Commutator polishing device

A commutator and equipment technology, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve problems such as commutator efficiency limitation, and achieve the effect of improving production efficiency and accurate insulation withstand voltage test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

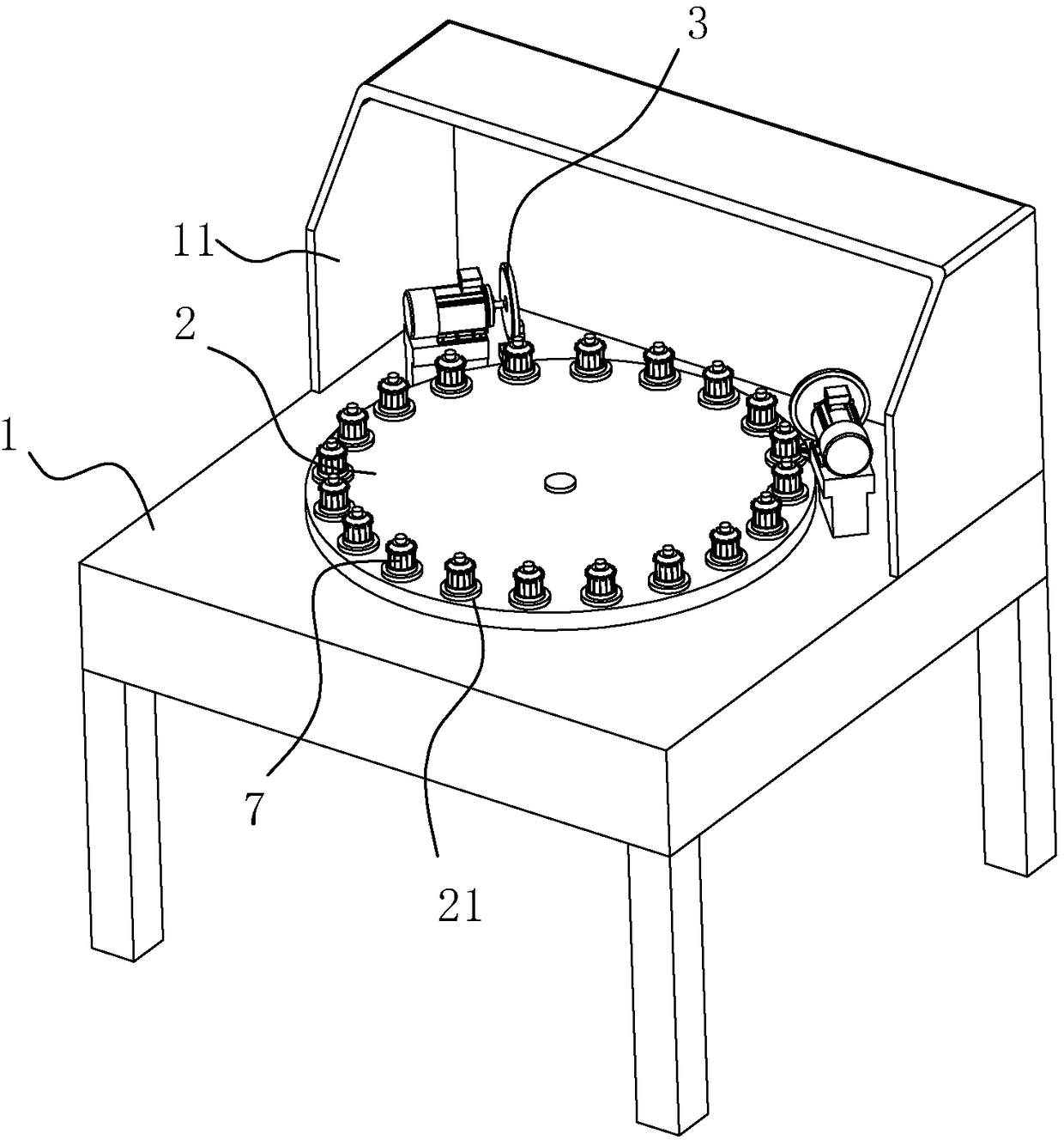

[0054] A kind of commutator polishing equipment, refer to figure 1 , which includes a body 1 and a disc-shaped workbench 2 rotatably arranged on the body 1 . The workbench 2 is driven by a stepping motor to realize the intermittent rotation of the workbench 2 .

