Running water valve with water-saving function

A tap water valve and functional technology, applied in the field of water supply and drainage, can solve the problems of effective control of water flow speed, waste of water resources, low sensitivity, etc., to avoid waste of water resources, avoid waste of water resources, and achieve remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

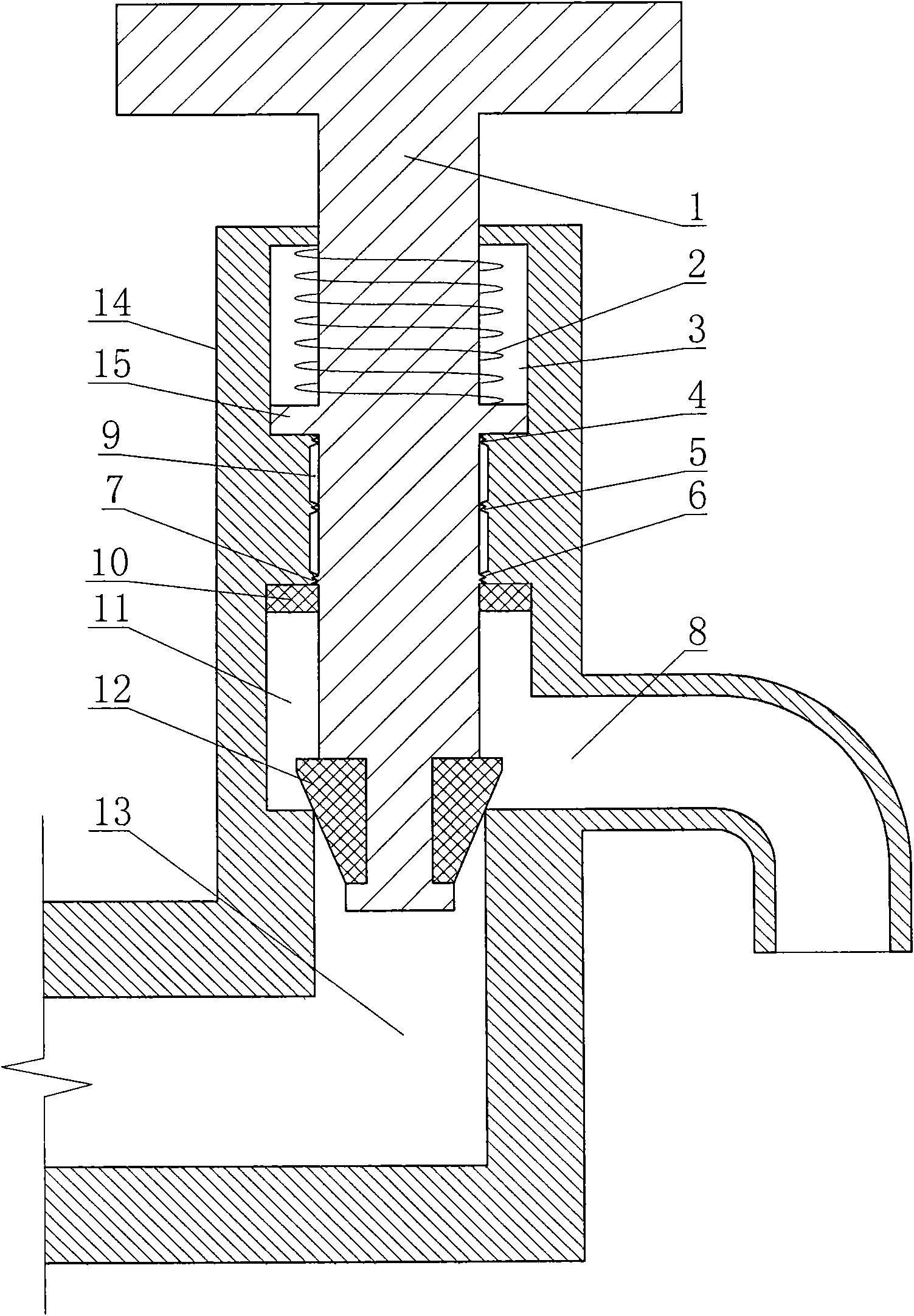

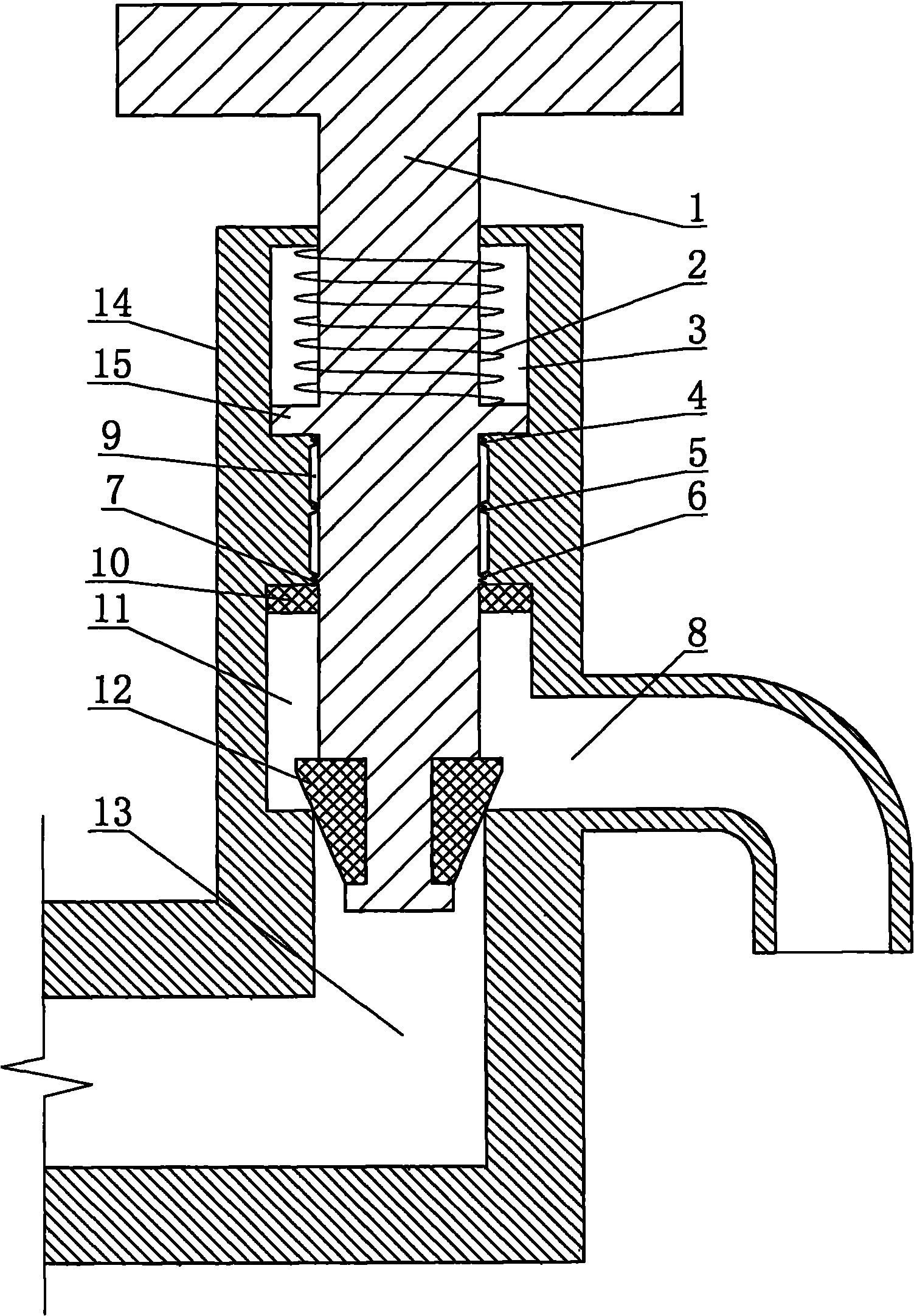

[0014] The tap water valve with water-saving function consists of torsion bar 1, spring 2, spring chamber 3, top thread 4, middle thread 5, bottom thread 6, torsion bar thread 7, outlet pipe 8, torsion bar through hole 9, sealing ring 10, A water chamber 11, a cone valve 12, a water supply pipe 13, a sleeve 14 and a snap ring 15 are formed.

[0015] The inside of the cylindrical sleeve 14 is connected to each other from top to bottom, a cylindrical spring chamber 3 coaxial with the sleeve 14, a torsion bar through hole 9 and a water passage chamber 11, wherein the spring chamber 3 It is equal to the diameter of the water chamber 11 and larger than the diameter of the torsion bar through hole 9 . The top of the spring cavity 3 has an axial through hole. On the side wall of the torsion bar through hole 9, there are top thread 4, middle thread 5 and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com