Bearing feeder

A feeder and bearing technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as safety risks and low efficiency, and achieve the effect of reducing bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

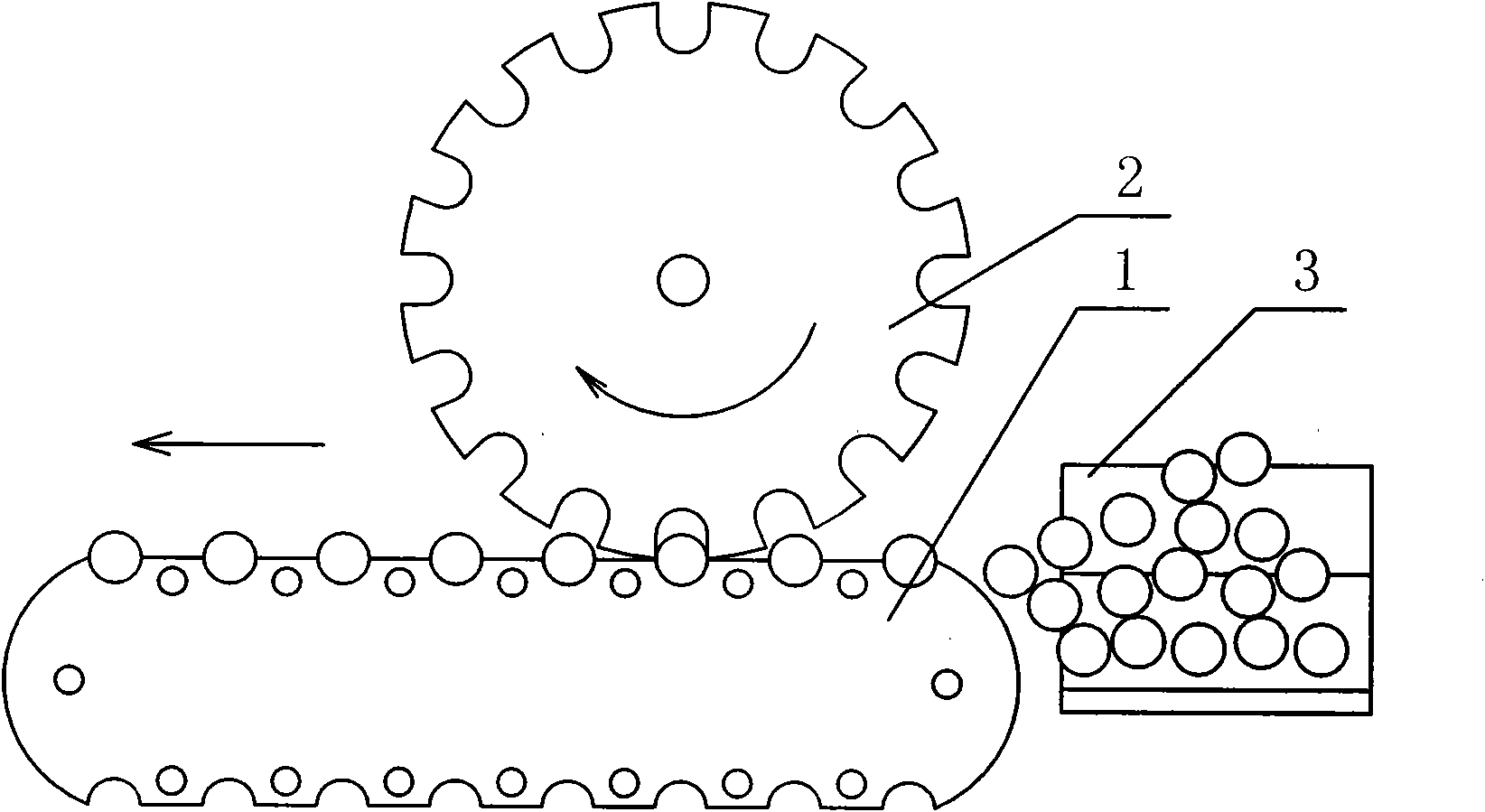

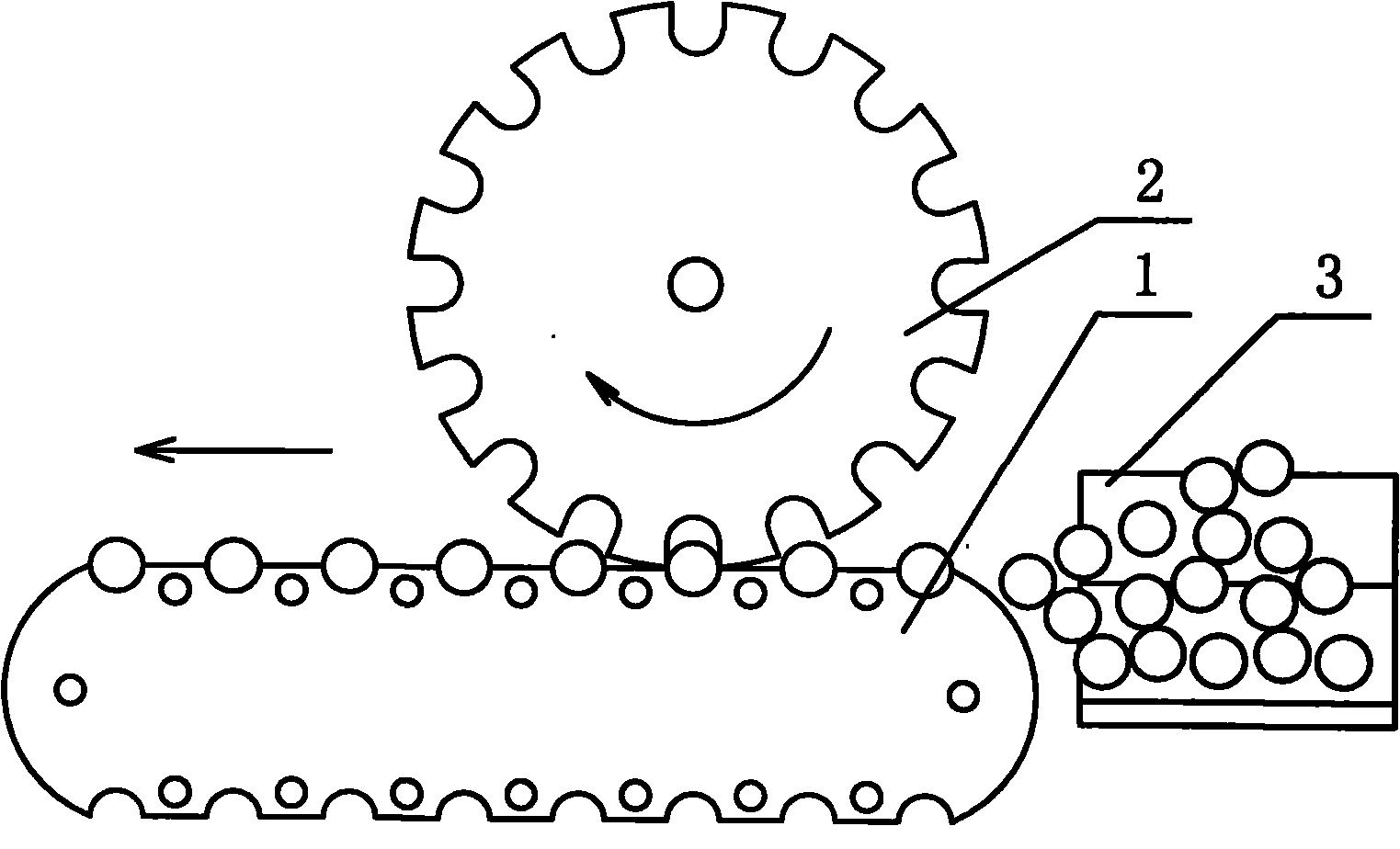

[0013] Such as Figure 1-2 As shown, a bearing feeding machine includes a conveyor belt 1, a feeding box 2 and a matching grooved gear 3. The conveyor belt 1 is an endless belt with a semicircular notch the same as the radius of the bearing, and the feeding end of the conveyor belt 1 is provided with The upper surface of the conveyor belt 1 is provided with a matching grooved gear 3, the