Patents

Literature

30results about How to "Avoid tedious work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

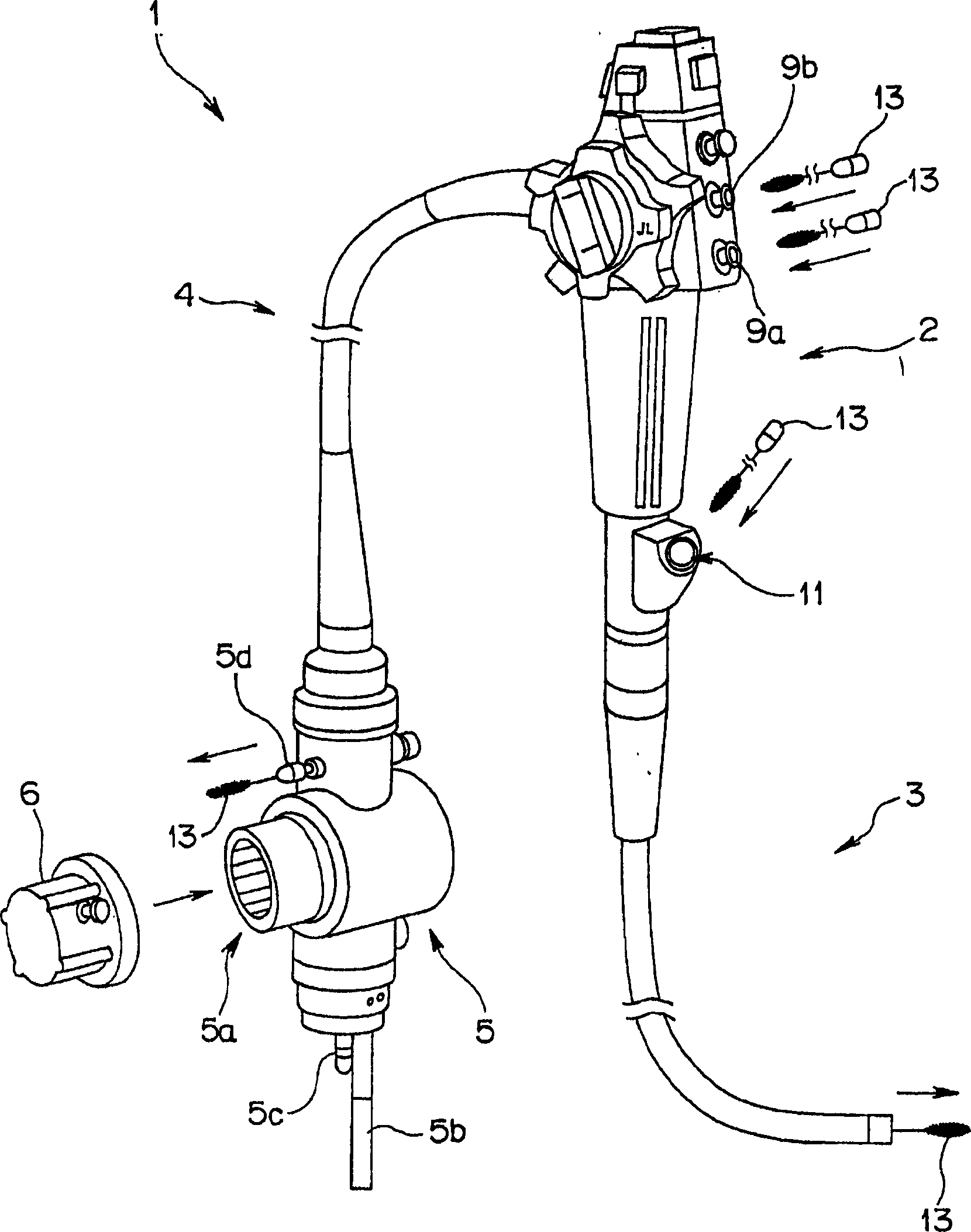

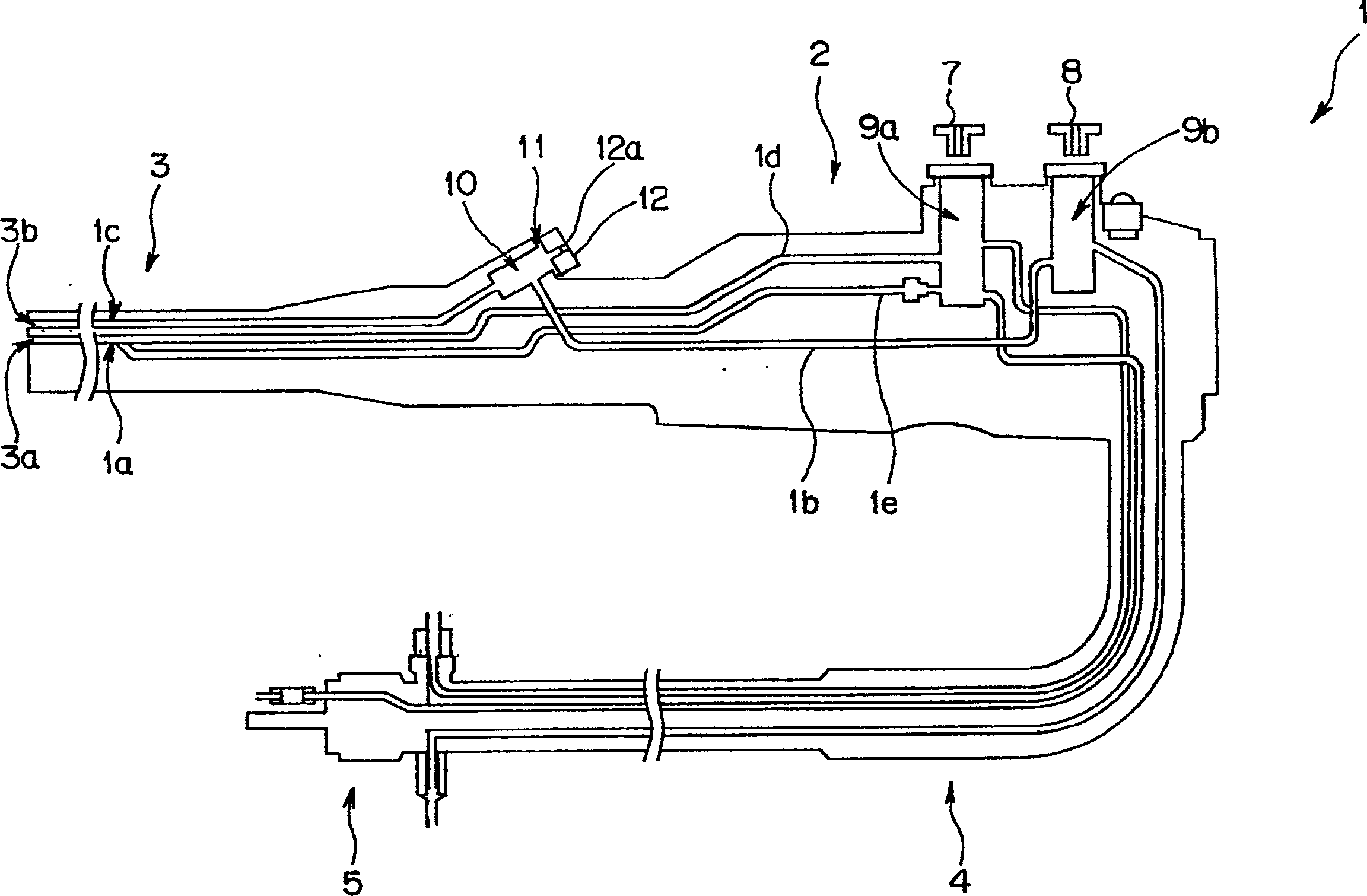

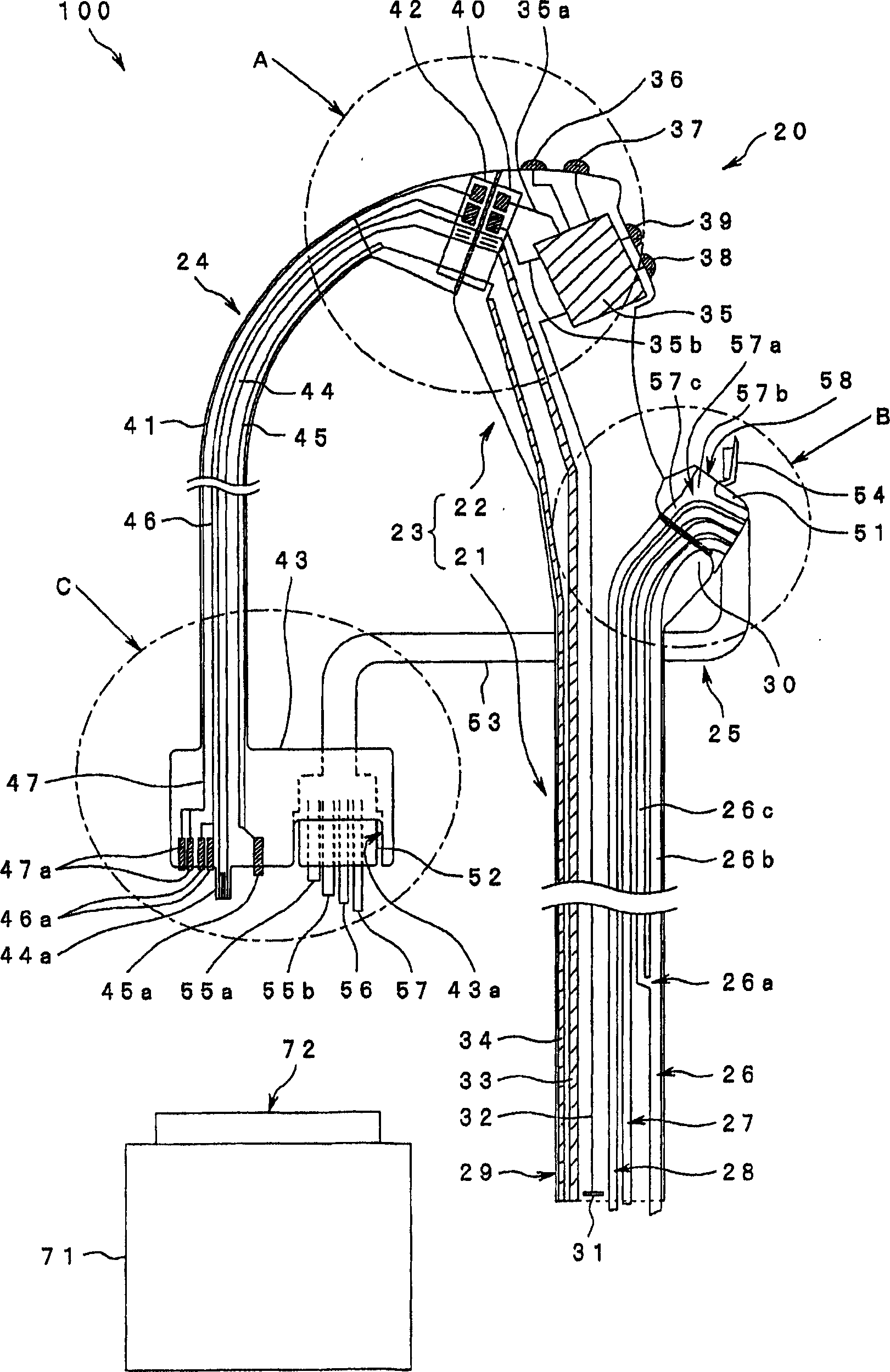

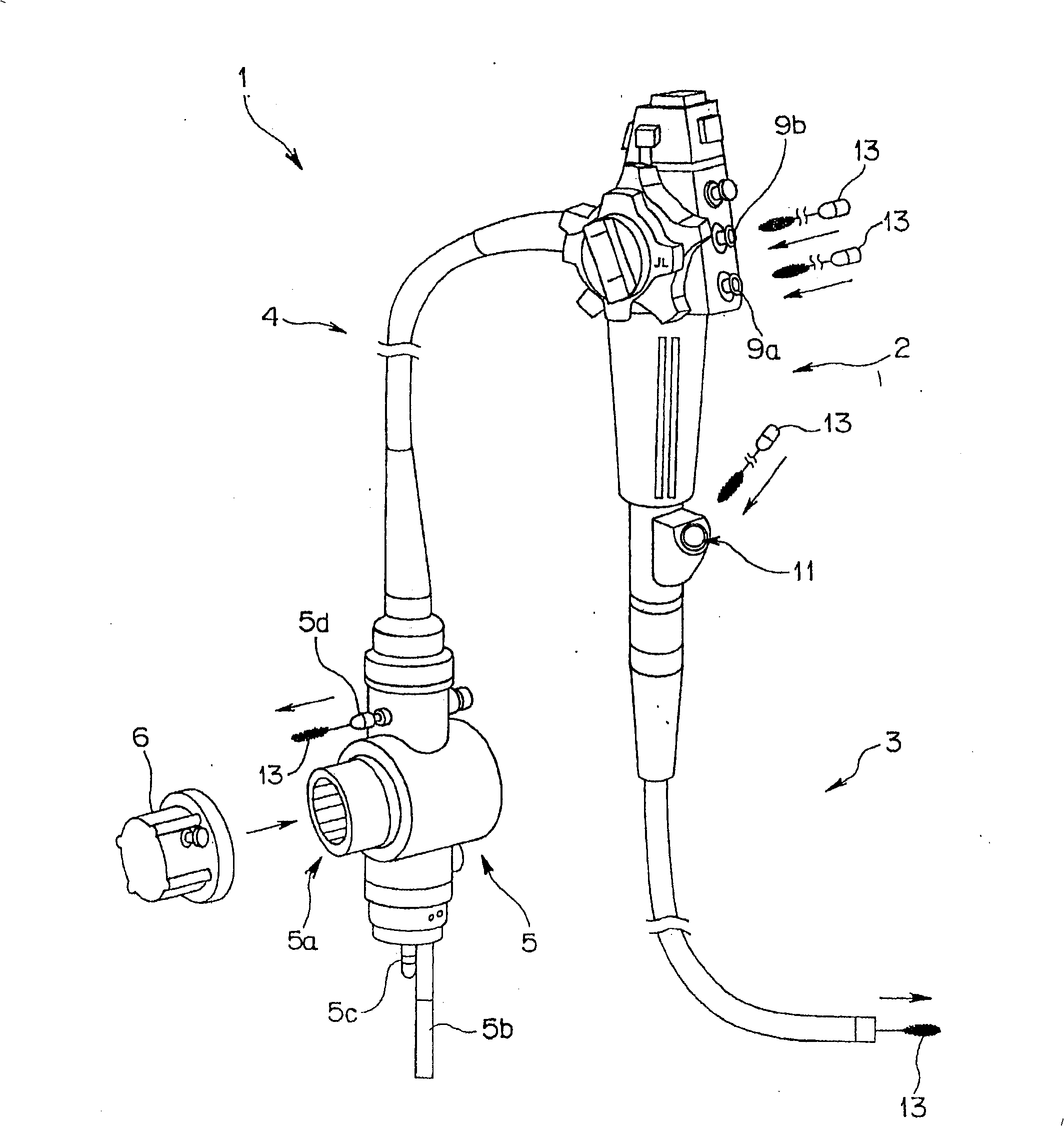

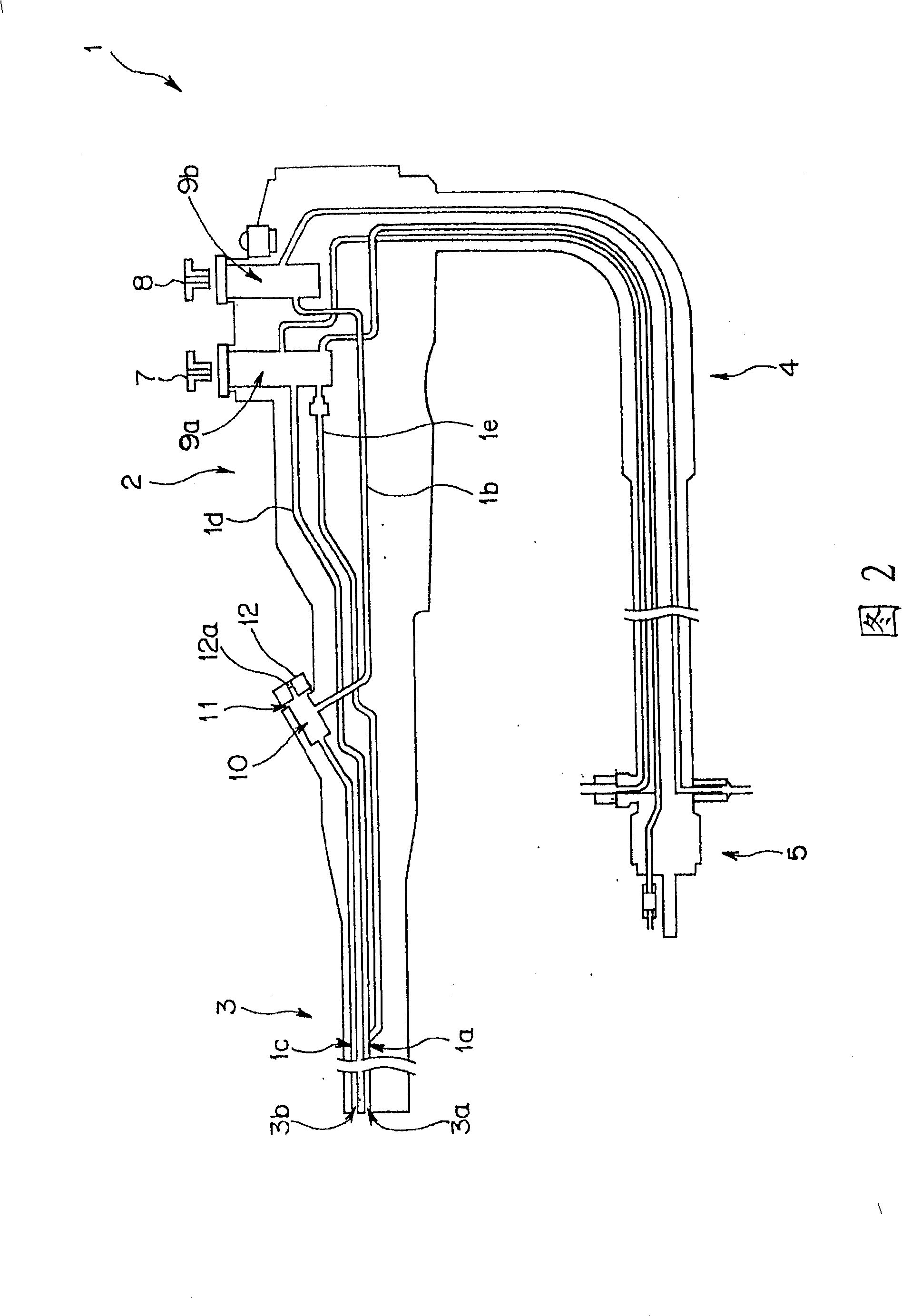

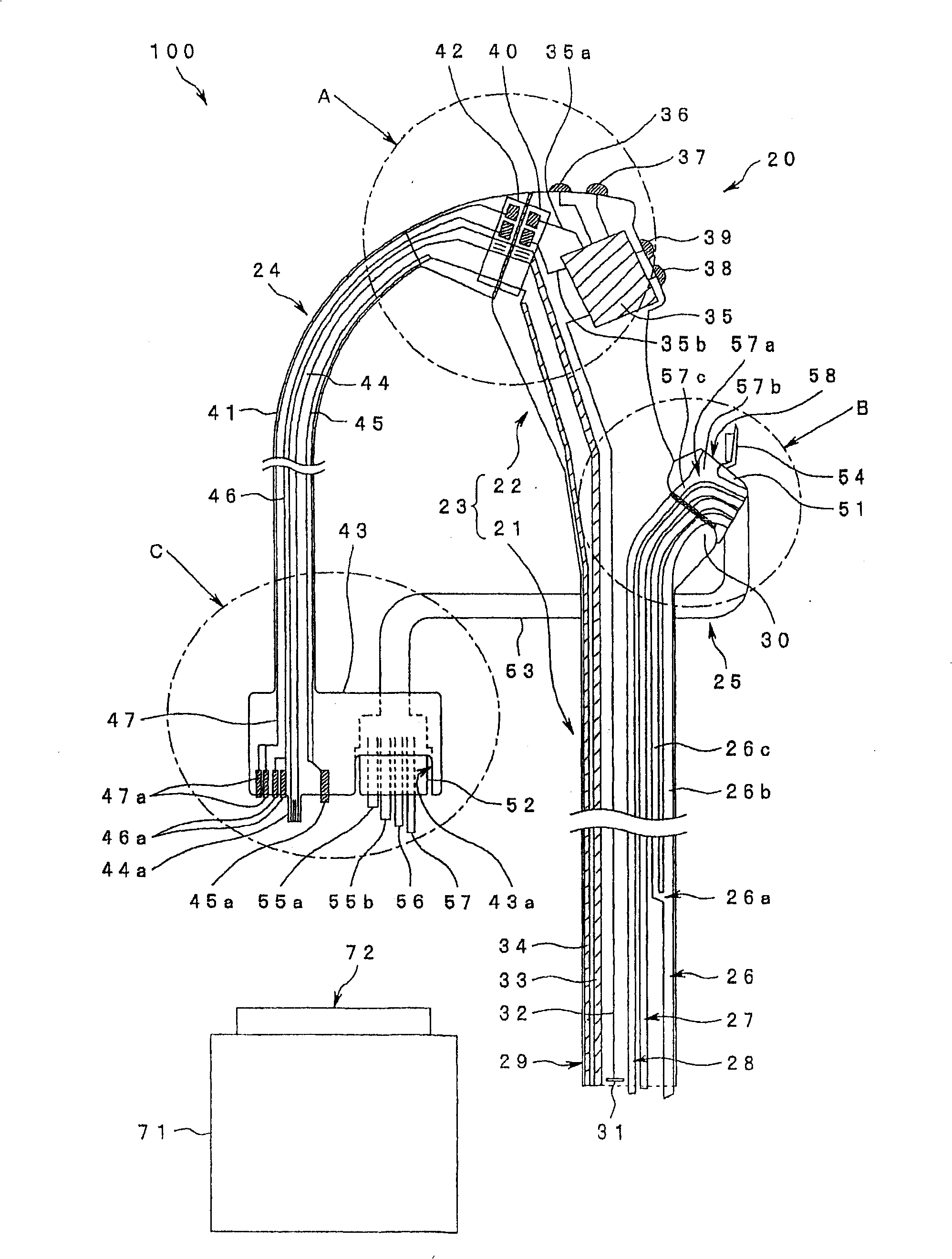

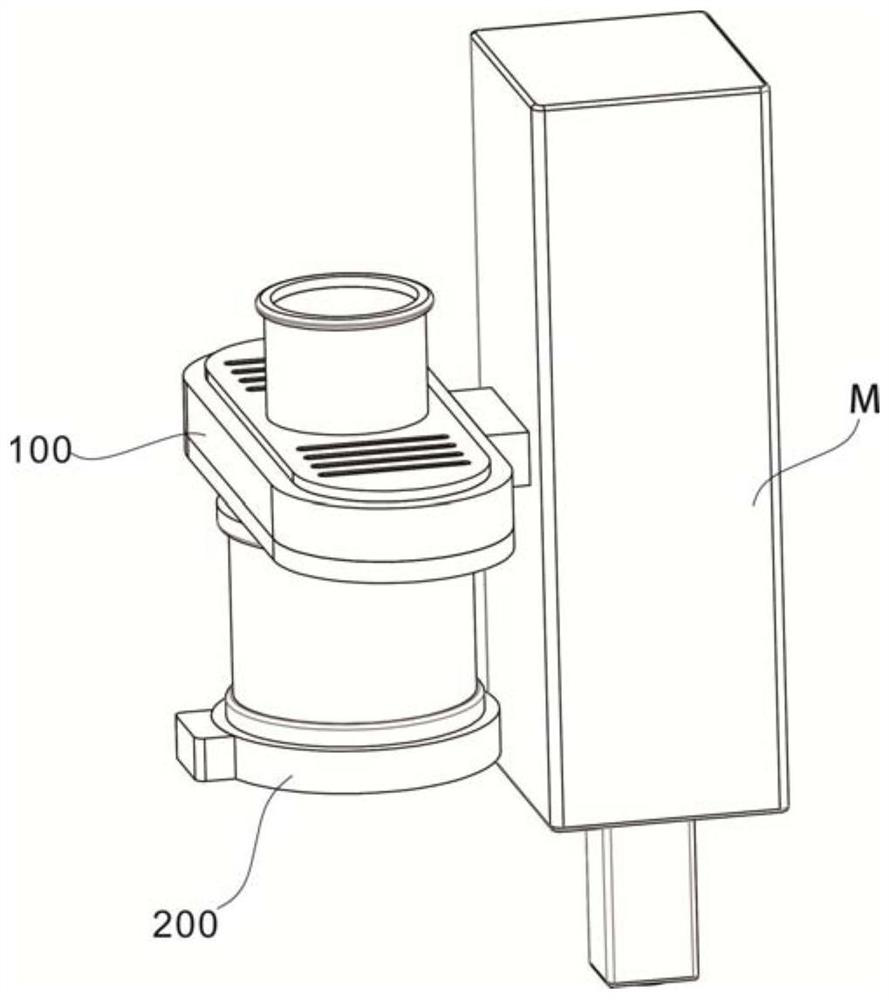

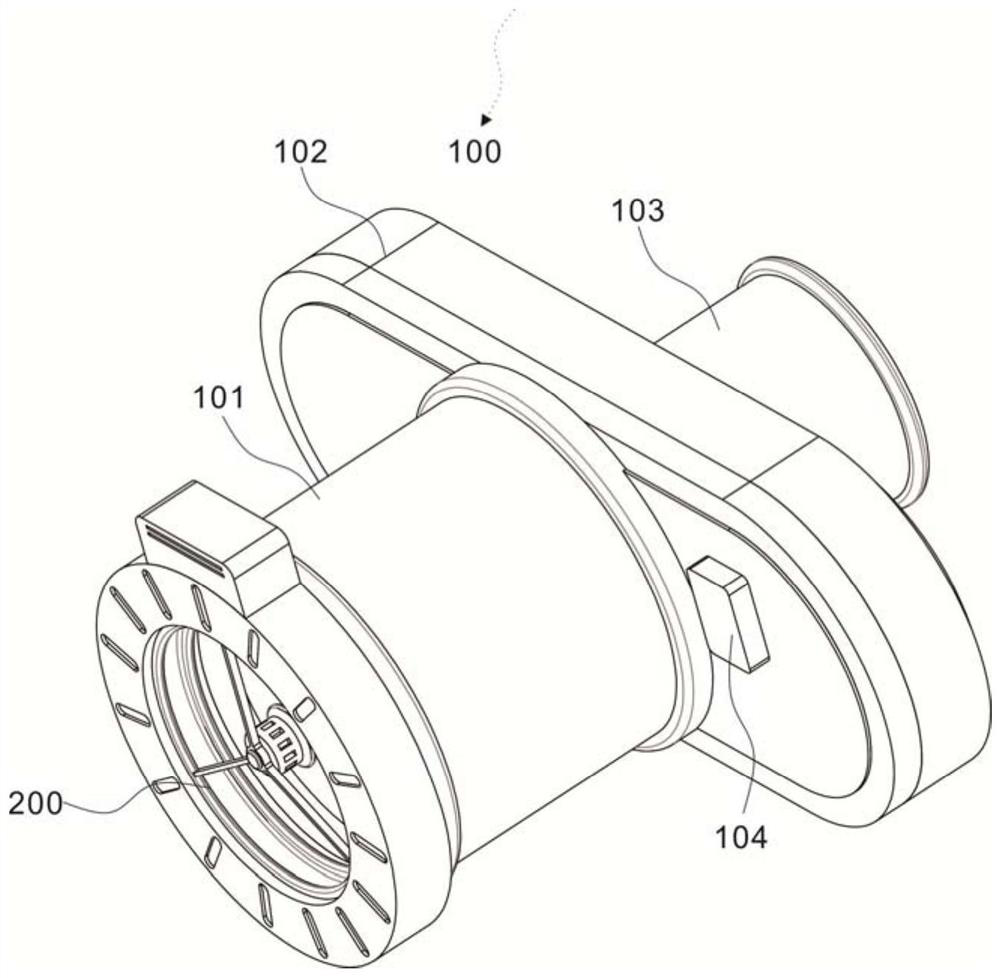

Endoscope system

An endoscope system capable of cleaning / sterilizing an endoscope more conveniently, comprising an endpscope provided with a body unit constituted by collecting at least various lines to a part, and a line unit being fixed removably to the body unit and having various lines communicating with the various lines collected at the body unit, and an endoscope controller comprising a pump / solenoid valve control unit for controlling supply or suction of fluid through various lines of the ecdoscope.

