Whole pulling and moving type whole-process unloading belt conveyor for coal mine underground filling

A technology for conveyors and coal mines, which is used in fillings, underground transportation, safety devices, etc., can solve the problems that the overall pulling cannot be unloaded in the whole process, and the structure cannot be realized, so as to reduce abnormal wear and tear, and the structure design is reasonable and reliable. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

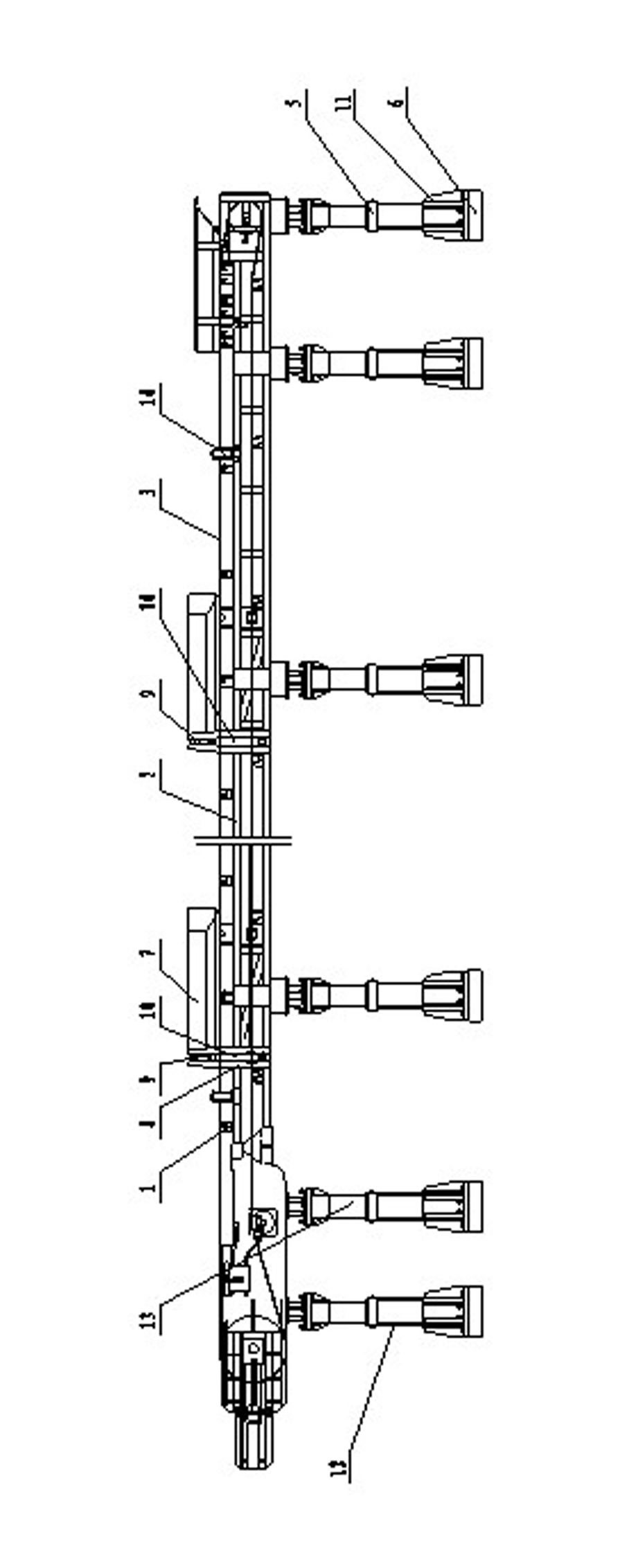

