Preparation technology of escalator component

A manufacturing process and component technology, applied in the field of manufacturing process of escalator components, can solve the problem of insufficient tensile elastic modulus and bending elastic modulus, unable to meet the tensile elastic modulus and bending elastic modulus, unreliable storage, etc. problem, to achieve the effect of good rigidity and anti-corrosion manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

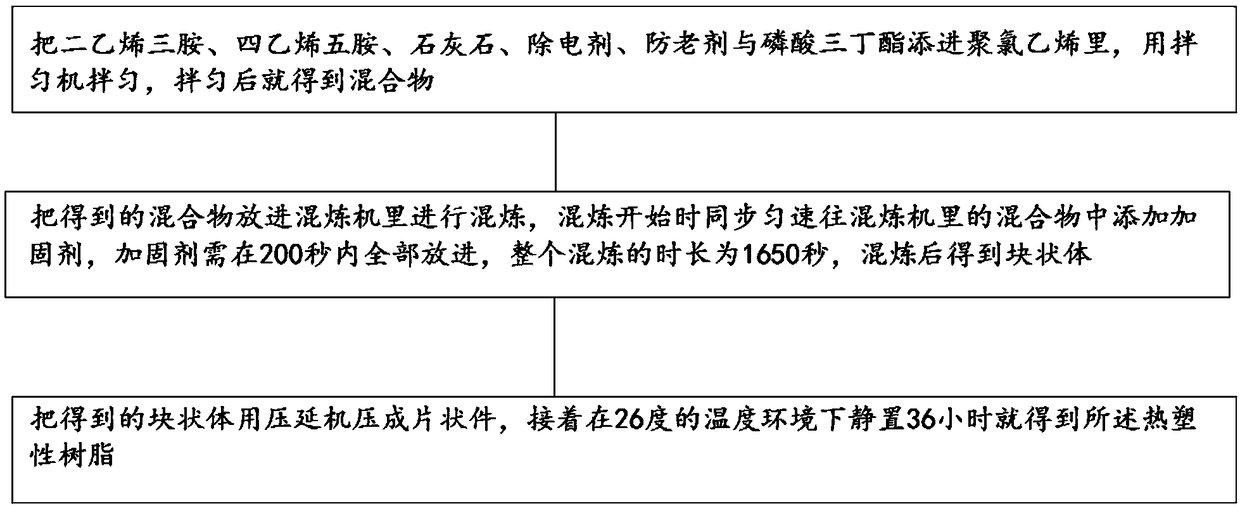

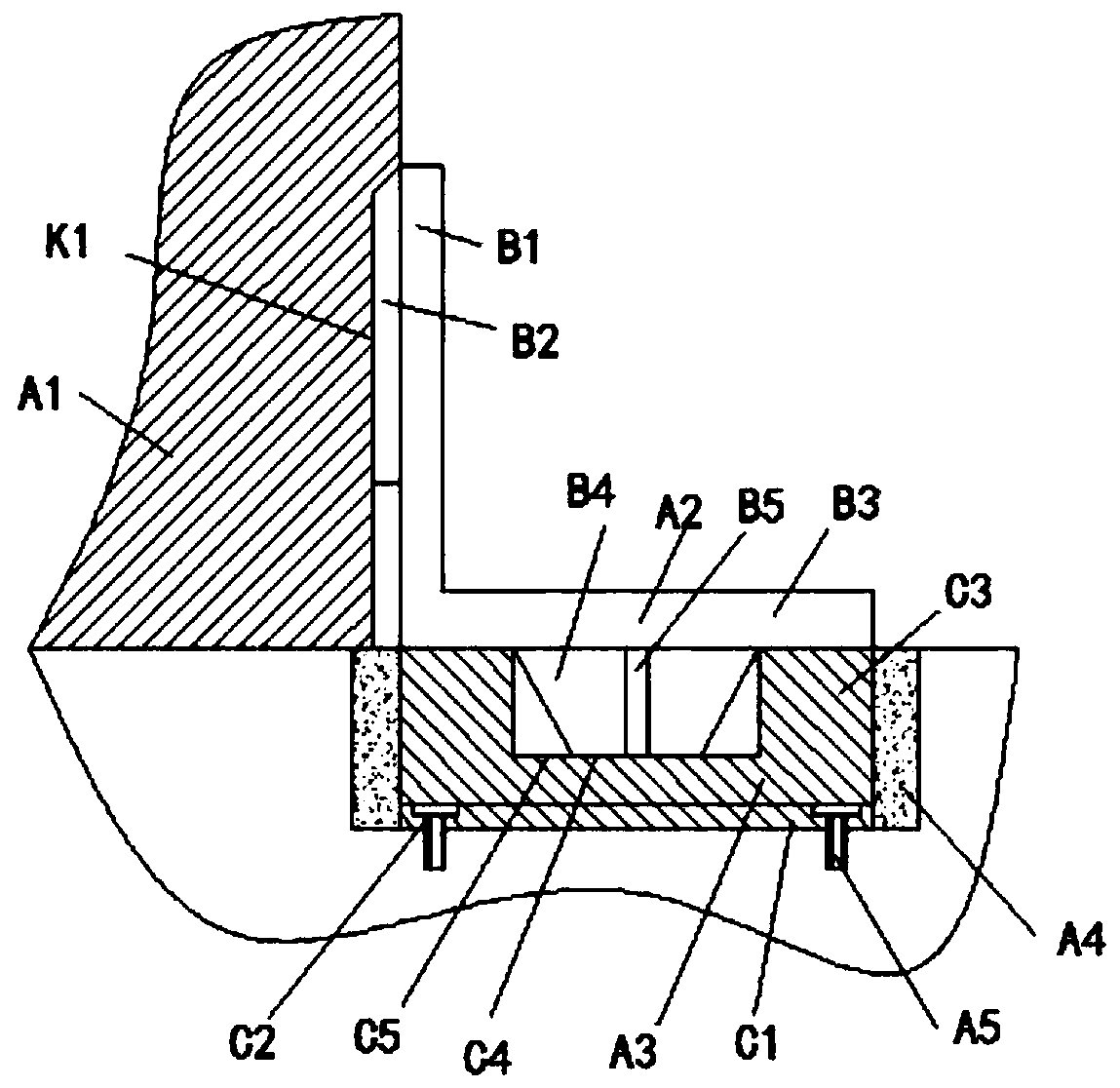

[0052] Such as Figure 1-Figure 6 As shown, the manufacturing process of escalator components, including the escalator handrail and the automatic escalator handrail described in the patent name "201480051163. Methods of manufacturing escalator handrails;

[0053] This escalator handrail is an escalator handrail provided with a composite material including a metal steel wire and a thermoplastic resin, the metal steel wire has a central strand and a plurality of strands arranged so as to surround the central strand, the The distance between the central strand and the strand is the same at each position in the extending direction of the central strand and the strand, and the thermoplastic resin is filled between the central strand and the strand without forming a cavity. resin.

[0054] The central strand and the strands are maintained in tension in the direction of extension of the central strand and the strands.

[0055] The central strand and the strands are twisted wires t...

Embodiment 2

[0078] The manufacturing process of escalator components, including escalator handrails and escalator handrails as described in the application number "201480051163.0", the application date is "2014.09.19" and the patent name is "Escalator Handrail and Escalator Handrail Manufacturing Method" Manufacturing method;

[0079] This escalator handrail is an escalator handrail provided with a composite material including a metal steel wire and a thermoplastic resin, the metal steel wire has a central strand and a plurality of strands arranged so as to surround the central strand, the The distance between the central strand and the strand is the same at each position in the extending direction of the central strand and the strand, and the thermoplastic resin is filled between the central strand and the strand without forming a cavity. resin.

[0080] The central strand and the strands are maintained in tension in the direction of extension of the central strand and the strands.

[...

Embodiment 3

[0104] The manufacturing process of escalator components, including escalator handrails and escalator handrails as described in the application number "201480051163.0", the application date is "2014.09.19" and the patent name is "Escalator Handrail and Escalator Handrail Manufacturing Method" Manufacturing method;

[0105] This escalator handrail is an escalator handrail provided with a composite material including a metal steel wire and a thermoplastic resin, the metal steel wire has a central strand and a plurality of strands arranged so as to surround the central strand, the The distance between the central strand and the strand is the same at each position in the extending direction of the central strand and the strand, and the thermoplastic resin is filled between the central strand and the strand without forming a cavity. resin.

[0106] The central strand and the strands are maintained in tension in the direction of extension of the central strand and the strands.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com