Time-sharing switching three-position four-way valve

A three-position four-way valve, reversing wheel technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of hydraulic balance imbalance in heating system, and achieve the effect of solving hydraulic imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

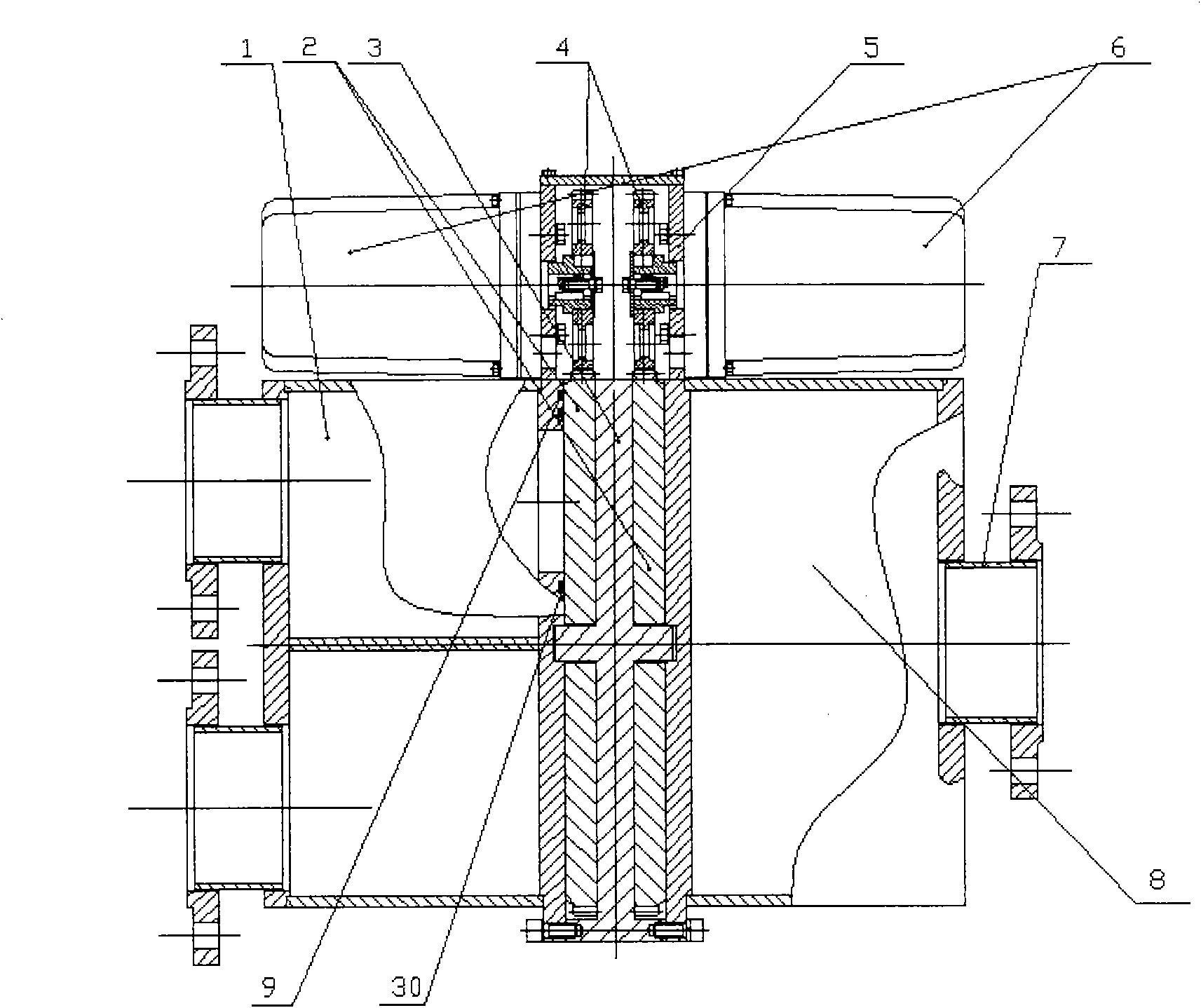

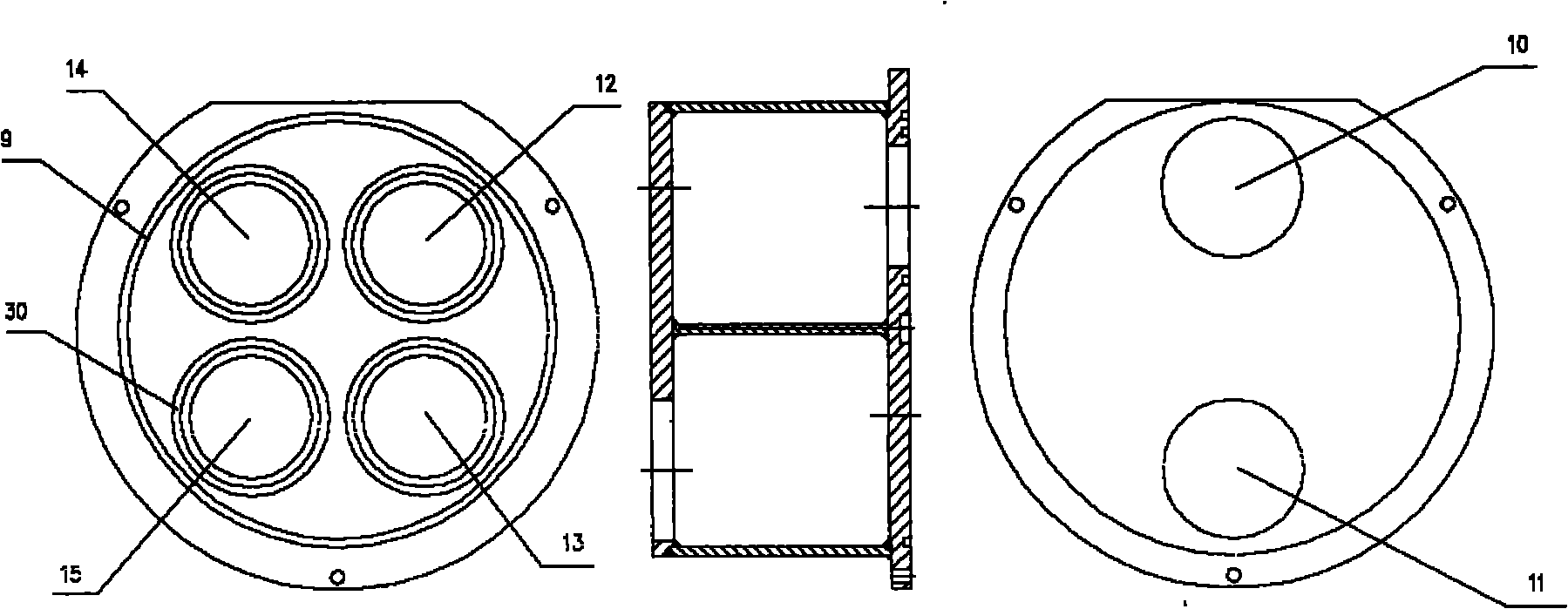

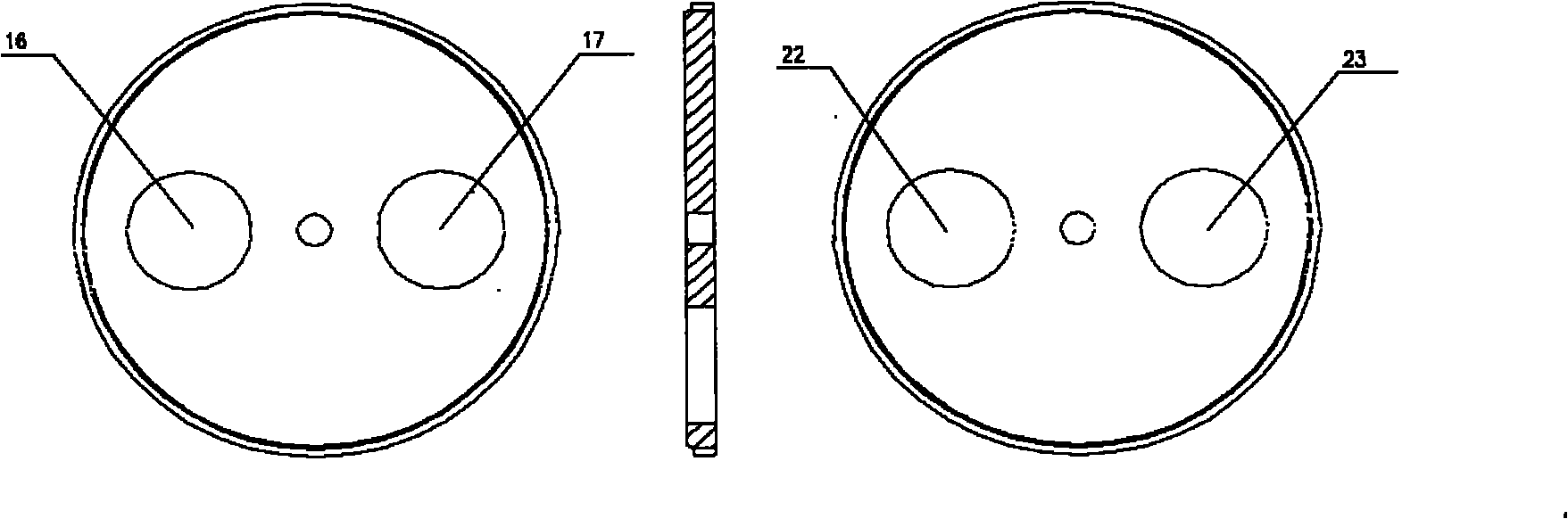

[0008] The implementation of the present invention is as follows, as explained below in conjunction with the accompanying drawings, the time-sharing switching three-position four-way valve of the present invention is mainly composed of a water inlet tank 1, a reversing wheel 2, a fixed wheel 3, a driving wheel 4, a casing 5, a driver 6, The water inlet and outlet 7, the water outlet 8, the sealing ring 9, and the sealing ring 30 are composed of the water inlet 1 and the water outlet 8. The structure is the same, but there is a 90° corner difference during installation. The box body 5 prevents debris from entering the valve body Inside, sealing ring 9 and sealing ring 30 prevent system water from flowing out of the valve body during the reversing conversion process. Its working principle is that at the beginning, the plate holes 12, 17, 18, 23, 26 in the device are concentric, and the plate holes 25, 22, 21, 16, 15 are concentric, and the hot water of the system enters the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com