Cross-row traveling wide-narrow row close planting hand-held rice transplanter

A technology of a rice transplanter and a wide and narrow row is applied in the field of rice transplanters with a wide and narrow row of dense planting, which can solve the problems of leakage of seedlings, poor sliding of blanket seedlings, and increase of complexity of the machine, so as to reduce the complexity, reduce the leakage of seedlings, and eliminate the Decrease adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

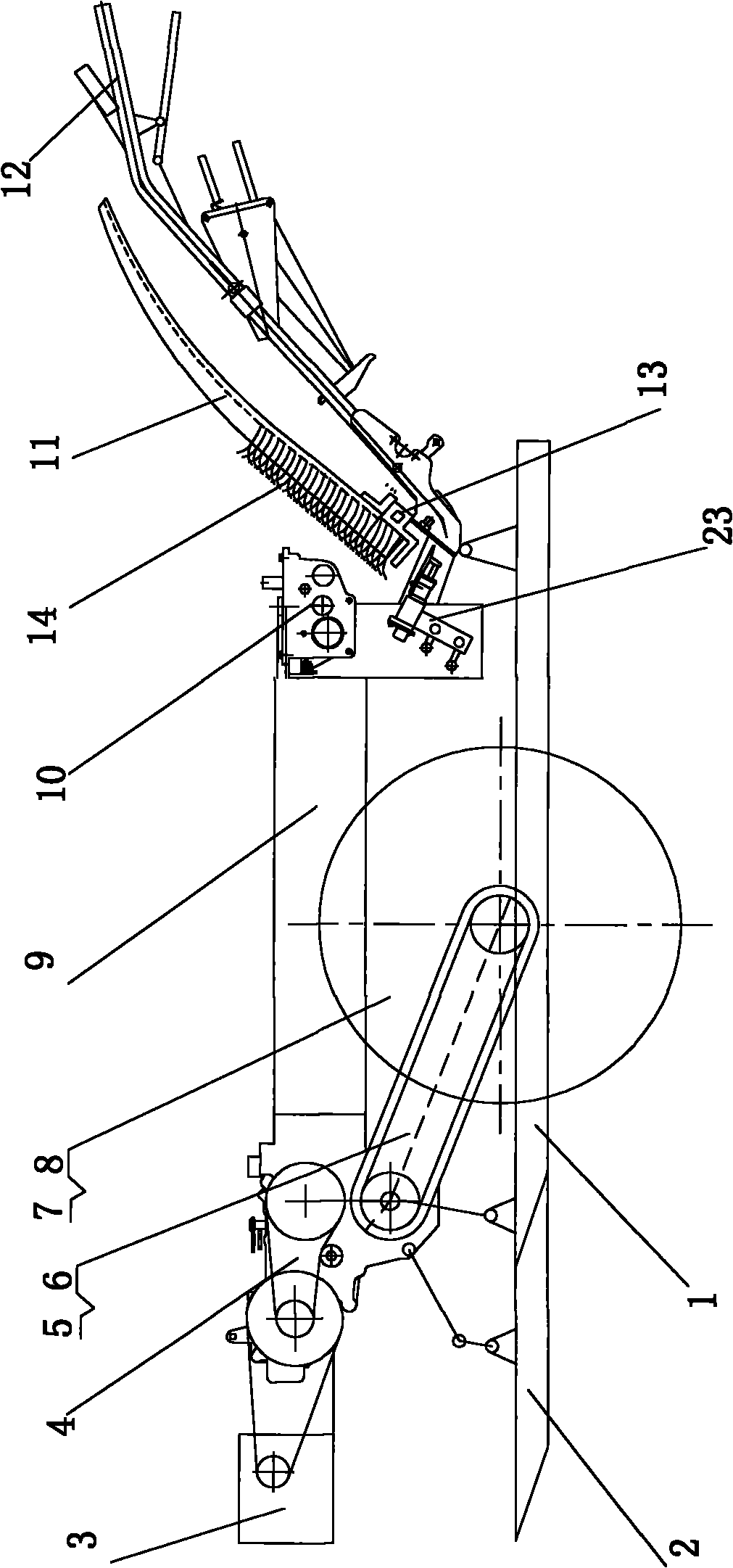

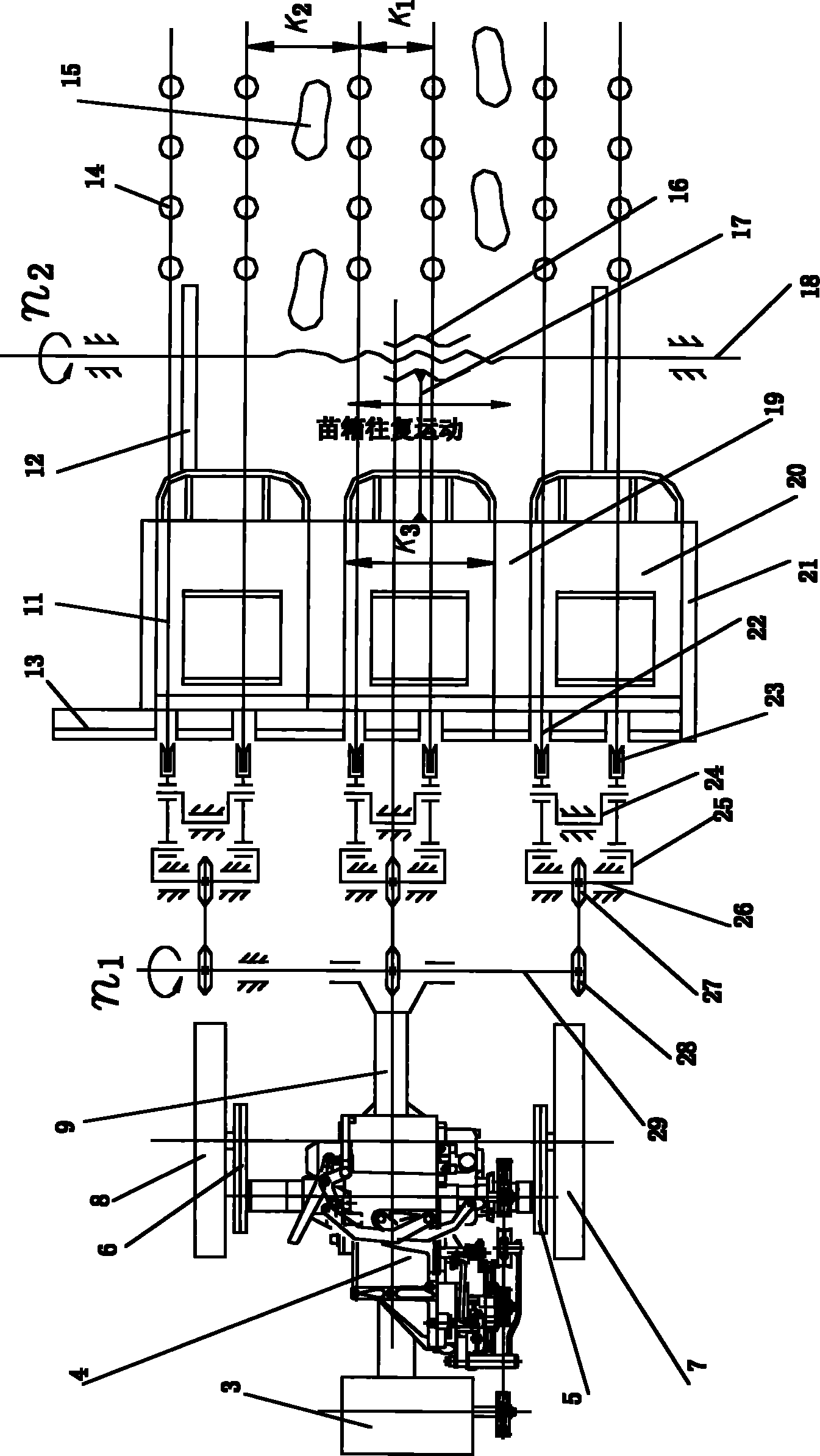

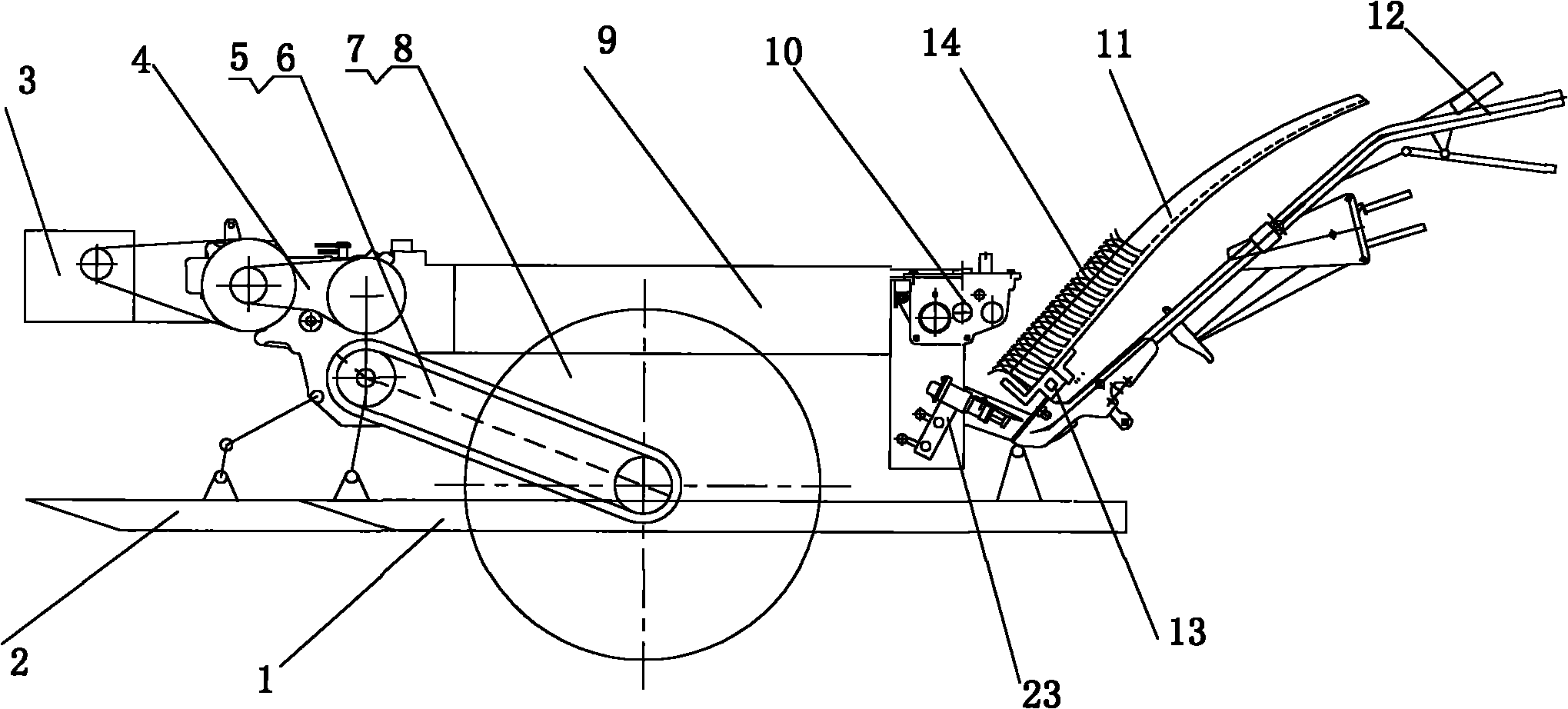

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose and effect of the present invention will become more obvious.

[0016] As shown in the figure, the wide and narrow row close-planting hand-held rice transplanter of the present invention includes a side floating plate 1, a middle floating plate 2, an engine 3, a gearbox 4, a left driving wheel sprocket box 5, and a right driving wheel sprocket box 6. Left driving wheel 7, right driving wheel 8, frame 9, box-moving mechanism transmission box 10, seedling box 11, handrail 12, slideway 13, double helix shaft nut 16, seedling box connecting rod 17, seedling box double helix Axle 18, spacer plate 19, Sheng seedling dish 20, side plate 21, seedling door 22, seedling claw 23, rocking bar 24, crank 25, seedling claw crankshaft 26, crankshaft sprocket wheel 27, intermediate shaft sprocket wheel 28, middle Axis 29.

[0017] The side floating board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com