Owner:OLYMPUS CORP

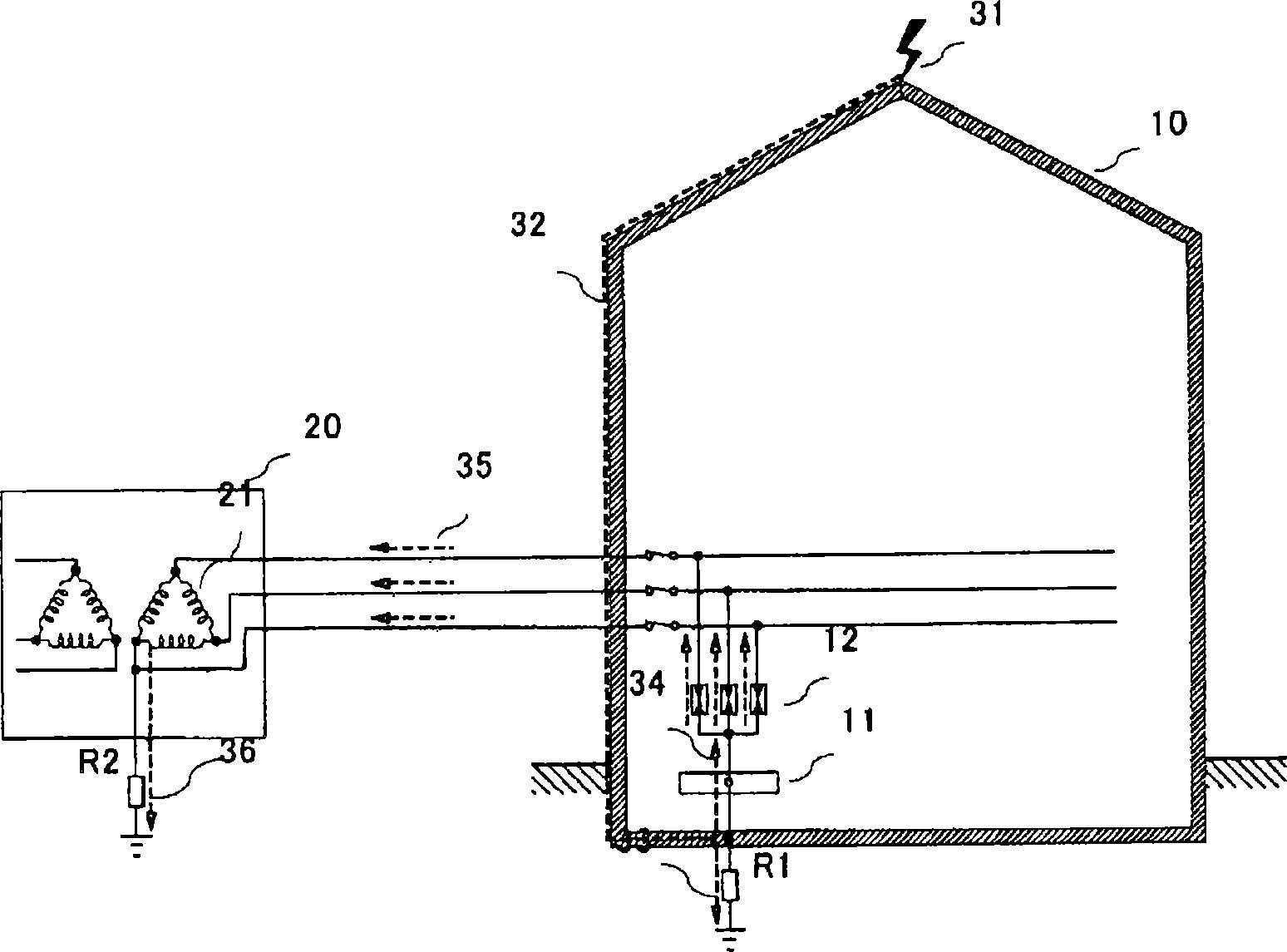

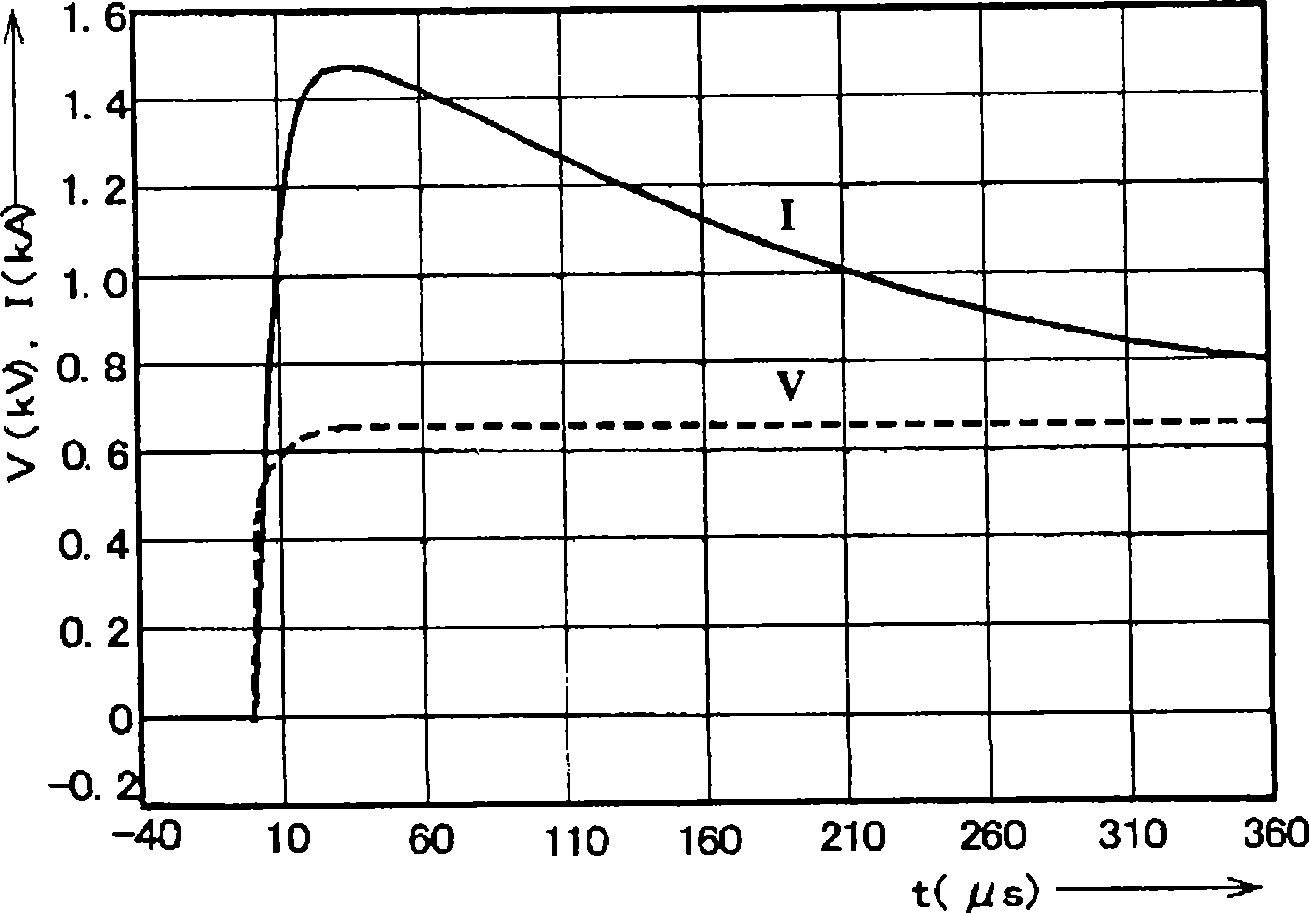

Spark gap arrestor

InactiveCN1918760AImprove self-blocking performanceAvoid tedious workSpark gap detailsEmergency protective arrangements for limiting excess voltage/currentVoltage dropCylindrical electrode

Owner:合资会社CSD

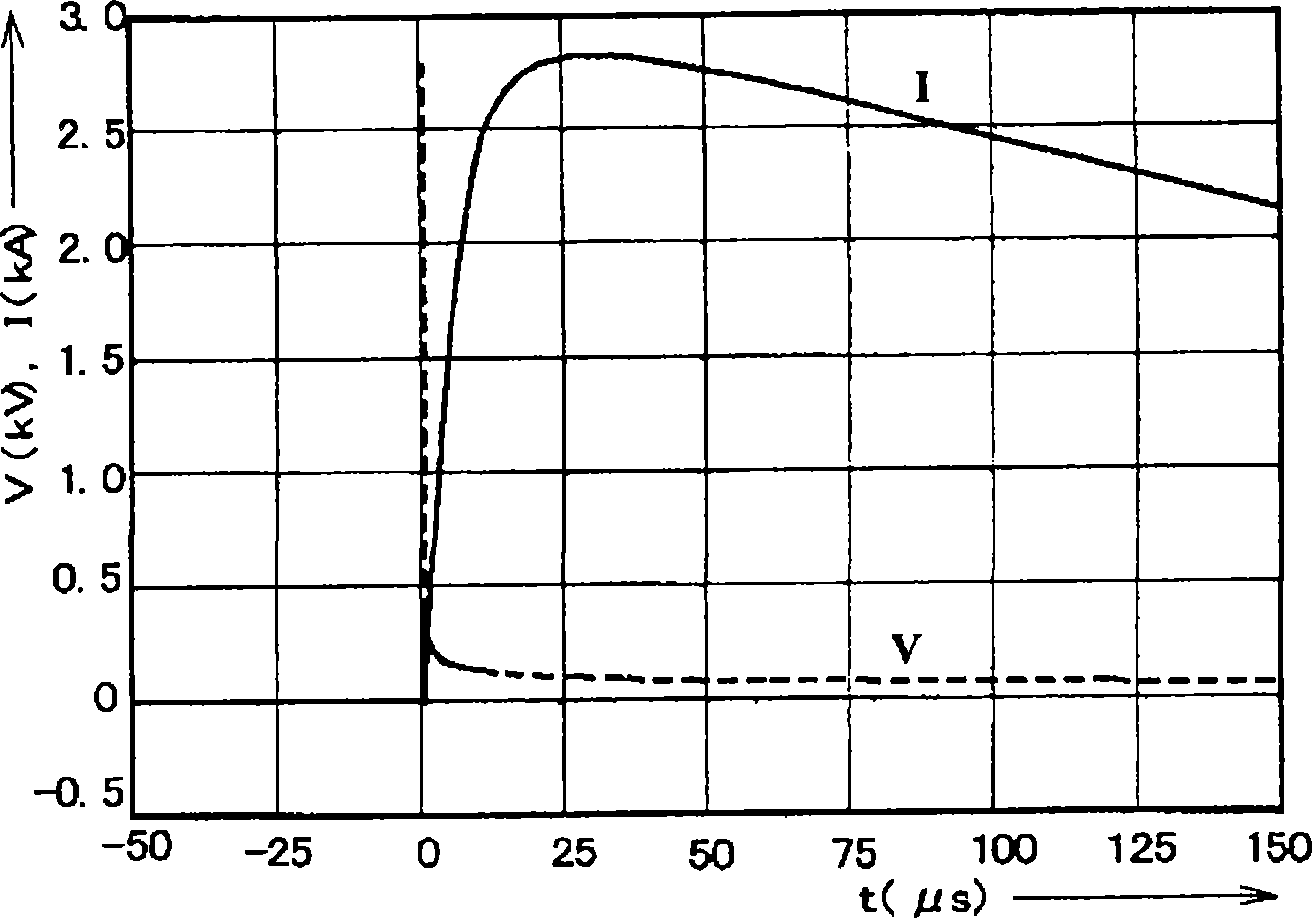

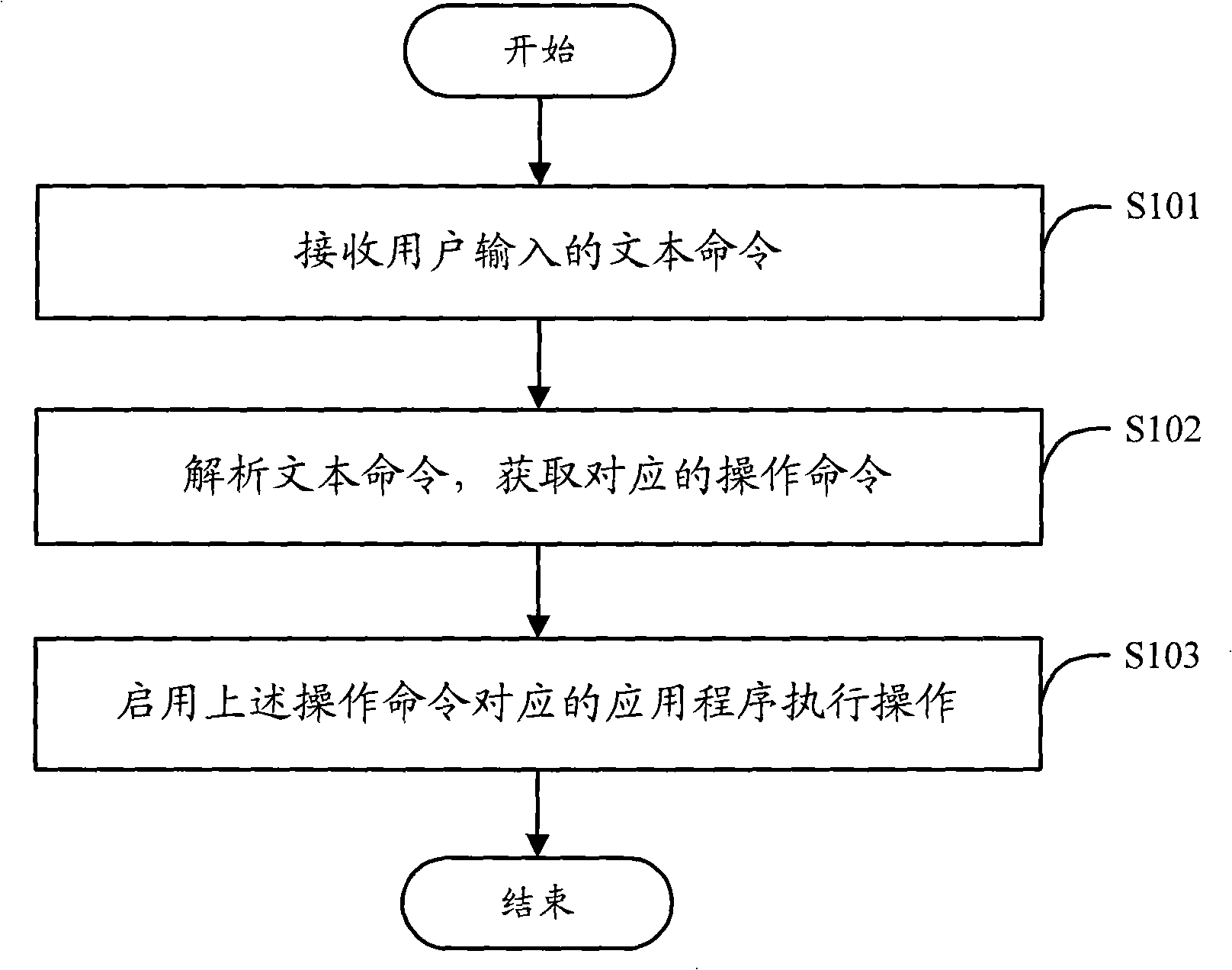

Human-machine interaction method and device of mobile phone

InactiveCN101272566AEasy to useAvoid tedious workSubstation equipmentRadio/inductive link selection arrangementsUser inputMan machine

The embodiment of the invention discloses a man-machine interactive method in a cell phone and a device, wherein, the method comprises the following steps: receiving the text command inputted by a user, analyzing the text command to obtain corresponding operation commands, and starting up applications corresponding to the operation commands to execute operation. Through receiving the text command inputted by the user, the text command is analyzed and the corresponding operation commands are obtained, then the applications corresponding to the operation commands are started up, thus finishing various operations in the manner of inputting the text command in the mode of command line, avoiding the cockamamie work in which various menus level by level, and facilitating the use of users.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

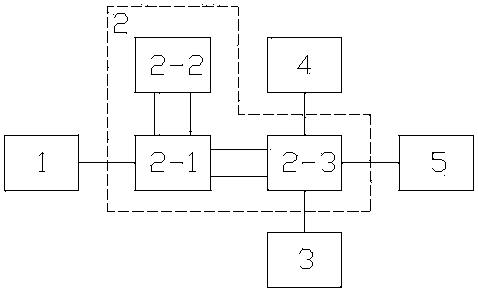

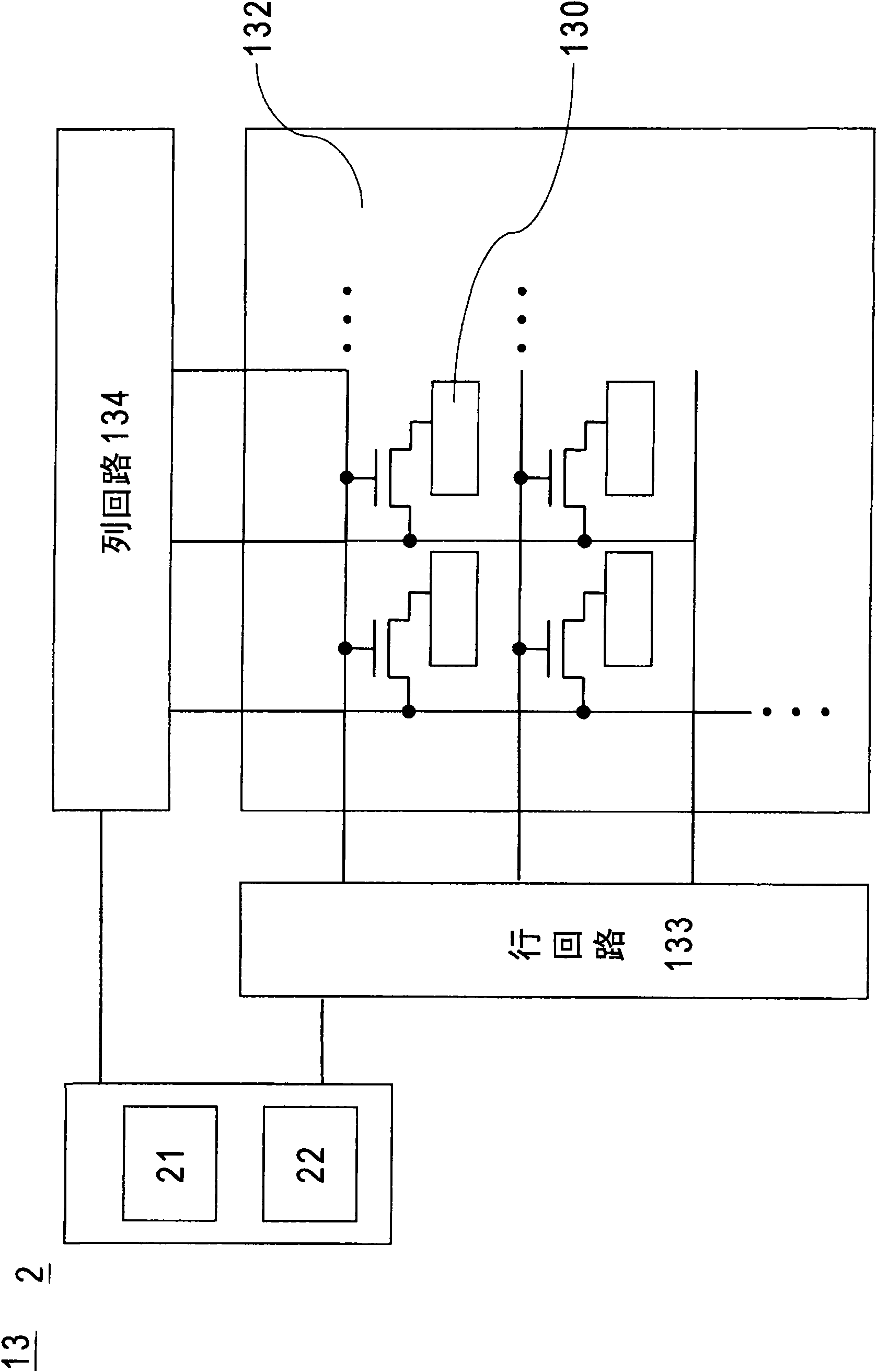

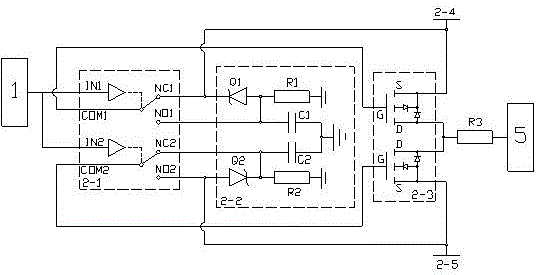

CCD detecting device

ActiveCN103837781AAvoid making operationsReduce consumptionElectrical testingSequence signalTerminal equipment

A CCD detecting device is characterized in that a pulse time sequence signal generating module, a CCD vertical time sequence driving circuit, a high-level direct-current source and a low-level direct-current source are included, the pulse time sequence signal generating module at least comprises a terminal device for man-machine interaction and a processing chip, operators input various preset control parameters into the processing chip through the terminal device, the processing chip generates corresponding pulse time sequence signals according to different control parameters, under the control effect of the pulse time sequence signals, the CCD vertical time sequence driving circuit can carry out time-sharing gating processing on the high-level direct-current source and the low-level direct-current source, and accordingly CCD driving signals corresponding to the pulse time sequence signals are obtained. The CCD detecting device has the advantages that one detecting circuit set can meet the detecting requirements of different types of CCDs, hardware consumption during a detecting process is lowered, trivial work that in the prior art, driving circuits need to be independently designed for different types of CCDs is avoided, and detecting working efficiency is indirectly improved.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

