Linear automatic screw driving machine

An automatic screwing machine, straight line technology, applied in the direction of thread trimming machine, thread trimming device, thread trimming feeding device, etc., can solve the problems of increasing labor intensity of workers and wasting manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

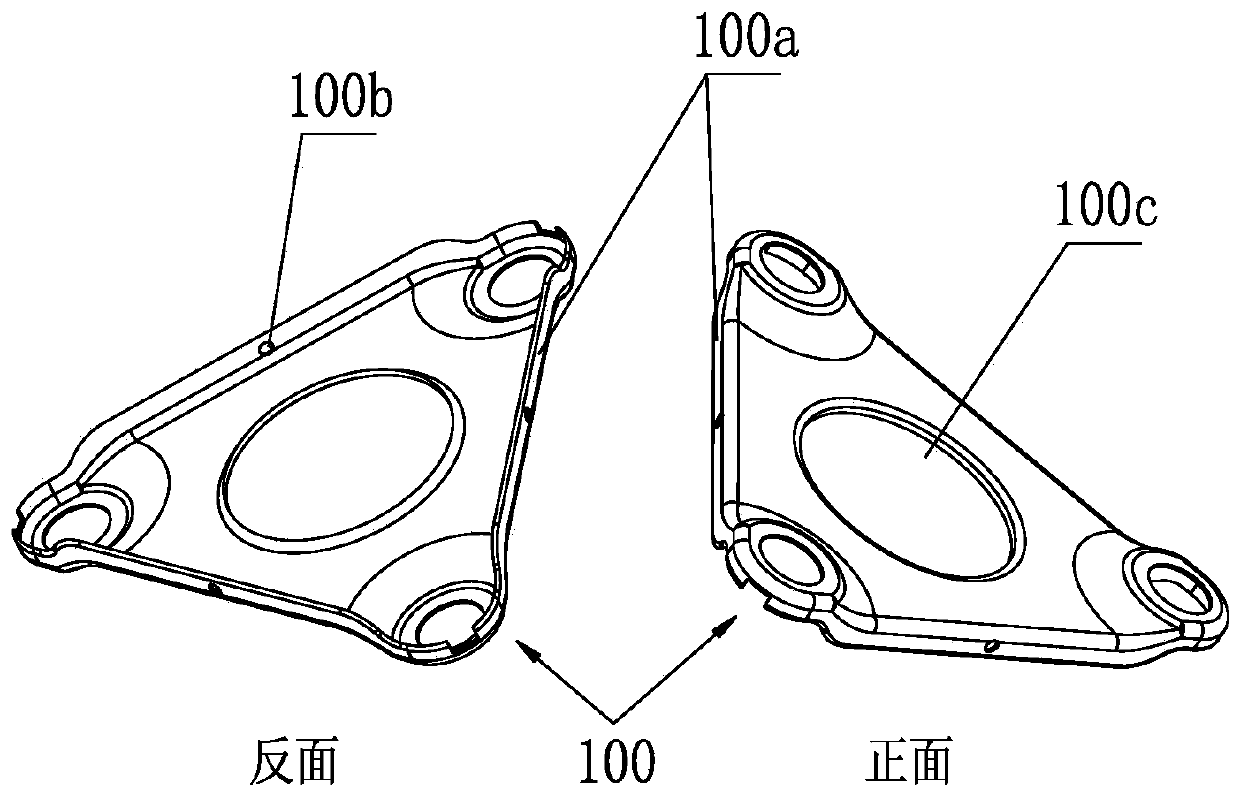

[0025] refer to figure 1, the tripod 100 provided in this embodiment is a stamped tripod 100, and its shape is an equilateral triangle. The middle part of the tripod 100 is stamped to form a through central ring 100c, and its three sides are respectively formed with side walls. 100a, a light hole 100b is reserved on the side wall 100a. The light hole 100b needs to be tapped and screwed in sequence. The purpose of screwing is to ensure that at least one of the threaded holes after tapping is used in the subsequent painting process. It is not covered by paint and protects the thread, which is convenient for subsequent installation or disassembly of the grounding wire.

