Fabric including low-melting fiber

A low-melting fiber and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of inability to apply, inability to control the physical properties of low-melting fiber fusion rate fabrics, and lack of physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

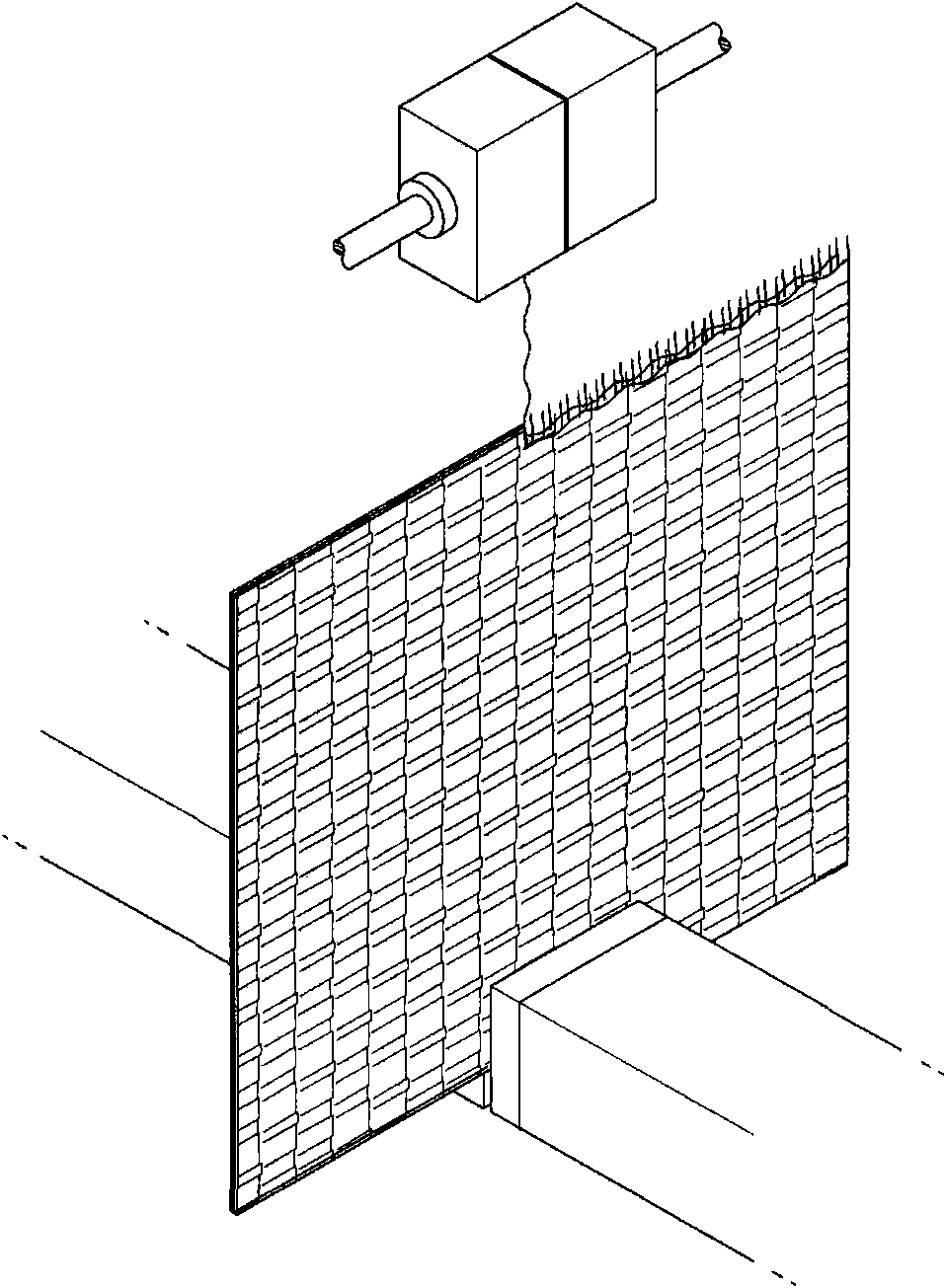

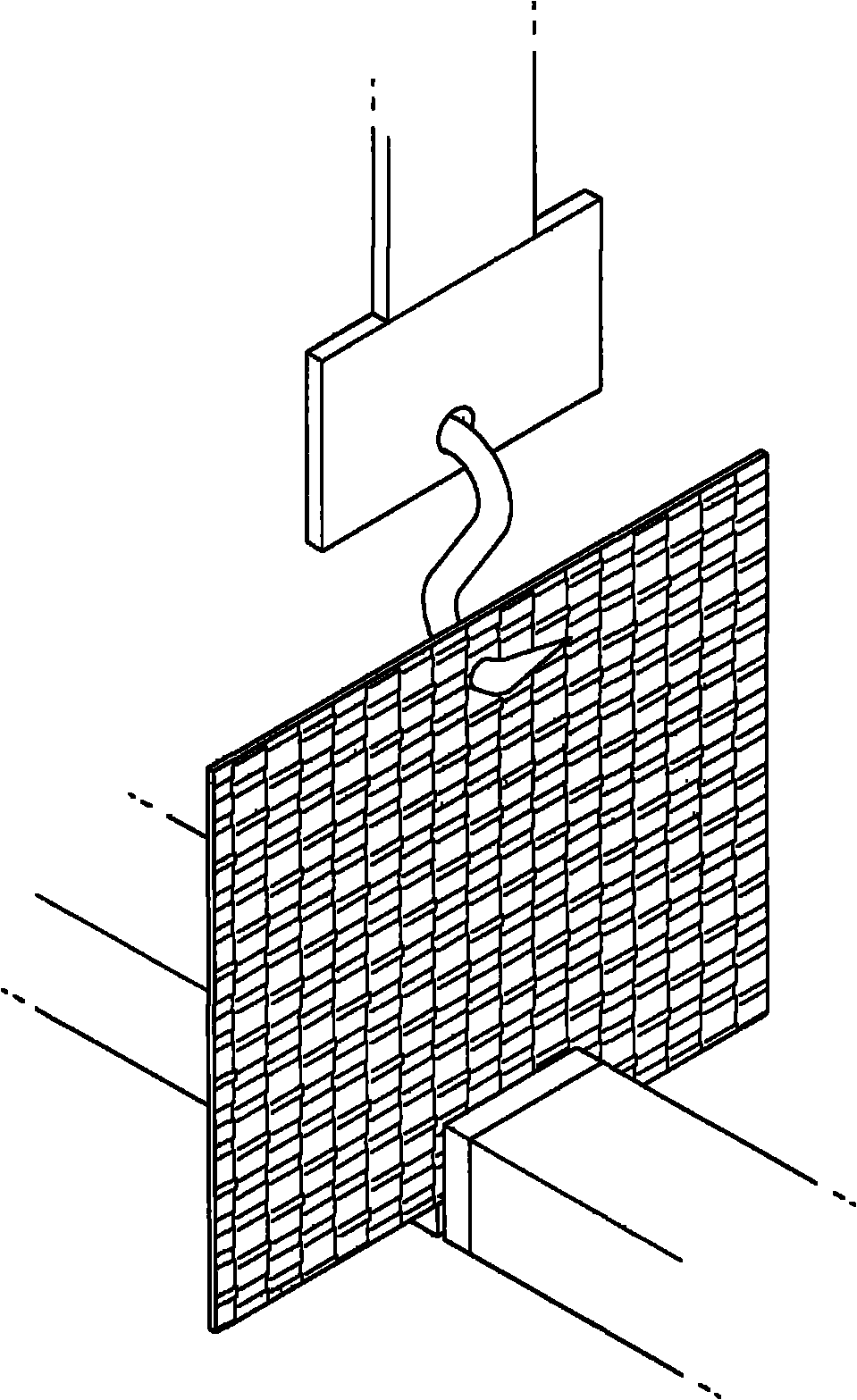

Method used

Image

Examples

Embodiment 1

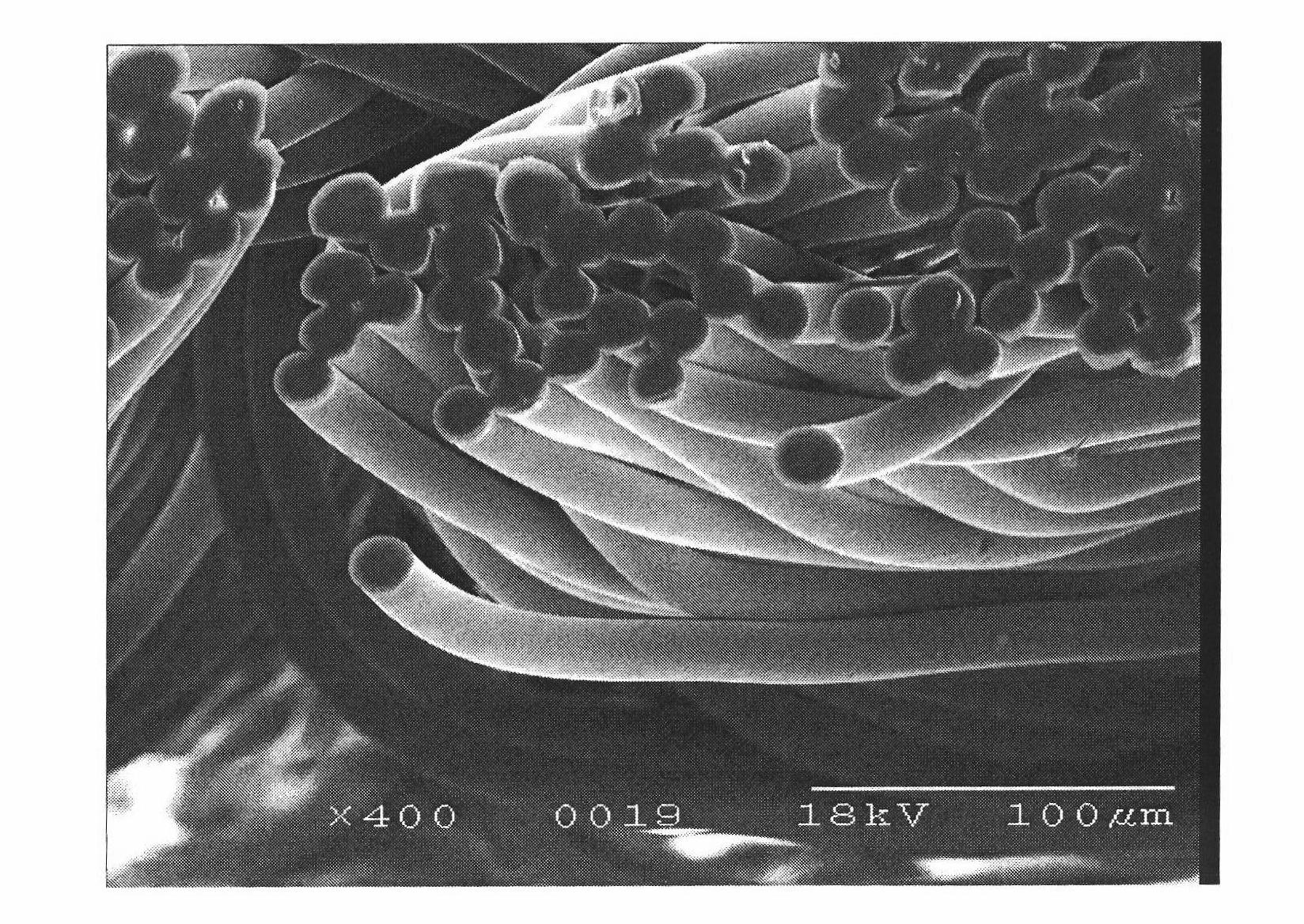

[0049] A fabric is produced by weaving conventional polyester fibers as warp threads and sheath / core type composite fibers as weft threads by plain weaving. The conjugated fiber is composed of twisted fibers of low-melting point polyester (30% by weight) as a sheath and conventional polyester (70% by weight) as a core. The fabric has a warp density of 100 yarns / inch and a weft density of 100 yarns / inch. The woven fabric was processed to adjust the fusion ratio of the low-melting point polyester to 30%.

Embodiment 2-5

[0051] Fabrics were produced in the same manner as described in Example 1, except that the fusion rates were adjusted to 50%, 70%, 90% and 100%, respectively.

Embodiment 6-10

[0053] Fabrics were produced in the manner described in Examples 1-5, except that the amount of the low melting point polyester was adjusted to 40% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com