Production line turntable locating pin

A positioning pin and production line technology, applied in the direction of bolts, etc., can solve the problems of insufficient lightness, fastness, and difficult control of the conveying method, and achieve the effect of high bending strength and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the drawings.

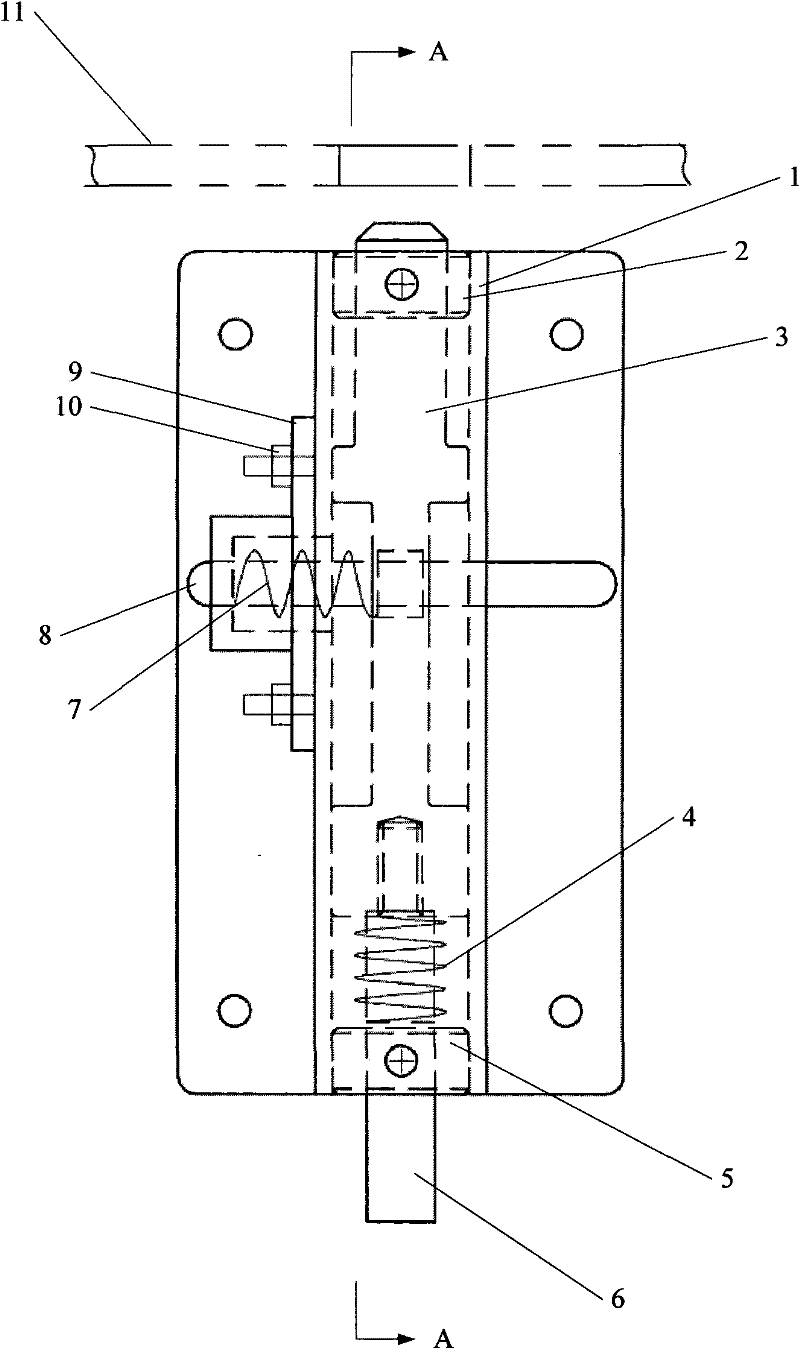

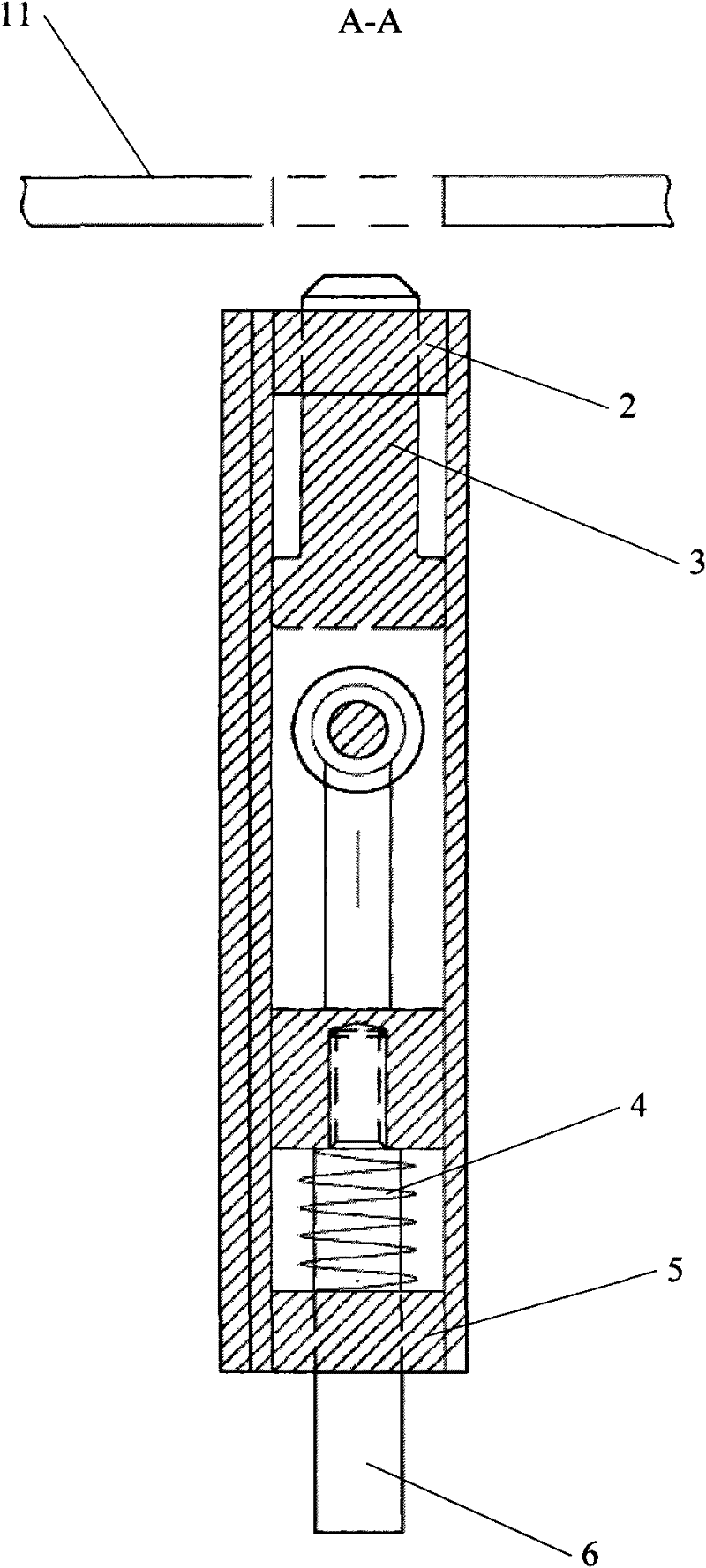

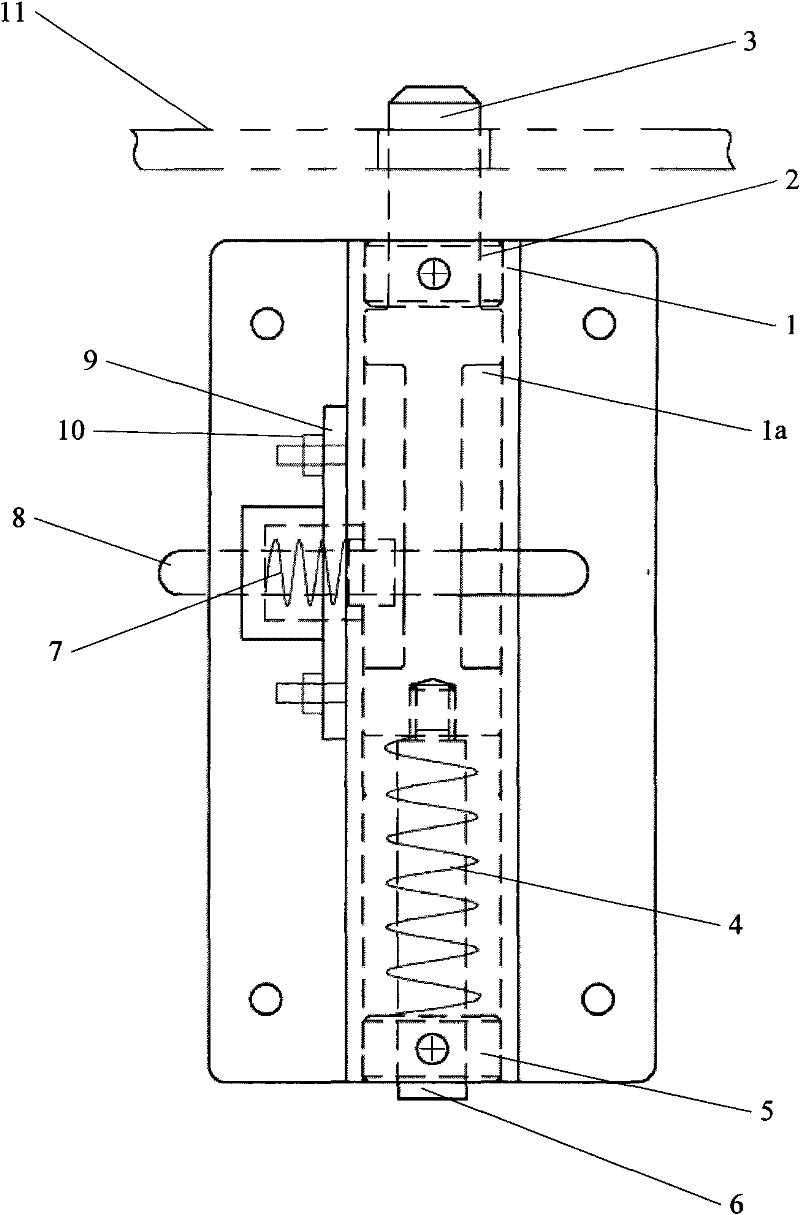

[0019] Such as figure 1 and figure 2 As shown, a production line turntable positioning pin includes a pin frame 1, the pin frame 1 is square tubular, and a through hole 1a is arranged radially in the middle; a pin button positioning rod 8 passes through the through hole 1a, and the pin The middle part of the button positioning rod 8 is a positioning block, and one end of the pin button positioning rod 8 is sleeved with a pin button spring 7, and the other end is controlled by a stopper (not shown); a pin rod 3 is arranged on the pin frame 1 In the square tube, the bottom of the pin rod 3 is provided with a push pin 6, and the push pin 6 is covered with a push spring 4. Move back and forth, so that the front end of the pin rod 3 extends out of the pin frame 1 and inserts a fixed element 11 or retracts into the pin frame 1; the front and rear ends of the pin frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com