Sterilizing composition

一种组合物、衍生物的技术,应用在外科器械灭菌的组合物领域,能够解决易受进入污物的影响、泡沫控制短暂等问题,达到优良去污能力、提高吸收、改善清洁效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Combine the following ingredients in the order listed:

[0081] Deionized water 91.9g

[0082] Neodol 91-6 TM (Shell) 0.50g

[0083] Plurafac LF-221 TM (BASF) 0.40g

[0084] Triethylene glycol 3.80g

[0085] Add buffer, dye

[0086] Adjust pH to 6.3-6.5

[0087] 50% Pharmaceutical Grade Glutaraldehyde 4.5g

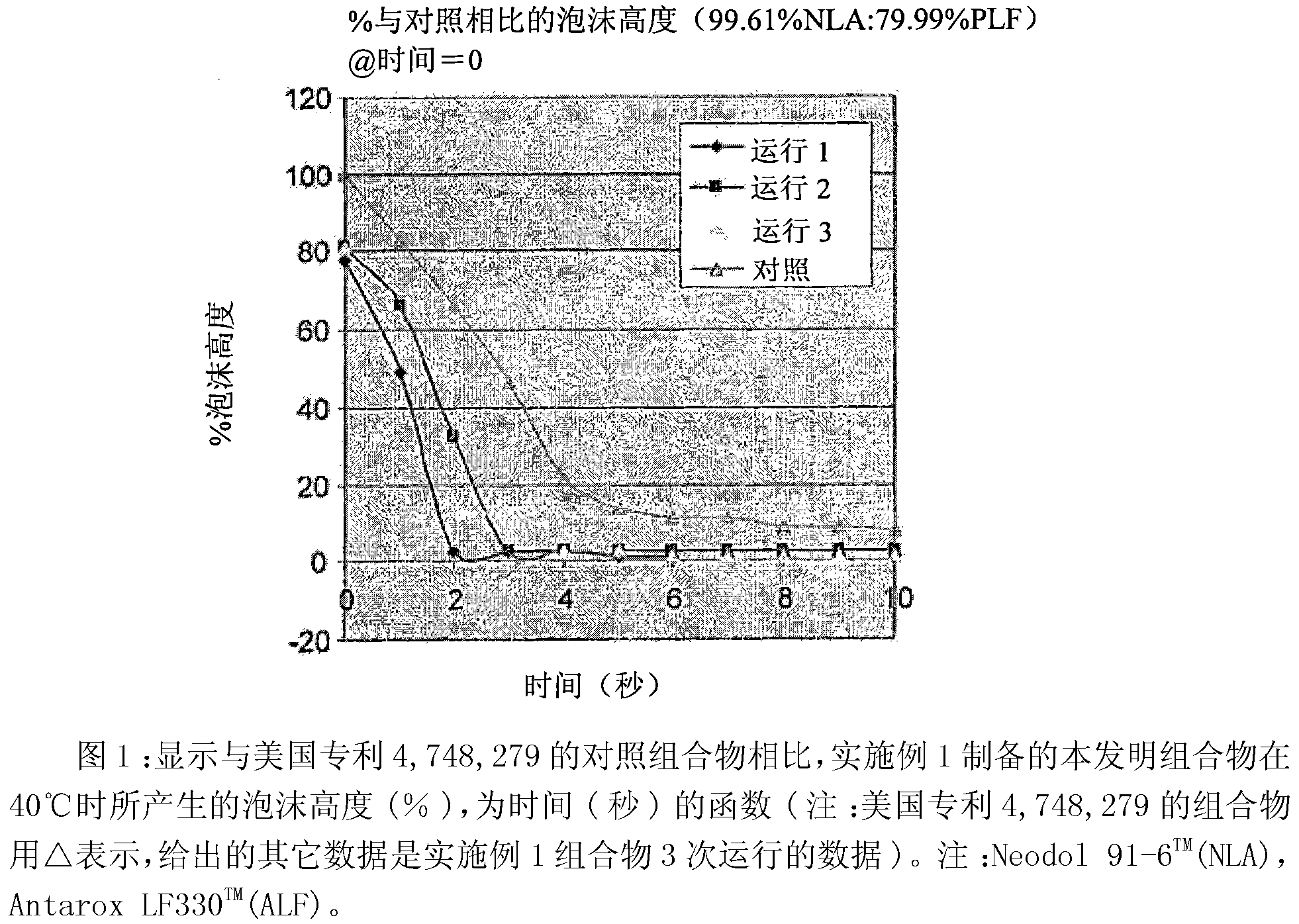

[0088] The foam height that this composition of the present invention produces is compared with 100% Neodol 91-6 TM (Equivalent to the prior art composition disclosed in US Patent No. 4,748,276) The foam height of the prepared composition was compared. This composition (Neodol 91-6 TM / Plurac LF221 TM ) was compared to the foam height obtained with the composition disclosed in US Pat. No. 4,748,276. The results are shown in Figure 1.

