Integral compressor motor and refrigerant/oil heater apparatus and method

A technology of compressors and motors, applied in the direction of machines/engines, pump control, mechanical equipment, etc., can solve the problems of low heat transfer efficiency of refrigerants and oil, problems in structure and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

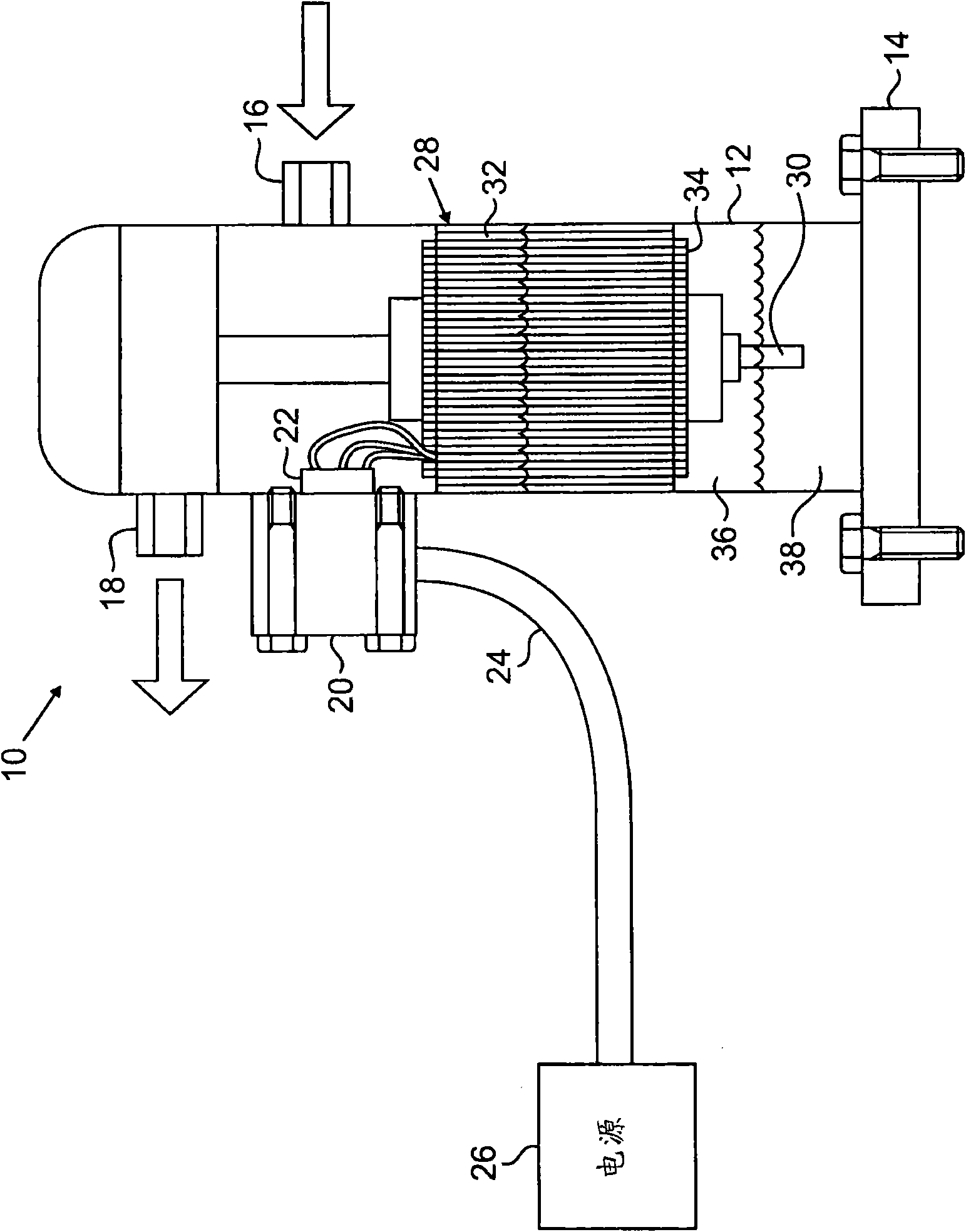

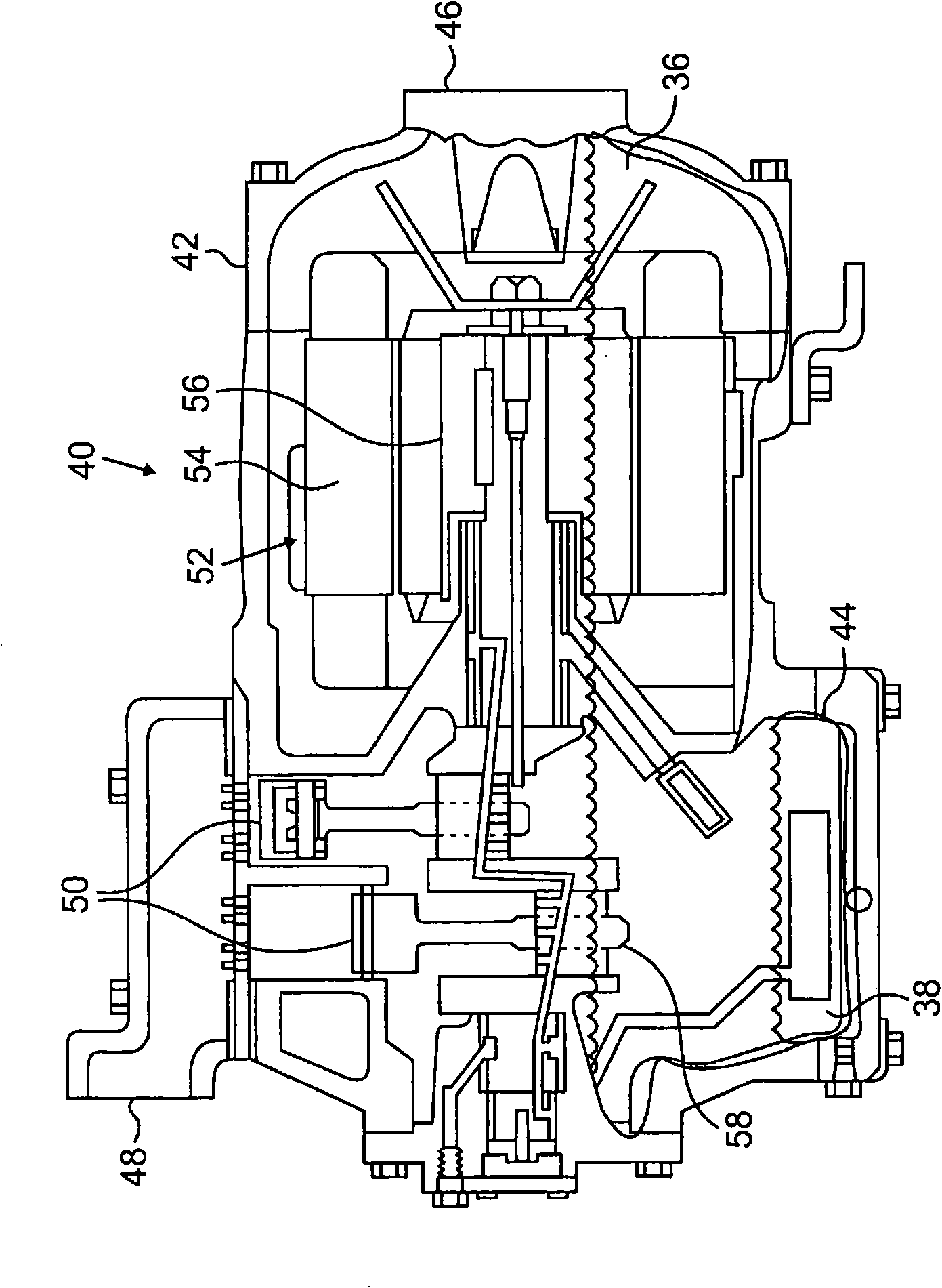

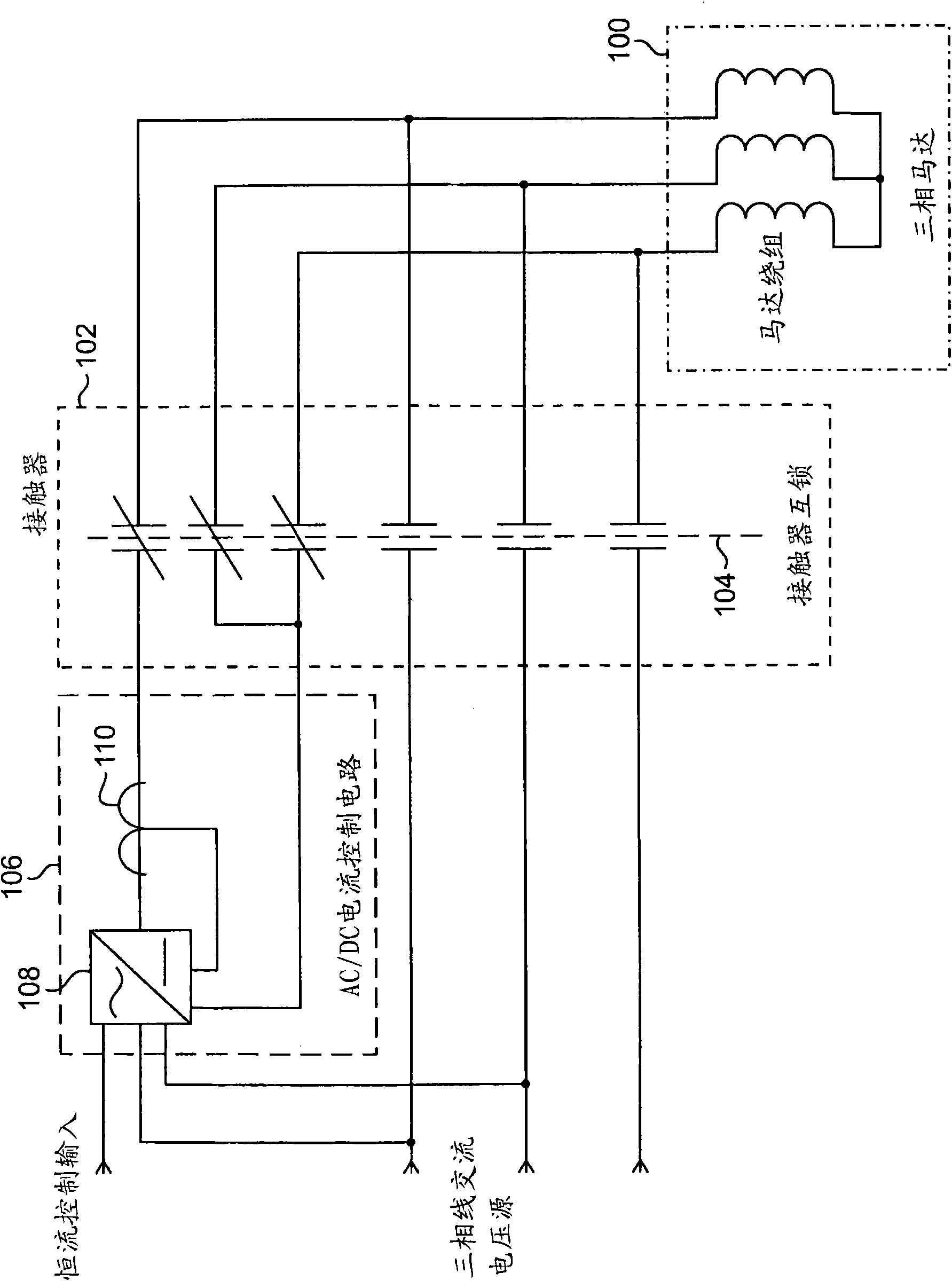

[0010] In general, exemplary embodiments of the present invention include connecting a motor such as an electric motor (eg, a compressor motor) to a constant current power source (DC or AC) that can heat the motor without generating a force output winding. This enables the motor to provide heater functionality during periods of motor shutdown, ie, when the motor is not providing force output (ie, performing mechanical work). For example, heat generated by a motor can be used to increase lubricant viscosity. Also, by utilizing the motor to generate heat for a selected period of time before starting the motor to generate force output, the motor can be controlled to reduce flooded starts, which would otherwise be critical for compressor motors with fluid that can migrate to the compressor Reliability issues may arise. While the invention provides many useful benefits when applied to compressor motors, the invention is also useful for other types of systems with motors.

[0011...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap