Touch pad of capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., can solve problems such as large resistance difference, reduce resistance difference, improve touch accuracy and touch control performance, the effect of reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0033] The first embodiment of the manufacturing method of the capacitive touch screen touch panel provided by the present invention comprises the following steps:

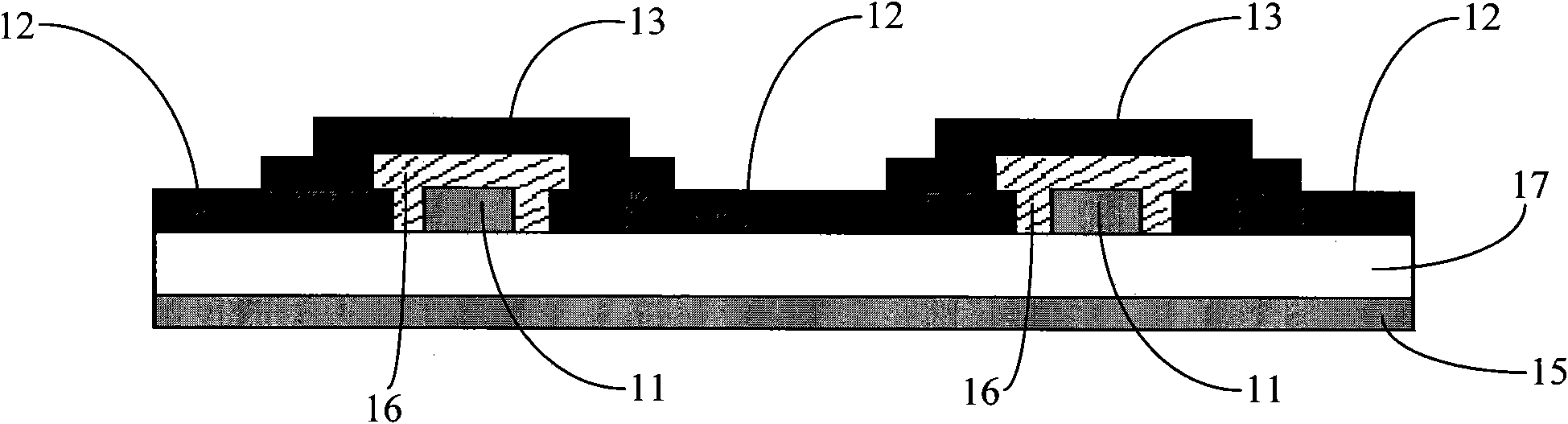

[0034] Step 41, coating one side of the substrate 37 with a transparent conductive film;

