Moving apparatus of sand box

A technology of mobile devices and sand boxes, which can be used in casting molding equipment, metal processing equipment, manufacturing tools, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

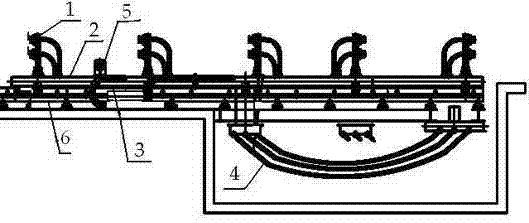

[0009] see figure 1 As shown, the present invention includes a vacuum beam body 2, a vacuum system 4 and a positioning device 5. The vacuum system 4 includes a vacuum valve 1 and a vacuum control device. The vacuum valve 1 is arranged on the vacuum beam body 2, and the vacuum beam body 2 is provided with a positioning device 5 and a guide wheel set, and a track 6 is laid under the vacuum beam body 2. The vacuum beam body 2 is connected to the track 6 through the guide wheel set, and between the vacuum beam body 2 and the track 6 A hydraulic cylinder 3 is provided. The working principle is:

[0010] Before the sand box needs to move forward on the line, the vacuum valve 1 opens the switch adsorbed on the sand box to start vacuuming, and the positioning device 5 is opened to position with the pallet truck at the base of the sand box. When the sand box needs to move forward, Driven by the hydraulic cylinder 3, the vacuum beam body 2 drives the guide wheel group to move forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com