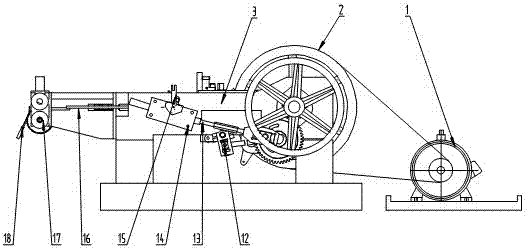

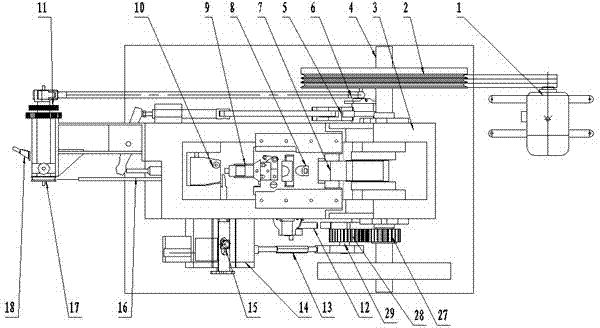

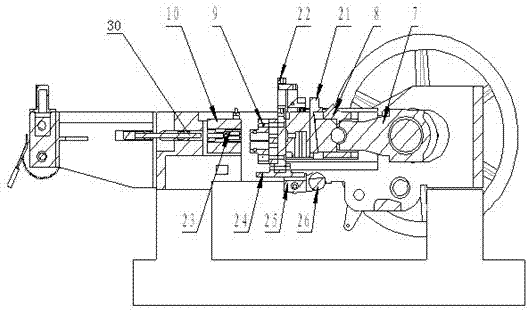

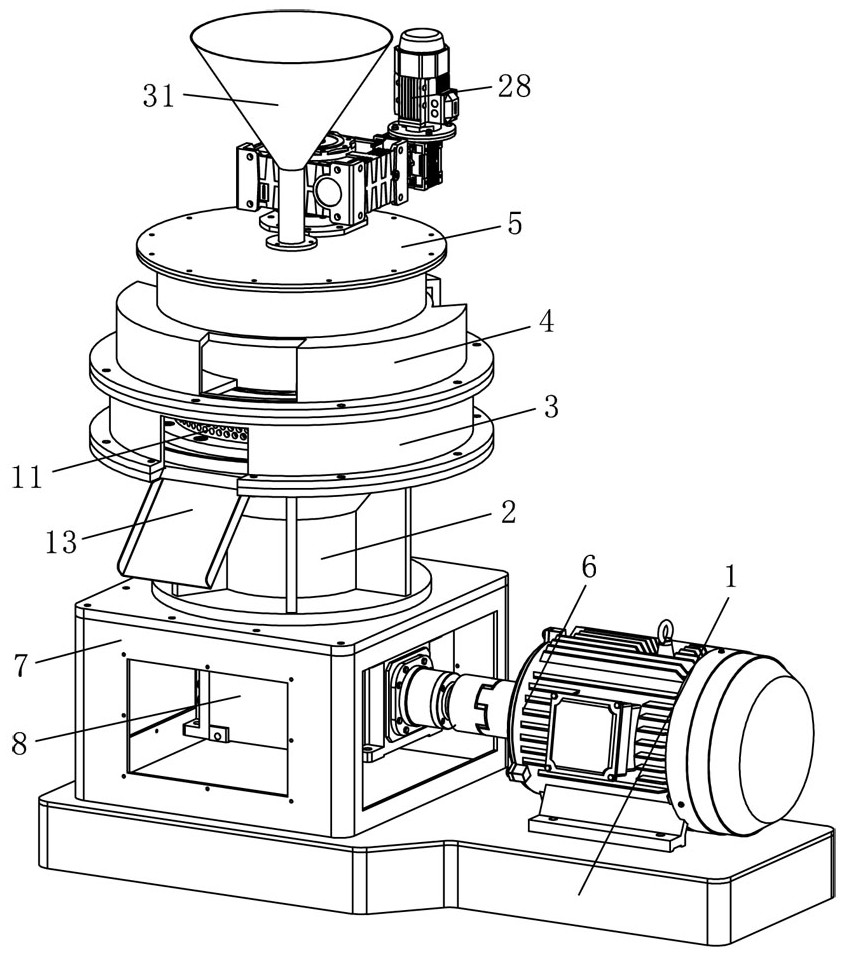

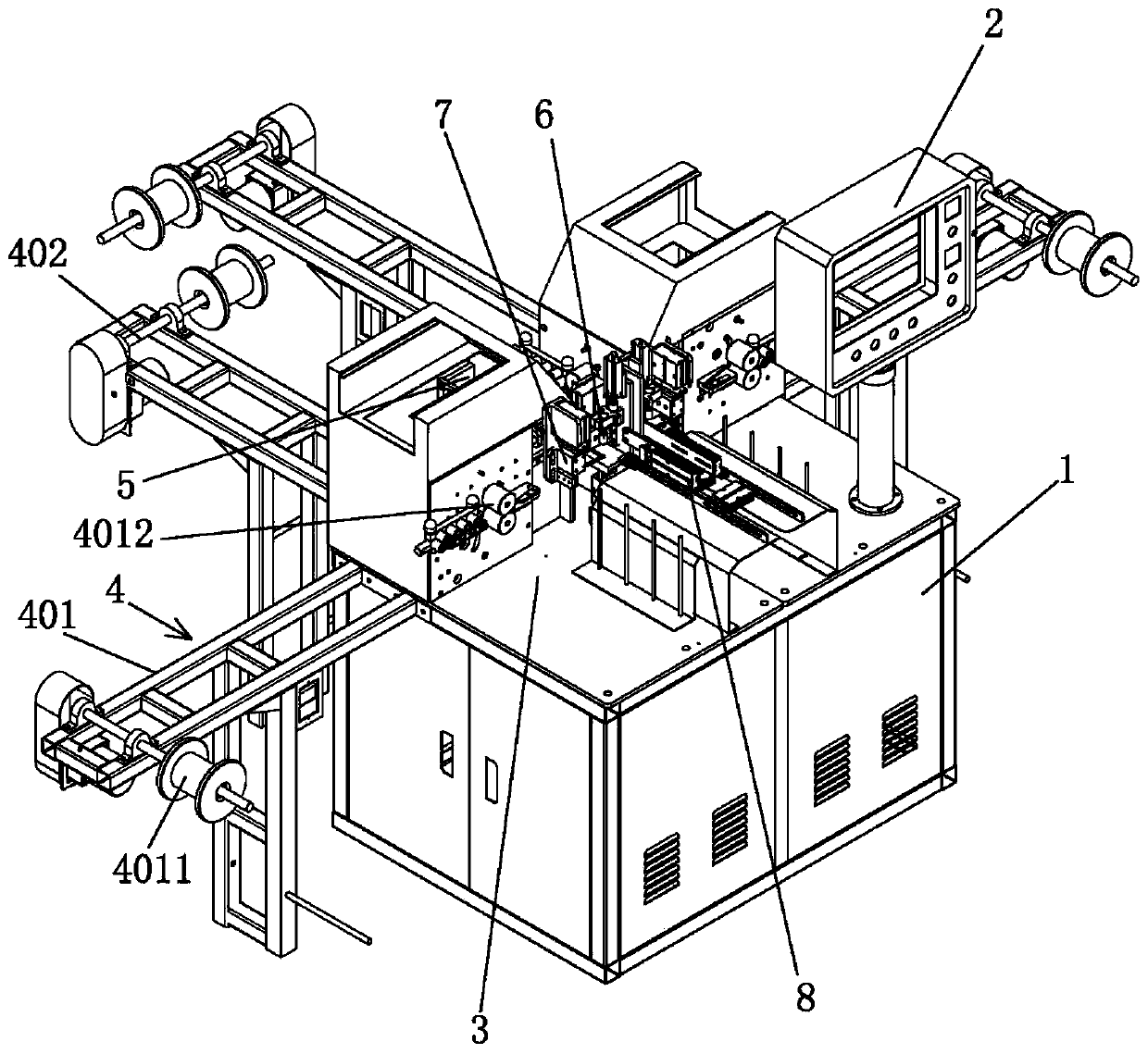

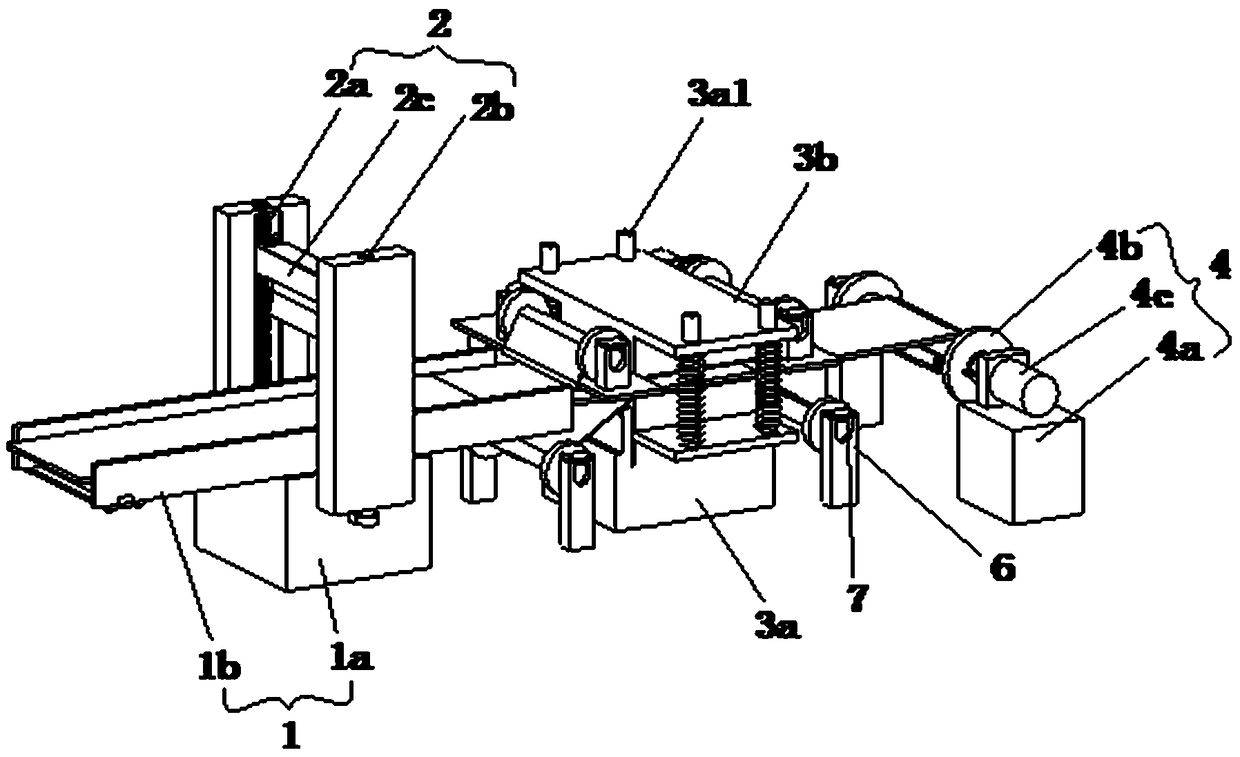

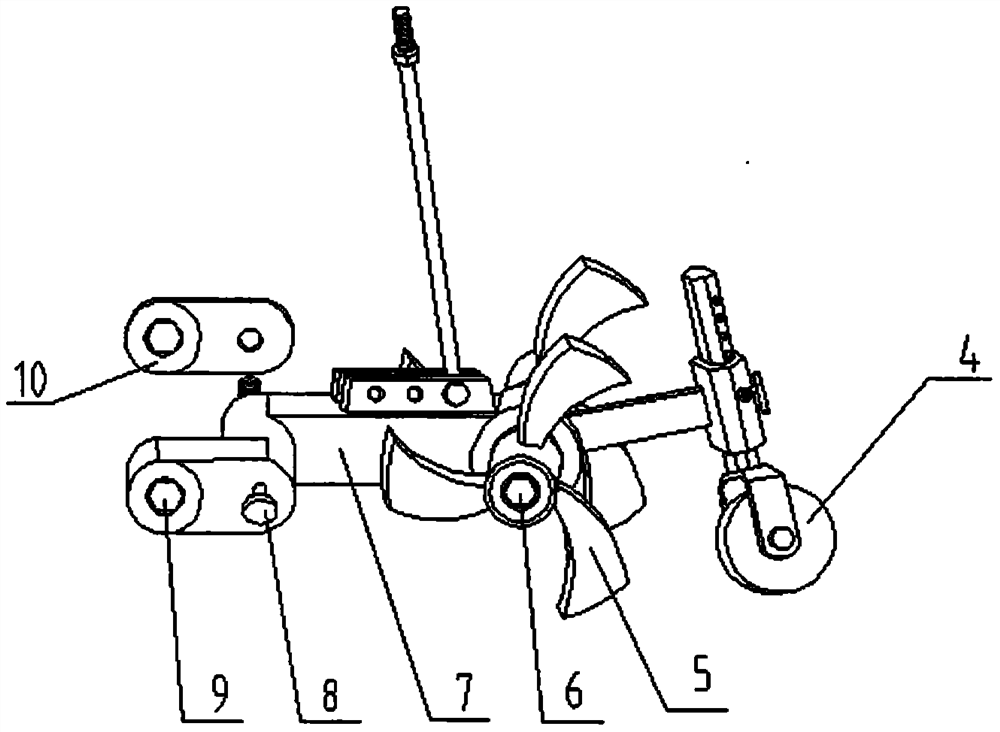

One-die two-stamping automatic warm upsetting forming machine

InactiveCN102728758AAvoid inefficiencyAvoid tedious workUpsetting pressesSwagging pressesAutomatic controlEngineering

The invention discloses a one-die two-stamping automatic warm upsetting forming machine, which comprises a forming machine tool body, a motor and a transmission device, wherein the tool body is provided with a feeding device, a heating device, a cutting device, an ejection device and an automatic controlled secondary stamping device; and the motor is respectively connected with the feeding device, the cutting device, the ejection device and the automatic controlled secondary stamping device through a transmission device and provides power for the feeding device, the cutting device, the ejection device and the automatic controlled secondary stamping device. Through the forming machine, continuous operation of heating, cutting and forging is realized, cost of materials is reduced, and energy consumption is reduced; the forming machine is safe and reliable; and the production benefits are improved by more than five times, and warm upsetting of complex parts is realized.

Owner:YIXING SHANGBIAO MACHINE TOOLS PLANT

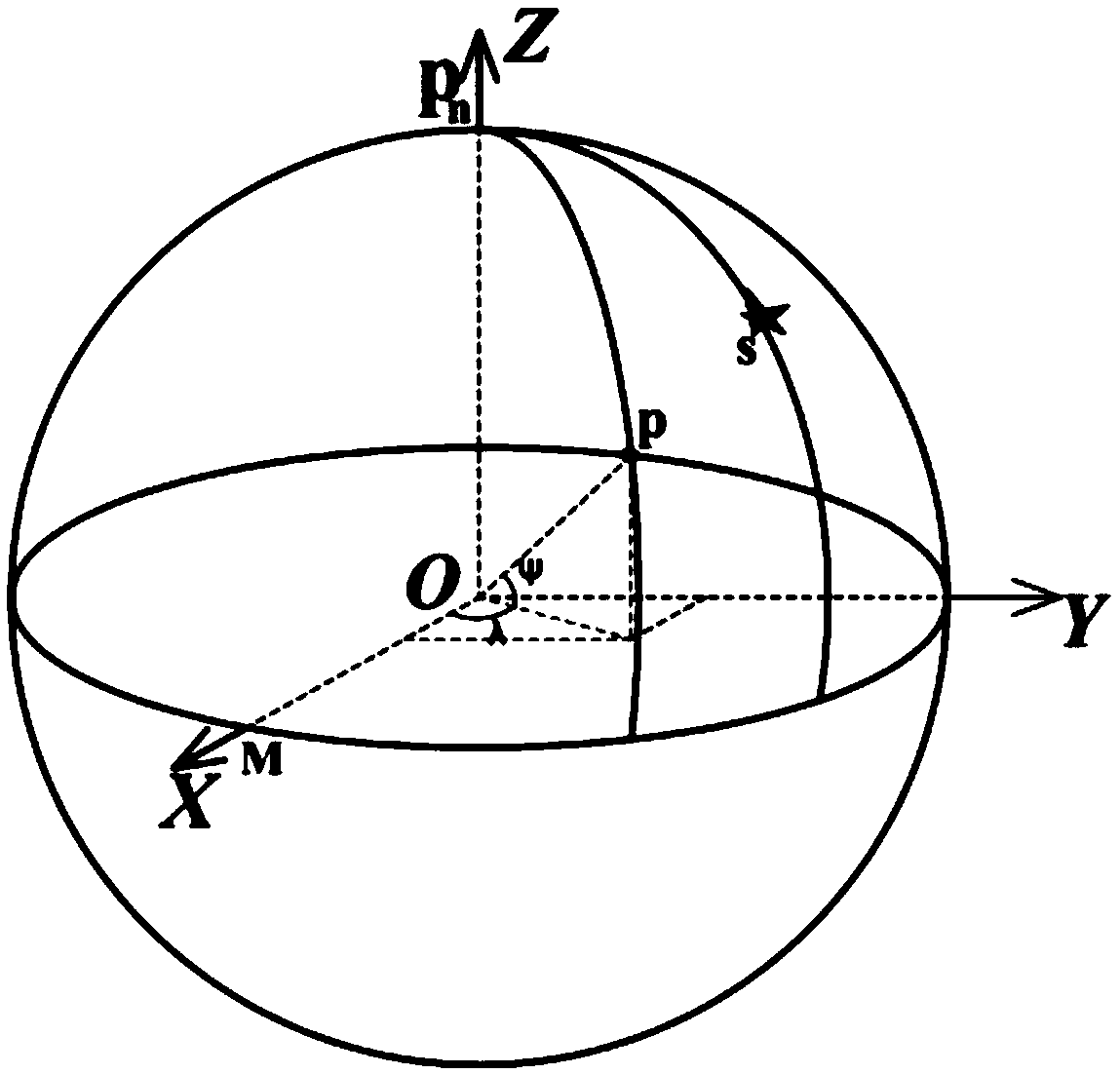

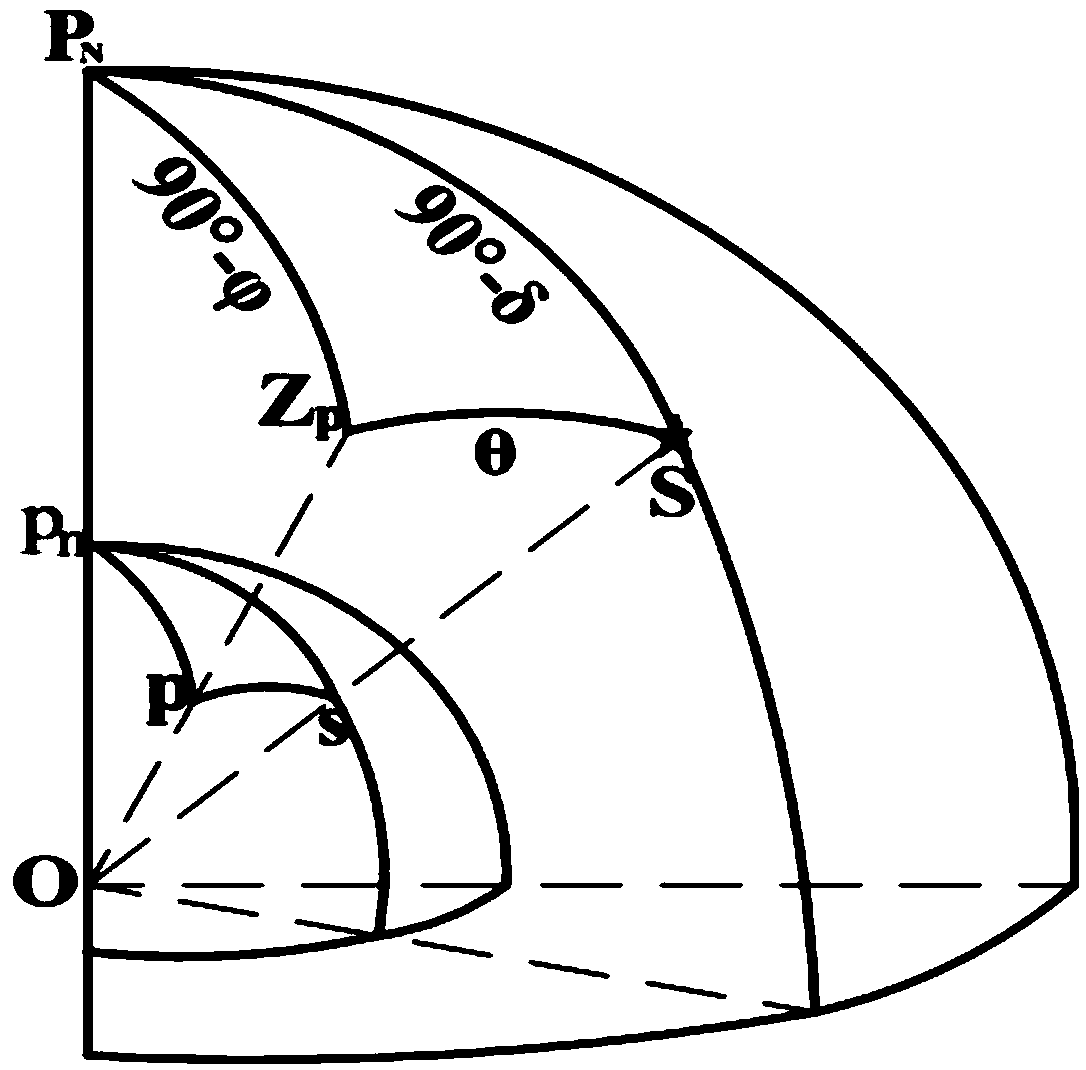

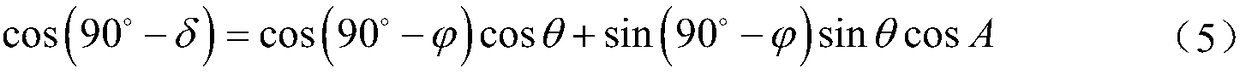

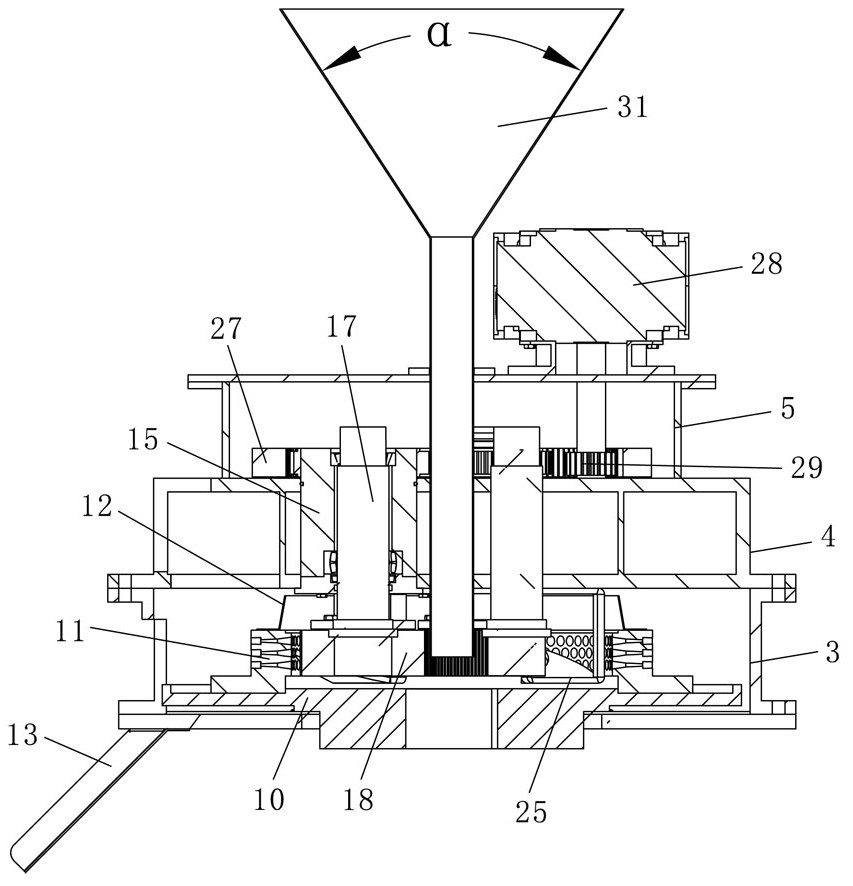

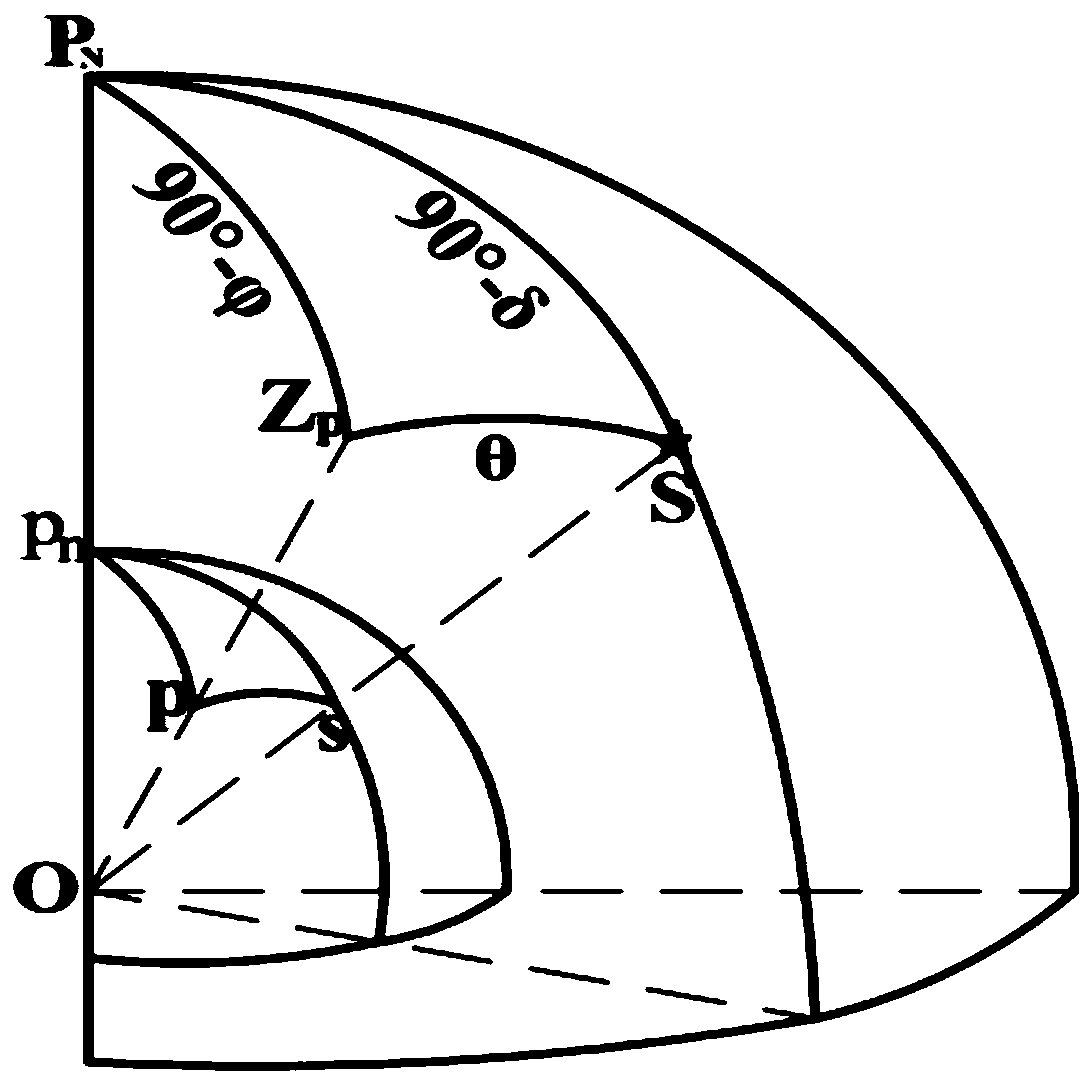

Fast and direct calculation method of celestial fix of single celestial body

InactiveCN109099905APrecise positioningAvoid tedious workNavigational calculation instrumentsNavigation by astronomical meansAzimuthMathematical model

The invention discloses a fast and direct calculation method of celestial fix of a single celestial body. The method comprises the following steps: step 1, establishing celestial fix coordinates; step2, deriving a spherical celestial fix formula based on an astronomical triangle; step 3, deriving a celestial fix mathematical model of the single celestial body via vector transformation; and step 4, solving the celestial fix mathematical model of the single celestial body via Newton iteration to obtain the longitude and latitude of a ship at an observation moment. According to the fast and direct calculation method disclosed by the invention, the celestial fix is performed by observing an azimuth angle and an elevating angle of the single celestial body at the same moment, the position of the ship is directly obtained through a numerical computation method, the cumbersome operation of a ship position line and an error introduced by replacing a curve with a straight line when the ship position line is drawn can be avoided, and the position of the ship can be determined quickly and accurately.

Owner:TIANJIN UNIV

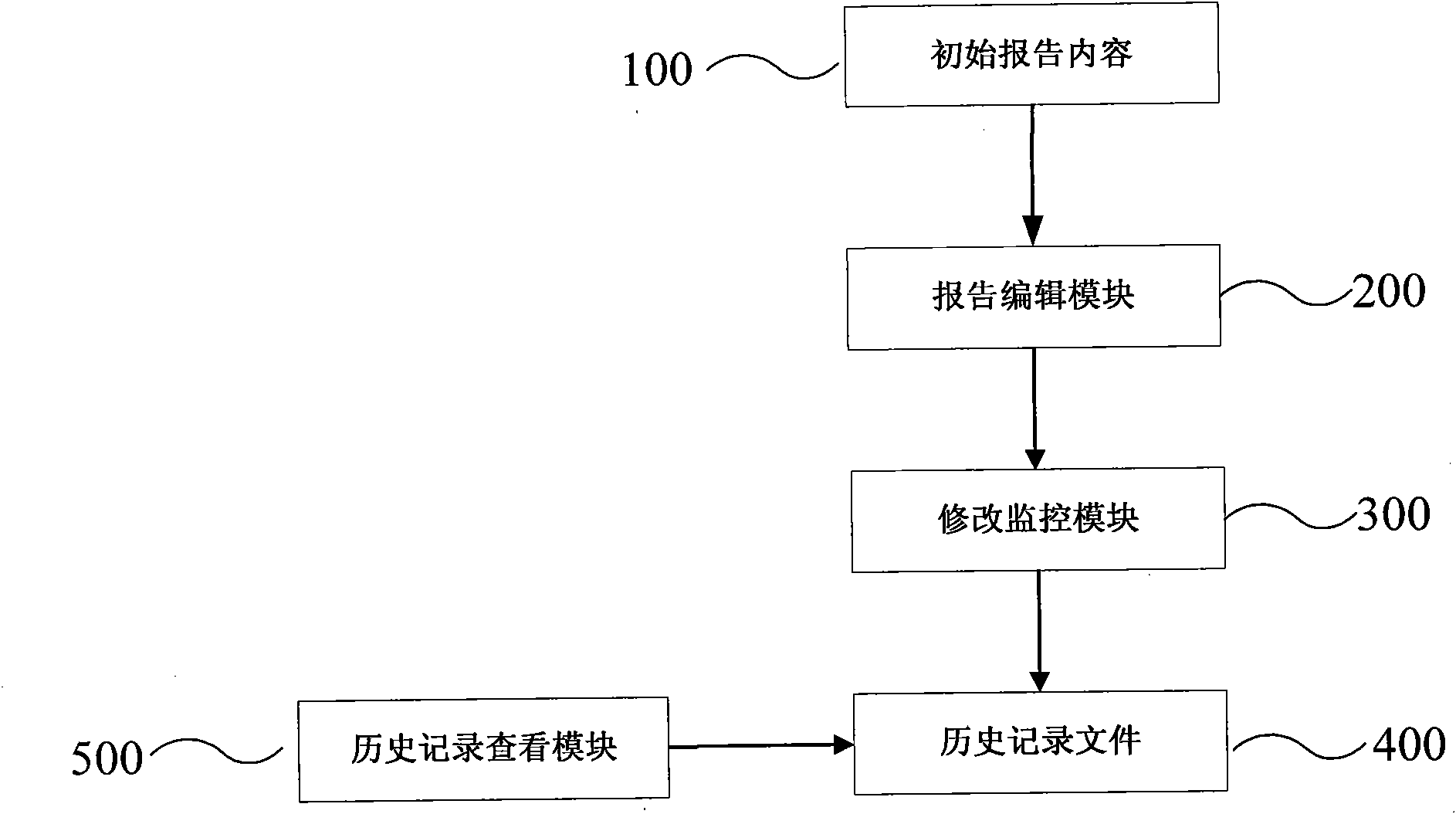

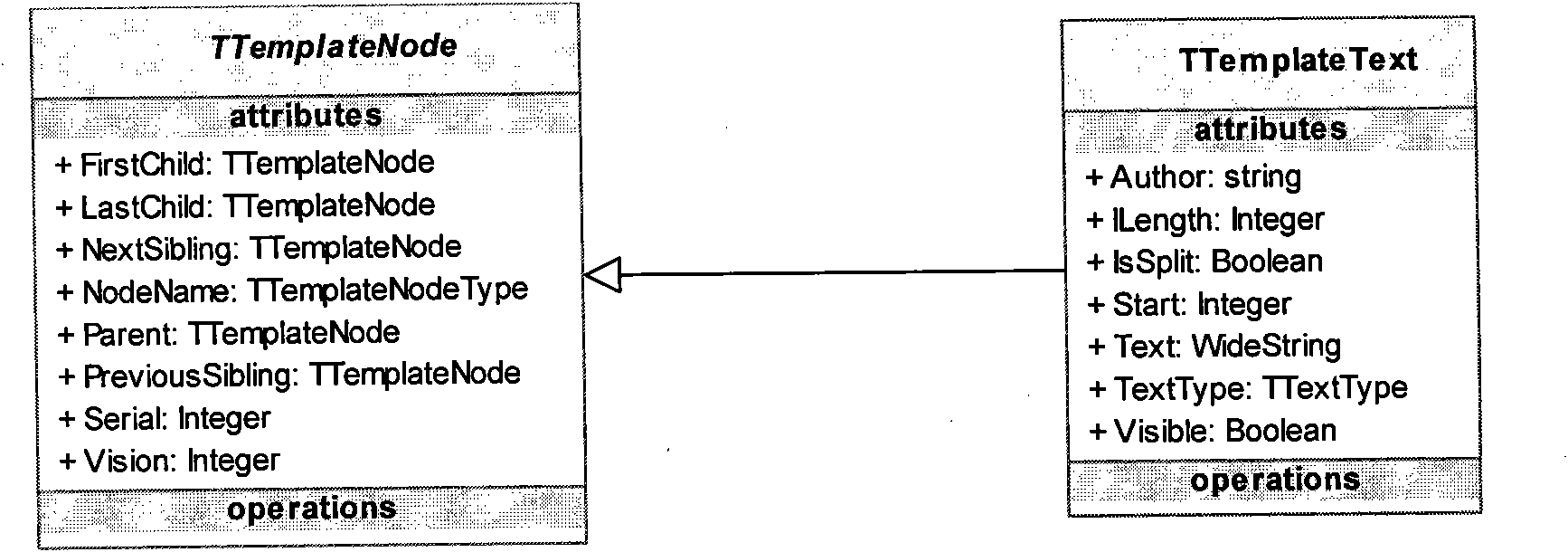

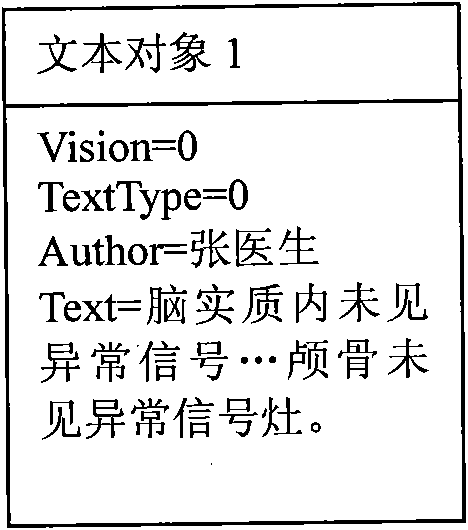

Method for implementing editing and modifying of medical examination report

InactiveCN101788977AImprove work efficiencyAvoid tedious workSpecial data processing applicationsXMLDatabase

The invention discloses a method for implementing editing and modifying of a medical examination report, which comprises the steps of: A1. establishing XML-format history record files and corresponding text node categories; A2. monitoring the contents of the input or modified medical examination report by a modifying monitoring module according to the keyboard message and mouse message and storing the contents of the input or modified medical examination report through instance objects of the text node categories when entering or editing the medical examination report; and A3. explaining all the instance objects according to the XML format and storing the explained contents in the history record files by the modifying monitoring module.

