One-die two-stamping automatic warm upsetting forming machine

A technology of one die, two punches and forming machines, which is applied in the direction of swaging presses, upsetting forging presses, driving devices of forging presses, etc., to achieve the effects of safety and reliability, energy saving and production efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

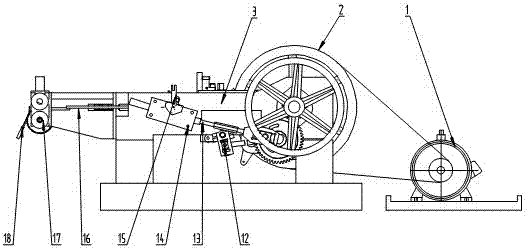

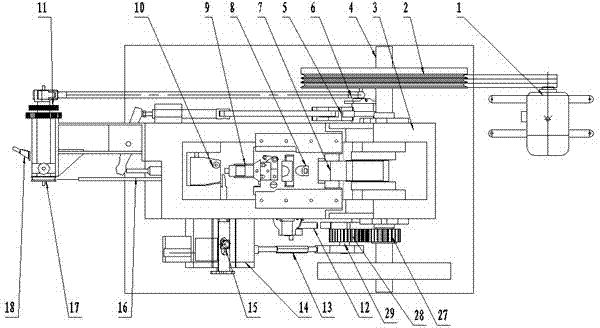

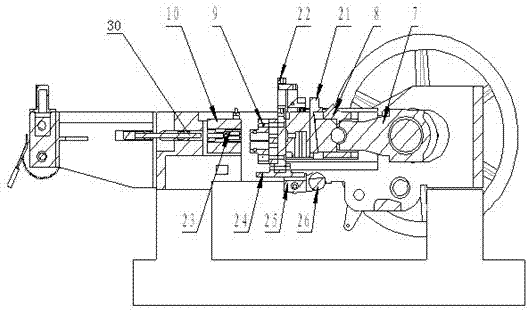

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a one-mold two-blow automatic warm heading forming machine, including a forming machine body 3, a motor 1 and a transmission device, and a feeding device, a heating device, a cutting device, a ejecting device and a transmission device are arranged on the bed. Automatically control the secondary stamping device, the motor is respectively connected to the feeding device, material cutting device, ejector The stamping unit provides power.

[0025] Described transmission device comprises flywheel 2, and described flywheel is connected with motor, and crankshaft 4 is installed on flywheel, and connecting rod 7 is sleeved in the middle of described crankshaft, and crankshaft gear 27 is installed on one side of crankshaft, and described crankshaft gear and countershaft gear 28, the countershaft gear is equipped with a countershaft 29, one end of the countershaft close to the count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com