Voltage source converter with ice melting function, and control method

A technology of a voltage source converter and a control method, which is applied in the direction of output power conversion device, conversion of AC power input to AC power output, electrical components, etc., and can solve the problem of limited operating range of DC voltage, increased device efficiency and cost, Affect the normal and safe operation of overhead lines and other issues, achieve the effect of realizing the operating range of DC voltage, reducing the risk of starting, and improving the utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

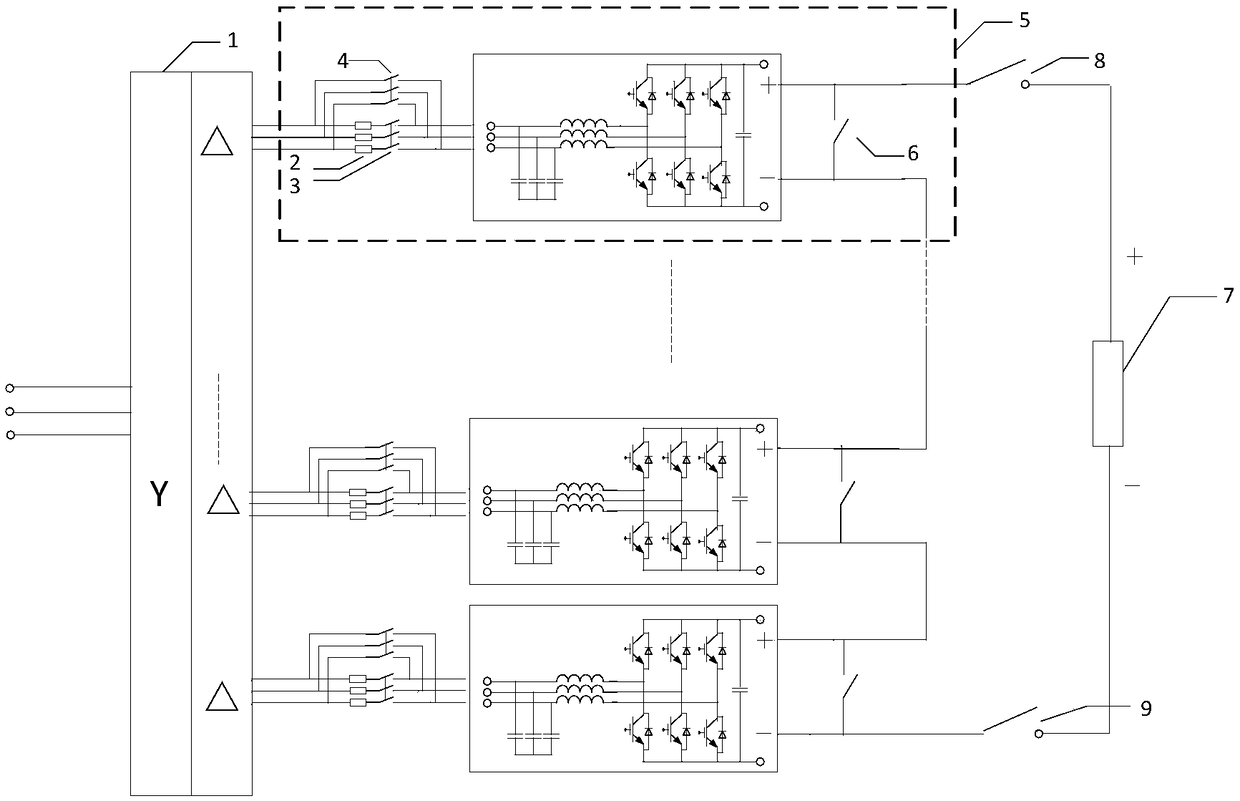

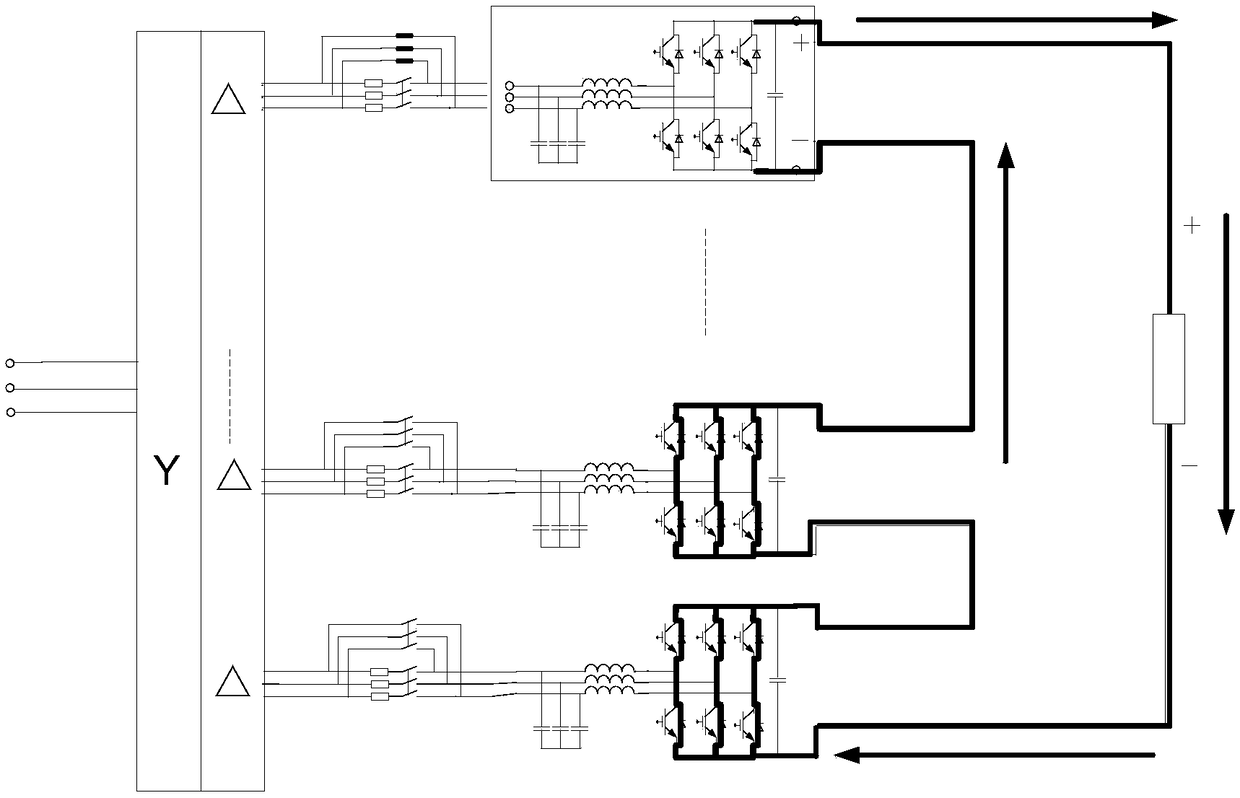

[0046] Such as figure 1 As shown, a voltage source converter with ice-melting function, the converter includes a multi-winding transformer and N converter modules, N≥2, the multi-winding transformer includes a primary winding and N secondary windings, the AC side of the converter module is connected to the secondary winding one by one, the DC side of the converter module is connected in series in sequence, the positive pole of the first converter module is used as the positive pole of the voltage source converter, The negative pole of the first converter module is connected to the positive pole of the second converter module, and so on, and the negative pole of the Nth converter module is used as the negative pole of the voltage source converter;

[0047] Wherein the converter module includes a first switch, a second switch, a resistor, a filter and an AC / DC converter, whe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap