Test structure and forming method thereof and testing method

A technology for testing structure and fixing structure, applied in microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of complex test process and low test structure accuracy, and achieve a small test range, a relatively high test range, Test the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background, when using the test equipment for detecting three-dimensional structures to test the existing test structure, the test process is complicated, and the accuracy of the obtained test structure is low.

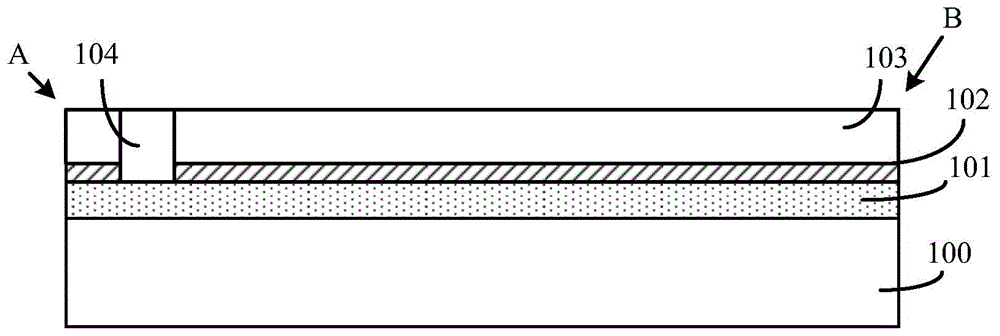

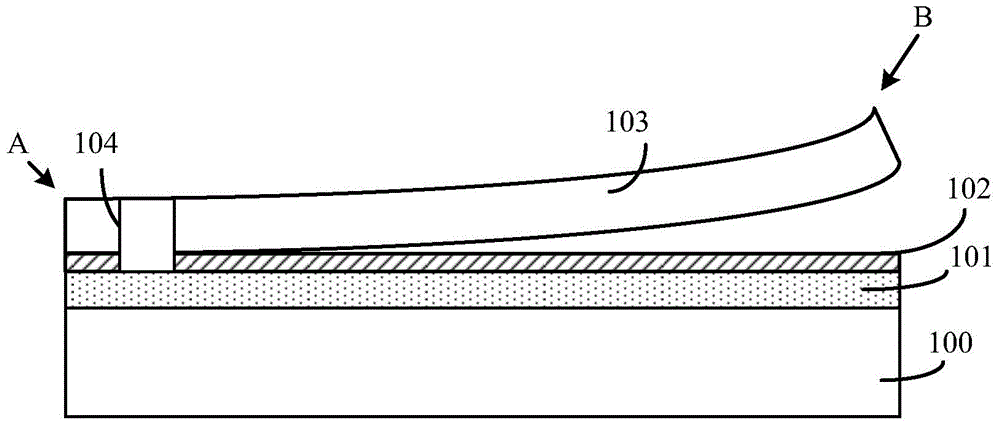

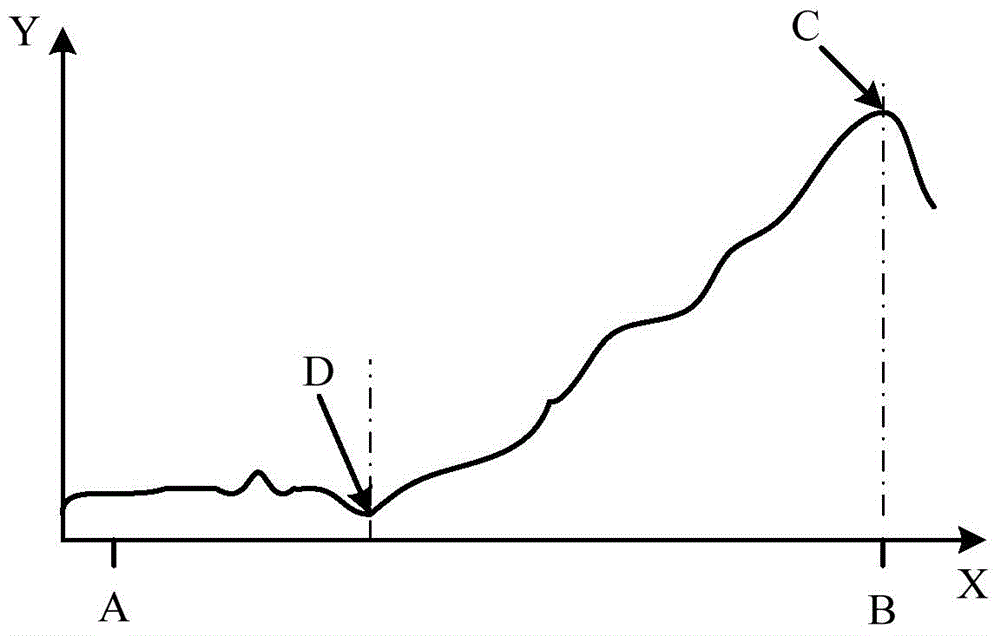

[0040] Please refer to figure 1 , figure 1 It is a schematic diagram of a test structure embodiment, including: a substrate 100; a dielectric layer 101 located on the surface of the substrate 100; a sacrificial layer 102 located on the surface of the dielectric layer 101; a stress layer 103 located on the surface of the sacrificial layer 102, and the sacrificial layer There is a lattice mismatch between the material of the stress layer 102 and the material of the stress layer 103, so that the surface of the stress layer 103 in contact with the sacrificial layer 102 is subjected to stress, and the A end of the stress layer 103 has a and a sacrificial layer 102 , and a plug 104 extending into the dielectric layer 101 , the plug 104 fixes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com