[0089] As can be seen from the figure, when the composition disclosed in U.S. Patent 4,748,276 (containing Neodol 91-6 TM ) by adding 0.4% Plurac LF221 TM After that, the foam height is the same as without Plurac LF221 ...

Embodiment 2

[0092] The same composition as Example 1 was prepared except that 20% Neodol 91-6 TM and 80% Antarox LF330 TM (Rhodia) constitutes a surfactant concentration other than 0.5%.

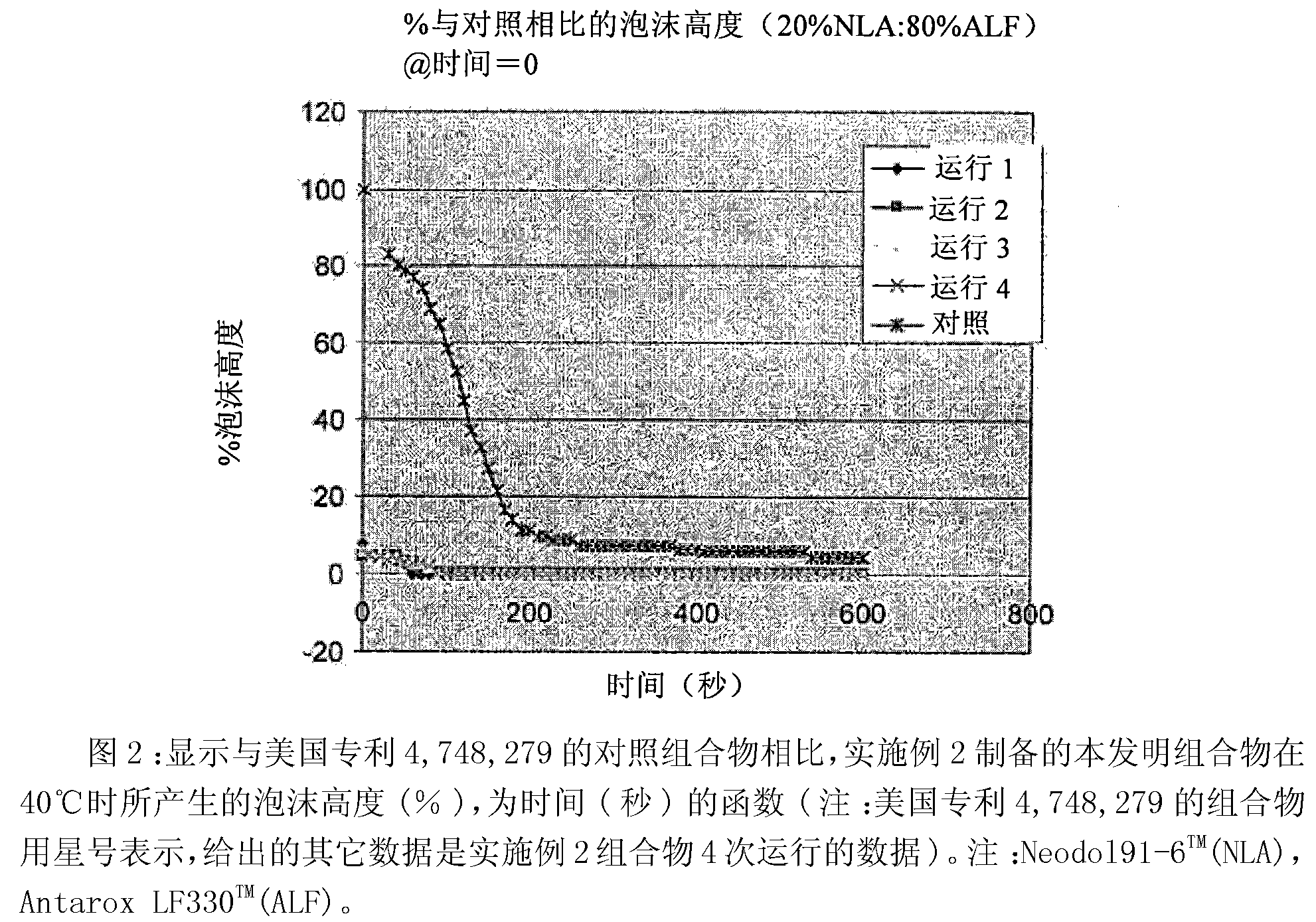

[0093] Comparing the foam height produced by this composition with 100% Neodol 91-6 TM (Equivalent to the prior art composition disclosed in US Patent No. 4,748,276) The foam height of the prepared composition was compared. This composition (Neodol 91-6 TM / Antarox LF330 TM ) was compared to the foam height obtained with the composition disclosed in US Pat. No. 4,748,276. The results are shown in Figure 2.

[0094] As shown in the figure, when composed of 20% Neodol 91-6 TM and 80% Antarox LF330 TM At a make-up surfactant concentration of 0.5%, the composition of the invention produced an exceptionally rapid decrease in foam height compared to the prior art composition.