Owner:SHENZHEN LANDWIND IND

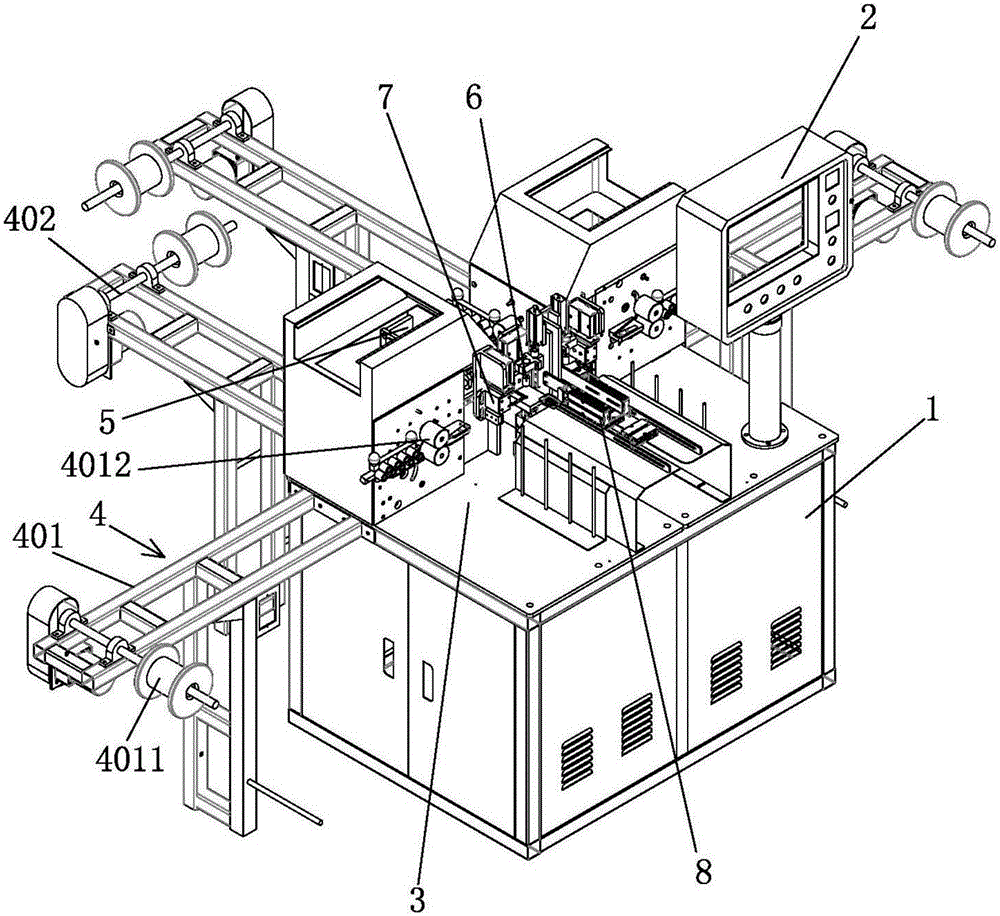

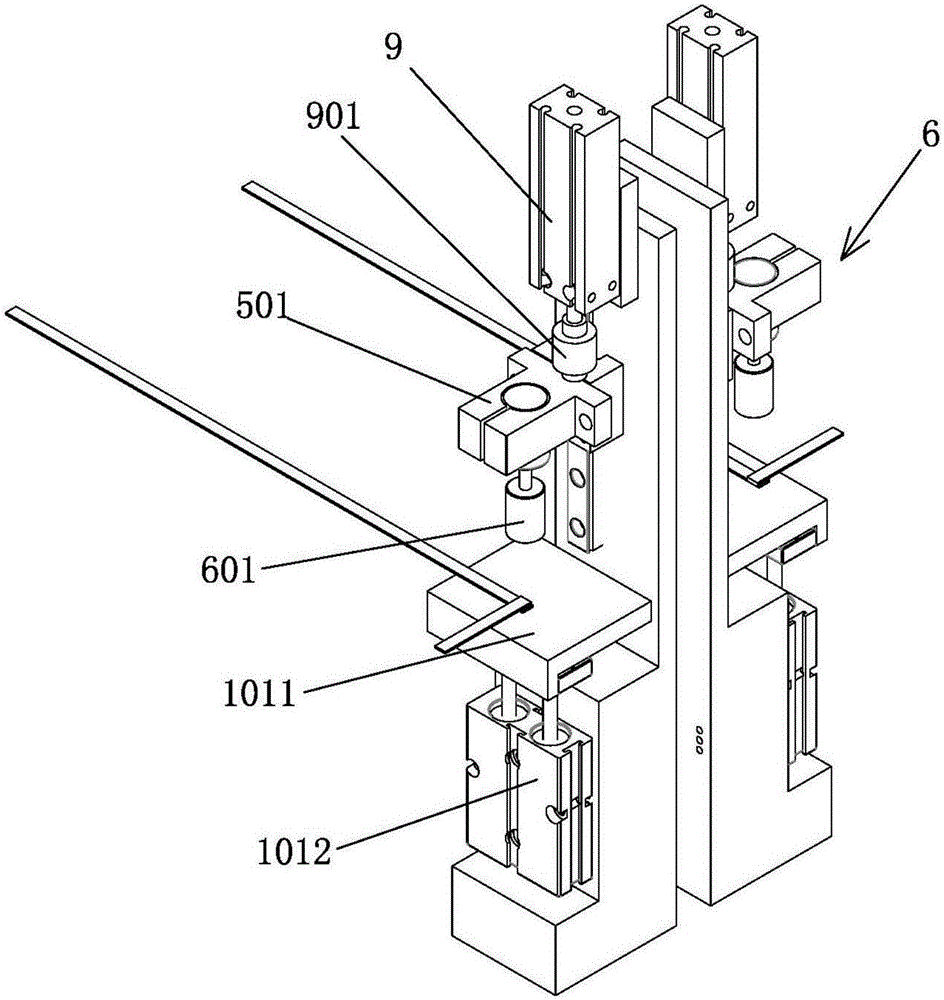

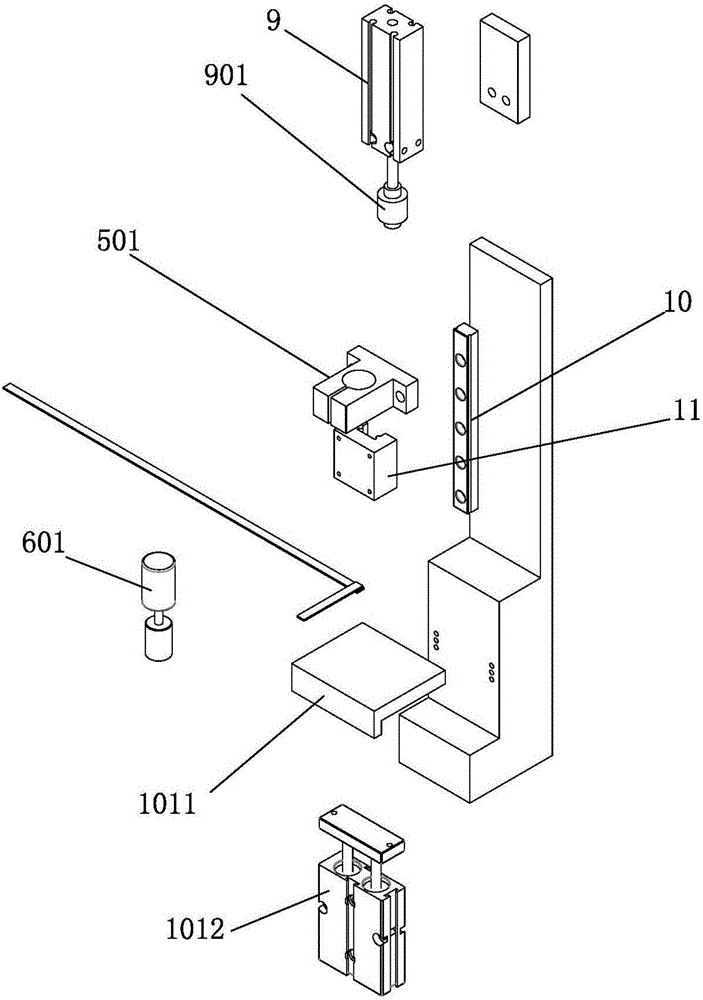

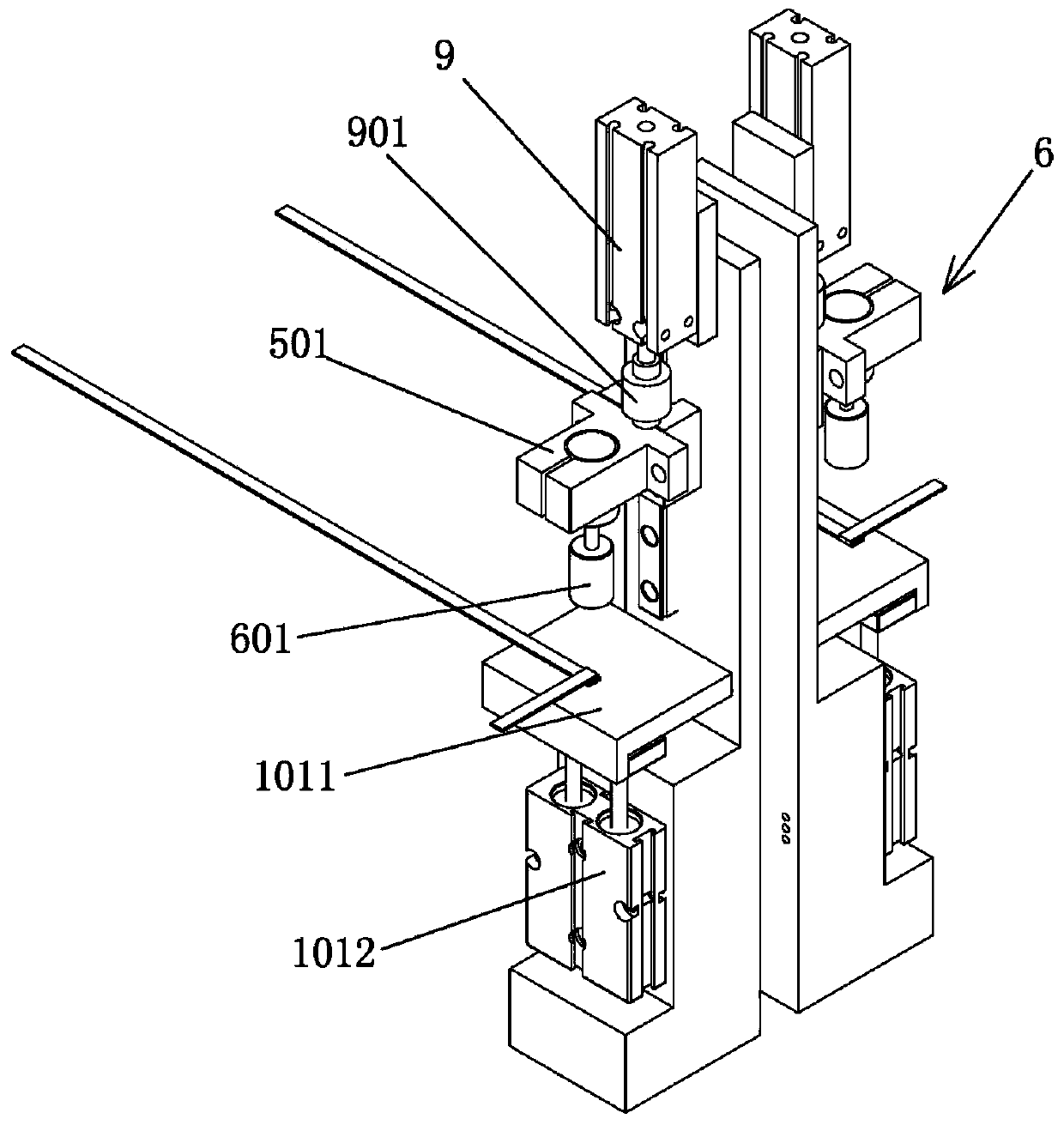

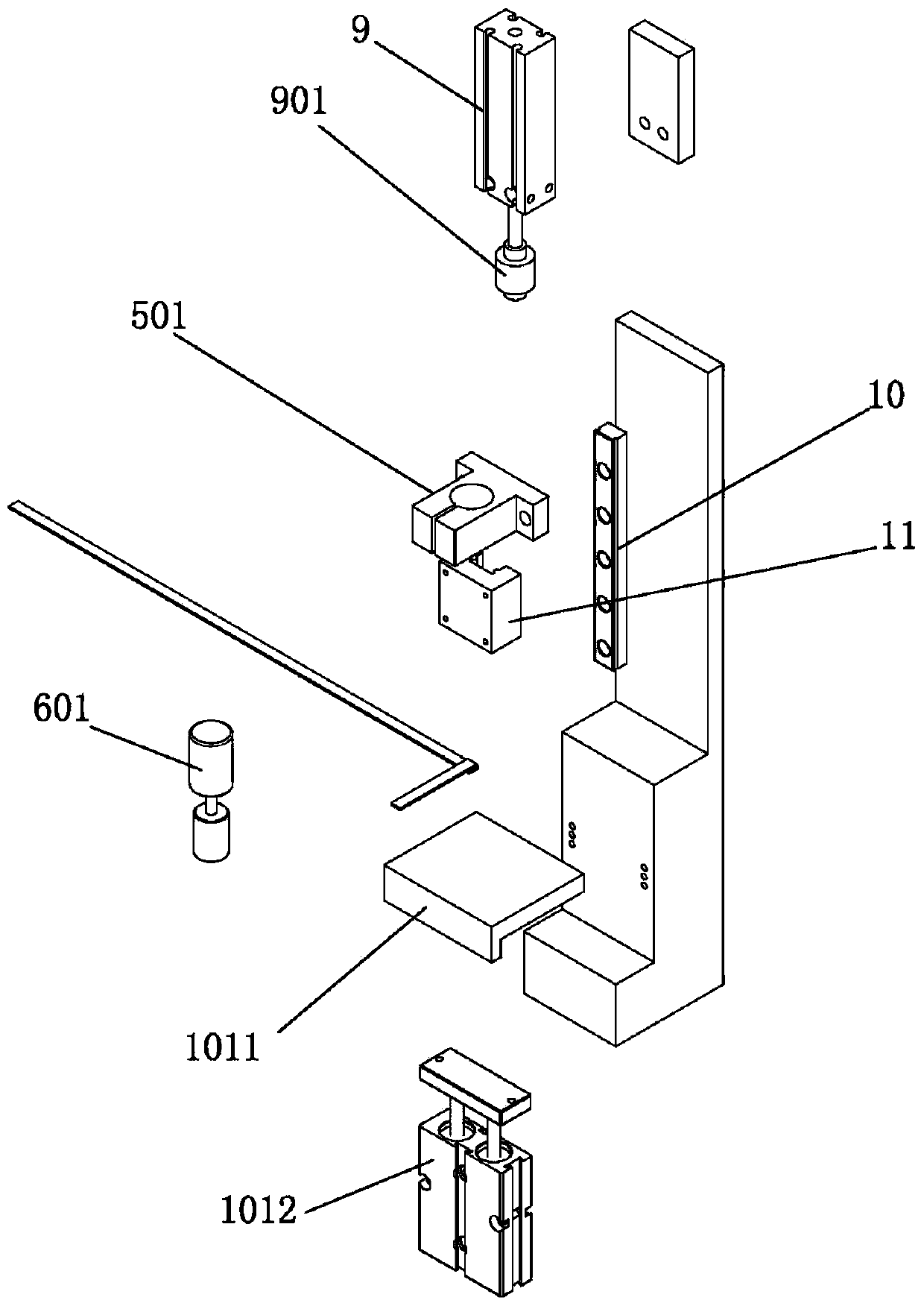

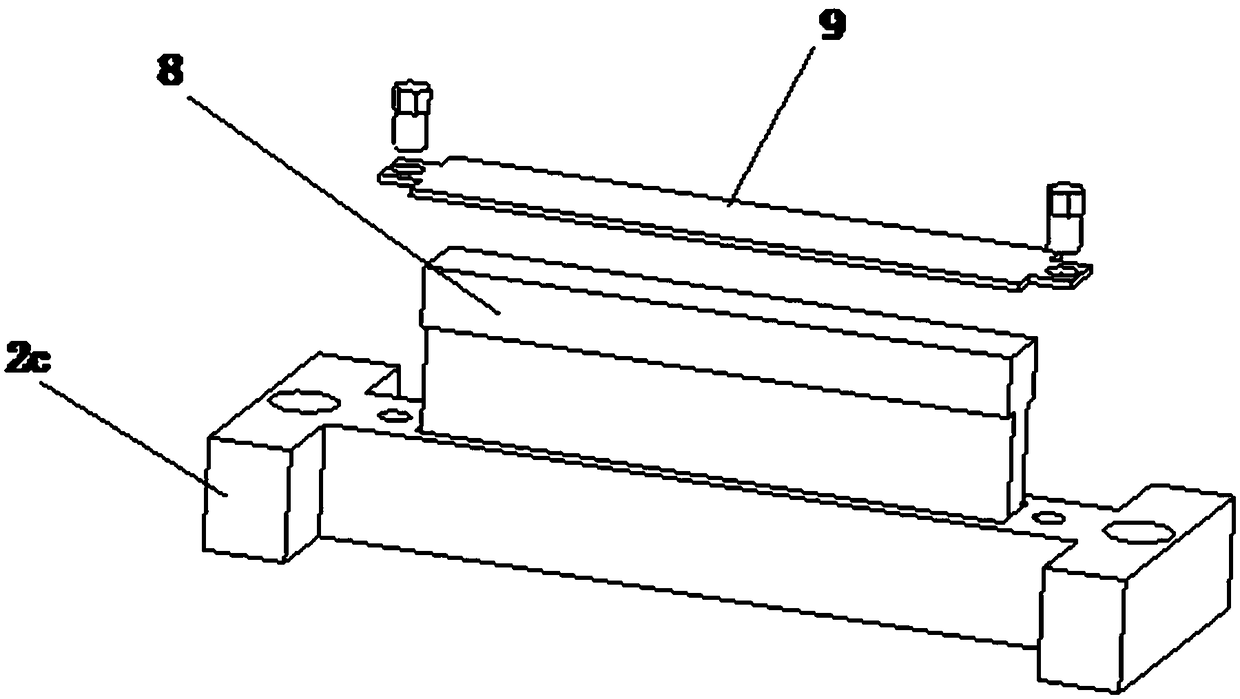

Convergence strip lap welding machine

ActiveCN106670608ASolve tedious tasksQuality improvementFinal product manufactureHeating appliancesPressure controllerEngineering

The invention discloses a convergence strip lap welding machine, which comprises a base. A control device and a workbench are arranged on the base; a material conveying device, a heating device, a welding device, a cutting device and a collecting device are arranged on the workbench and are controlled by the control device to run; the material conveying device comprises a first conveying device and a second conveying device and is used for loading and conveying materials; the welding device comprises a welder and a pressure controller; the welder is connected with the pressure controller; the pressure controller controls welded pressure output by the welder and is used for welding two input material lapped butt ends; the heating device is connected with the welding device and is used for heating welding tin of the welding device; the cutting device is provided with a cutting die and a first drive device; the first drive device drives the cutting die to cut off a welded material; and the collecting device is arranged under the welding device and is used for collecting welded finished product materials. The convergence strip lap welding machine has the advantages of automatic welding, simplicity and convenience in operation, and high production efficiency.

