Method for measuring wrapped ash state after burning of cigarette

A cigarette and condition technology, which is applied in the field of measuring the condition of ash after burning of cigarettes, can solve problems such as quantitative evaluation, and achieve the effect of good experimental reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Determination of Ash Value of Cigarette Package in Smoldering State

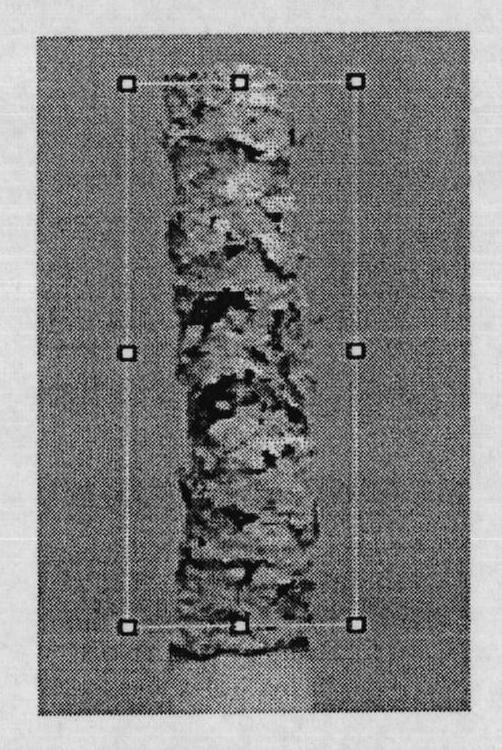

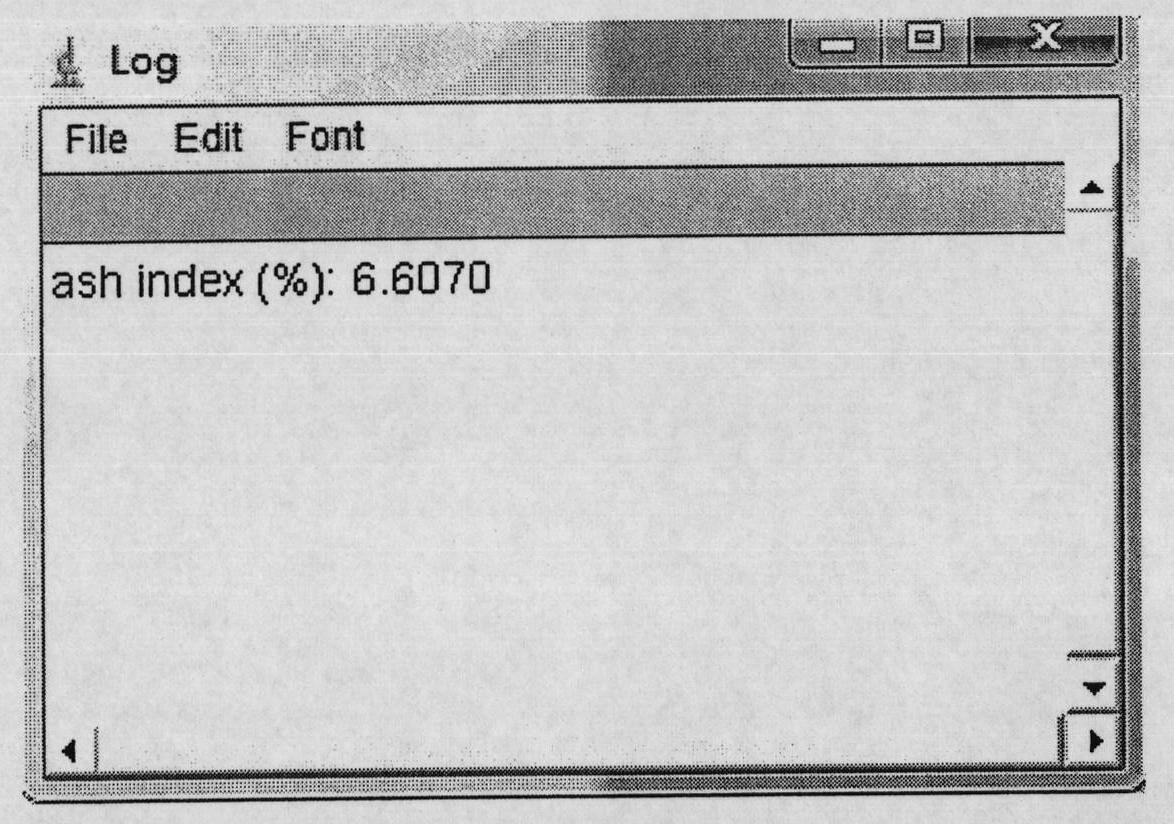

[0028] Place the cigarette to be tested in an upright position in a well-lit and shadowless lighting environment, and connect the filter of the cigarette to the burning seat of the smoking machine. Light the cigarette and turn on the smoking machine to make the cigarette burn completely under smoldering conditions. When the cigarette is smoldering to a distance of 3mm from the tipping paper, turn off the smoking machine, use a digital camera with more than 5 million pixels and a macro function, and focus on the middle of the ash package at a distance of 150mm from the ash package, and use the macro mode Capture digital images (see figure 1 ). Input the collected image into the computer, start the ImageJ software, open the digital image file, first click Image->Adjust->Threshold, set the threshold for analyzing the image, then select the analysis area of the analyzed image, click set, Click Analyz...

Embodiment 2

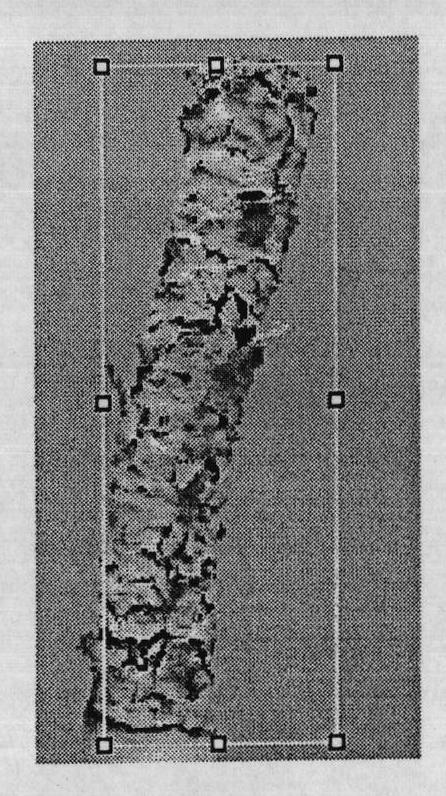

[0030] Repeat the operation of embodiment 1, measure the cigarette of another brand, the results are shown in image 3 , Figure 4 . Depend on Figure 4 It can be seen that, in the ash content of the cigarette, the content of the part with poor ash coating condition accounts for 14.4618%.

Embodiment 3

[0032] Determination of Ash Value of Cigarette Packs Satisfied with ISO / FTC Smoking Conditions

[0033] Repeat Example 1, with the following differences: choose another brand of cigarettes to measure, start the smoking machine, and smoke once at intervals of 60s according to the 35ml suction capacity of the simulated human normal smoking state (ISO / FTC). The smoking duration is 2s, and the cigarette smoking process is completed. The collected digital images and final measurement data are shown in Figure 5 , 6 . It can be seen from the figure that the content of the part with poor ash inclusion in the ash accounts for 11.0316%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com