Three-dimensional laser scanning measurement method and device

A three-dimensional laser and measurement method technology, applied in the field of laser measurement, can solve the problems of reducing the measurement efficiency, undersampling, and spatial resolution of the three-dimensional laser scanner, and achieve the effect of improving the measurement efficiency and the spatial measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

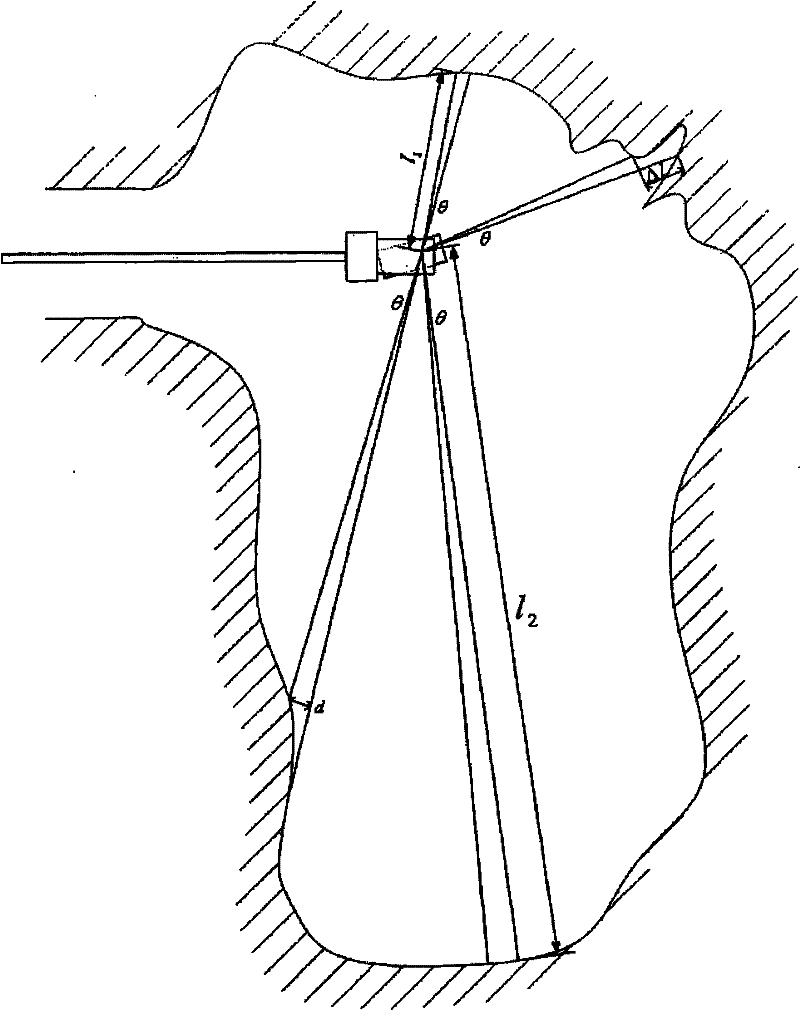

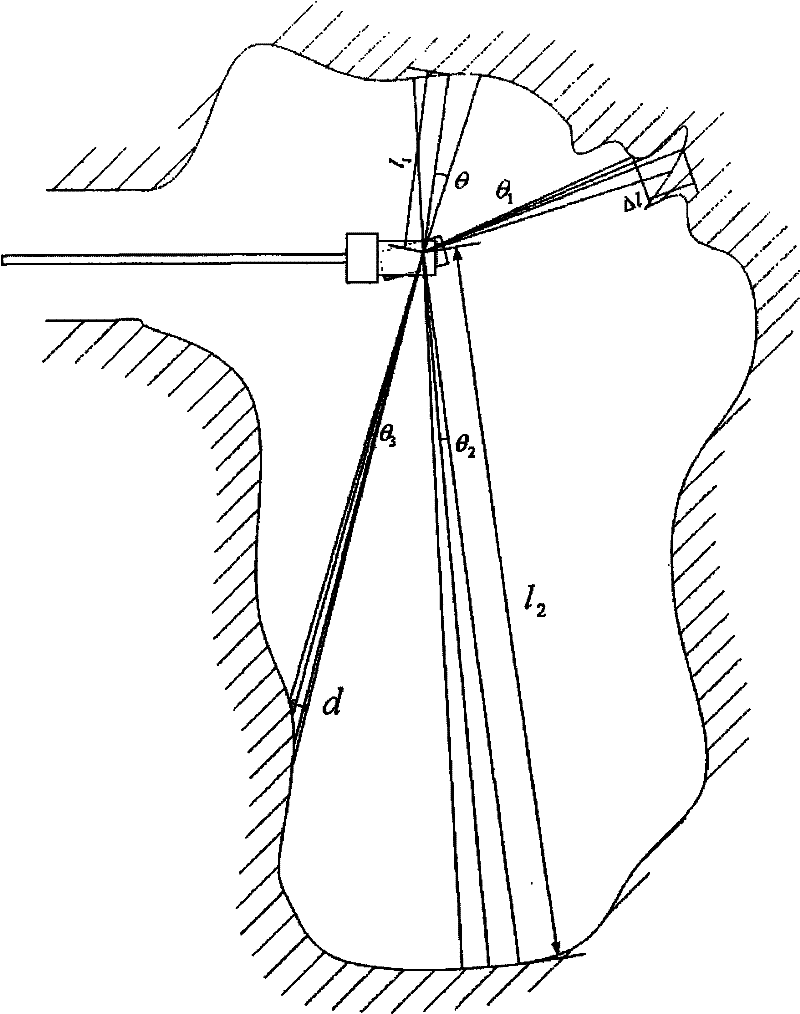

[0031] In this embodiment, a three-dimensional laser scanner is used to scan the measured object to obtain the three-dimensional spatial shape structure of the measured object. The above-mentioned three-dimensional laser scanner mainly includes: a host, a rotatable measuring head, an axial angle measuring device, a radial angle measuring device, an axial driving device and a radial driving device; wherein, the rotatable measuring head can Driven by the driving device and the radial driving device, it rotates in the axial and radial directions, and measures the distance of the measurement point on the surface of the measured target. The rotation angle of the rotatable measuring head is measured by the axial angle device and radial angle measurement device acquisition.