notch of the grooved gear 2 is the same as the radius of the bearing, and the grooved gear 2 and the conveyor belt 1 cooperate to advance through the semicircular gap and groove Mouth fit, the bearings are forwarded regularly one by one.

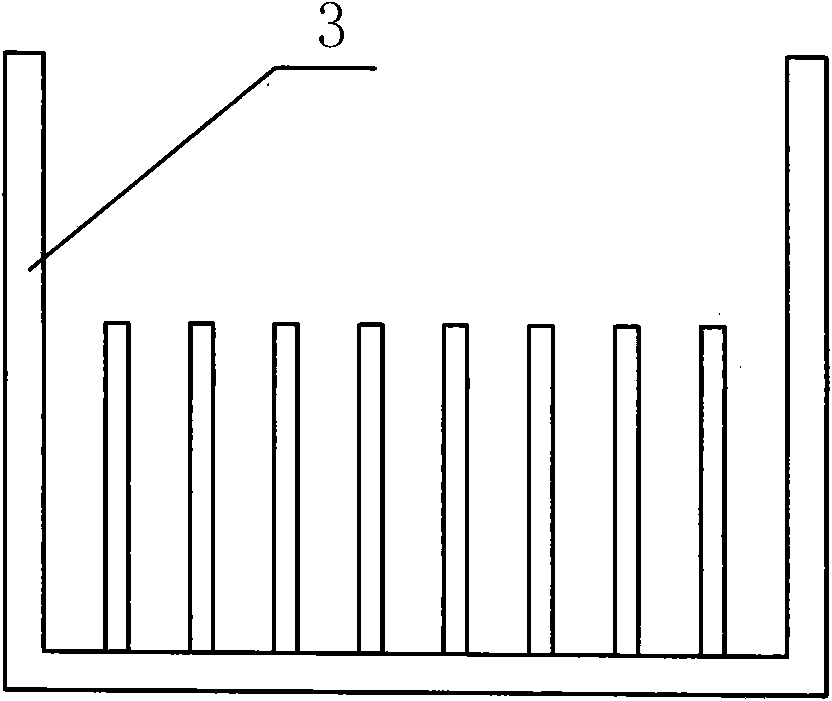

[0014] A further design is that several longitudinal compartments are provided in the feeding box 2, and the width of the compartments is the same as that of the bearings, so that the bearings can vertically fall into the compartments.

[0015] In order to further make the function of the upper material box 2 better, the upper material box can be placed obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com