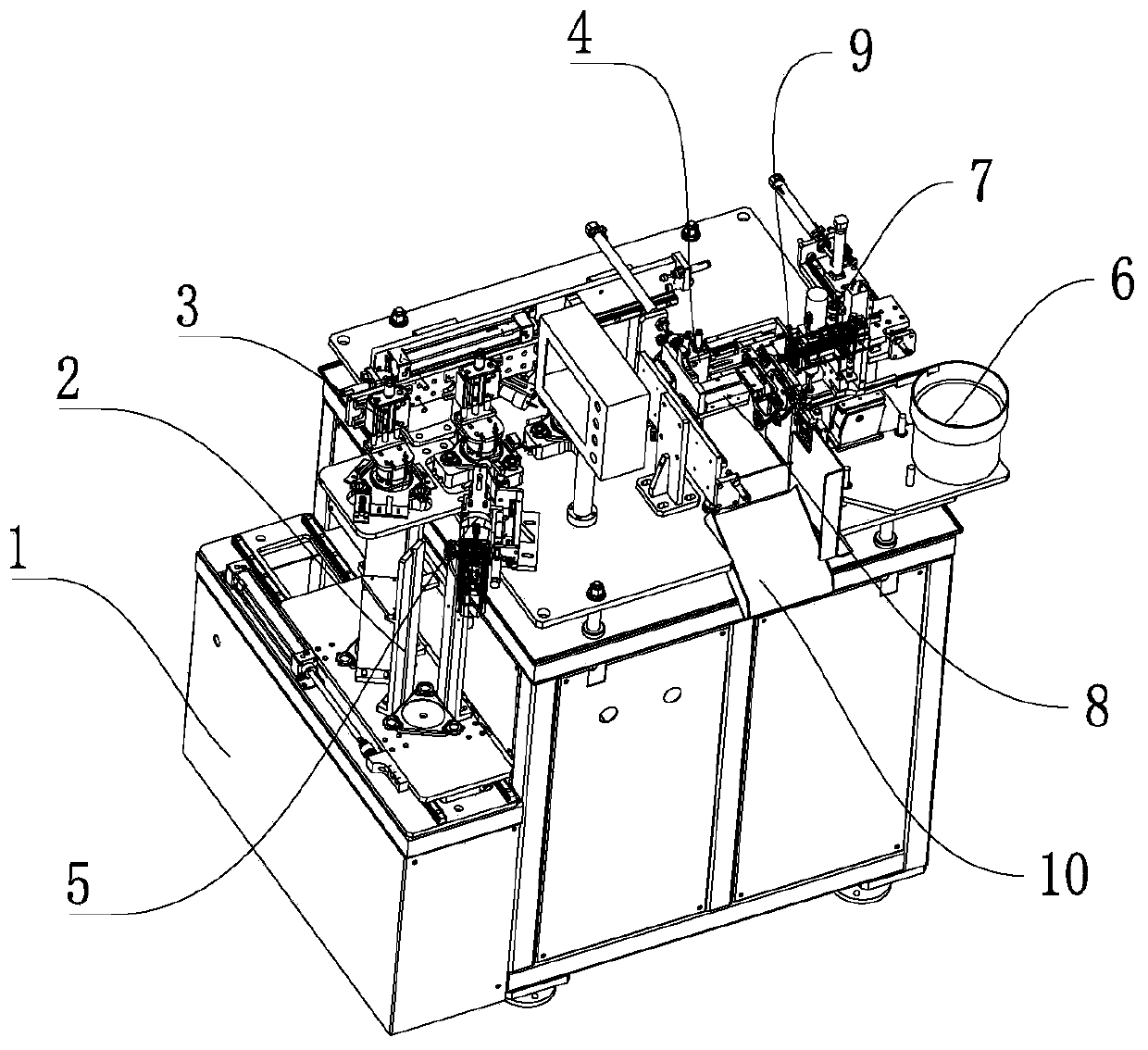

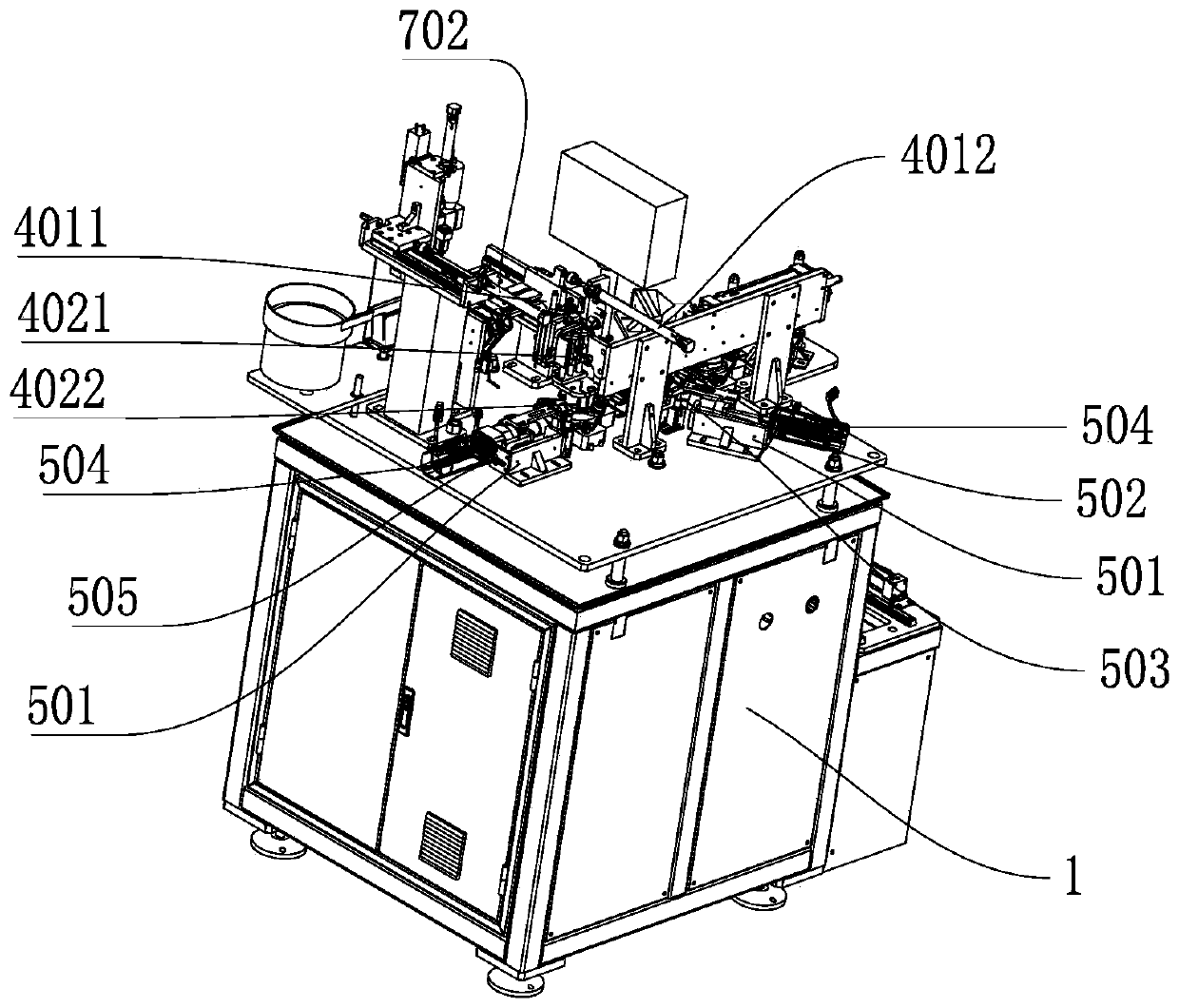

[0026] refer to figure 2 , a kind of straight line automatic screwing machine that the present embodiment provides, is used for realizing the tapping of tripo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com