[0032] A schematic diagram of the implementation principle of a three-dimensional laser scanning measurement method with adaptive resolution provided by this embodiment is as follows: figure 2 As shown, the sp...

Embodiment 2

[0059] This embodiment provides a three-dimensional laser scanning measurement device, the specific structure of which is as follows Figure 4 As shown, it can specifically include:

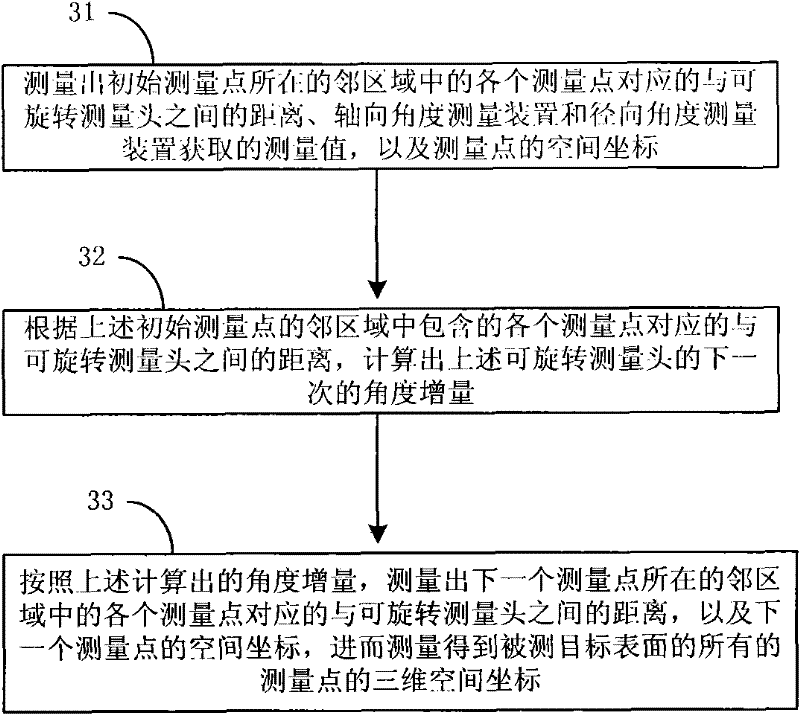

[0060] The initial measurement point measurement module 41 is used to measure the distance between each measurement point in the adjacent area where the initial measurement point is located and the rotatable measurement head of the three-dimensional laser scanner;

[0061] The angle increment calculation module 42 is used to calculate the rotatable measuring head according to the set algorithm according to the distance between each measuring point obtained by the initial measuring point measuring module and the rotatable measuring head of the three-dimensional laser scanner the next angle increment. The angle increment calculation module 42 calculates the next angle increment θ of the rotatable measuring head through the following calculation formula

[0062] θ = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com