ccd vertical timing drive circuit

A timing-driven, circuit-based technology, applied in TVs, electrical components, color TVs, etc., can solve the problems of cumbersomeness, heavy workload and hardware consumption, and high production costs, and achieve the effects of avoiding cumbersome work, reducing hardware consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

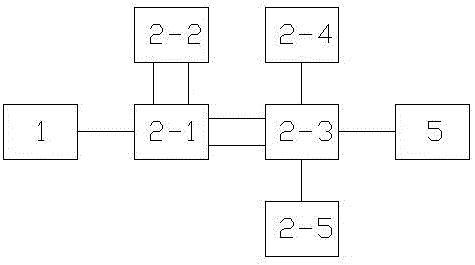

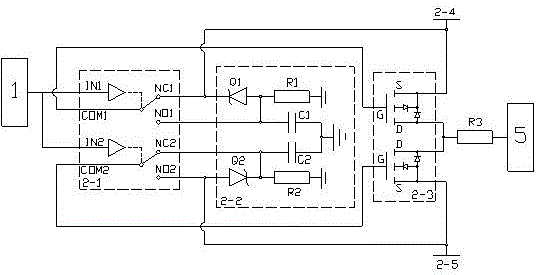

[0012] A CCD vertical sequential drive circuit is characterized in that: the CCD vertical sequential drive circuit consists of a switch module 2-1, a voltage stabilizing circuit 2-2, a power amplitude amplification circuit 2-3, a high-level DC source 2-4 and The low-level DC source 2-5 is composed; the power amplitude amplification circuit 2-3 is composed of a P-channel FET and an N-channel FET, and the grid G of the P-channel FET and the N-channel FET forms two An input node, the source S of the P-channel FET and the N-channel FET are respectively connected to the high-level DC source 2-4 and the low-level DC source 2-5, and the P-channel FET and the N-channel FET The drain D of the tube is short-circuited to form the output end of the CCD vertical timing drive circuit; the power amplitude amplifier circuit 2-3 can process one of the high-level DC source 2-4 and the low-level DC source 2-5 and output through the output terminal; the voltage stabilizing circuit 2-2 can provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com