Apparatus and method for concentrating a fluid

A liquid and distillation device technology, applied in chemical instruments and methods, membranes, total evaporation, etc., can solve problems such as low energy efficiency and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Hereinafter, the present invention will be illustrated with reference to the following examples. The descriptions of the various aspects of this embodiment are to be considered as illustrative and not restrictive.

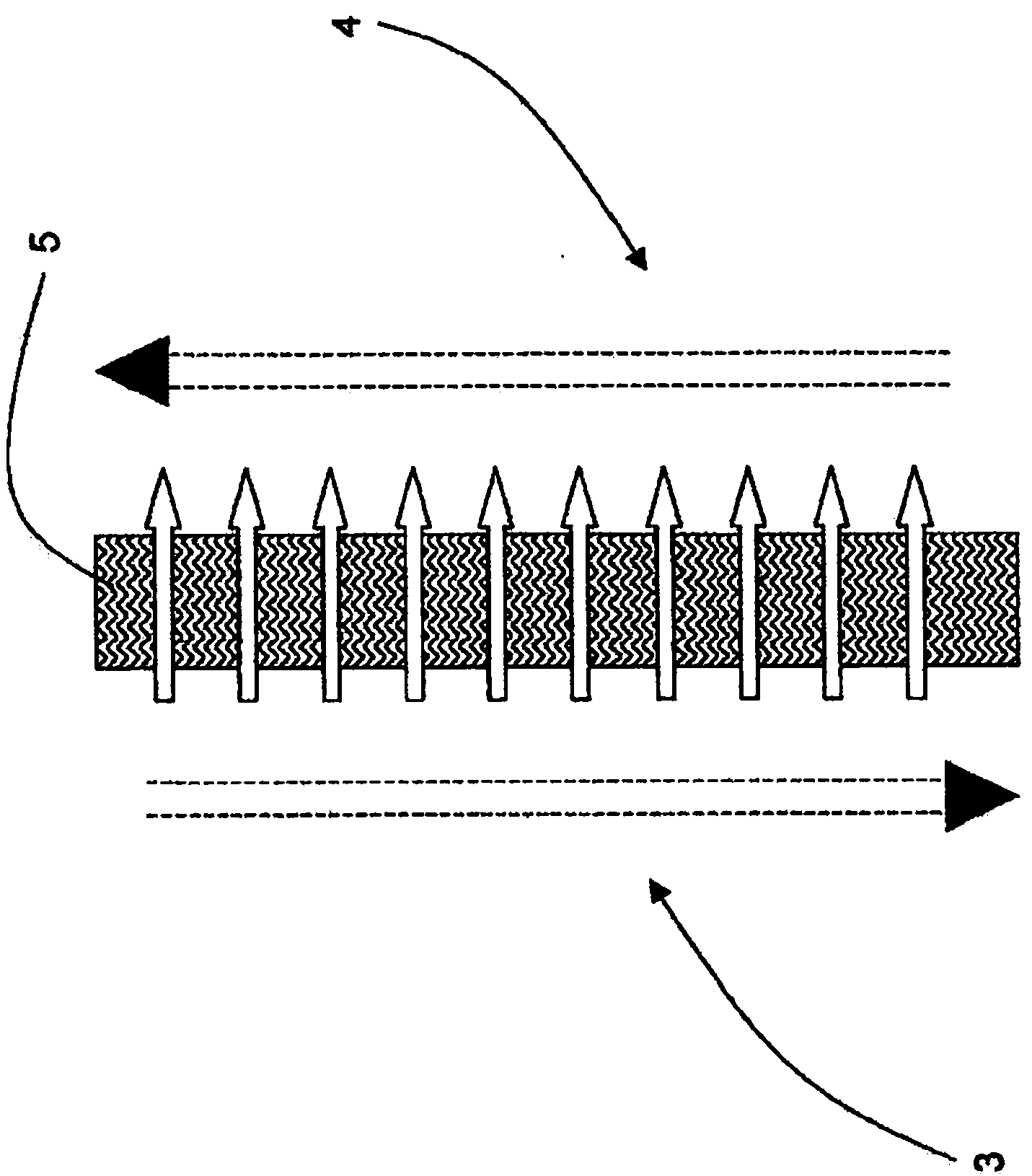

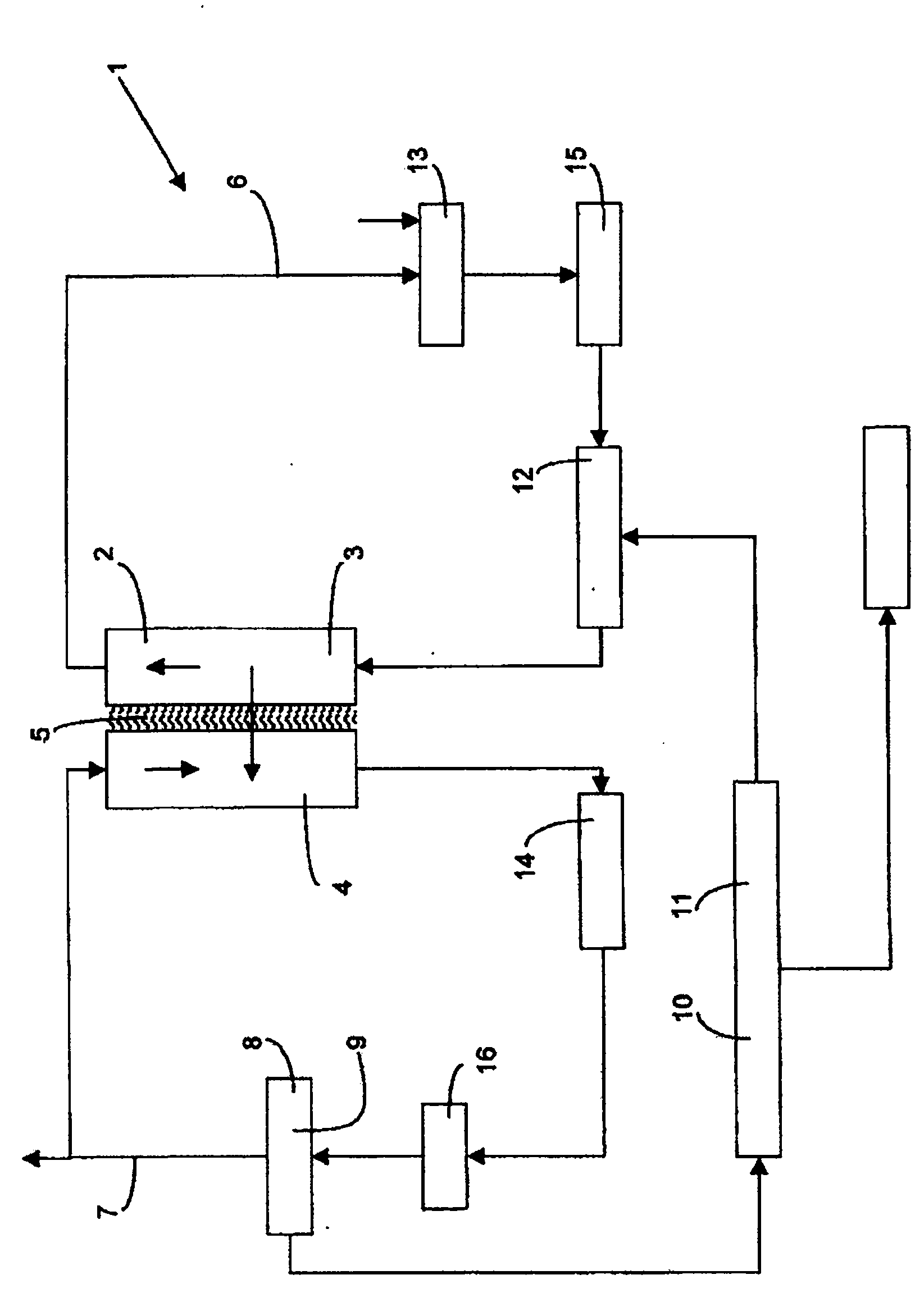

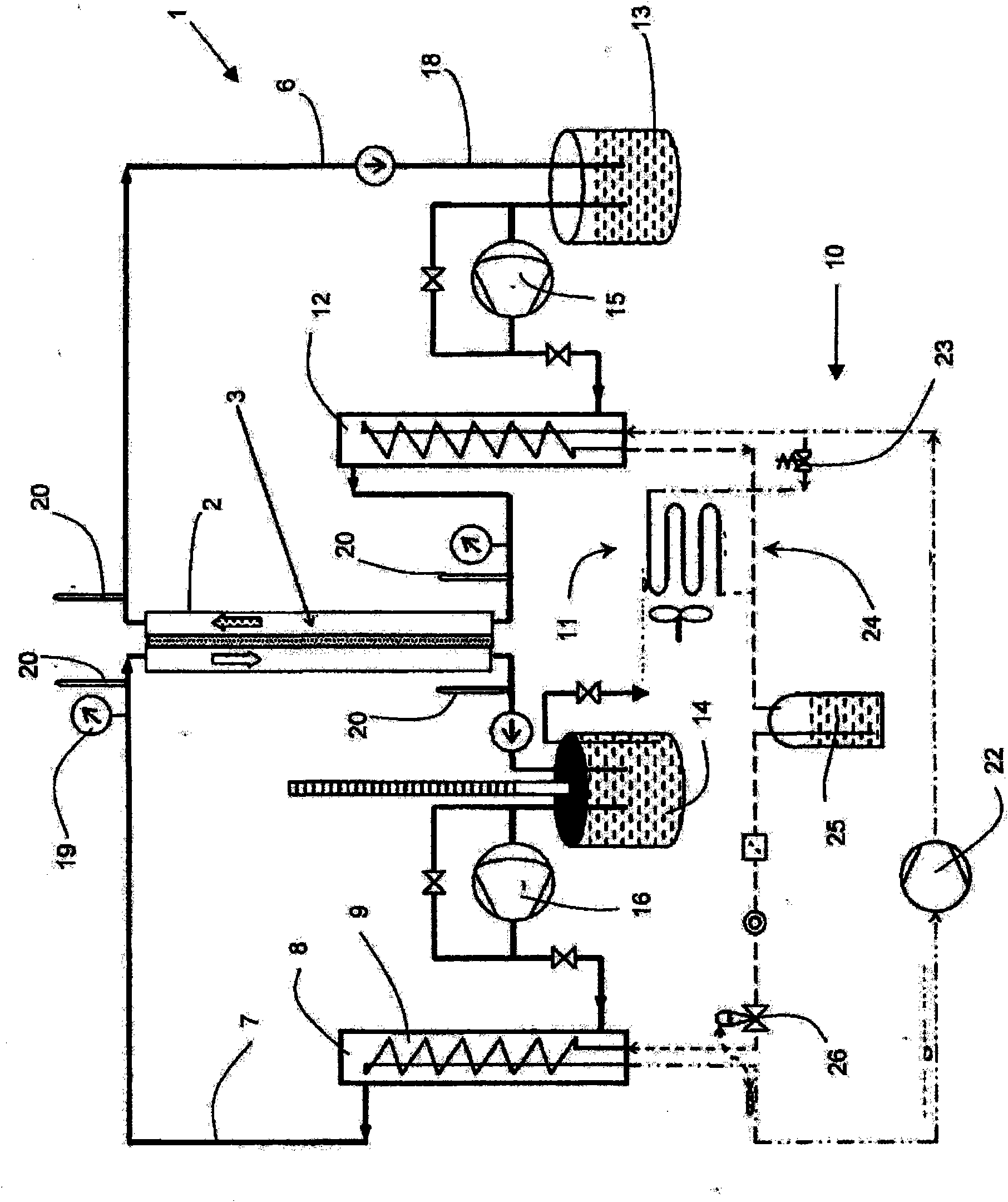

[0105] Glucose is concentrated according to the present invention using a small-scale MD process (see schematic diagrams in Figures 2 and 3), operating conditions are as follows:

[0106] ·Feed liquid inlet temperature T fi =40°C

[0107] · Permeate inlet temperature T pi =20°C

[0108] · Feed liquid velocity ω f =0.6m.s -1

[0109] · Permeate liquid velocity ω p =0.5m.s -1

[0110] The feed liquid is a glucose solution with a concentration of 30% (weight percent)

[0111] · Thin film module HL50 (Siemens Water Technologies, Australia)

[0112] (Note in Figure 4: T fo is the feed outlet temperature, T po is the permeate outlet temperature)

[0113] The glucose solution was concentrated from 30% to 60% by weight (4.2 kg glucose) in about 13 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com