Underwater pipe clamp mounting method

An installation method and clip technology, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the cumbersome installation steps, increase the working time of the concentricity error rate of the pipe clip 1, and cannot be in place at one time to avoid cumbersome operations, reduce the amount of underwater operations, and improve overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

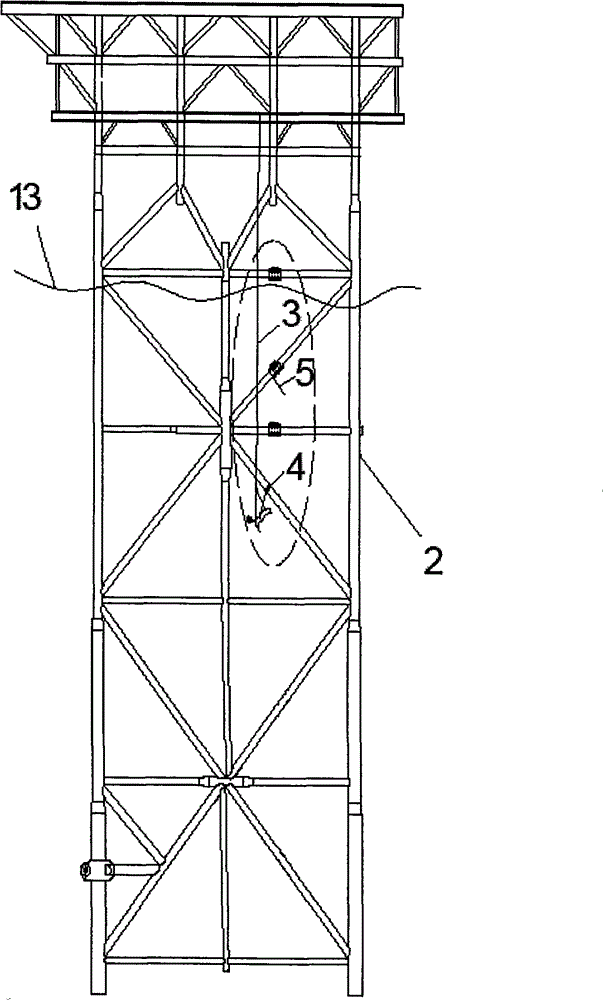

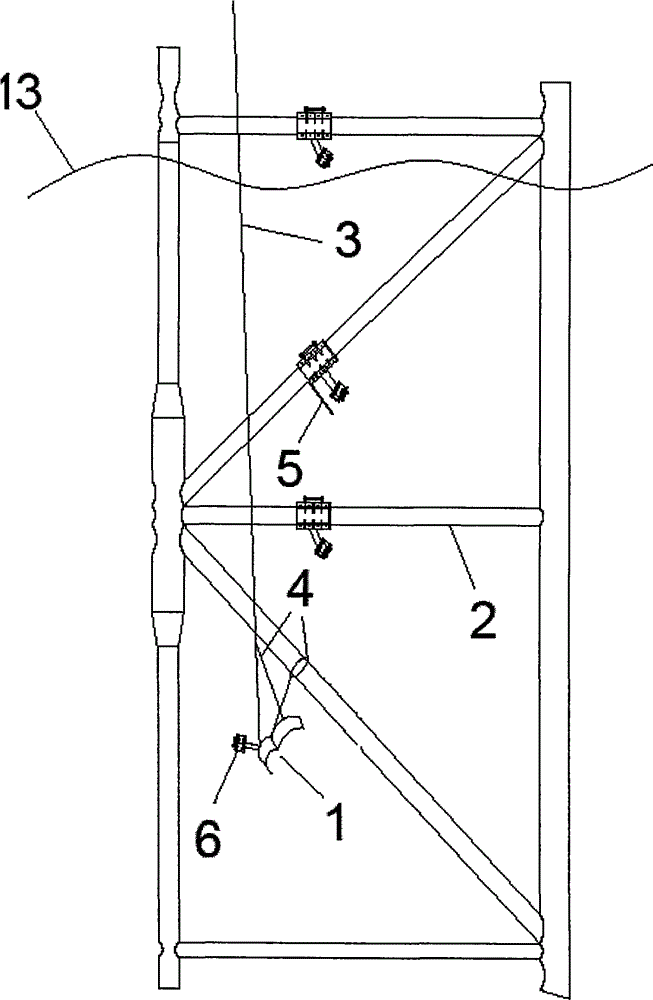

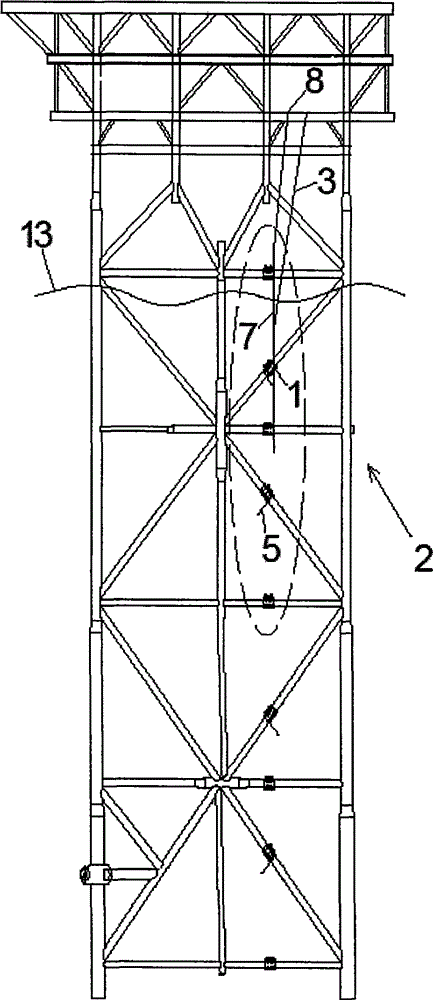

[0039] Such as Figure 5-Figure 6 As shown, the present invention includes:

[0040] 1) Install and fix several underwater pipe clamps 1 on the jacket member 2 respectively,

[0041] 2) Coaxially adjust several underwater clips 1, so that the centers of outer clips 6 of all several underwater pipe clips 1 installed and fixed on the jacket member 2 are on the same axis;

[0042] Such as Figure 5-Figure 6 As shown, the present embodiment takes the installation of 9 underwater riser clips 1 as an example to illustrate the above-mentioned installation steps as follows:

[0043] (1) Determine the installation position of the underwater riser clamp 1 and the placement positions of the three platform winches:

[0044] ① According to the structure of the jacket and the technical requirements of construction, determine the installation position of the clip 1 of the underwater riser;

[0045] ②Clean the marine organisms on the jacket member 2 at the installation point of the underwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com