Owner:苏州羿驰辉科技有限公司

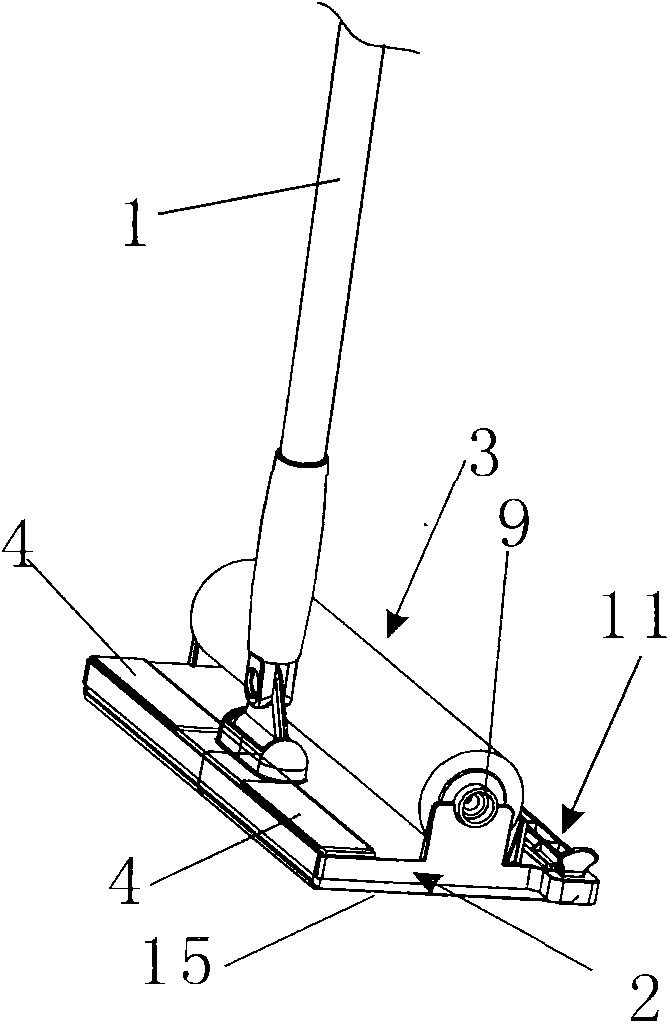

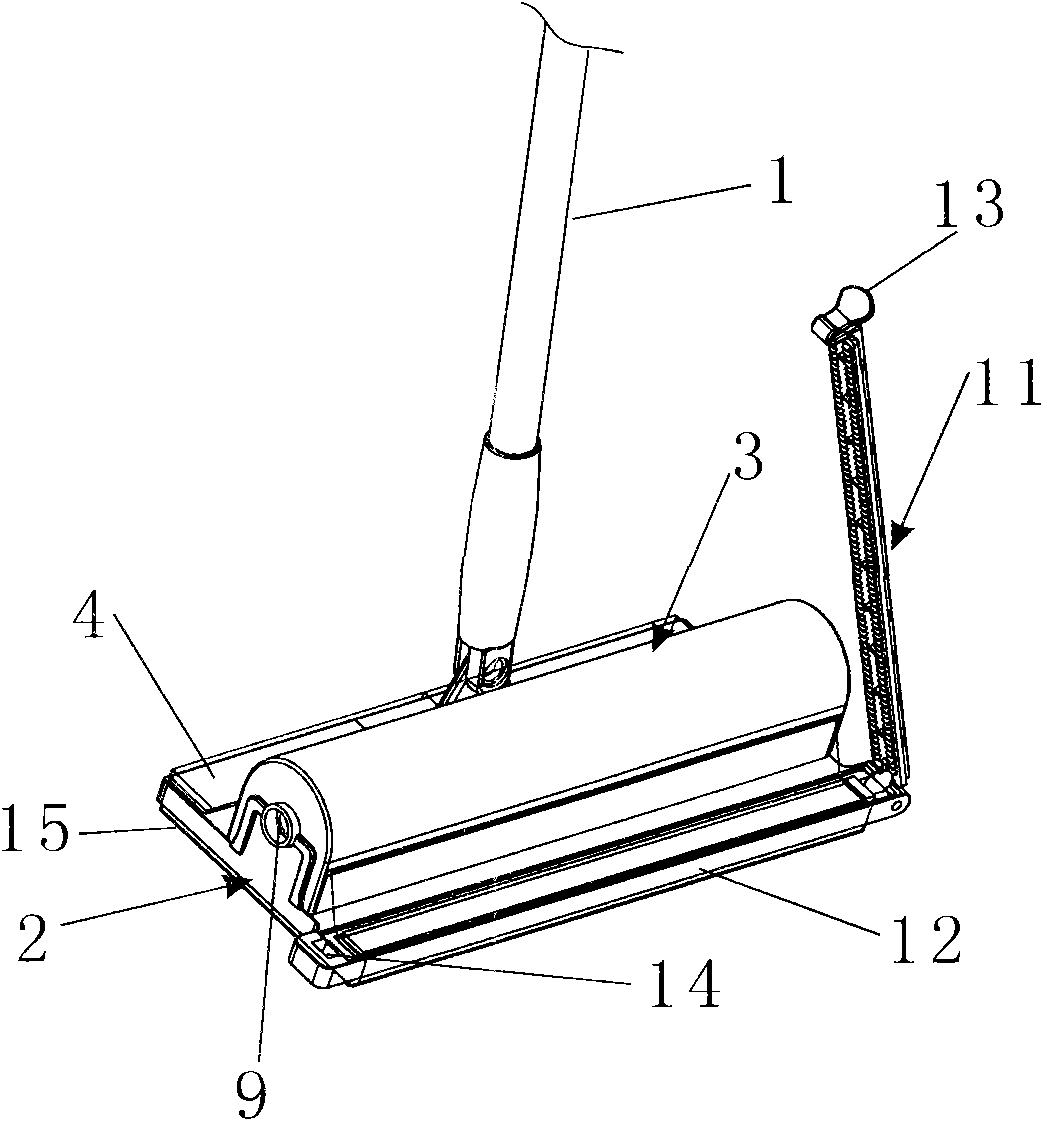

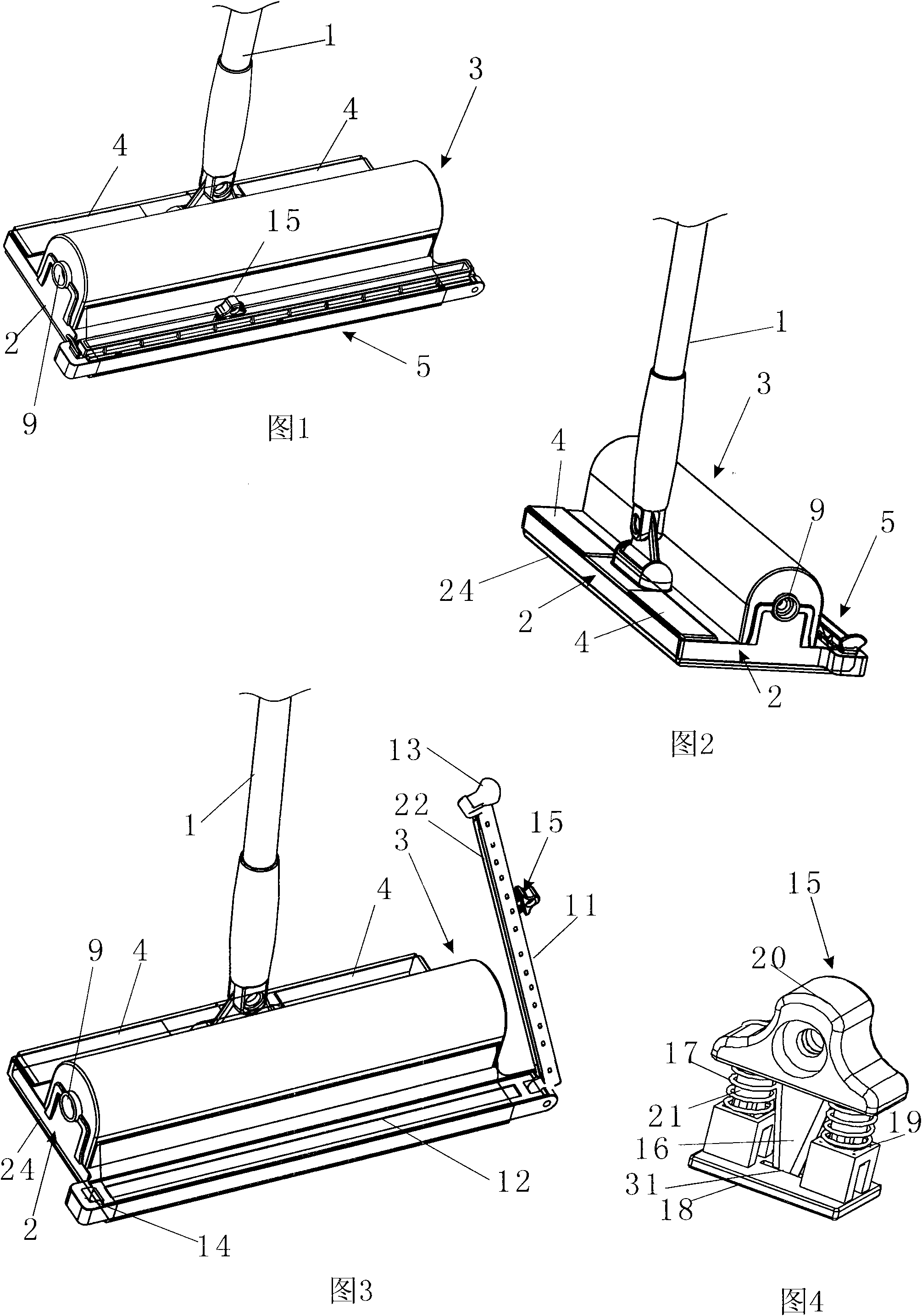

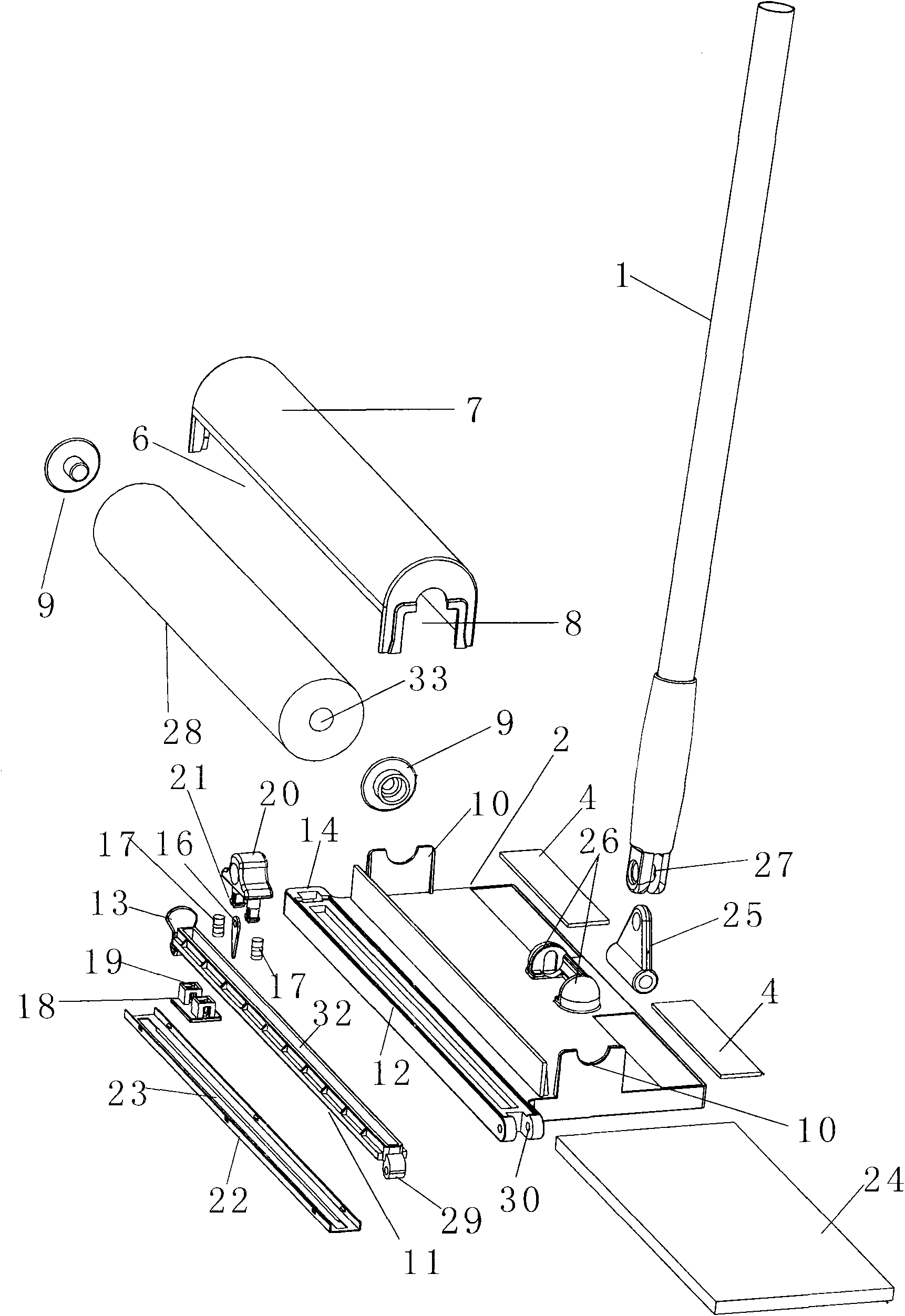

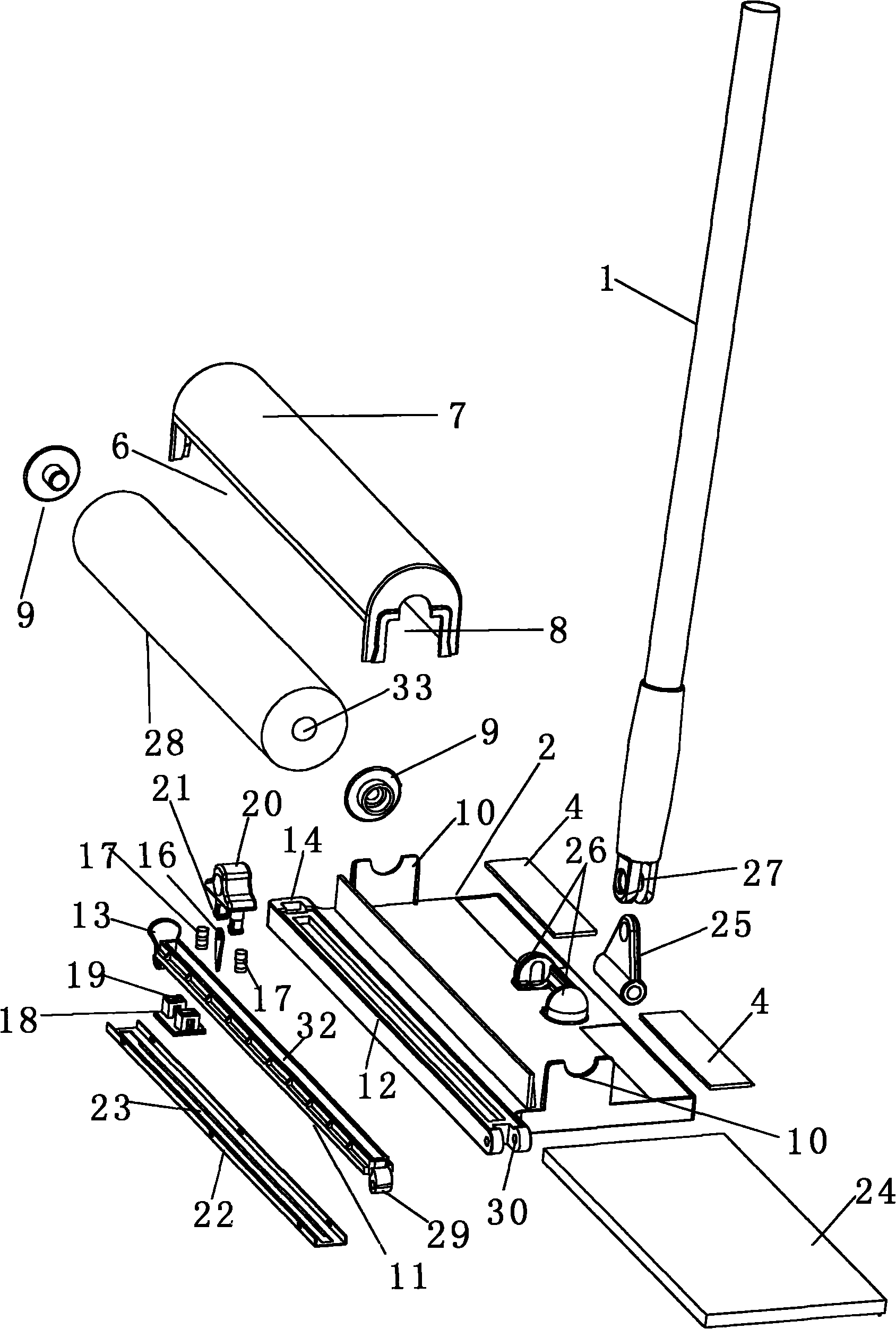

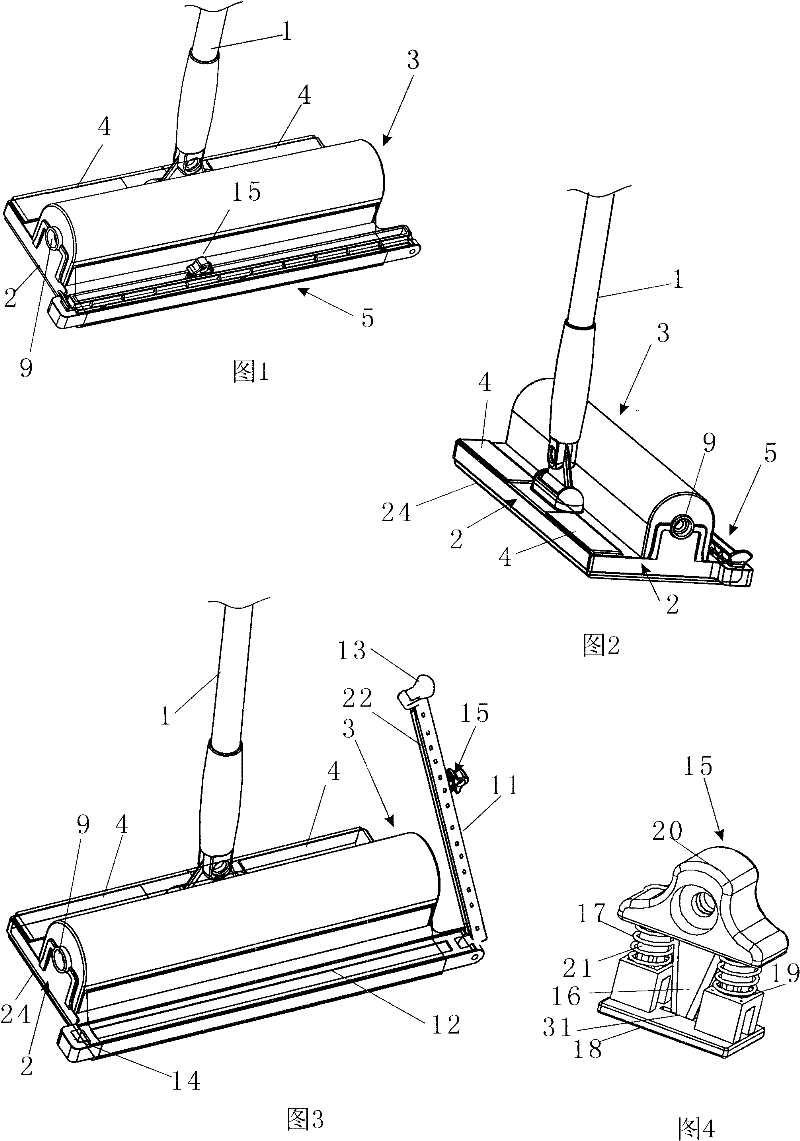

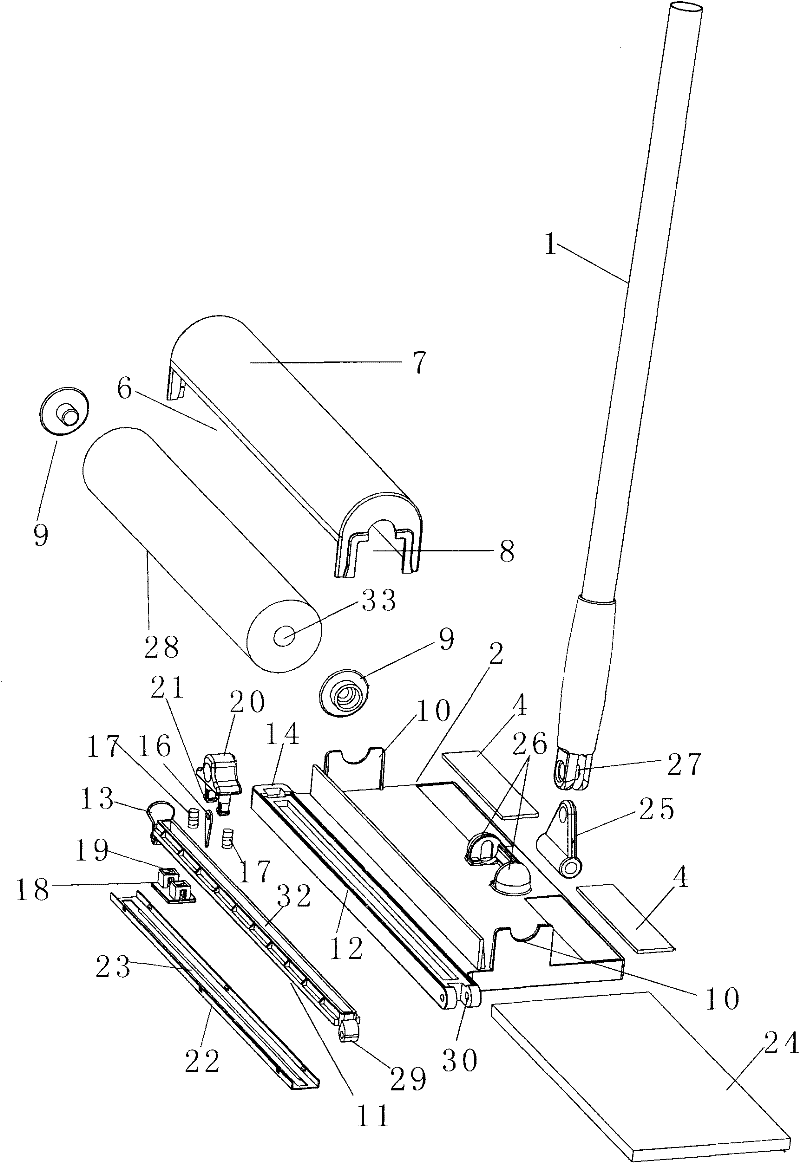

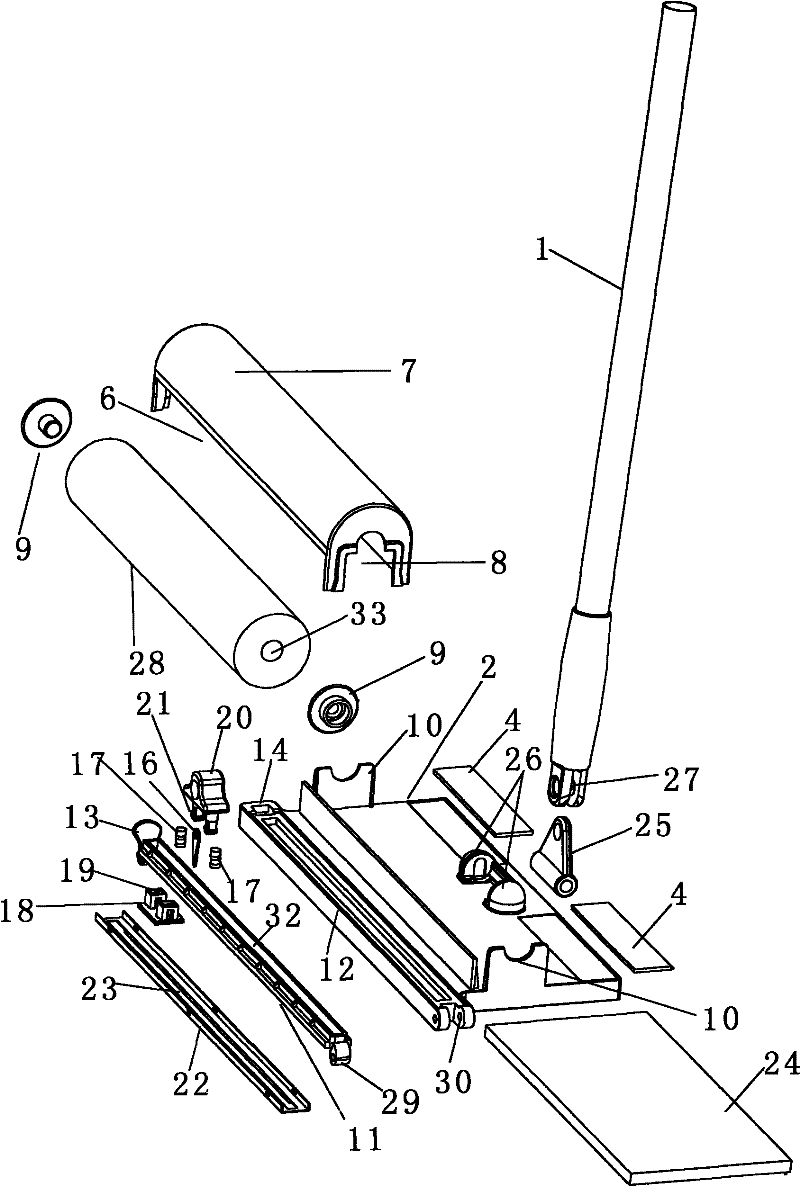

Novel mop with dedusting paper

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

Convenient dedusting paper mop

ActiveCN102058358BEasy to clean upEasy to useCarpet cleanersFloor cleanersPulp and paper industryPaper sheet

The invention discloses a convenient dedusting paper mop which comprises a handle and a base, wherein the handle is movably connected with the base. The convenient dedusting paper mop is characterized in that a paper fixing member for fixing dedusting paper is arranged on the rear end of the base, and a paper accommodating device is arranged on the base in front of the paper fixing member. The invention has the advantage of convenience and quickness in use because the dedusting paper is directly arranged on the base of the mop.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

Endoscope system

Owner:OLYMPUS CORP

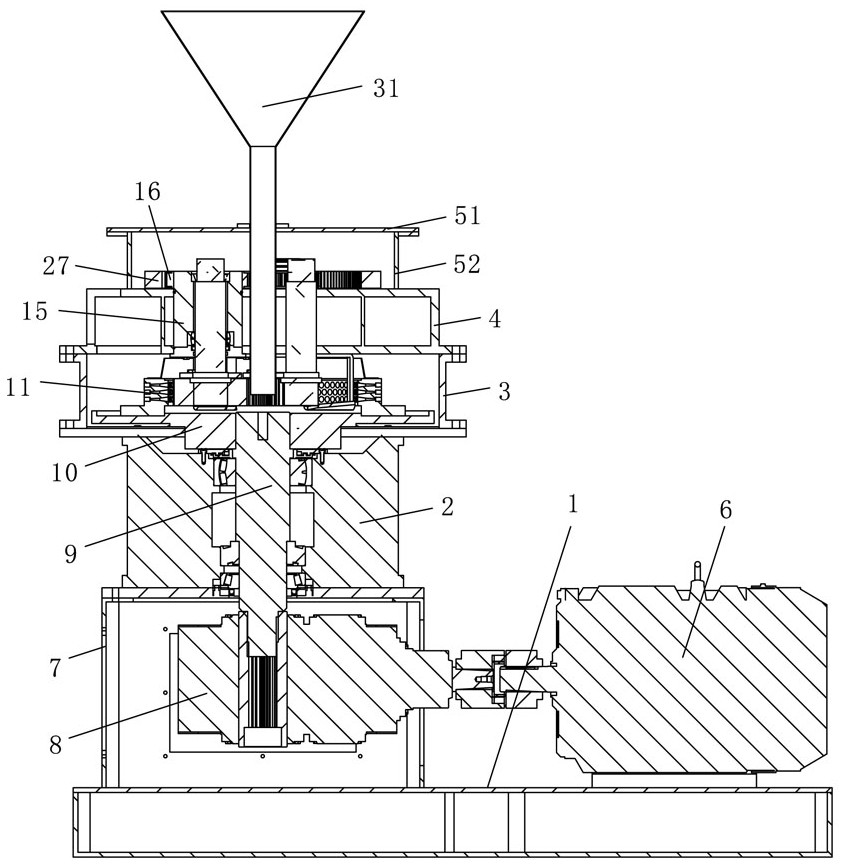

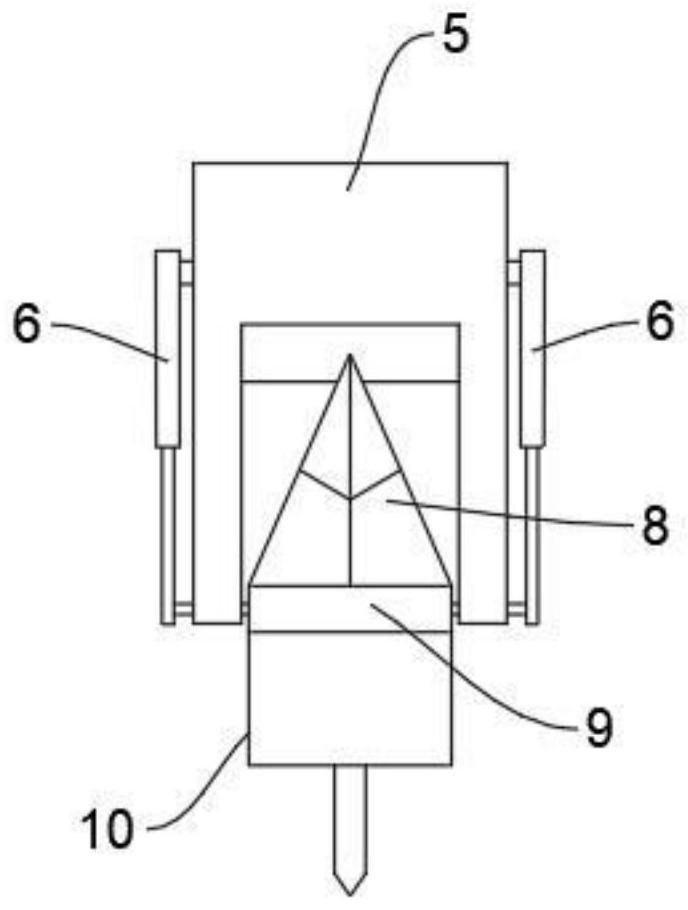

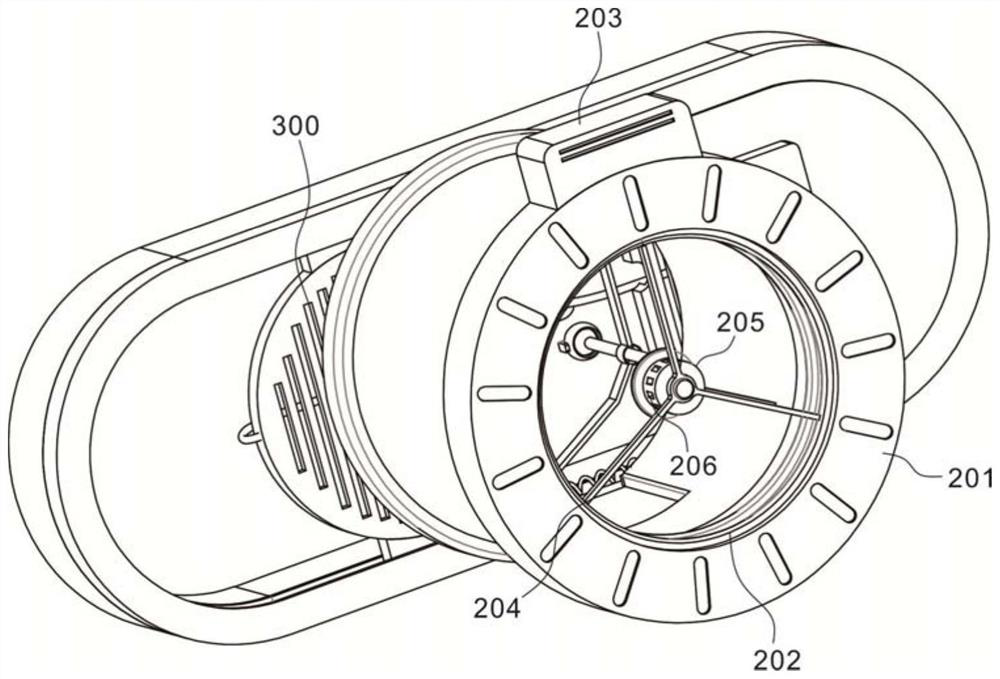

Suspended sludge granulator

PendingCN114768676AGuarantee of distribution uniformityGuaranteed automatic lubrication effectGranulation by material expressionSludgeGear wheel

The invention relates to a suspension type sludge granulator which comprises a machine base, a driving mechanism, a box body, a supporting cavity, a mounting cavity and a lubricating cavity, the supporting cavity, the mounting cavity and the lubricating cavity are sequentially arranged above the box body, and a bottom plate, a circular mold and a guide ring are arranged in the supporting cavity; three compression roller assemblies are arranged in the mounting cavity in the circumferential direction, and each compression roller assembly comprises an eccentric sleeve, an adjusting gear, a compression roller shaft and a compression roller; the eccentric sleeve and the compression roller shaft are not coaxial, a material raising frame is arranged below the mounting cavity, and the material raising frame and the compression roller are alternately arranged in the ring die in the ring direction; a gap adjusting mechanism is arranged on the lubricating cavity, the gap adjusting mechanism comprises an inner gear ring and a speed reducer which are in gear transmission connection, and three adjusting gears are meshed with the inner gear ring respectively; a discharging pipe is arranged on the lubricating cavity, and the lower end of the discharging pipe extends downwards to be arranged in the middle of the circular mold. The problems of non-uniform feeding, lubricating of rotating parts, difficulty in adjustment of roller die gaps, overflow of raw materials and abrasion of parts of the sludge granulator are solved.

Owner:郑州市格沃环保开发有限公司

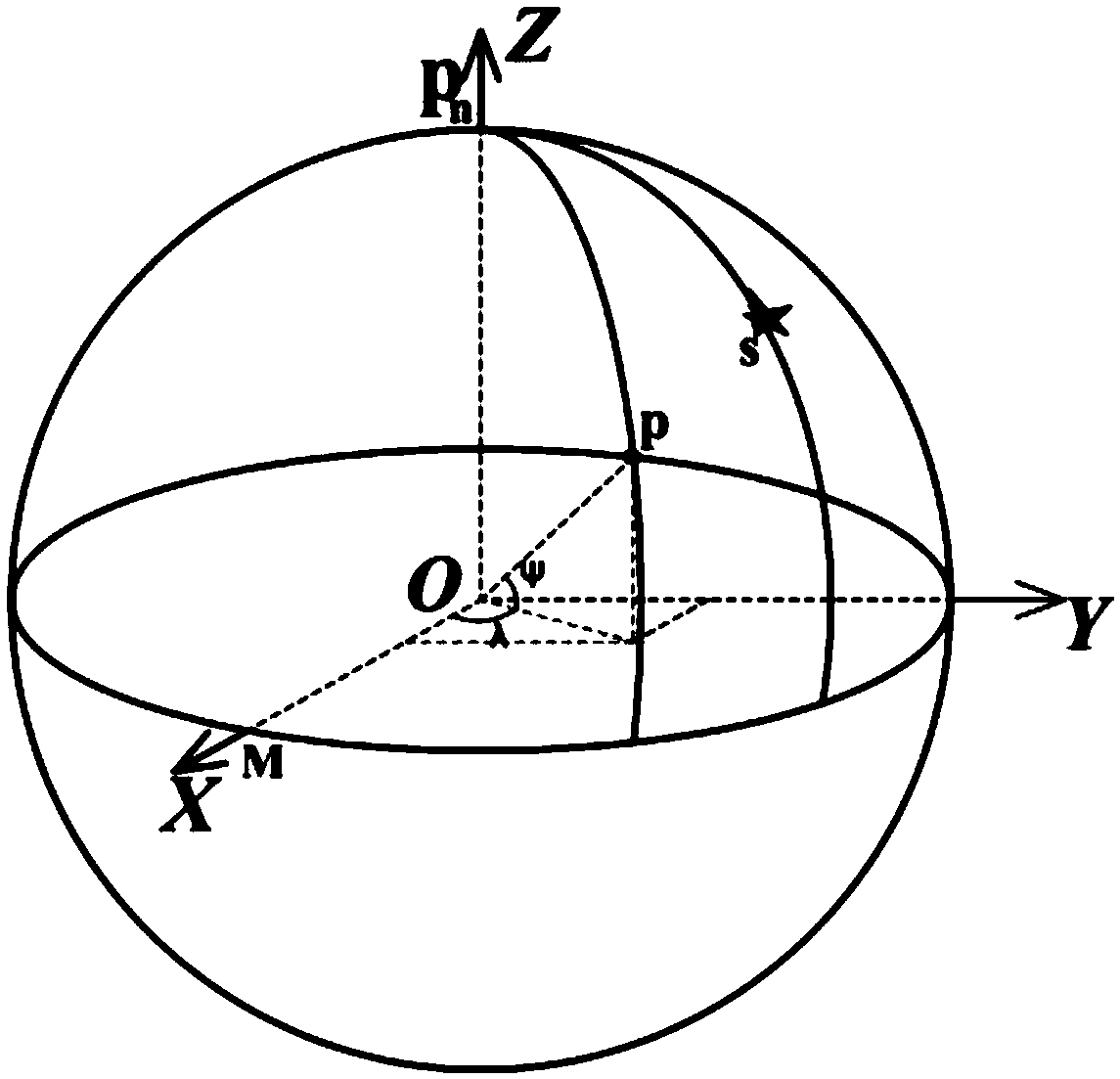

Direct calculation method of celestial fix of double celestial bodies

InactiveCN109099906ARapid positioningPrecise positioningNavigational calculation instrumentsNavigation by astronomical meansCelestial bodyMathematical model

The invention discloses a direct calculation method of celestial fix of double celestial bodies. The method comprises the following steps: step 1, establishing celestial fix coordinates; step 2, deriving a spherical celestial fix formula based on an astronomical triangle; step 3, deriving a celestial fix mathematical model of the double celestial bodies via vector transformation; and step 4, solving the celestial fix mathematical model of the double celestial bodies via Newton iteration to obtain the longitude and latitude of a ship at an observation moment. According to the direct calculationmethod disclosed by the invention, the position of the ship is directly obtained through the Newton iteration method, the cumbersome operation of a ship position line and an error introduced by replacing a curve with a straight line when the ship position line is drawn can be avoided, and the position of the ship can be determined quickly and accurately. Therefore, fast, instantaneous and accurate celestial fix of the double celestial bodies can be realized.

