Quick tester for printing ink paint

A tester and paint technology, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of wasting time and energy, incorrect test structure, etc., and achieve the effect of accurate test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

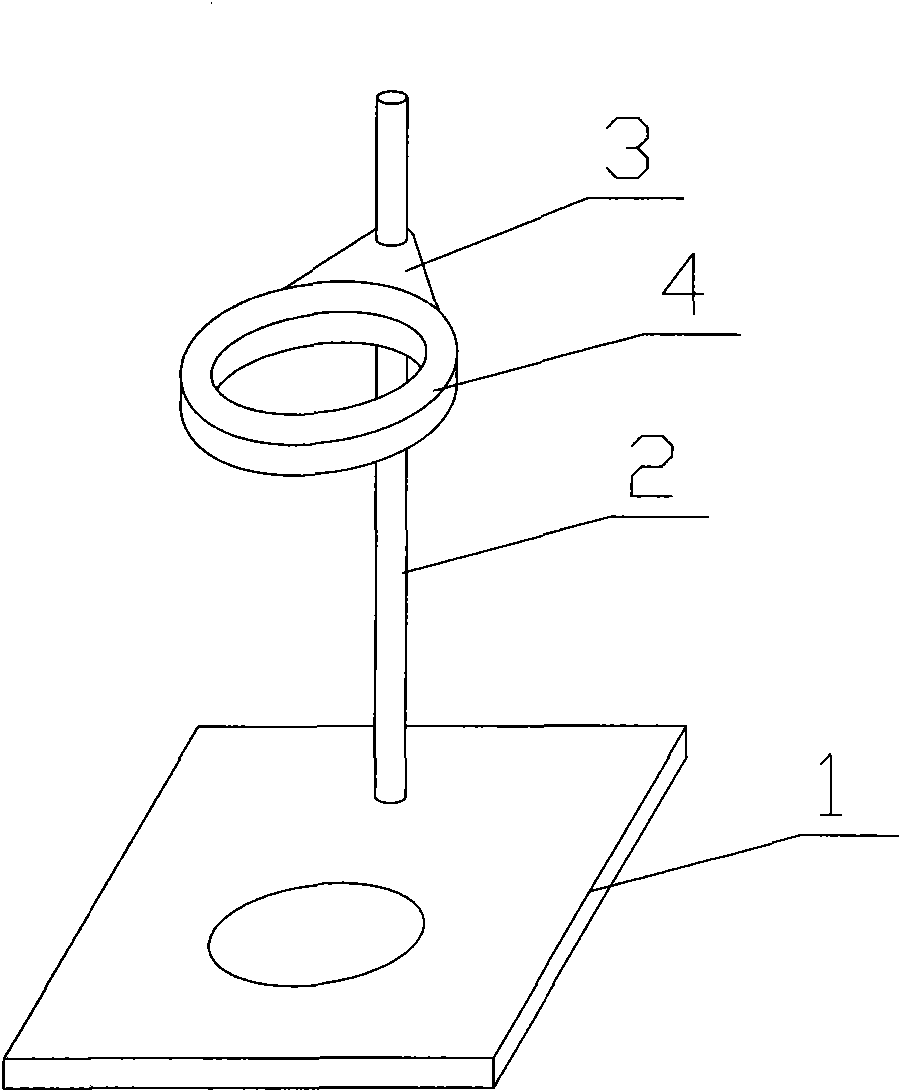

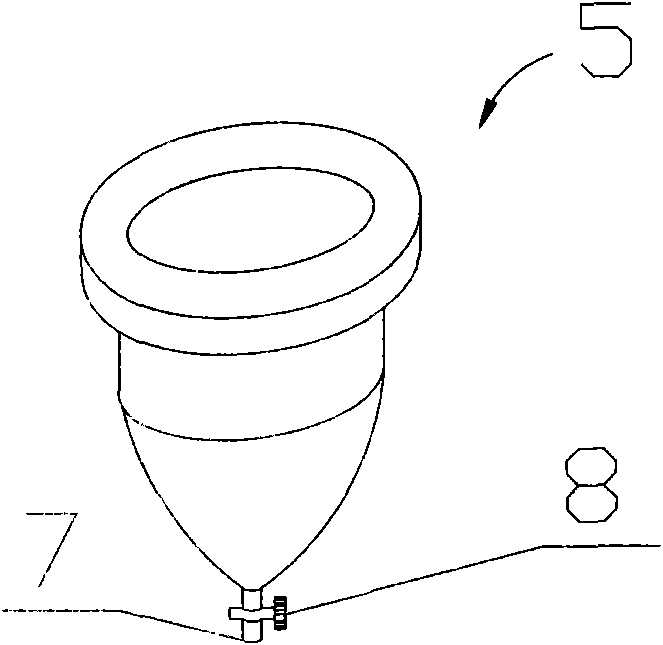

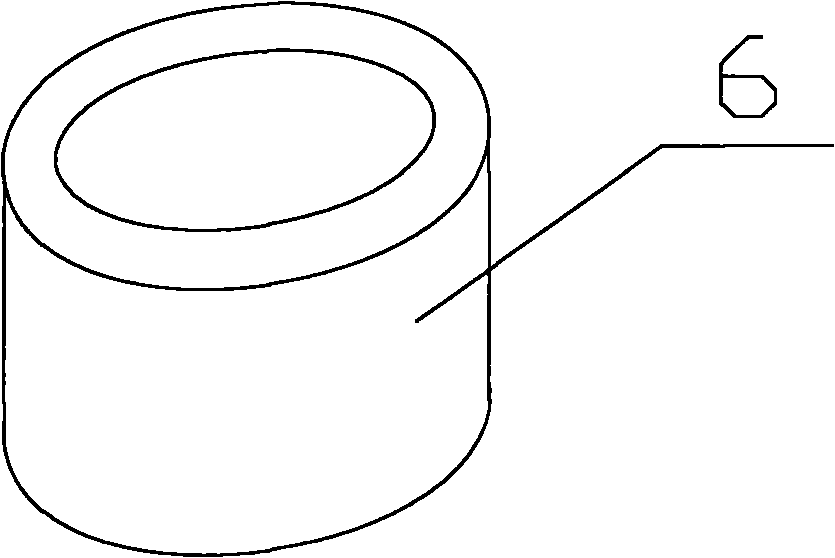

[0011] combine Figure 1~3 A kind of quick tester of ink coating shown, is provided with support, and described support is provided with base 1, vertical support bar 2 and the horizontal support bar 3 that is connected vertically with vertical support bar 2, and on described horizontal support bar 3 There is a fixed ring 4 (such as figure 1 ), then a funnel 5 is placed in the fixed ring 4, and an opening regulating valve 8 is provided on the opening 7 of the bottom of the funnel 5 (such as figure 2 ), adjust the size of the opening 7 through the opening regulating valve 8 on the opening 7 of the lower part of the funnel 5, so that the different opening sizes through which the tested ink or pen and ink in the funnel 5 passes drop out into the cup 6 placed on the base 1, So as to test the viscosity of ink or pen ink from different aspects.

[0012] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com