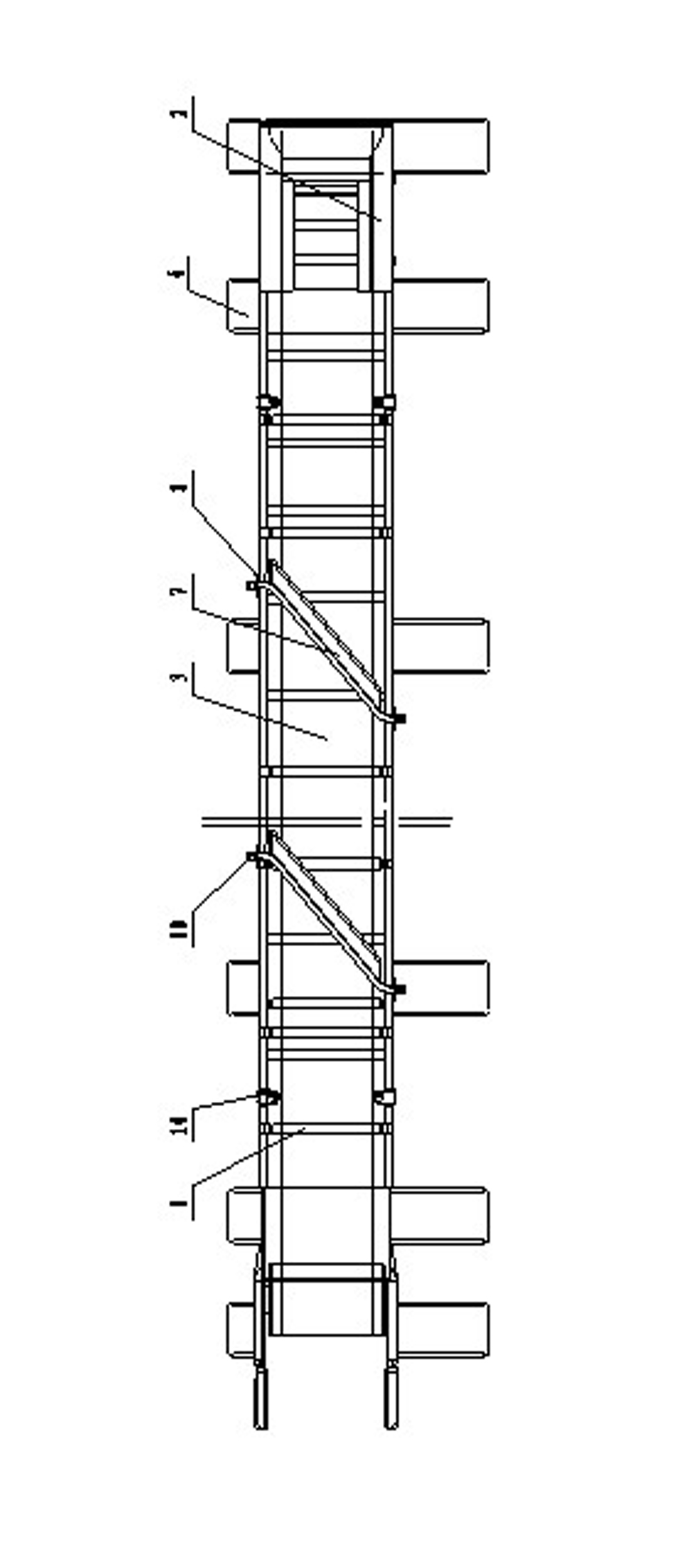

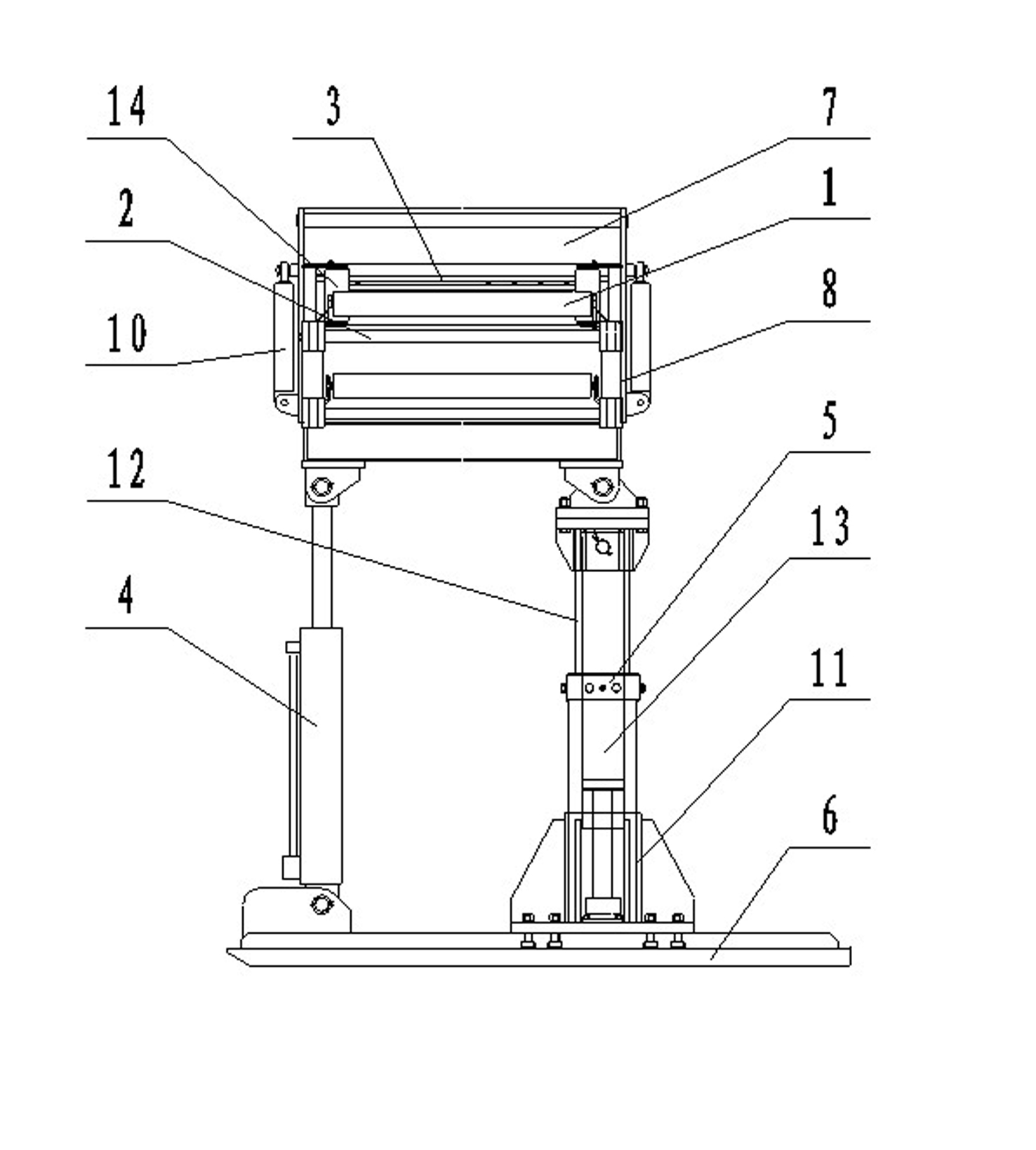

[0017] The integral pull-type whole-process unloading belt conveyor for coal mine underground filling includes a frame 2, and a number of idler rollers 1 supporting the conveyor belt 3 are arranged on the upper and lower sides of the frame 2, and idler rollers 1 on the upper side of the frame 2 The axes are on the same plane, the bottom of the frame 2 is provided with a sliding base 6, and a support is fixed between the frame 2 and the sliding base 6, and a number of vertically placed and parallel to the conveyor belt 3 are arranged above the conveyor belt 3. The angled unloading plate 7, the left and right ends of the frame 2 are fixed with a guide seat 8 corresponding to the position of the unloading plate 7, and a lifting cylinder 10 is fixed between the guide seat 8 and the lower end of the corresponding unloading plate 7 . The support is composed of several pairs of support cylinders 4 and support adjustment frames 5 placed in the left and right directions. The upper ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com