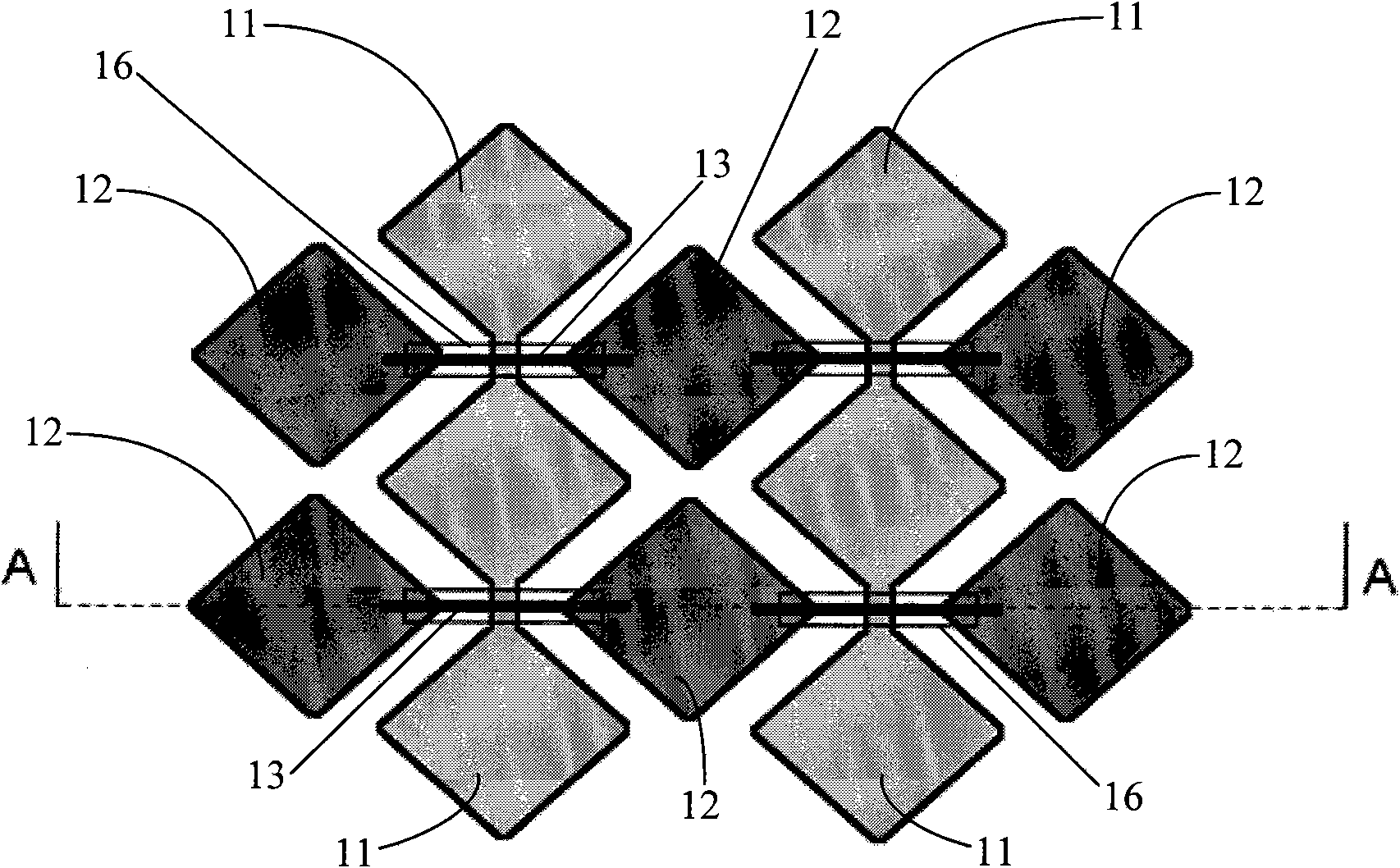

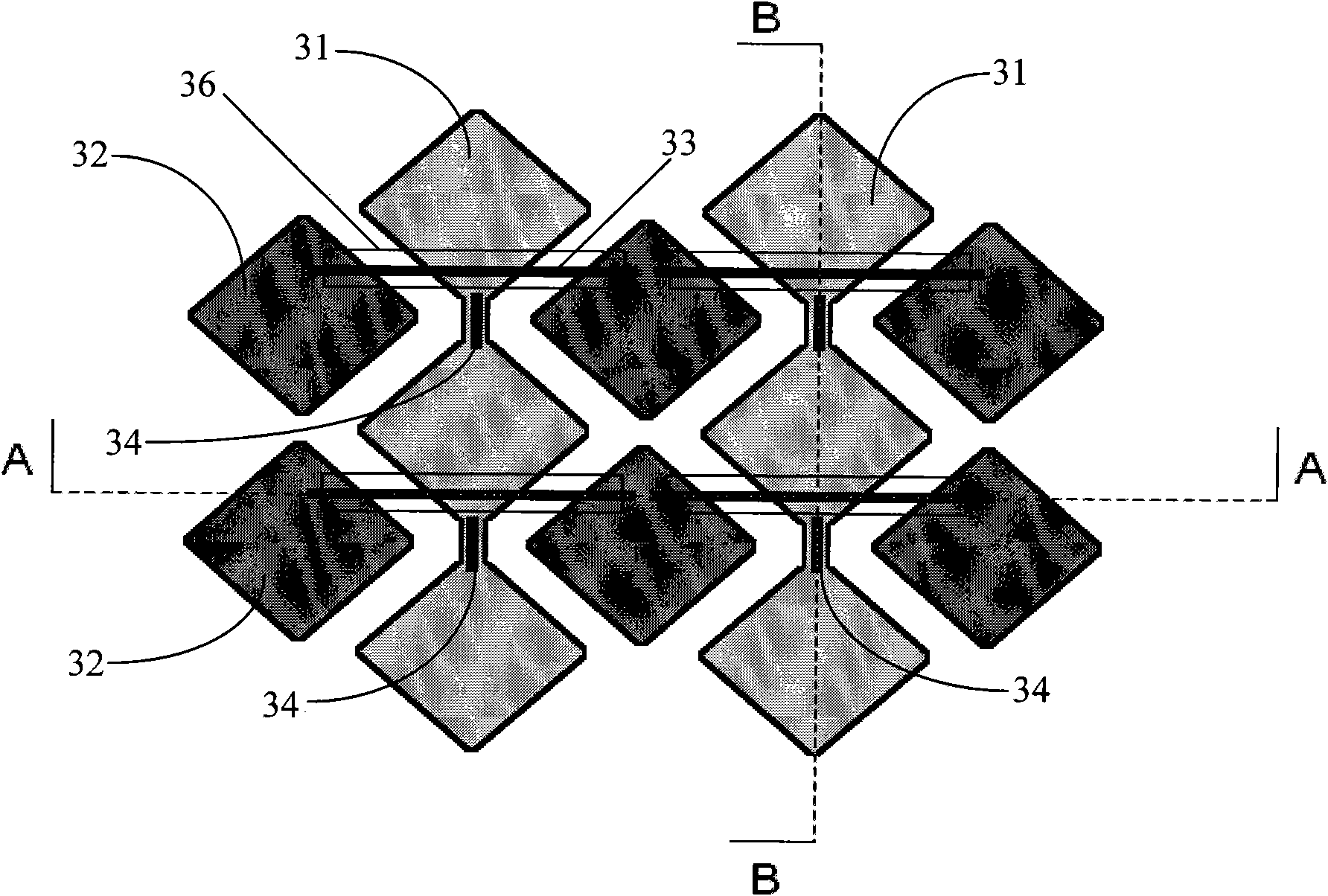

[0035] Step 42, photoetching the first layer of transparent conductive film, etching out the first group of conductive film lines 31 and the second group of conductive film lines 32, wherein the first group of conductive film lines 31 are continuous transparent conductive film lines, and the second group of conductive film lines The conductive film lines 32 are divided into sections by the first group of conductive film lines 31;

[0036] Step 43, coating a layer of insulating film on the first layer of transparent conductive film;

[0037] Step 44, photoetching out the insulating film line 36;

[0038] Step 45, plate a low-resistance conductive film on the first layer of transparent conductive film and the insulating film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com