Owner:TIANJIN UNIV

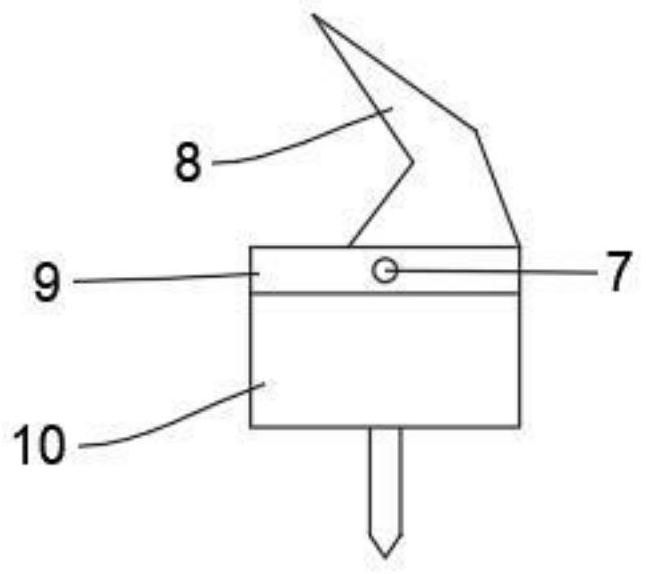

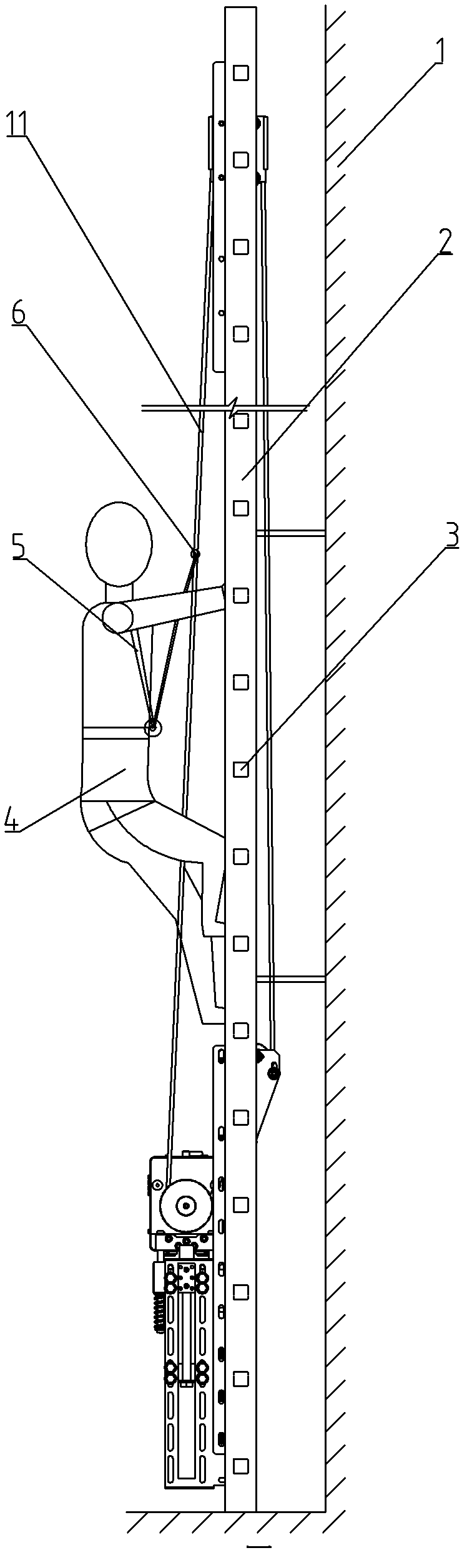

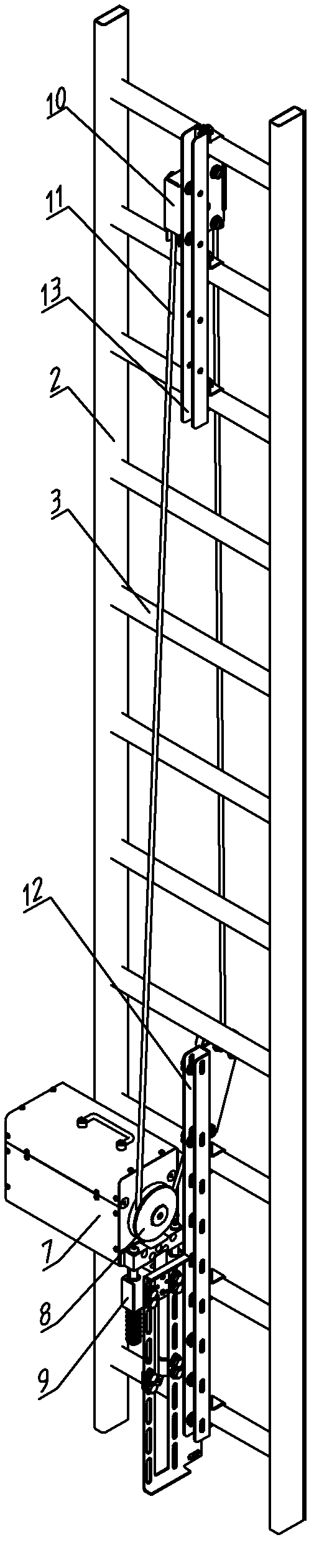

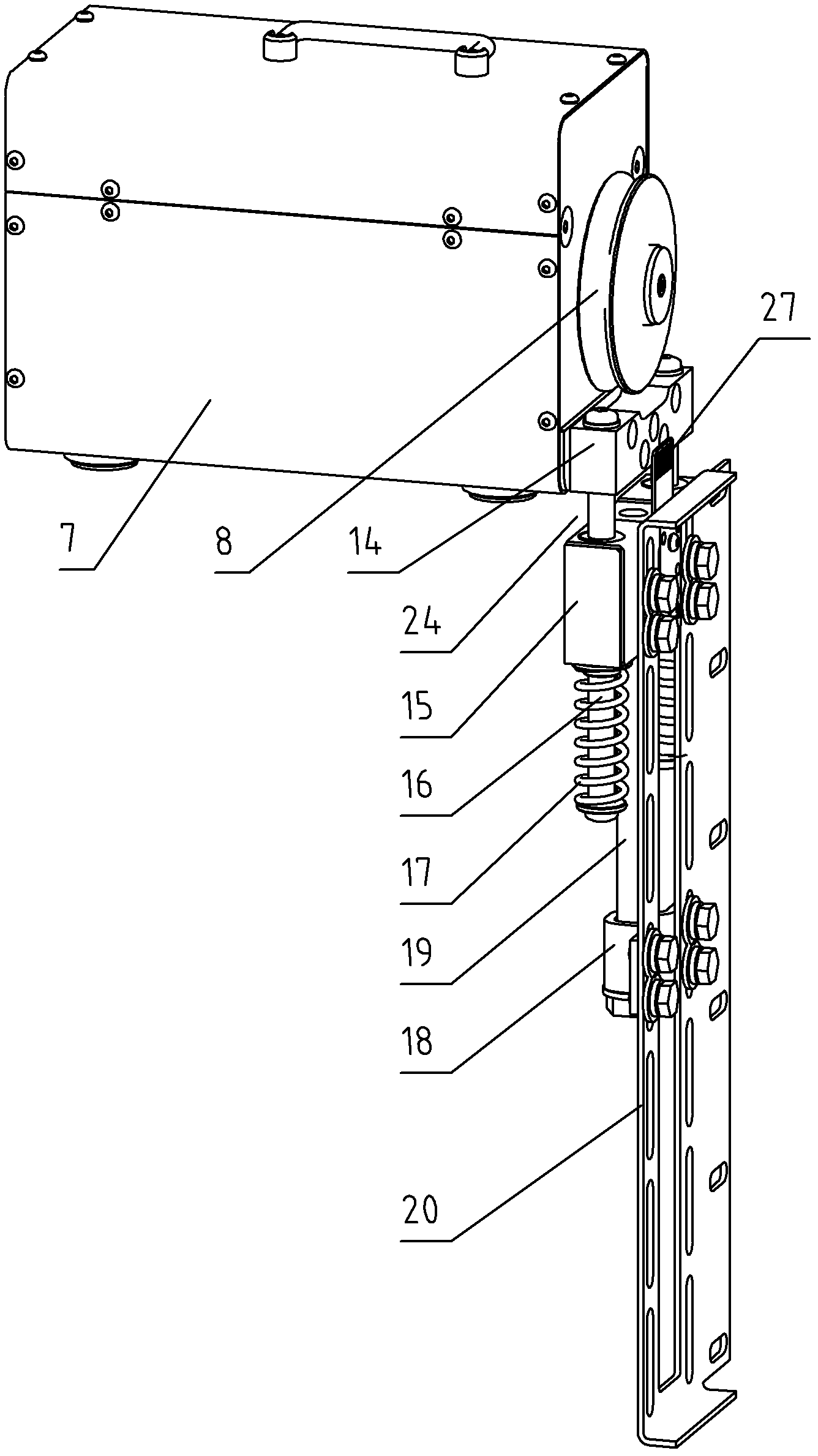

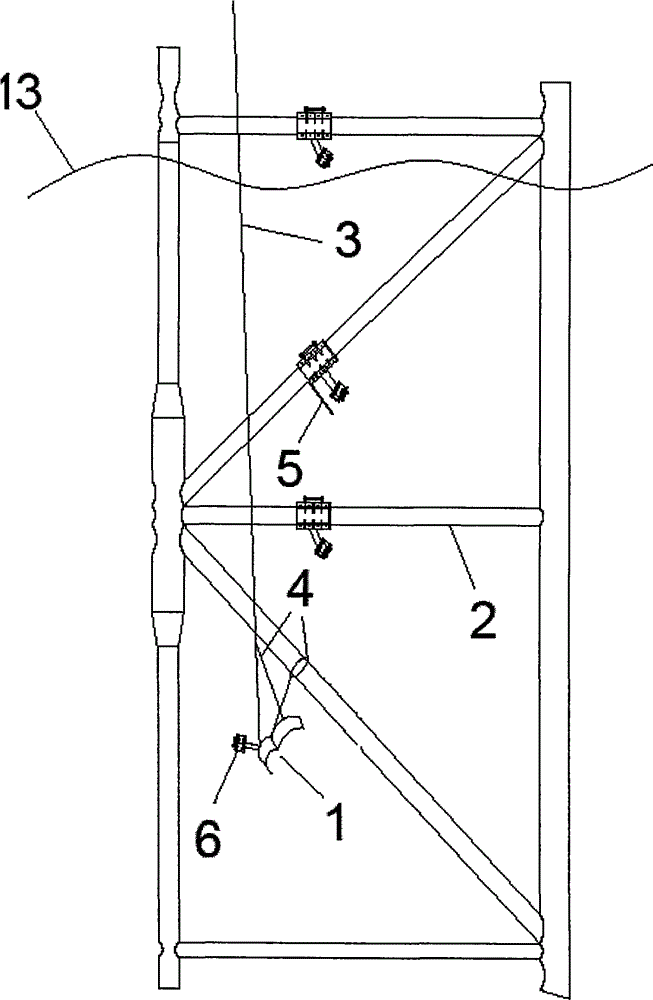

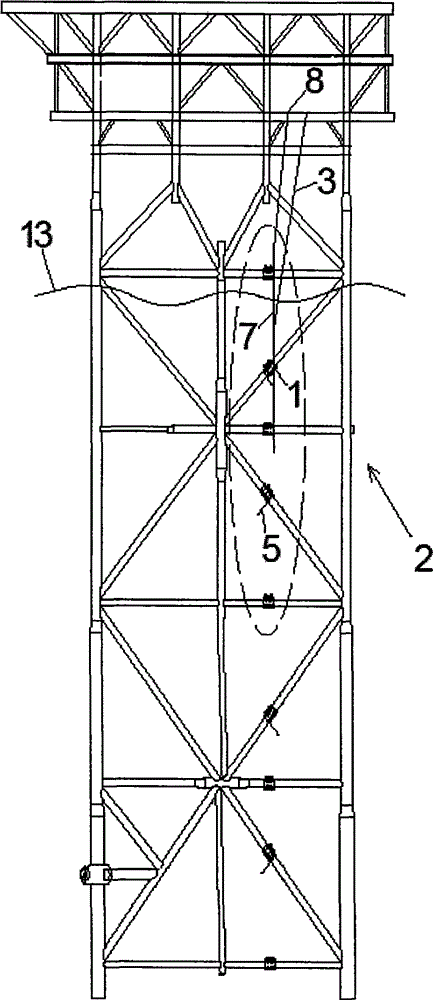

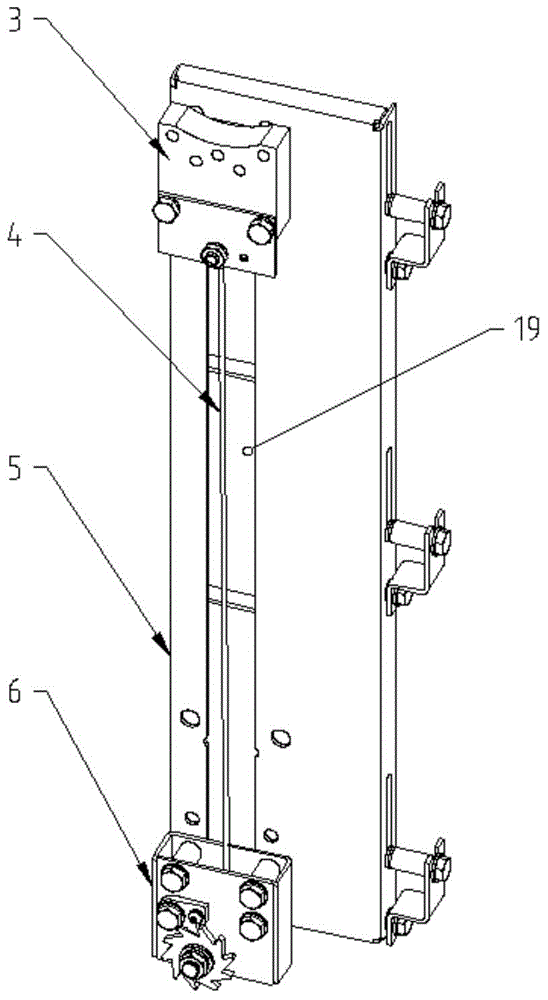

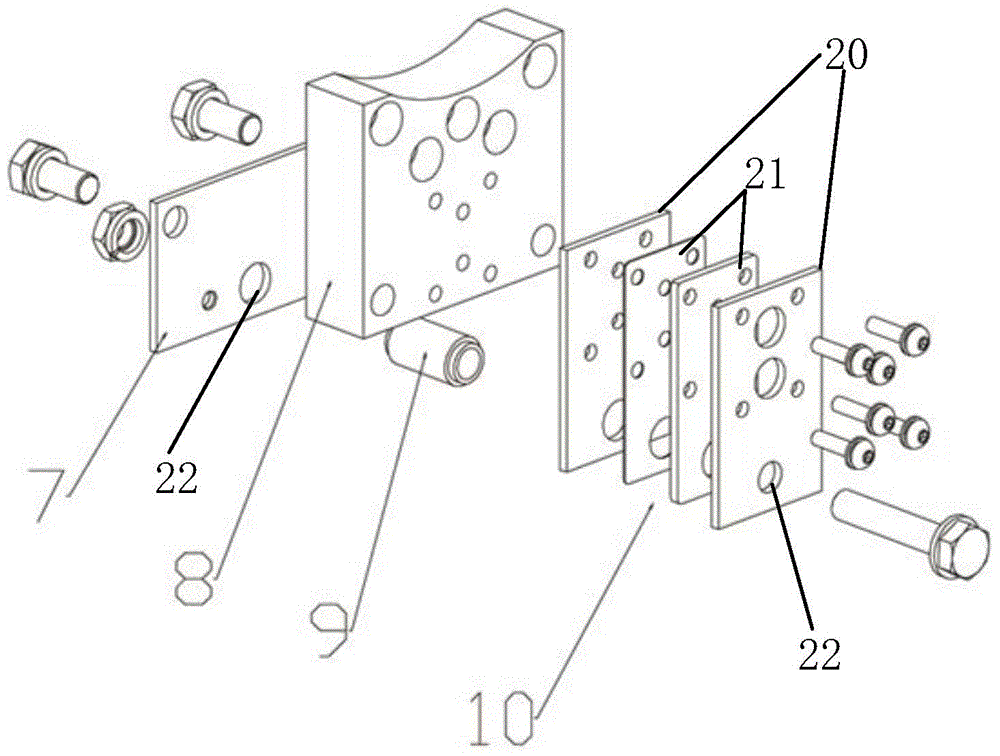

Uphill assisting device and operation method thereof

ActiveCN102536107BIntuitive determination of tensionIntuitively judge whether the tension is in the available rangeLaddersSteering wheelDrive wheel

Owner:上海和蕴机电科技有限公司

Confluence belt lap welding machine

ActiveCN106670608BImprove operationEasy to operateFinal product manufactureHeating appliancesEngineeringWelding

The invention discloses a convergence strip lap welding machine, which comprises a base. A control device and a workbench are arranged on the base; a material conveying device, a heating device, a welding device, a cutting device and a collecting device are arranged on the workbench and are controlled by the control device to run; the material conveying device comprises a first conveying device and a second conveying device and is used for loading and conveying materials; the welding device comprises a welder and a pressure controller; the welder is connected with the pressure controller; the pressure controller controls welded pressure output by the welder and is used for welding two input material lapped butt ends; the heating device is connected with the welding device and is used for heating welding tin of the welding device; the cutting device is provided with a cutting die and a first drive device; the first drive device drives the cutting die to cut off a welded material; and the collecting device is arranged under the welding device and is used for collecting welded finished product materials. The convergence strip lap welding machine has the advantages of automatic welding, simplicity and convenience in operation, and high production efficiency.

Owner:苏州羿驰辉科技有限公司

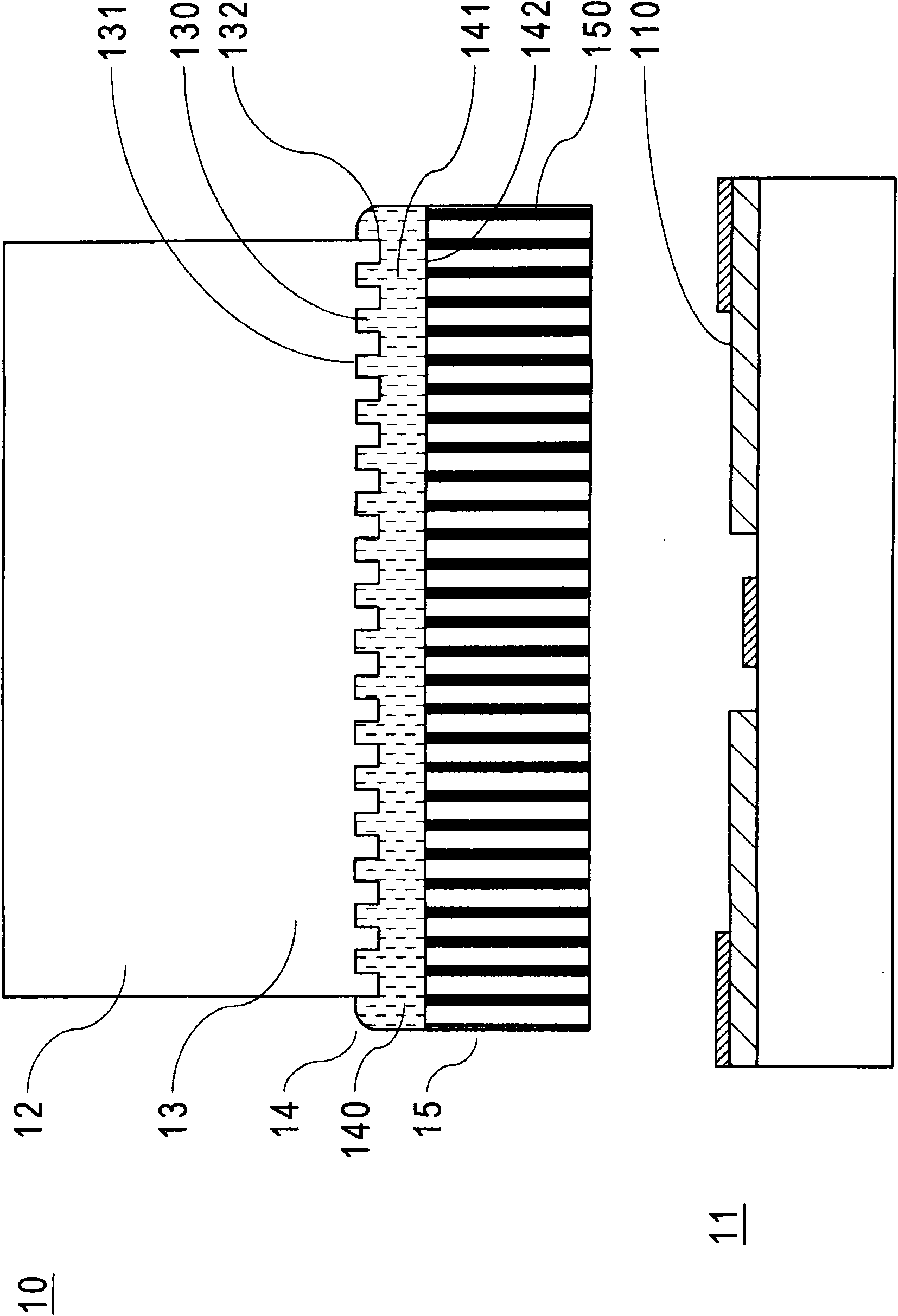

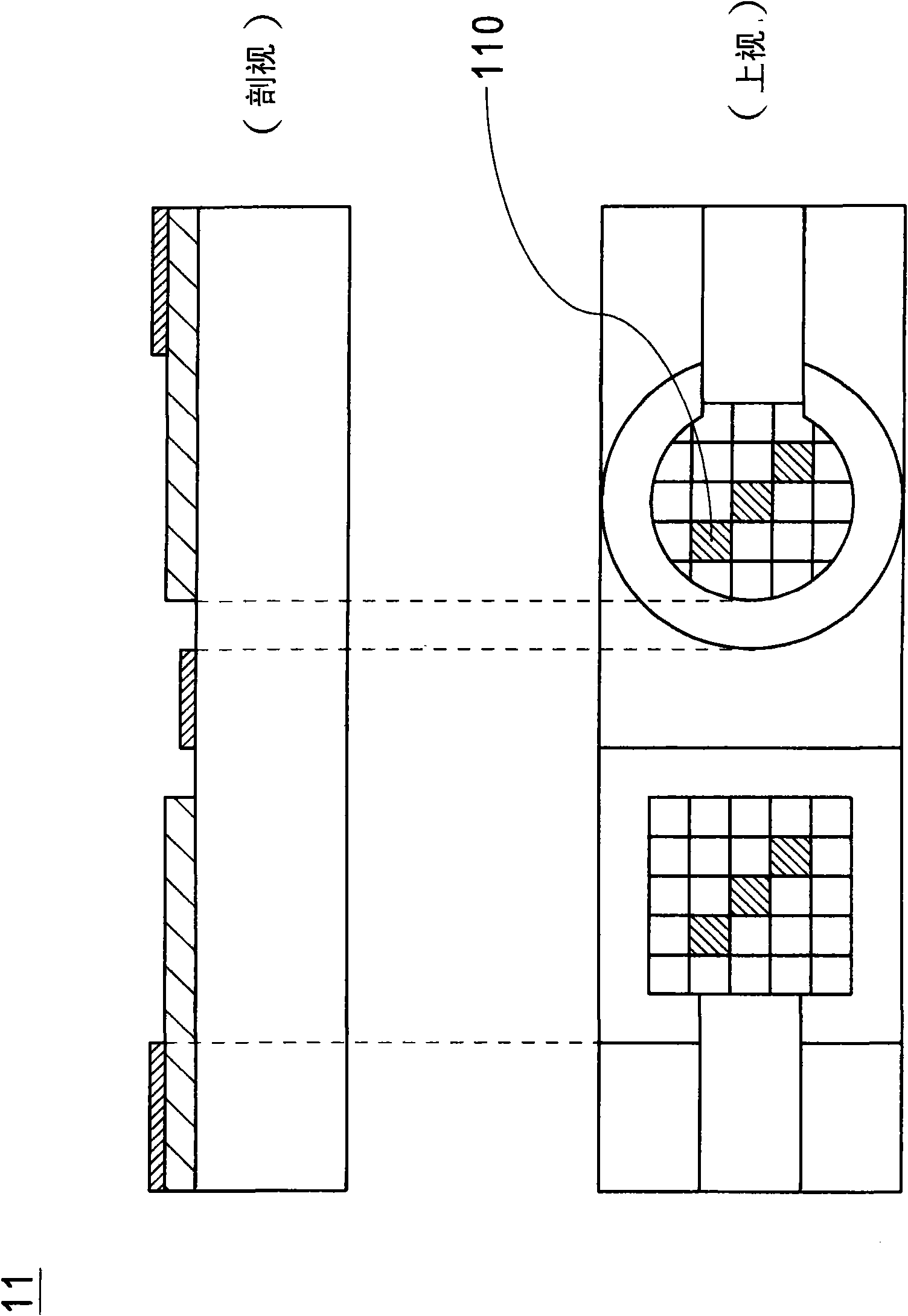

Separation testing method of pixel of electric testing point and testing device thereof

InactiveCN101825682AAccurateAvoid replacementElectronic circuit testingSemiconductor/solid-state device detailsComputer moduleComputer science

The invention provides a separation testing method of a pixel of an electric testing point and a testing device thereof. The separation testing method of the pixel of the electric testing point comprises the steps of: providing a testing plate which comprises a conductive layer and a glass base plate; operating a row loop and a line loop for controlling the electric conductivity of a pixel contact of the conductive layer; providing at least one electric element; forming a first circuit layout by the electric testing point of the electric element; forming a preset gap between the electric testing point of the electric element and the pixel contact of the testing plate; providing a control module for operating the row loop and the line loop of the conductive layer; enabling the pixel contact to form a second circuit layout; providing an alignment procedure; enabling the second circuit layout to correspond to the first circuit layout; and operating a testing procedure for testing the first circuit layout.

Owner:吕佳玲

Paper storage device used for dedusting paper mop

InactiveCN102058357AEasy to useAvoid tedious workCarpet cleanersFloor cleanersPulp and paper industry

