Led module with optical diffusion layer formed

A technology of light-emitting diodes and light-diffusing layers, applied to semiconductor devices, light sources, electric light sources, etc. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

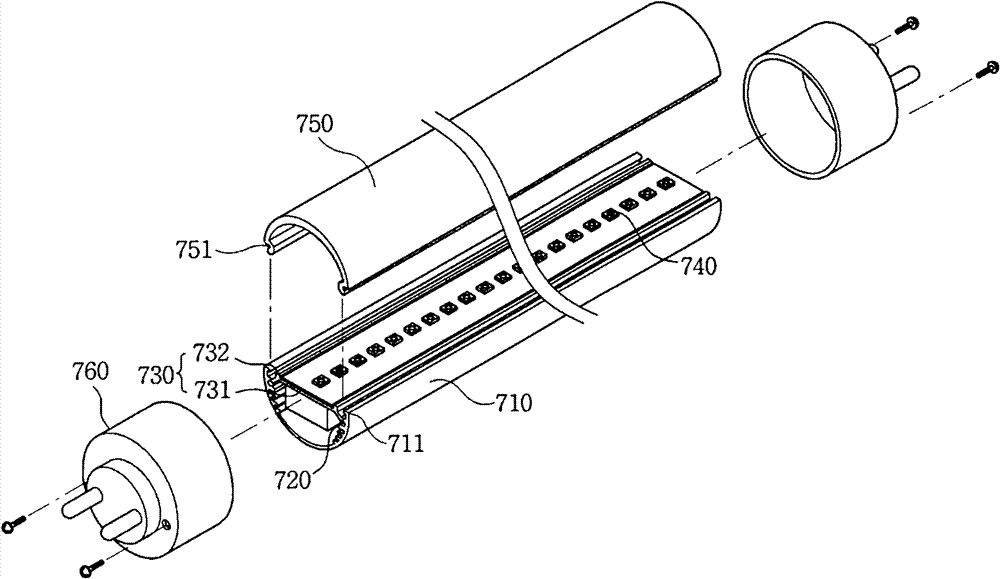

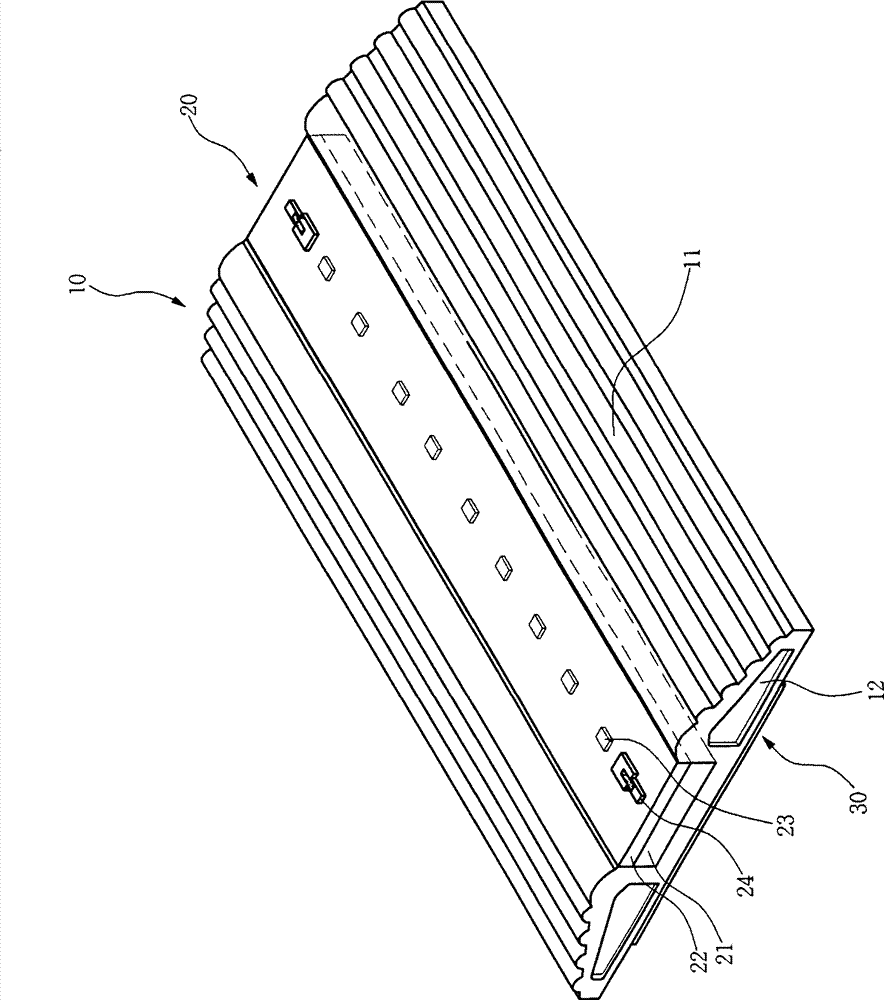

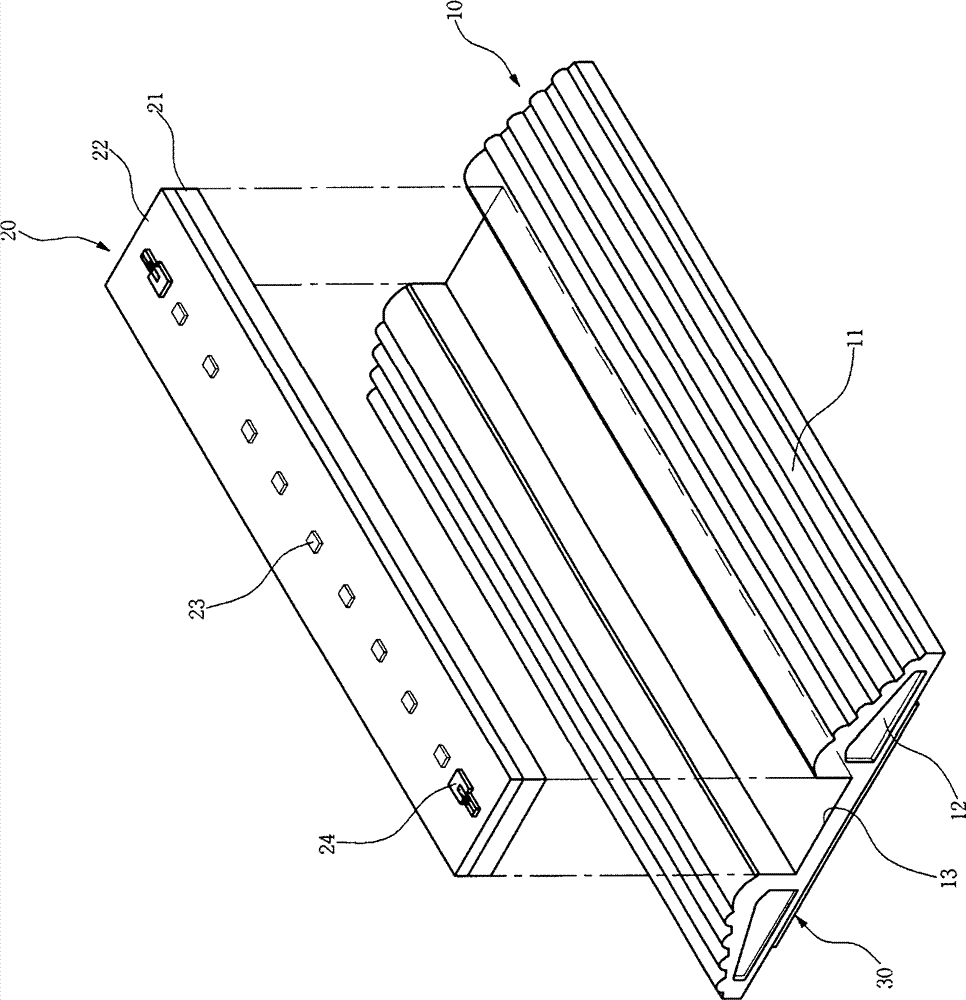

[0024] figure 2 It is a perspective view of an LED module formed with a light diffusion layer according to the present invention, image 3 It is an exploded view of an LED module formed with a light diffusion layer according to the present invention, Figure 4 It is a top view of an LED module formed with a light diffusion layer according to the present invention, Figure 5 It is a side view of an LED module formed with a light diffusion layer according to the present invention, Figure 6 yes Figure 5 The enlarged schematic diagram of part A in Figure 7 is a schematic diagram of the heat conduction direction of the heat dissipation diffusion plate involved in the present invention, Figure 8 It is the first embodiment of the LED module formed with the light diffusion layer according to the present invention, Figure 9 It is the 2nd Example of the LED module in which the light-diffusion layer was formed concerning this invention.

[0025] Hereinafter, the constituent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com