Expansive type thermostatic hot water system

A hot water system and expansion type technology, which is applied in the field of constant temperature hot water supply system of gas boilers, can solve the problems of high maintenance cost of intelligent gas boilers, inability to control the outlet water temperature well, and the influence of normal heat consumption of heat consumption units. Achieve the effect of less failure, lower equipment maintenance costs, and shorter downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

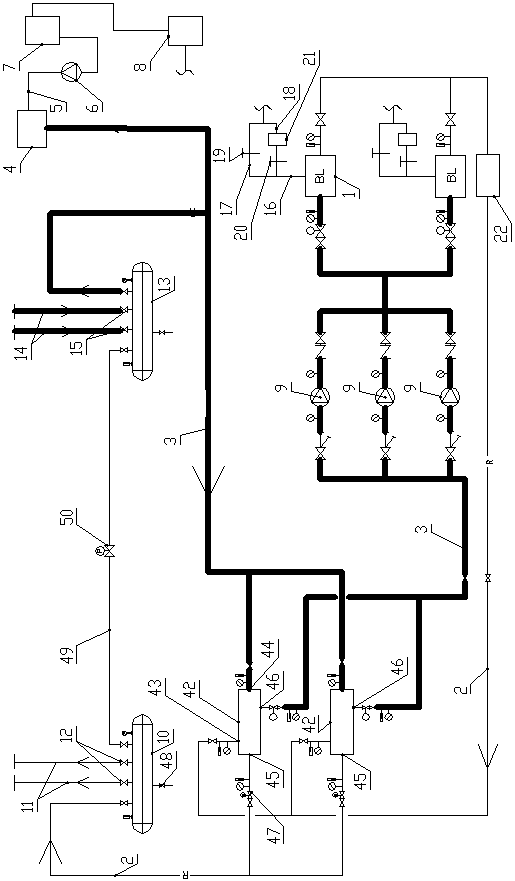

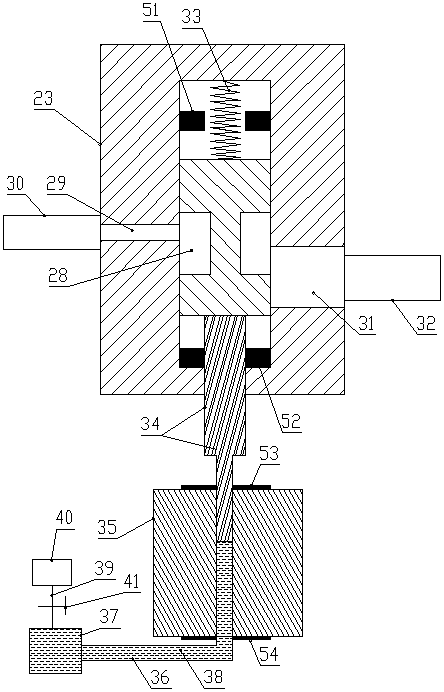

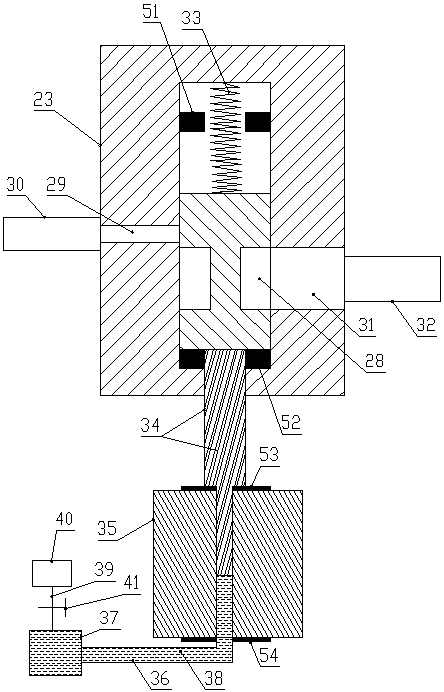

[0031] like Figure 1 to Figure 4 As shown, the present invention discloses an expansion type constant temperature hot water system, comprising a gas boiler 1, a water supply main pipe 2 and a return water main pipe 3, the water inlet of the gas boiler 1 is connected with the return water main pipe 3, and the water outlet of the gas boiler 1 It is connected with the main water supply pipe 2; the water return main pipe 3 is connected with an expansion water tank 4, and the expansion water tank 4 is connected with a water supply pipe 5, and the water supply pipe 5 is connected with a water supply pump 6, and the water supply pump 6 is connected with a water supply tank 7, and the water supply tank 7 is connected with There is a water softener 8, and the water softener 8 is connected to the municipal tap water pipe network; the return water main pipe 3 at the inlet of the gas boiler 1 is provided with a circulating pump 9;

[0032] The end of the main water supply pipe 2 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com