[0095] The composition of the present invention has a surface tension of 22.4 dynes / cm. The surface tension of the prior art...

Embodiment 3

[0097] The same composition as Example 1 was prepared except that 20% Neodol 91-6 TM and 80% Antarox BL240 TM (Rhodia) constitutes a surfactant concentration other than 0.5%.

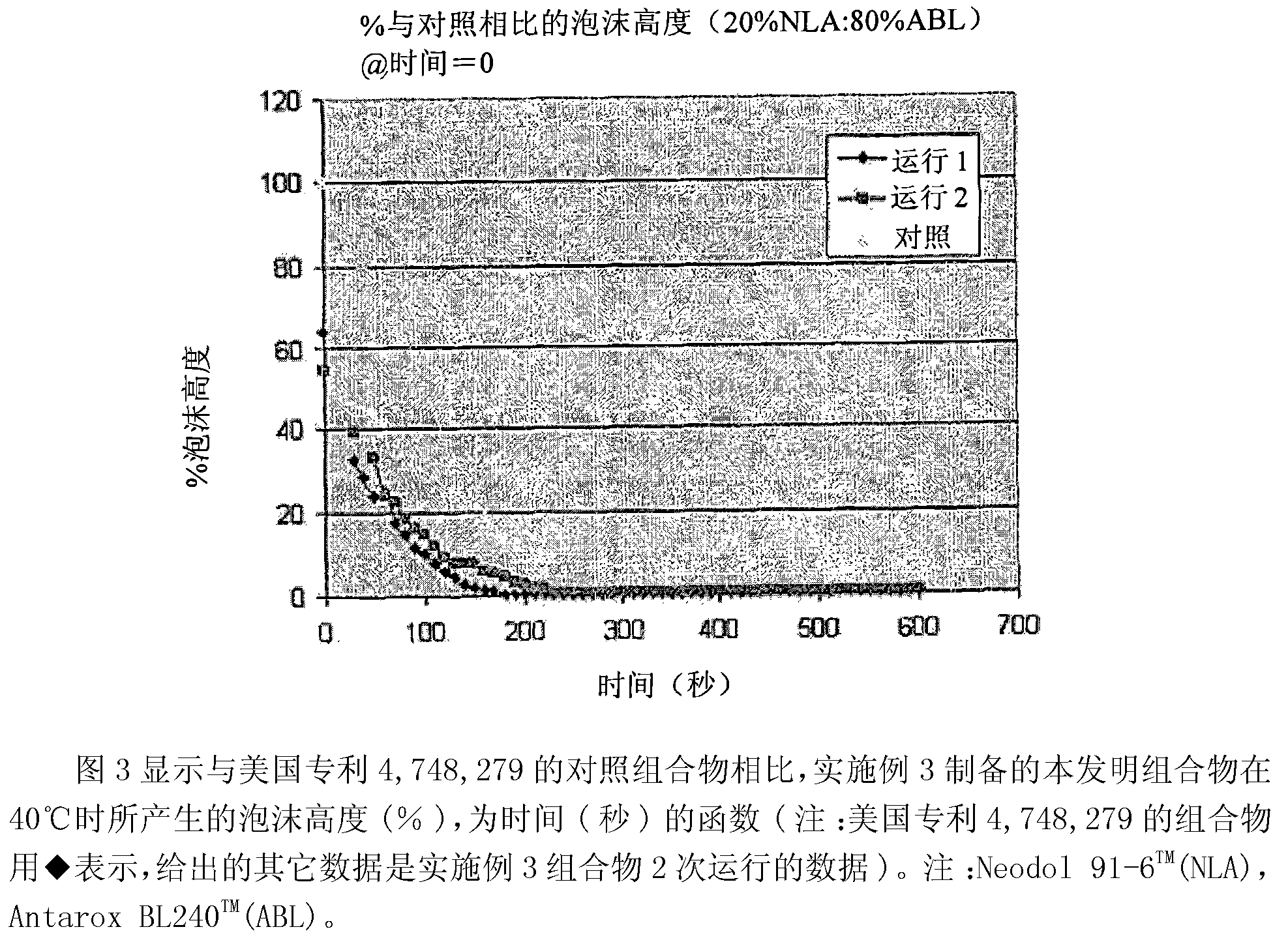

[0098] Comparing the foam height produced by this composition with 100% Neodol 91-6 TM (Equivalent to the prior art composition disclosed in US Patent No. 4,748,276) The foam height of the prepared composition was compared. This composition (Neodol 91-6 TM / Antarox BL240 TM ) was compared to the foam height obtained with the composition disclosed in US Pat. No. 4,748,276. The results are shown in Figure 3.

[0099] As shown in the figure, when composed of 20% Neodol 91-6 TM and 80% Antarox BL240 TM At a surfactant concentration of 0.5%, the compositions of the present invention produced significantly lower foam heights than prior art compositions.

[0100] The surface tension of the composition of the present invention is 29.0 dynes / cm. The surface tension of the prior art composition is 28 dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com