[0055] refer to figure 1 , in order to improve the safety of the withstand voltage test, the body 1 is provided with a protective cover 11 covering the workbench 2 .

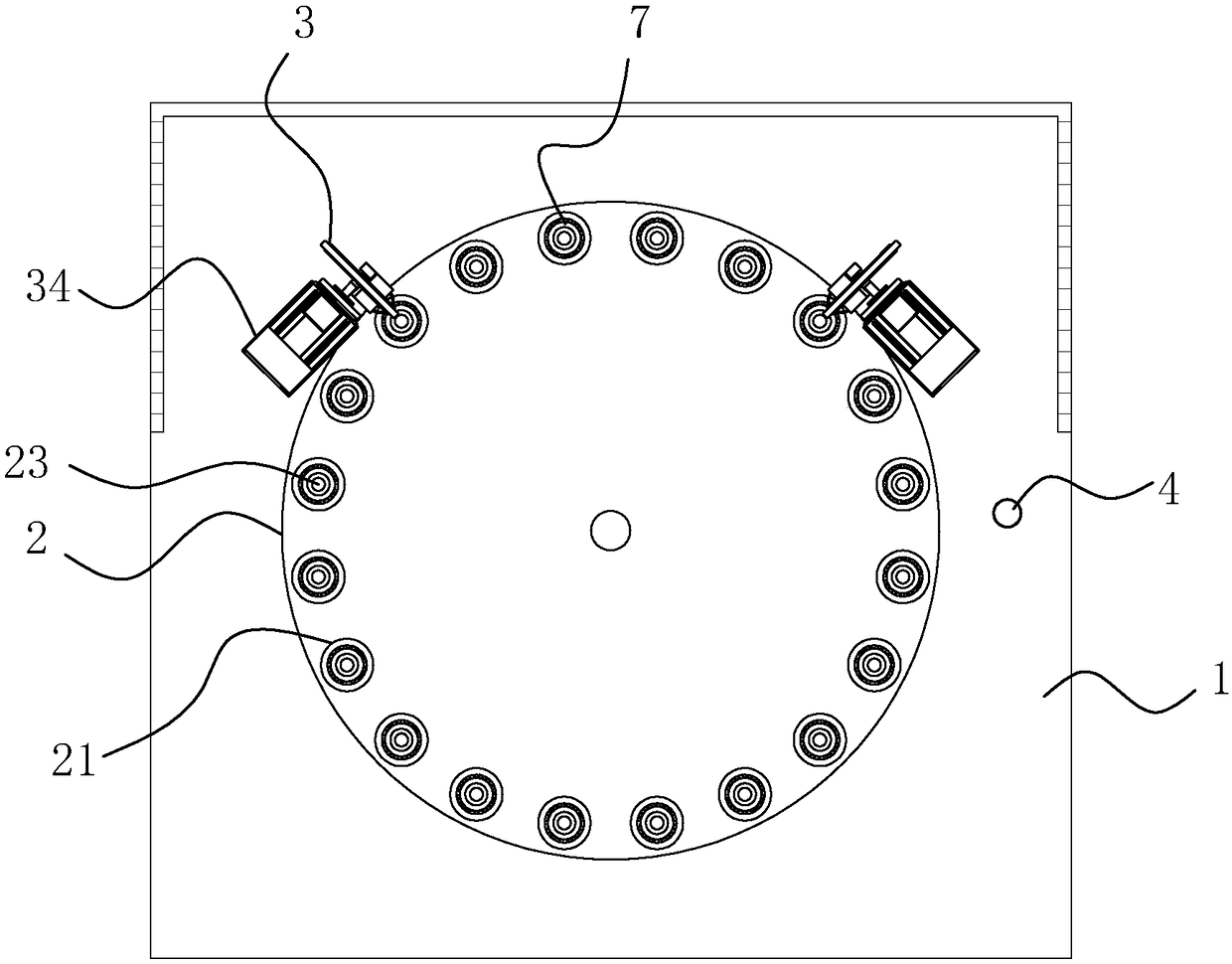

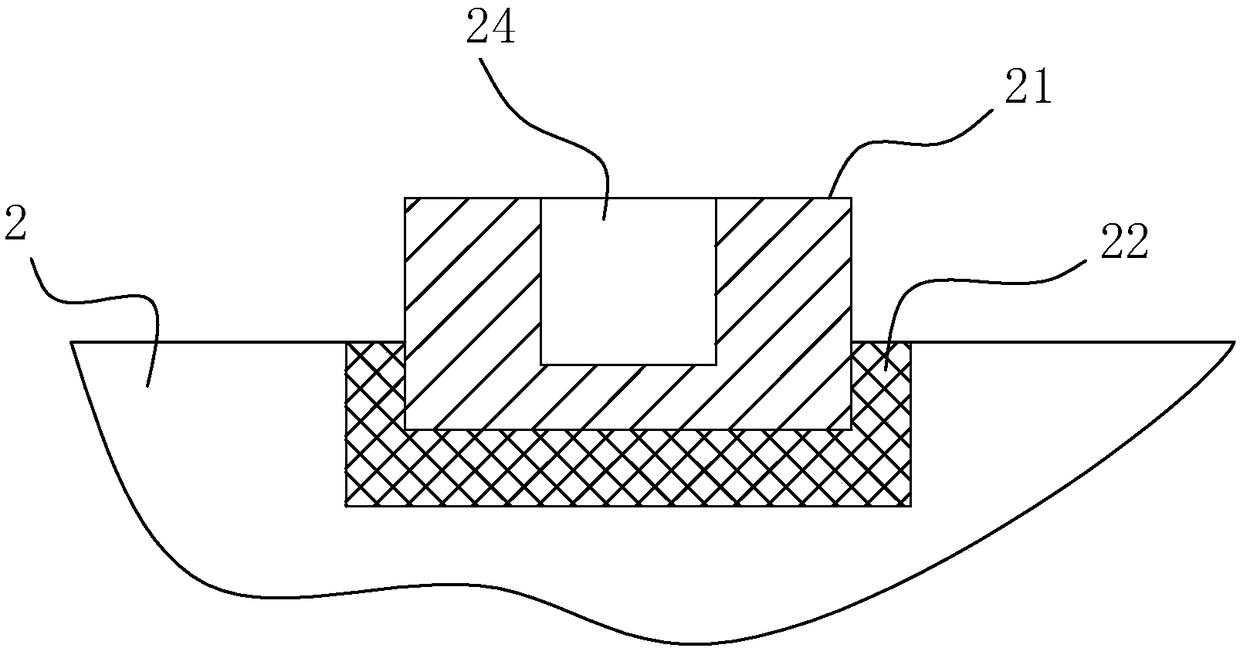

[0056] see figure 2 and image 3 A plurality of station seats 21 are uniformly fixed on the periphery of the worktable 2, and the station seats 21 are provided with sockets 24 for vertically inserting a mandrel 23 made of conductive metal. The commutator 7 is sleeved on the mandrel 23 to realize the placement of the commutator 7 during polishing. A polishing station is also provided on the machine body 1 , and the polishing station includes a polishing wheel 3 and a motor 34 for driving the polishing wheel 3 to rotate. When the commutator 7 moves...

Embodiment 2

[0064] The only difference from Example 1 is that see Figure 7 and Figure 8 , body 1 (see figure 2 ) is provided with a master controller, the master controller is used to control the stepper motor 34 (refer to figure 2 ) Working parameter control, power output of high voltage power supply. To avoid grinding wheel 3 during the start-up phase of the polishing job (see Figure 4 ) live with commutator segment 71 (refer to Figure 4 ) contact to generate electric sparks and set up a protective mechanism for intermittent conduction test voltage. The protection mechanism includes a micro switch 64 arranged in the negative conductive frame 61 , and a relay coupled to the micro switch 64 . The micro switch 64 is fixed on the bottom of the negative conductive frame 61 and faces the conductive sheet 62 . During the process of the station seat 21 pressing the conductive sheet 62 to the inner side of the negative conductive frame 61, the conductive sheet 62 touches the micro sw...

Embodiment 3

[0066] The only difference with embodiment 1 is: see Figure 9 , in order to ensure that during the polishing operation, a comprehensive pressure test is carried out on the outer circumference of the commutator 7 . The polishing wheel 3 is slightly inclined relative to the mandrel 23, and the radial axis of the polishing wheel 3 deviates from the vertical direction by 10°-20°. Through the above structure, during the polishing process of the commutator 7 by the polishing wheel 3 , the polishing wheel 3 simultaneously drives the commutator 7 to rotate around the mandrel 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com