Soil and stone crushing operation device

A working device, soil and rock technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve problems such as low work efficiency and troublesome operation, and achieve the effect of avoiding cumbersome work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

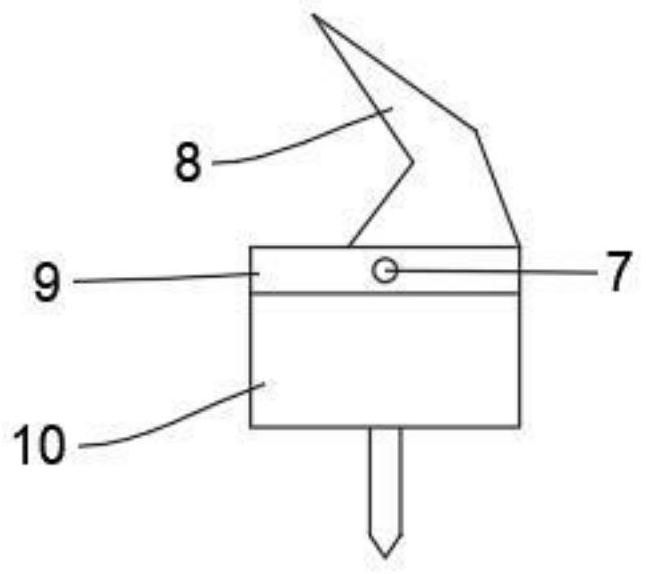

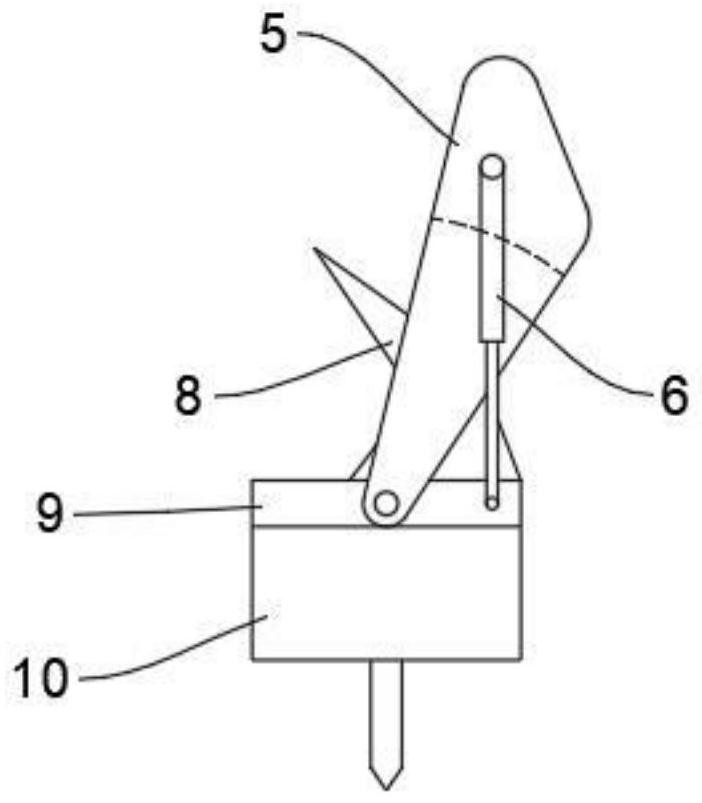

[0035] like figure 1 As shown, the soil and rock crushing operation device described in the embodiment of the present application includes a crushing mechanism, and the crushing mechanism includes a ripper mechanism 8 and a breaker mechanism 10 .

[0036] The ripper mechanism 8 can be selected from common rippers on the market. The ripper has the functions of breaking and turning loose. It can be divided into a ripper for excavators and a ripper for bulldozers. The ripper for excavators is also called bucket hook. , generally a single tooth, an integrally cast loosening tooth with ear holes on the upper part, which are hinged with the bucket rod and bucket cylinder respectively, and the front end of the tooth tip has a hard alloy surfacing tooth cap. , push the tines to forcibly insert and turn the soil. Scarifiers are used to excavate cracked rock, break up frozen soil, and also to excavate asphalt pavements. The ripper is suitable for the crushing and splitting of hard soi...

Embodiment 2

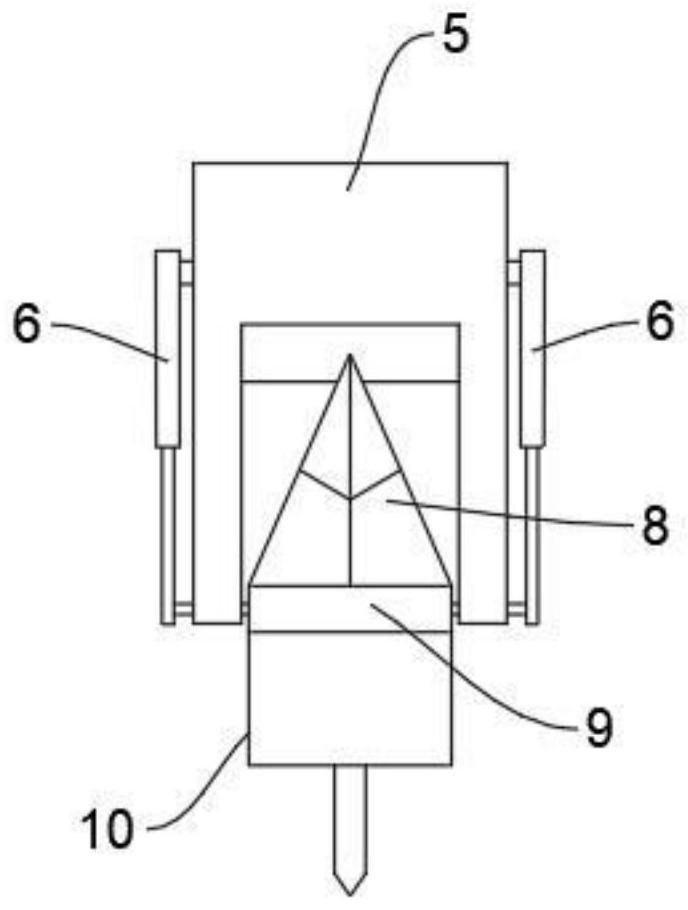

[0056] The main difference between the second embodiment and the first embodiment is that the setting method of the adjusting telescopic member 6 is different, such as Figure 7-Figure 9 As shown, in the embodiment of the present application, the adjusting telescopic member 6 is located in the plane where the rotation direction of the crushing mechanism is located. That is, the upper end of the adjusting telescopic piece 6 can be hinged on the side of the stick 5 away from the main body 1 of the excavator, and the lower end of the adjusting telescopic piece 6 can be hinged on a certain side of the crushing mechanism, which is not the connection of the ripper mechanism 8 It is neither the connecting surface of the breaker mechanism 10 nor the connecting surface where the fork arm is located.

[0057] Another difference between the second embodiment and the first embodiment is that the structural form of the connecting member 9 is different, such as Figure 7 As shown, the ripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com