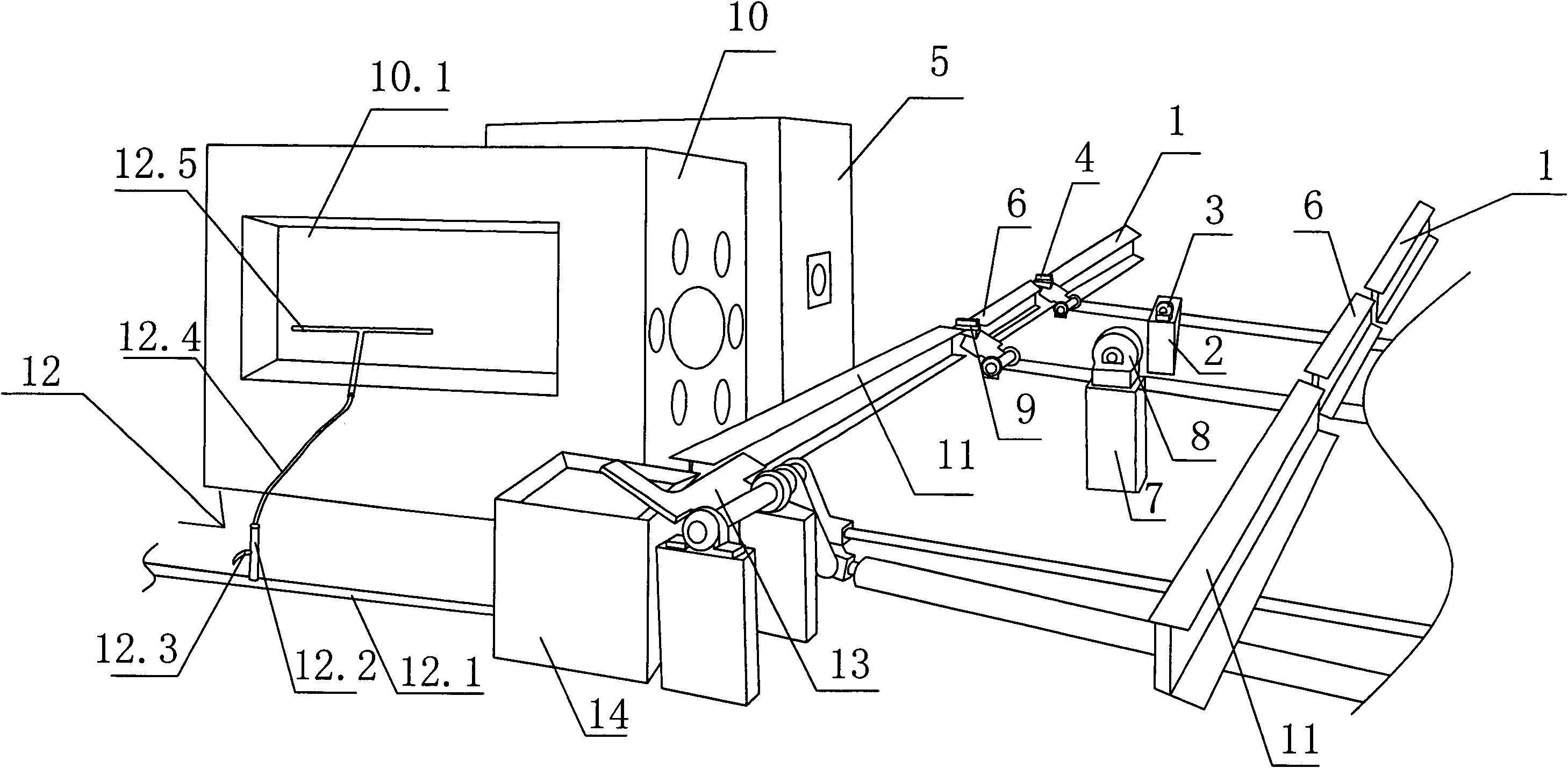

[0019] like figure 1 , The present invention relates to a heating, upsetting and cooling device for the pipe end of a drill pipe, which includes a first track 1, a first drive wheel support 2, a heating furnace 5, a second track 6, a second drive wheel support 7, and a hydraulic press 10 and the third track 11;

[0020] The first track 1, the second track 6 and the third track 11 have several pieces, the first track 1, the second track 6 and the third track 11 are vertically arranged, and the rear end of the second track 6 is the first A track 1, the front end of which is a third track 11, a first dial 4 is arranged between the first track 1 and the second track 6, and is used to transport the drill rod from the first track 1 to the second track 6; A second shifting block 9 is arranged between the second track 6 and the third track 11 for transporting the drill rod from the second track 6 to the third track 11;

[0021] The heating furnace 5, the first shifting block 4 and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap