CCD detecting device

A technology of testing equipment and pulse timing, which is applied in the direction of measuring equipment, measuring electricity, and measuring electrical variables, etc., can solve the problems of the CCD vertical timing driving circuit, such as specific problems, large workload and hardware consumption, and lack of versatility, so as to reduce Effects of hardware consumption, reduction of hardware consumption, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

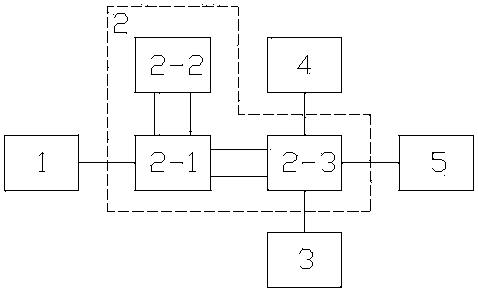

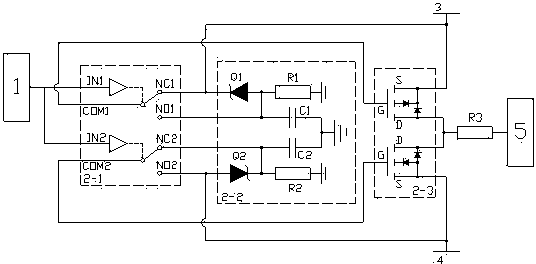

[0013] A kind of CCD testing device, it is characterized in that: comprise pulse sequence signal generation module 1, CCD vertical sequence drive circuit 2, high level DC source 3 and low level DC source 4; In described pulse sequence signal generation module 1 at least include A terminal device for human-machine dialogue and a processing chip. The operator inputs various preset control parameters into the processing chip through the terminal device, and the processing chip generates corresponding pulse timing signals according to different control parameters; Under the control of the signal, the CCD vertical timing drive circuit 2 can perform time-sharing gate processing on the high-level DC source 3 and the low-level DC source 4, so as to obtain the CCD drive signal corresponding to the pulse timing signal.

[0014] Further, the CCD vertical timing drive circuit is composed of a switch module 2-1, a voltage stabilizing circuit 2-2 and a power amplitude amplification circuit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com