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

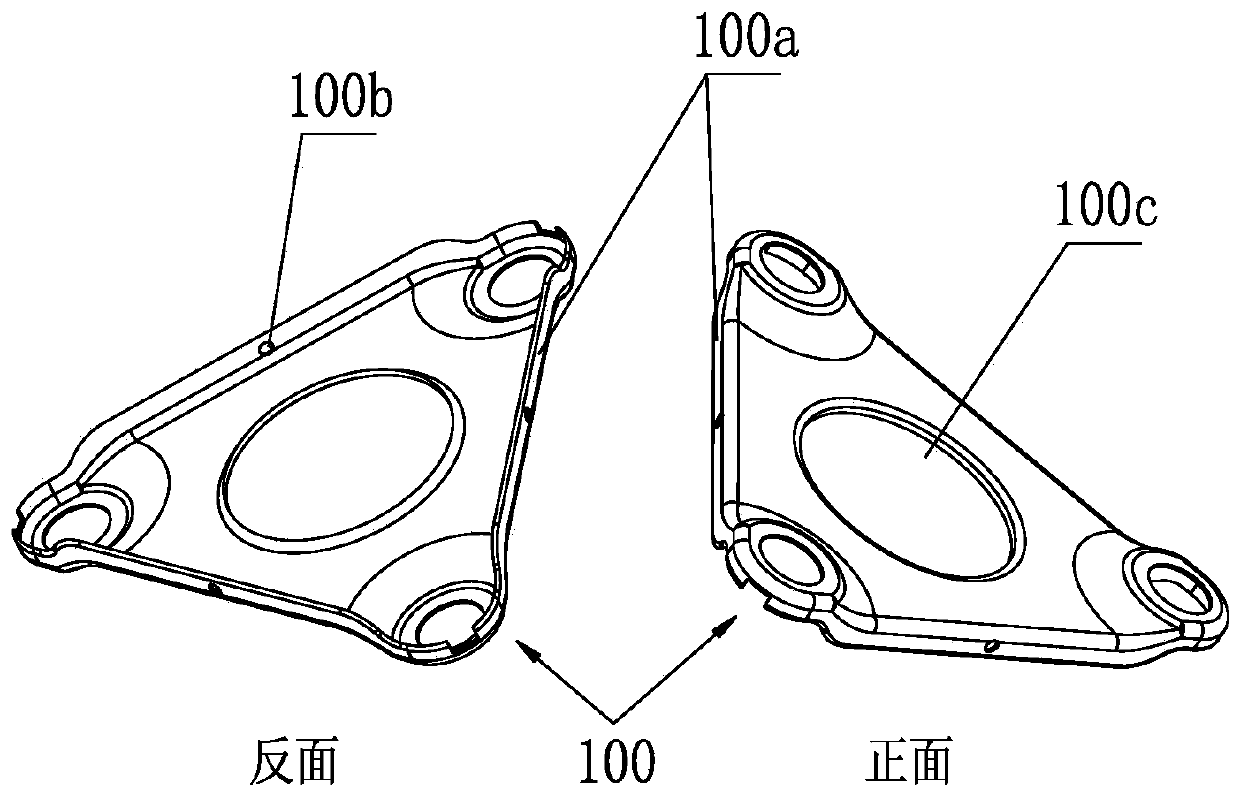

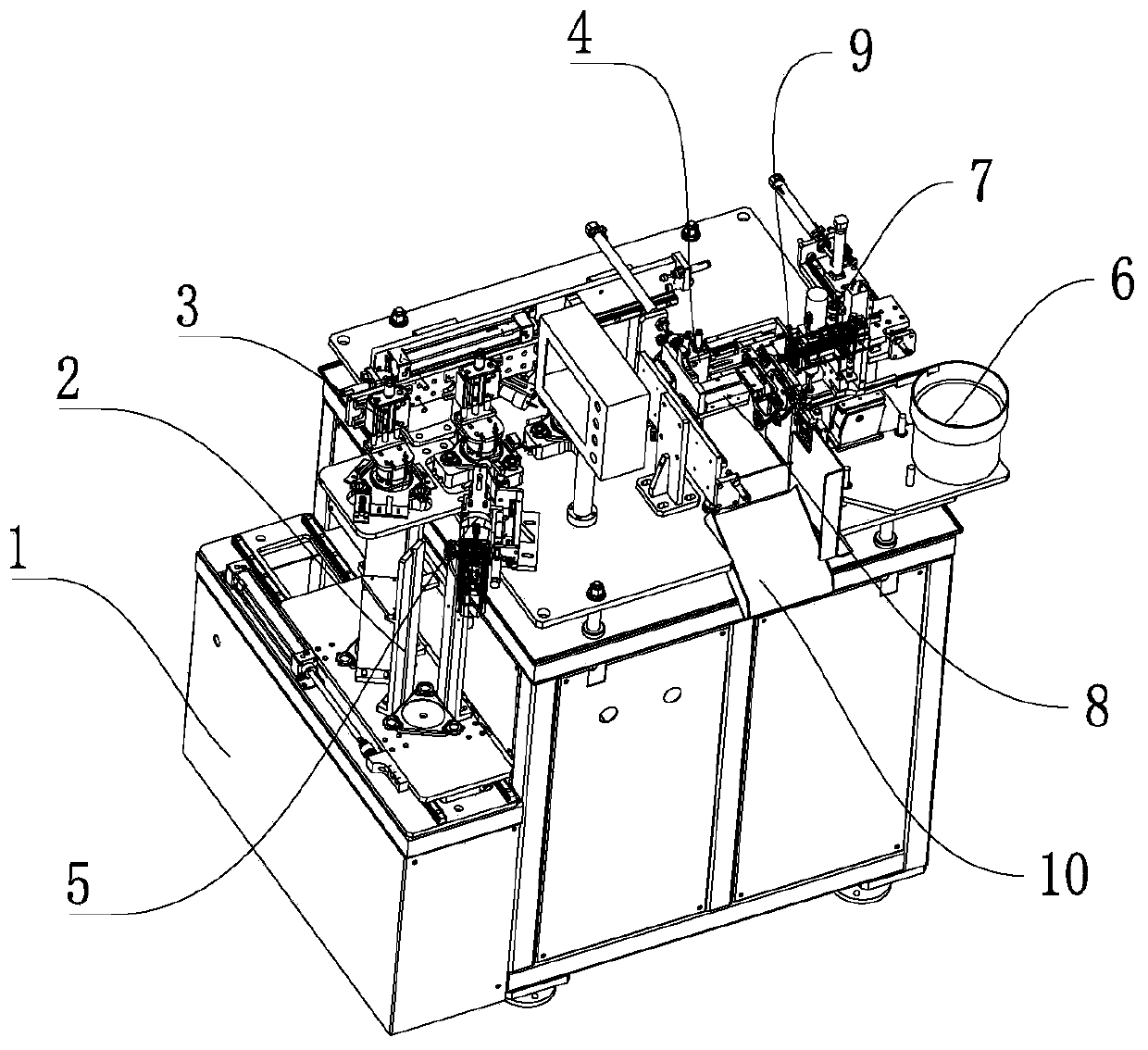

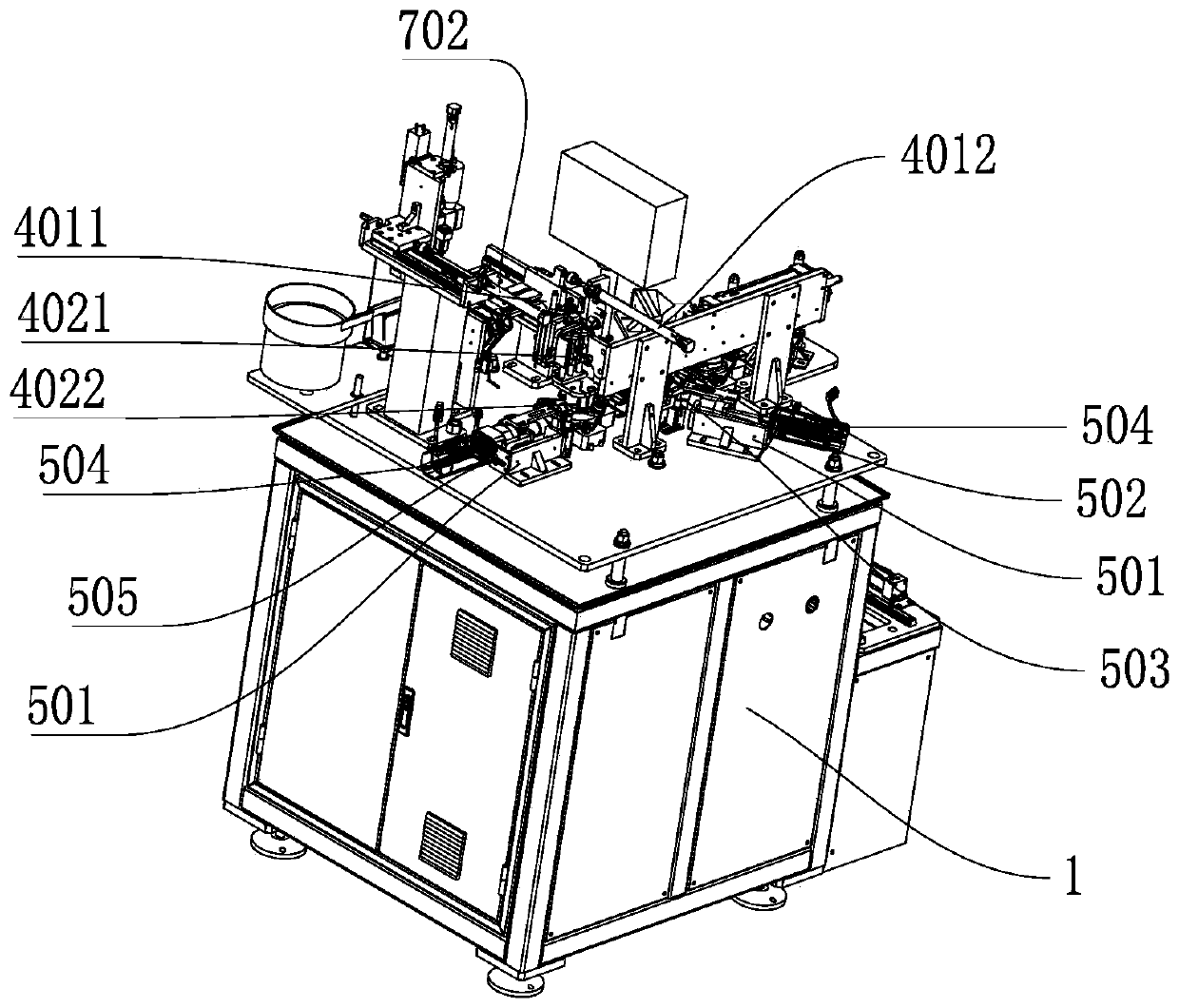

Linear automatic screw driving machine

PendingCN111014841ARealize automatic processingEasy to stapleThread cutting feeding devicesThread cutting machinesControl engineeringStructural engineering

The invention provides a linear automatic screw driving machine, which belongs to the field of machining equipment. Automatic feeding is achieved through a feeding mechanism; a tapping conveying mechanism is used for automatically conveying a triangular foot stool to a corresponding tapping position; the three tapping modules are used for automatically tapping unthreaded holes in the three side walls of the triangular foot stool respectively; a screw loading and conveying mechanism is used for overturning the triangular foot stool with the three tapped unthreaded holes by 90 degrees; one unthreaded hole is in a horizontal state; convenient screw loading operation is achieved; a screw loading module is used for automatic screw loading of the unthreaded hole in the horizontal state; a discharging device is used for discharging the triangular foot stool which completes tapping and screw loading; a control module coordinates the feeding mechanism, the tapping conveying mechanism, the tapping mechanism, the screw loading and conveying mechanism, the screw feeding mechanism and the screw loading mechanism to execute respective functions, and the device solves the problem of tedious operation of repeated disassembly, assembly and fixation, reduces the labor intensity, achieves automatic machining, and improves the production efficiency.

Owner:GUANGZHOU YATA METALWORK

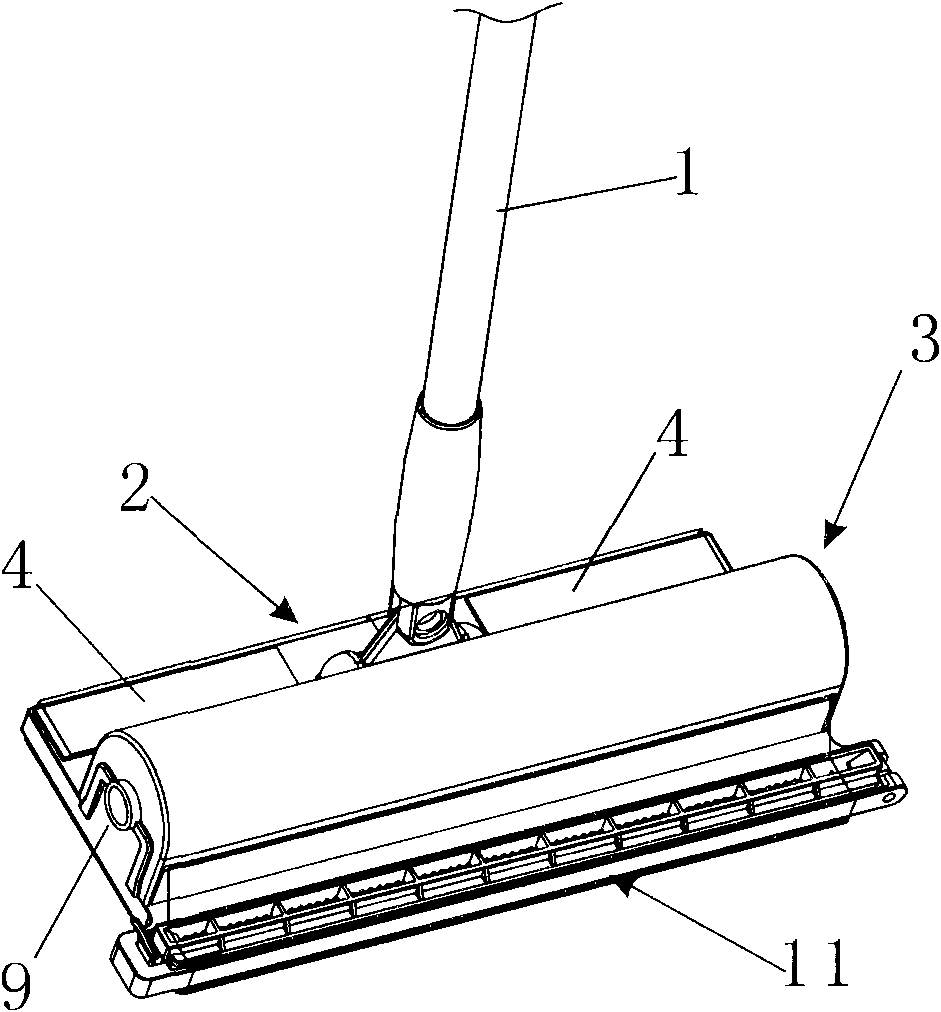

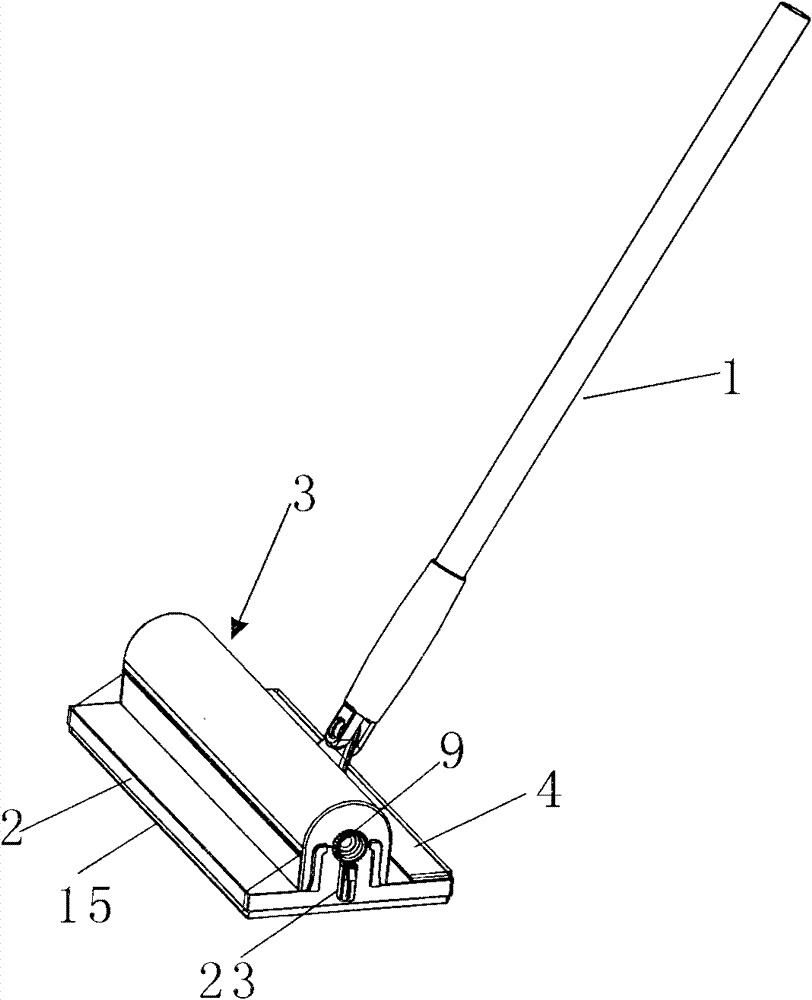

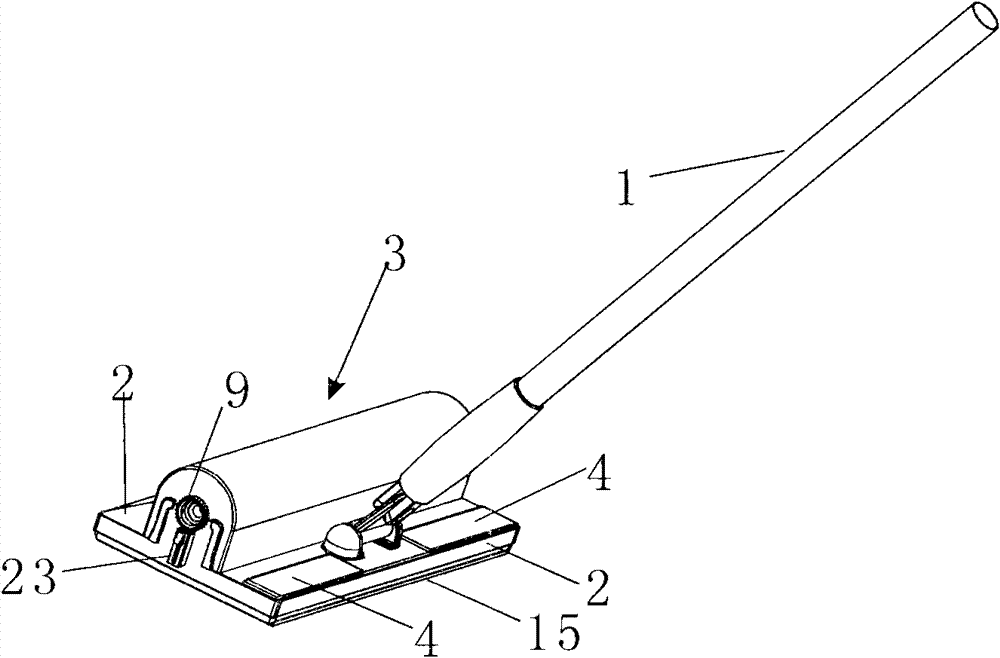

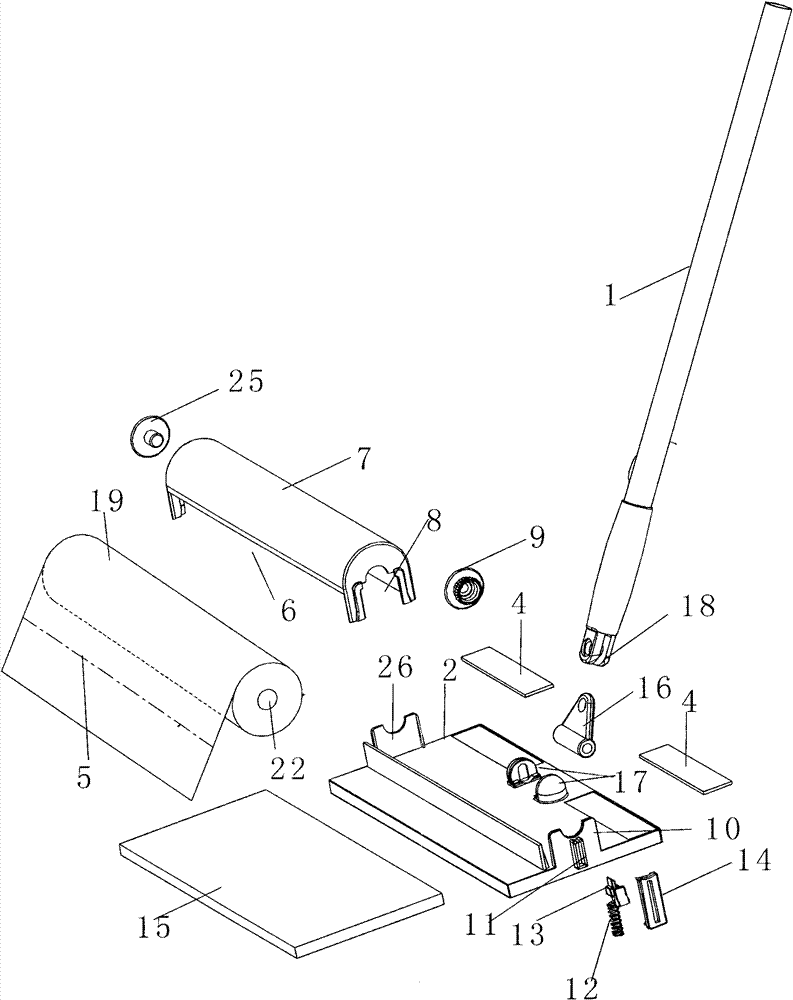

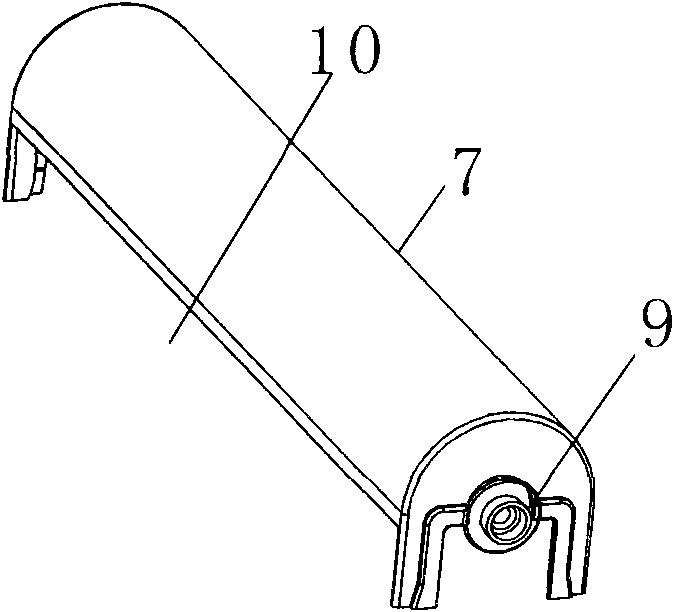

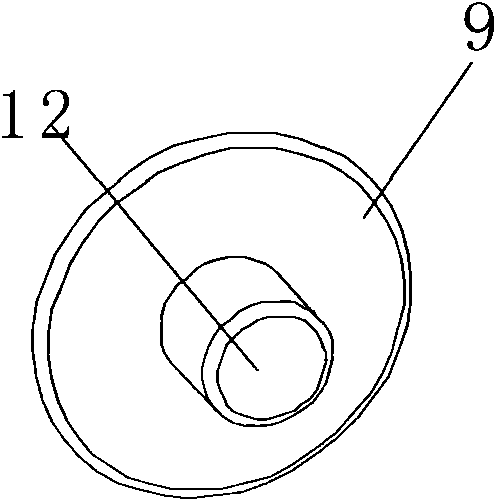

Dedusting paper mop

ActiveCN102058359AEasy to useAvoid tedious workCarpet cleanersFloor cleanersPulp and paper industryPaper sheet

The invention discloses a dedusting paper mop, comprising a hand lever and a base in loose joint with the hand lever. The dedusting paper mop is characterized in that the front end of the base is provided with a paper cutting device, the rear end of the base is provided with a paper fastener for fixing dedusting paper, and a paper loading device is arranged on the base between the paper cutting device and the paper fastener. In the invention, dedusting scroll paper is directly arranged on the mop base which has a paper cutting function, therefore, the advantages of convenience and rapidness in use are achieved.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

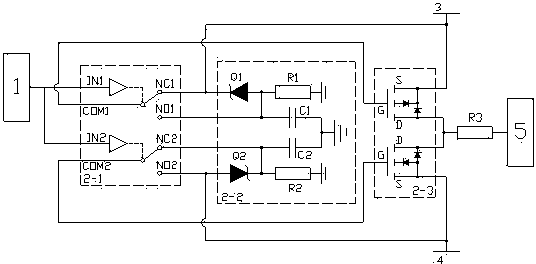

ccd vertical timing drive circuit

ActiveCN103826074BReduce consumptionImprove efficiencyTelevision system detailsColor television detailsControl signalComputer module

The invention discloses a vertical time sequence drive circuit for a charge coupled device (CCD). The vertical time sequence drive circuit comprises a switch module, a voltage stabilizing circuit, a power amplitude amplifying circuit, a high-level direct current source and a low-level direct current source, wherein the power amplitude amplifying circuit can process one of the high-level direct current source and the low-level direct current source and outputs outwards through the output end; the voltage stabilizing circuit can provide four paths of control signals; the switch module can control the action of the power amplitude amplifying circuit by controlling four paths of control signals. The vertical time sequence drive circuit has the beneficial technical effects that a test circuit can generate corresponding CCD drive signals according to different time sequence pulses; one set of test circuit can meet the test requirements of different types of CCDs, the hardware consumption in the test process is reduced, fussy work in the prior art that drive circuits need to be independently designed for different types of CCDs is avoided, and the test work efficiency is indirectly improved.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Dedusting paper mop

ActiveCN102058359BEasy to useAvoid tedious workCarpet cleanersFloor cleanersPulp and paper industryFastener

The invention discloses a dedusting paper mop, comprising a hand lever and a base in loose joint with the hand lever. The dedusting paper mop is characterized in that the front end of the base is provided with a paper cutting device, the rear end of the base is provided with a paper fastener for fixing dedusting paper, and a paper loading device is arranged on the base between the paper cutting device and the paper fastener. In the invention, dedusting scroll paper is directly arranged on the mop base which has a paper cutting function, therefore, the advantages of convenience and rapidness in use are achieved.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

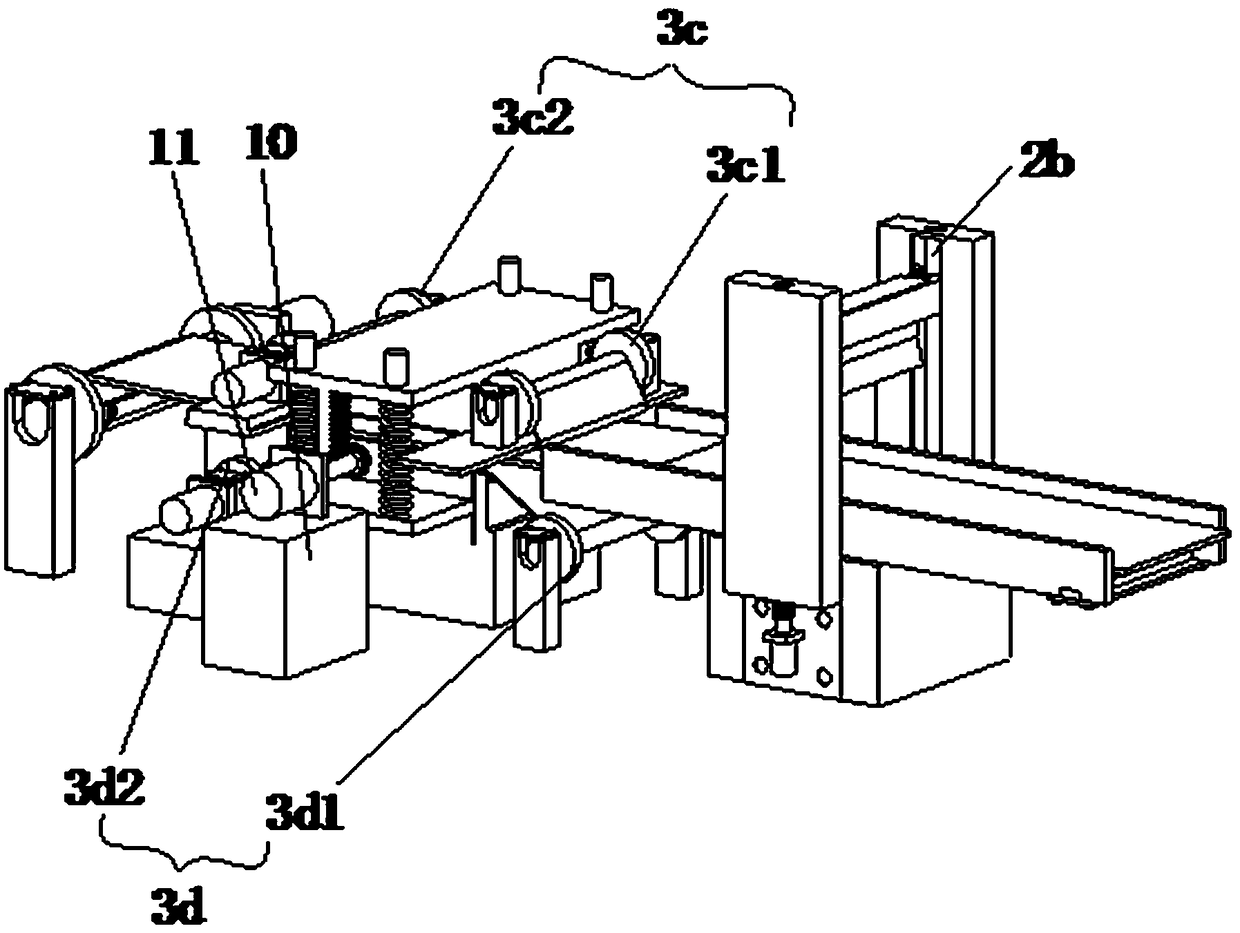

Working method of automatic aluminum alloy strip cleaning device

InactiveCN109332243ARealize automatic replacementAvoid tedious workCleaning using toolsMetalAluminium alloy

The invention discloses an automatic aluminum alloy strip cleaning device, and belongs to the technical field of metal plate strip machining equipment. The automatic aluminum alloy strip cleaning apparatus comprises a feeding platform, a sweeping mechanism, a cleaning mechanism and a rolling-up mechanism. Cleaning is finished through friction of the cleaning mechanism to an aluminum alloy, compared with the prior art, an upper wool felt conveying mechanism of the automatic aluminum alloy strip cleaning apparatus is composed of first material collecting wheels and first material conveying wheels, the first material conveying wheels are intertwined with a roll of wool felt, the roll of the wool felt is spread into a cleaning plane part through pulling of the first material collecting wheels,after the part loses the cleaning effect, the part without the cleaning effect of the wool felt is directly rolled up by the first material collecting wheels, and meanwhile, a part of unadopted woolfelt on the first material conveying wheels is pulled out again to form a new plane part. According to a working method of the automatic aluminum alloy strip cleaning apparatus, automatic changing ofthe wool felt is achieved, tedious work of wool felt replacing in a traditional technique is avoided, and the manual replacing cost is reduced.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Protective device of cutting machine

InactiveCN114012288AAvoid blockingImprove cooling efficiencyLaser beam welding apparatusForeign matterTraction cord

The invention discloses a protective device of a cutting machine, and belongs to the technical field of cutting machines. The device comprises a cutting machine body; a shell assembly, the end part of an air guide pipe being fixedly connected with a waist-shaped shell, and the surface of the waist-shaped shell being fixedly connected with a communicating pipe; a pneumatic balance assembly, an air guide ring being embedded in the inner surface of the annular seat, and the air guide ring being connected with air injection equipment through a connecting pipe; and a blocking assembly, arranged in an inner cavity of the kidney-shaped shell. Air flow is evenly blown to the hollow seat through the air guide ring, when foreign matter enters the air guide pipe, pneumatic balance is broken after the foreign matter passes through the blown air flow surface, air pressure in the spherical sleeve is changed, the positioning disc is driven to move forwards along the guide column, the tensioning acting force on the traction rope is relieved, the blocking plates draw close to each other and are combined under the action of the connecting springs, and the blocking plates are driven to enter the inner cavity of the air guide pipe under the action of the reset springs, so that the ventilation efficiency is improved, the tedious operation of subsequent maintenance is avoided, and the problem of foreign matter blockage is avoided.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

