Spark gap arrestor

A lightning arrester and discharge electrode technology, which is applied in the field of lightning arrester structure, can solve the problems of load circuit power supply blockage, wiring or appliance influence, and inability to stop continuous current, etc., to achieve the effect of suppressing material costs and avoiding cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

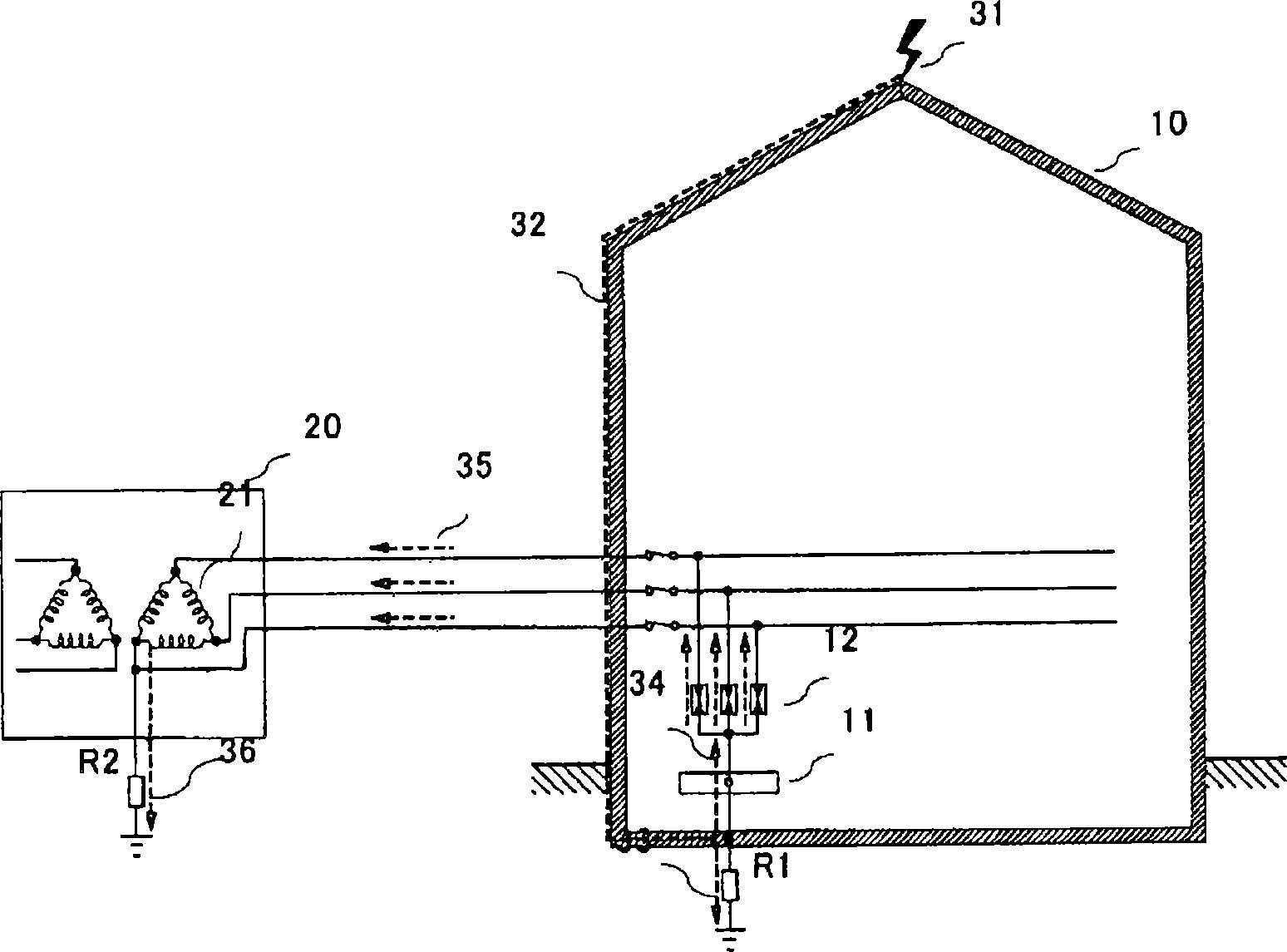

[0056] Below, refer to Figure 7 , Figure 8 The structure and function of the lightning arrester for low-voltage AC power supply circuit of the present invention will be described in detail.

[0057] Figure 7 It is a longitudinal sectional view of a cylinder-enclosed arrester. The components are manufactured and arranged in rotational symmetry with respect to the central axis. The bases of both discharge electrodes are made of copper members 102a and 102b which are common conductors, and the front ends are made of copper tungsten sheets 101a and 101b excellent in heat resistance and arc resistance. The base parts 102a, 102b and the front end parts 101a, 101b are integrated by fitting the convex part of the front part into the concave part of the base part, without performing complicated processes such as welding. The concavo-convex part of the base part and the front part may be reversed combination. The discharge electrode is conical in this embodiment. Instead of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com