Protective device of cutting machine

A protection device and cutting machine technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult cleaning, accumulation of dust on the screen, blocking of ventilation passages, etc., to improve heat dissipation efficiency, improve ventilation efficiency, The effect of avoiding tedious work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

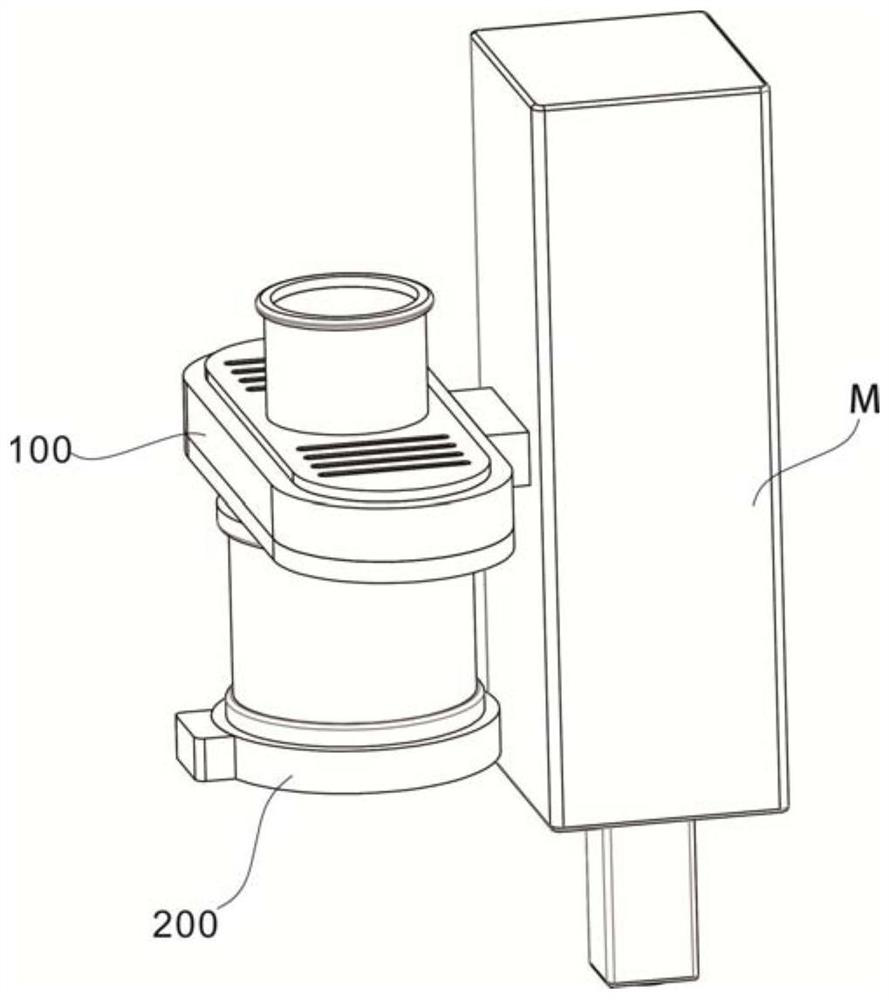

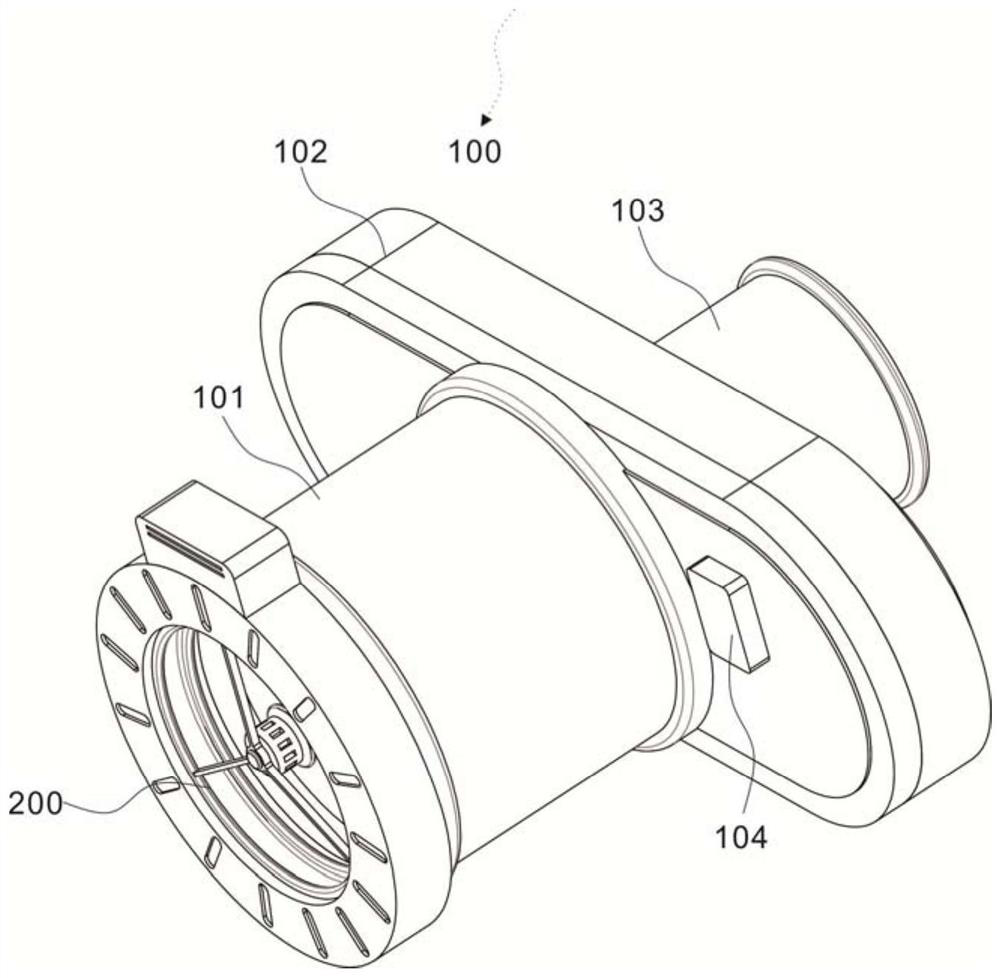

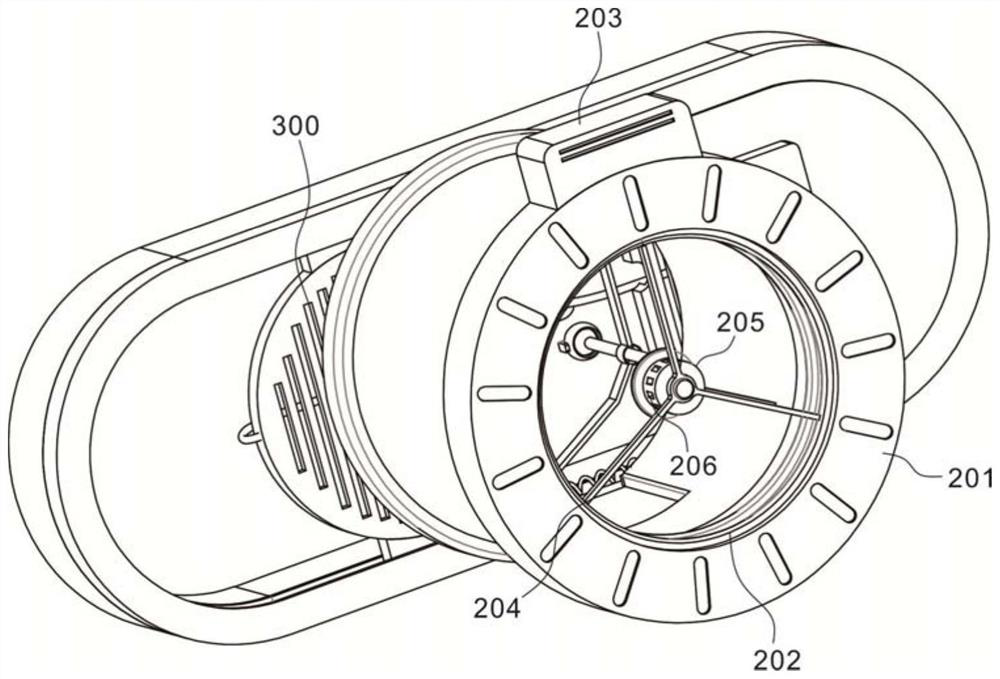

[0027] Example 1: Please refer to figure 1 , the present invention provides a protective device for a cutting machine, comprising: a cutting machine body M; a housing assembly 100, the housing assembly 100 is arranged on one side of the cutting machine body M, and includes an air guide pipe 101, and the end of the air guide pipe 101 is fixedly connected with The waist shell 102, the connecting pipe 103 is fixedly connected to the waist shell 102 surface, and the waist shell 102 surface is provided with a controller; An air guide ring 202 is embedded on the inner surface, and the air guide ring 202 is connected to the air injection device 203 through a connecting pipe;

[0028] see figure 2 and image 3 , the center of the wind guide ring 202 is provided with a hollow seat 205, the hollow seat 205 is fixedly set by the triangular bracket 204, the end of the triangular bracket 204 is fixedly connected with the inner wall of the annular seat 201, and the surface of the hollow ...

Embodiment 2

[0031] Example 2: Please refer to Figure 3-5 , the blocking assembly 300 includes a fixed support rod 301 fixed up and down symmetrically in the inner cavity of the waist shell 102, a positioning plate 302 is arranged between the fixed support rods 301, and a guide column 303 is provided on the positioning plate 302, and the guide column 303 One end is fixedly connected to the end of the fixed pole 301, and the other end of the guide column 303 is fixedly connected to the installation bracket 304, and the guide column 303 is provided with a reset spring 305, and the installation bracket 304 is fixed to the inner cavity of the communication pipe 103.

[0032] The guide column 303 moves along the guide column 303 through the control of the push cylinder 306, and the push cylinder 306 is electrically connected to the controller. The air pressure in 209 changes, which drives the positioning plate 302 to move forward along the guide column 303, and releases the tension force on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com