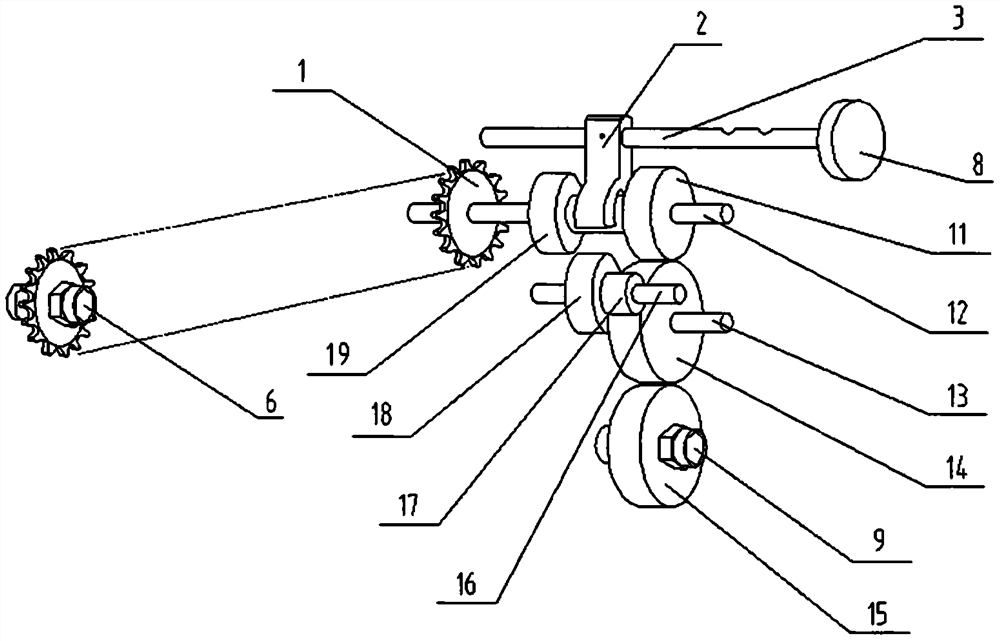

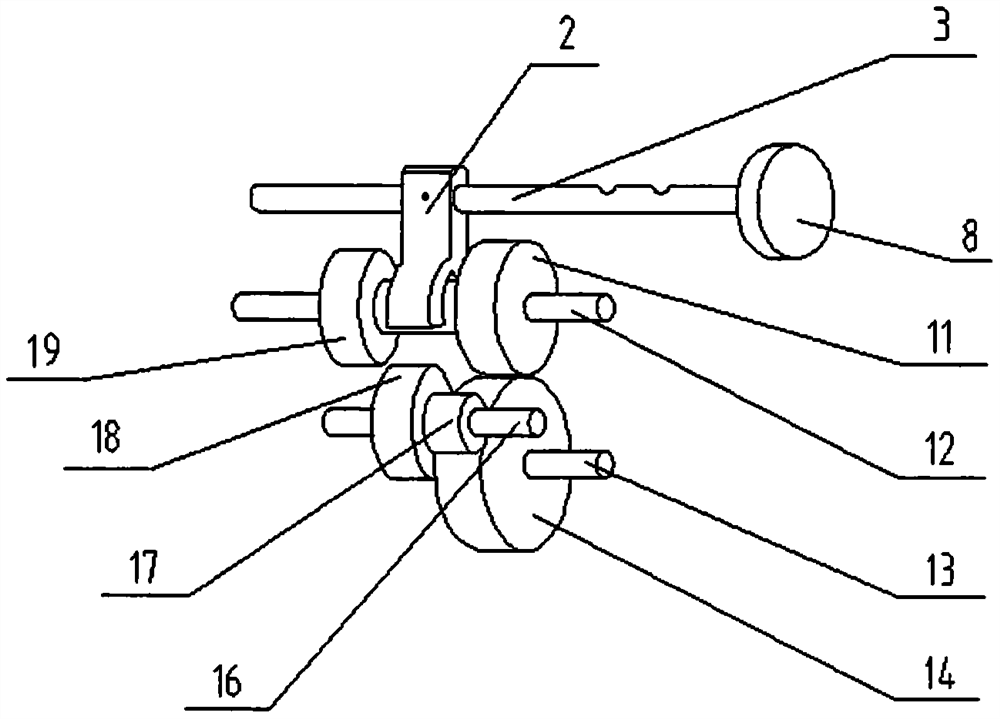

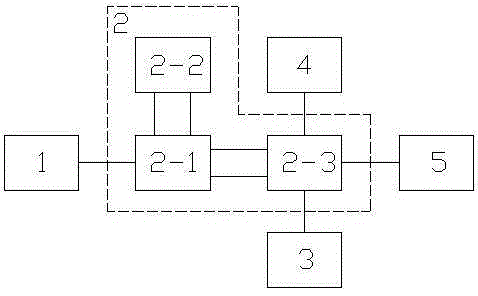

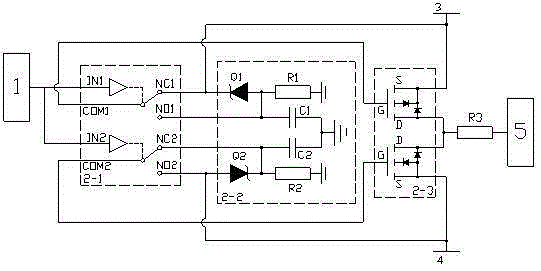

Shifting fork and shifting fork shaft of additional power output device of mini-tiller

The invention discloses a shifting fork and shifting fork shaft of an additional power output device of a mini-tiller. The shifting fork and the shifting fork shaft comprise a shifting fork body, a shifting fork shaft body, a control device and a positioning device. A variable-speed gear-shifting component on the additional power output device of the mini-tiller which locally rotates up and down can be effectively controlled. The power output shaft can output variable-speed and variable-direction power. The shifting fork and the shifting fork shaft are provided for operation of a ditching cutter and a rotary tillage cutter, and can meet the tillage requirement of a user. The structure is simple, and the maintenance is convenient. The labor amount of operators is reduced, the time is saved, and the operation efficiency is improved.

Owner:姜建中

ccd test device

A CCD detecting device is characterized in that a pulse time sequence signal generating module, a CCD vertical time sequence driving circuit, a high-level direct-current source and a low-level direct-current source are included, the pulse time sequence signal generating module at least comprises a terminal device for man-machine interaction and a processing chip, operators input various preset control parameters into the processing chip through the terminal device, the processing chip generates corresponding pulse time sequence signals according to different control parameters, under the control effect of the pulse time sequence signals, the CCD vertical time sequence driving circuit can carry out time-sharing gating processing on the high-level direct-current source and the low-level direct-current source, and accordingly CCD driving signals corresponding to the pulse time sequence signals are obtained. The CCD detecting device has the advantages that one detecting circuit set can meet the detecting requirements of different types of CCDs, hardware consumption during a detecting process is lowered, trivial work that in the prior art, driving circuits need to be independently designed for different types of CCDs is avoided, and detecting working efficiency is indirectly improved.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

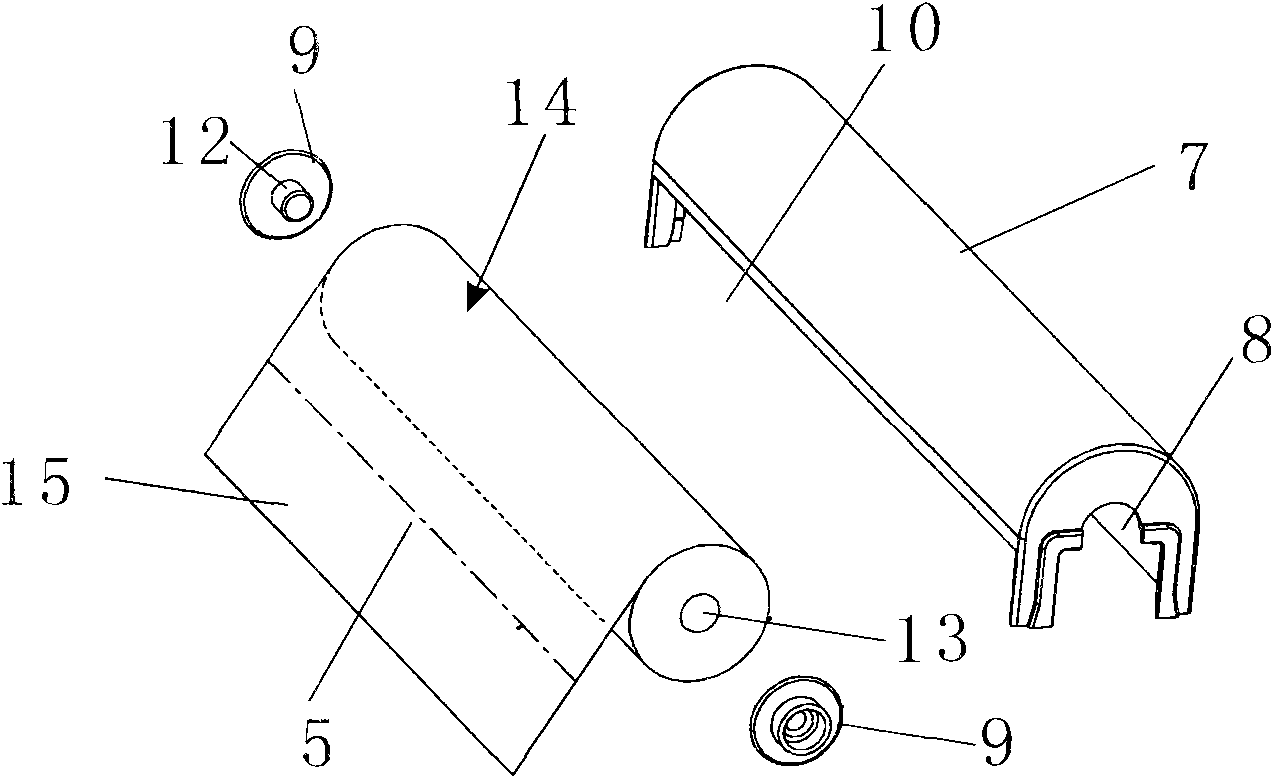

Underwater pipe clamp mounting method

InactiveCN101929581BImprove installation efficiencyHigh precisionPipe laying and repairEngineeringWinch

The invention relates to an underwater pipe clamp mounting method, which comprises the following steps: (1) the mounting position of an underwater pipe clamp (1) and the positions of three platform winches are determined; (2) the mounting datum line of a plurality of pipe clamps is determined; (3) the concentricity position of a plurality of pipe clamps is determined; (4) a plurality of pipe clamps are mounted, namely 1) a first steel wire (9), a second steel wire (10) and a third steel wire (11) of the three platform winches are adjusted, so as to form a three-dimensional coordinate system; 2) one pipe clamp (1) is placed to the mounting position, a flange tightener steel wire (12) is taken as the mounting datum line of an outer clamp (6), the mounting position and angle of the pipe clamp (1) are determined, the pipe clamp (1) encircles a pipe frame construction member (2), and the pipe clamp (1) is fixed; and the rest pipe clamps (1) are mounted by repeating the steps 1) and 2). The invention can simultaneously respectively carry out pipe clamp mounting fixing and coaxial adjusting, and underwater pipe clamp mounting efficiency and the coaxial accuracy ratio of pipe clamps are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

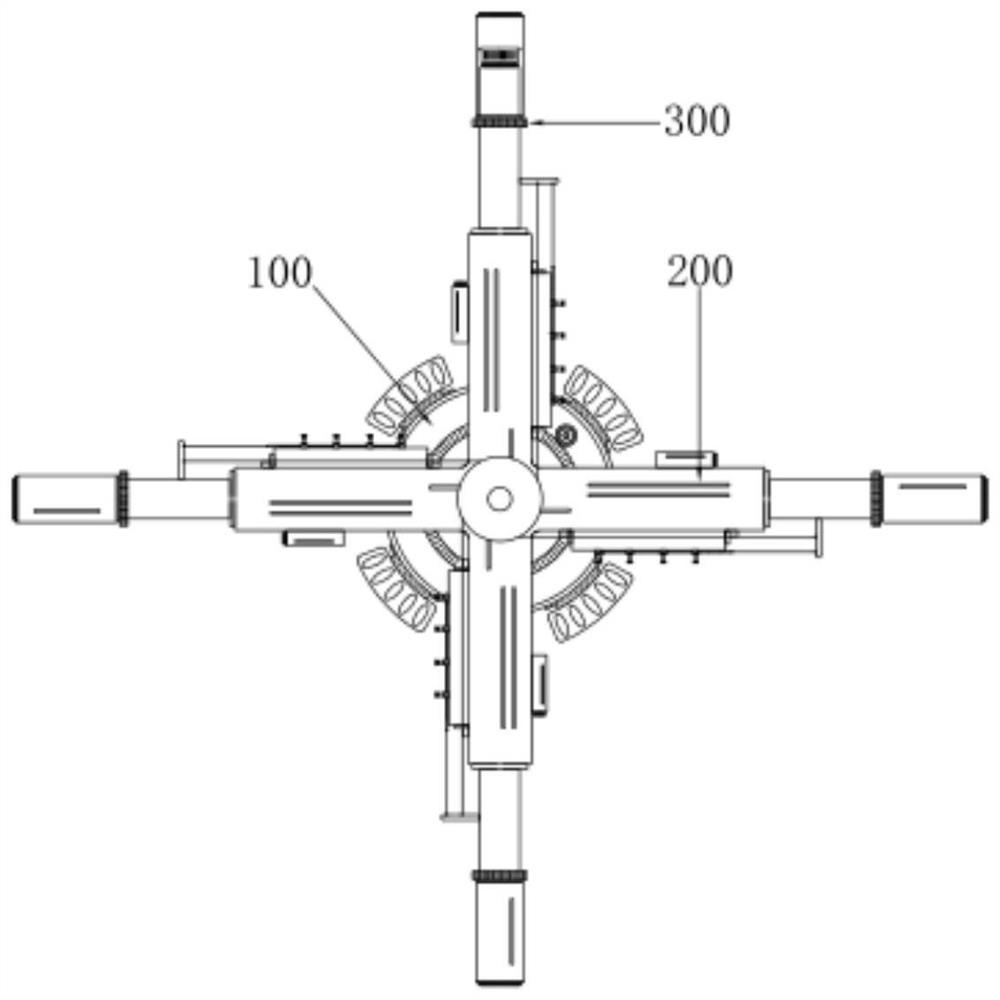

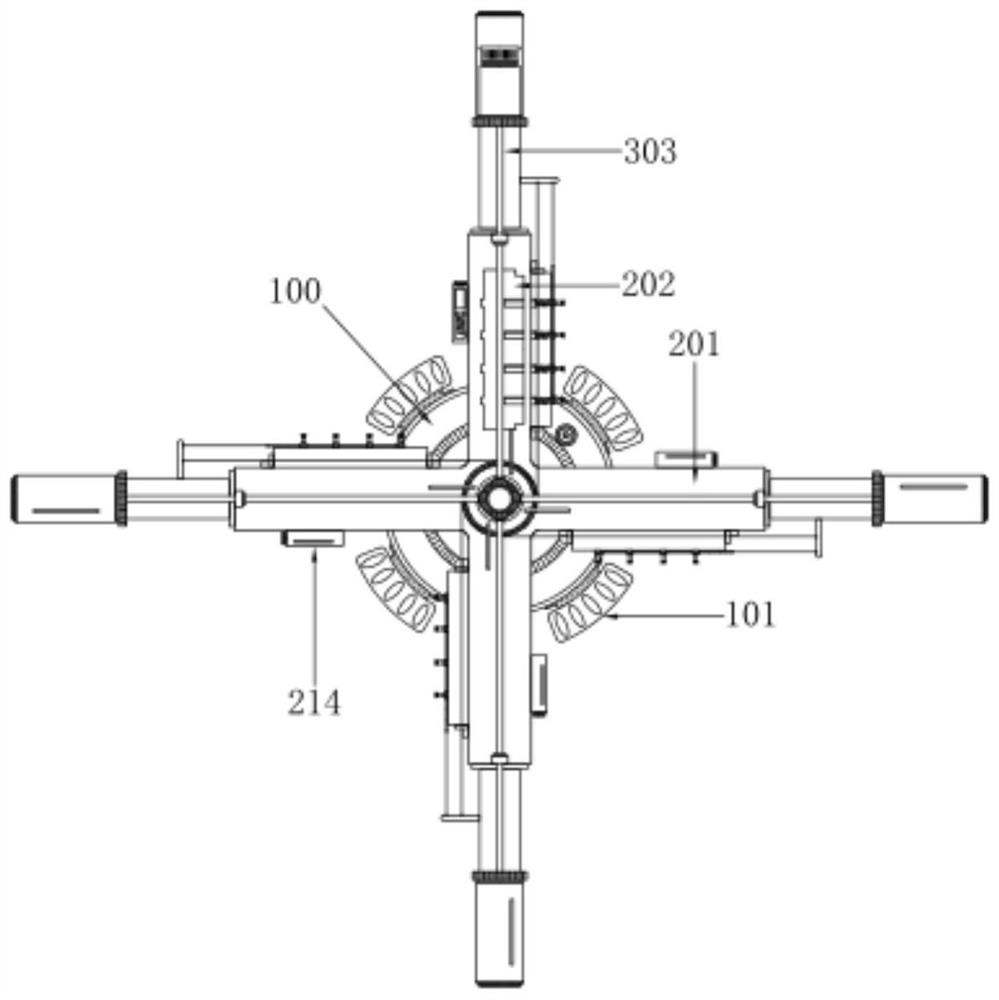

Riverbed sludge down-flow self-propelled multi-section collecting device

InactiveCN113324798AAvoid tedious workReduce labor intensityWithdrawing sample devicesCircular discSuction force

The invention discloses a riverbed sludge down-flow self-propelled multi-section collecting device in the technical field of riverbed governance. The device comprises a walking support, a circulation collection assembly and a driving anti-blocking assembly, wherein the middle section of the walking support is composed of a sealing pipe, and two ends of the walking support are composed of discs; a collection cavity is formed in each branch section of an inner cavity of the cross-shaped piece; and the driving anti-blocking assembly is arranged on the outer surface of the cross-shaped piece. The device is advantaged in that a driving gear ring is driven to rotate through a rotating gear, a cross-shaped piece is driven to rotate, when each supporting foot makes contact with the riverbed surface, the supporting feet rotate, meanwhile, a conical fluted disc rotates to drive a conical gear to rotate, drawing operation is conducted in an inner cavity, upward suction force is generated in a collecting cavity, then sludge is sucked into the collecting cavity, and in the collection process, the gear insertion rods are gradually pulled out outwards, and a certain length of riverbed sludge is sequentially subjected to segmented collection operation in the water flow direction, so tedious operation of placing and taking one by one is avoided, labor intensity is reduced, and collection efficiency and quality are improved.

Owner:马兴业

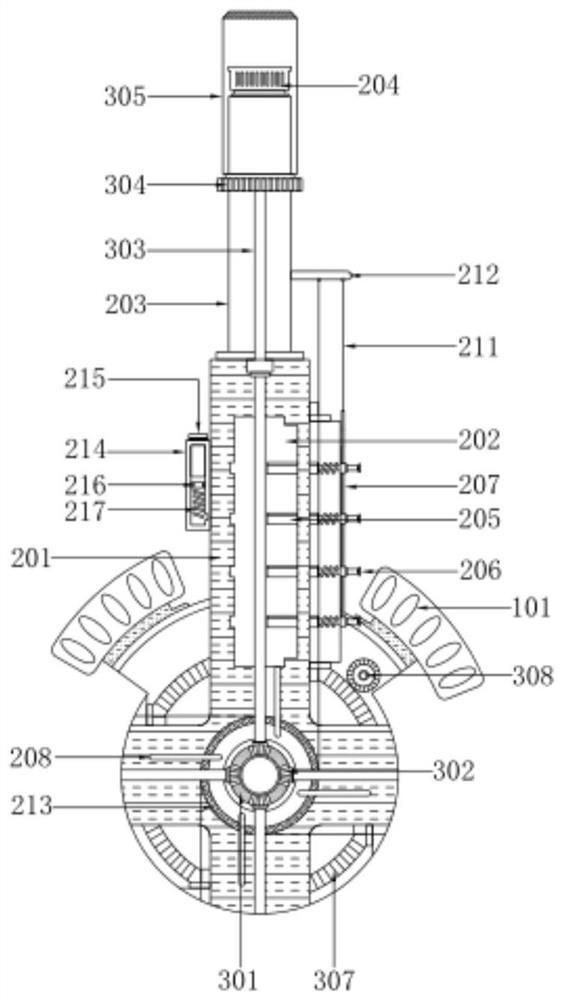

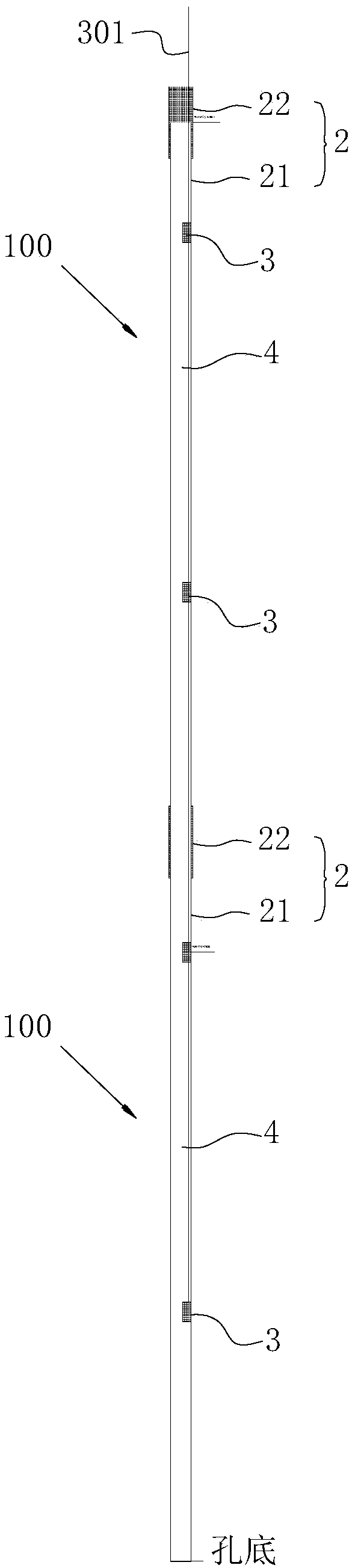

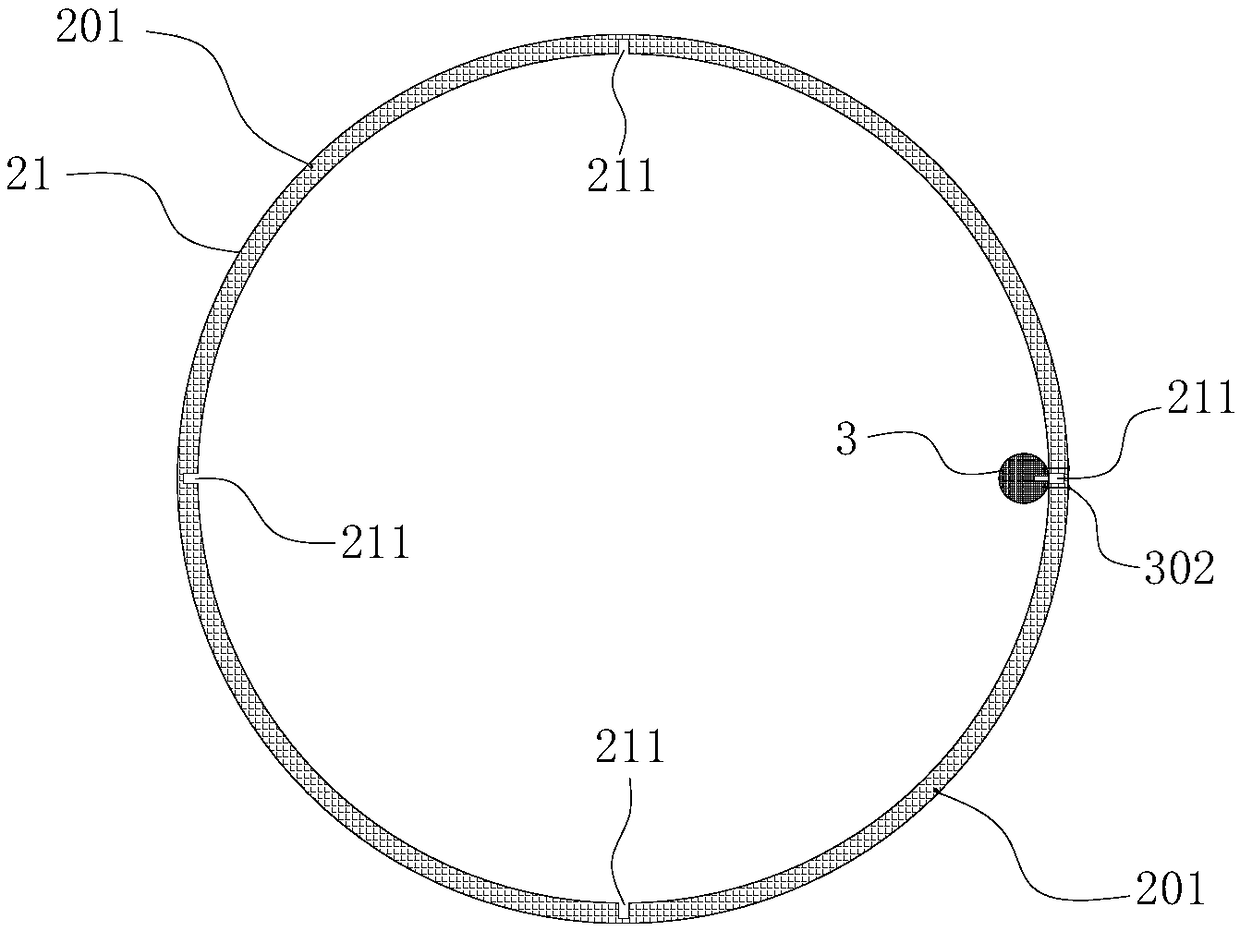

Precast tilt measuring device

InactiveCN108755648AReduce installation errorsAvoid tedious workFoundation testingIn situ soil foundationClassical mechanicsBuilding construction

The invention provides a precast tilt measuring device which is pre-buried in the ground and used for observing the horizontal displacement of the interior of rock and soil mass. The precast tilt measuring device comprises a plurality of tilt measuring modules, each tilt measuring module comprises a tilt measuring pipe, a plurality of sensors arranged in the tilt measuring pipe in the length direction of the tilt measuring pipe at intervals, and a filling agent completely arranged in the space in the tilt measuring pipe in a filling manner. The precast tilt measuring device adopts the precasttilt measuring modules, the sensors are pre-fixed and mounted in the corresponding tilt measuring pipe, the sensors are reinforced by filling the inner space of the tilt measuring pipe with the filling agent, the tedious operation of welding and mounting the sensors by using screws in the construction site in the prior art is avoided, the mounting error of the sensors is reduced, the cost is reduced, and the construction process is refined.

Owner:中铁西北科学研究院有限公司深圳南方分院

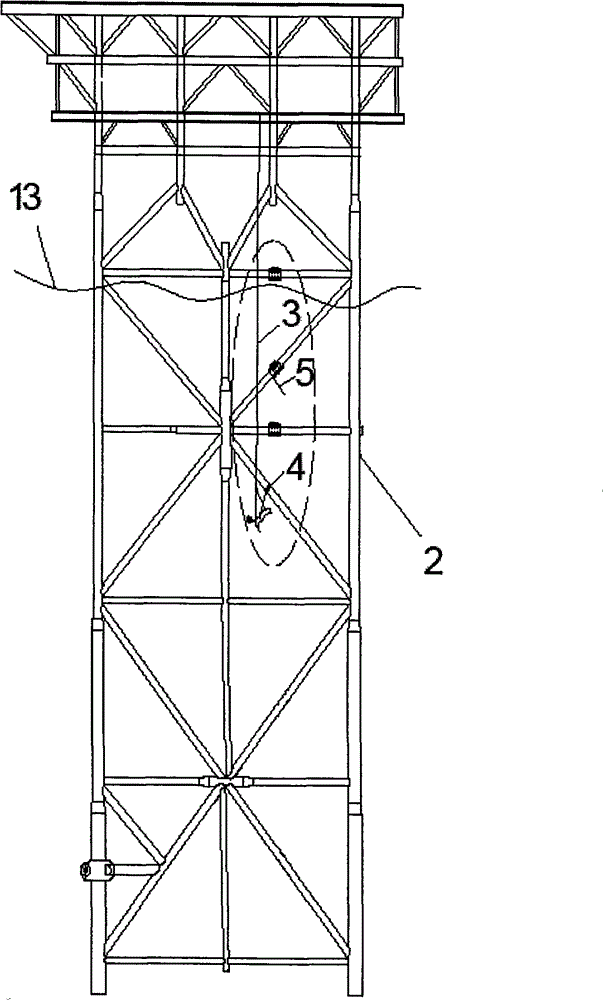

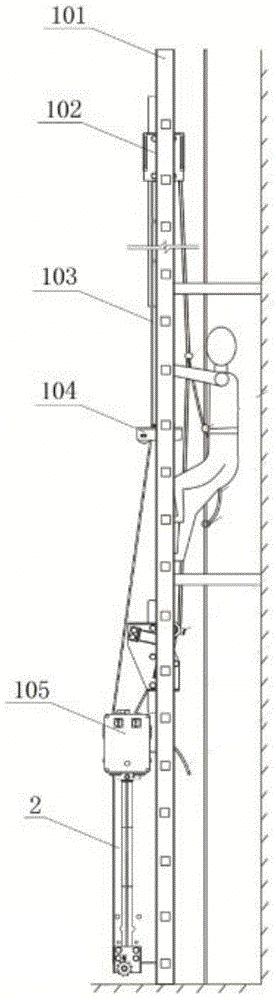

Climbing power assisting device, rope tension device thereof, and application method

PendingCN104895483AObserve available rangeAchieve permanent deformationLaddersEngineeringMechanical engineering

The invention provides a climbing power assisting device, a rope tension device thereof, and an application method. The rope tension device comprises a tensioning bracket assembly, a ratchet wheel tensioning device, a tensioning connecting rope, and a main machine fixing assembly; the tensioning bracket assembly is provided with the ratchet wheel tensioning device; the tensioning connecting rope is used for connecting the ratchet wheel tensioning device with the main machine fixing assembly; the ratchet wheel tensioning device is capable of driving the main machine fixing assembly to slide along the tensioning bracket assembly by tightening the tensioning connecting rope. According to the rope tension device, the ratchet wheel tensioning device is capable of driving the main machine fixing assembly to slide along the tensioning bracket assembly by tightening the tensioning connecting rope, and a driving rope which is arranged on a main machine can be tightened via the main machine fixing assembly. The rope tension device is capable of allowing operators to observe usable range of tensile force and current tensile force conditions in a simple and intuitive manner; compensation of permanent deformation of the driving rope can be realized via simple operation; and on-site complicated operation such as repeat tightening and knotting is avoided.

Owner:上海和蕴机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com