Cotton fabric with yarn of binding structure and preparation method thereof

A cotton fabric and yarn technology, applied in the direction of fabric, yarn, textile, etc., can solve the problems of limited performance and low yarn strength, and achieve the effects of low production cost, soft hand feeling and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

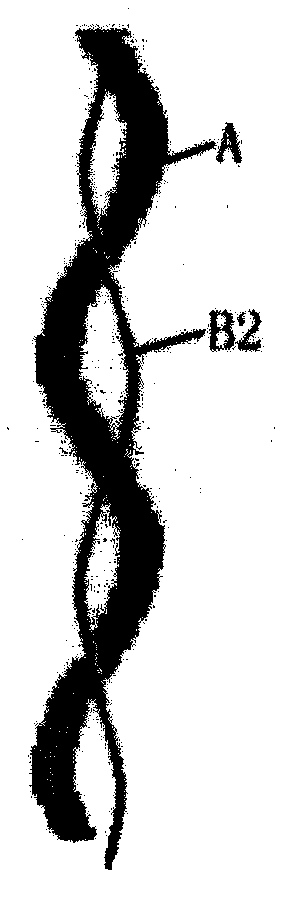

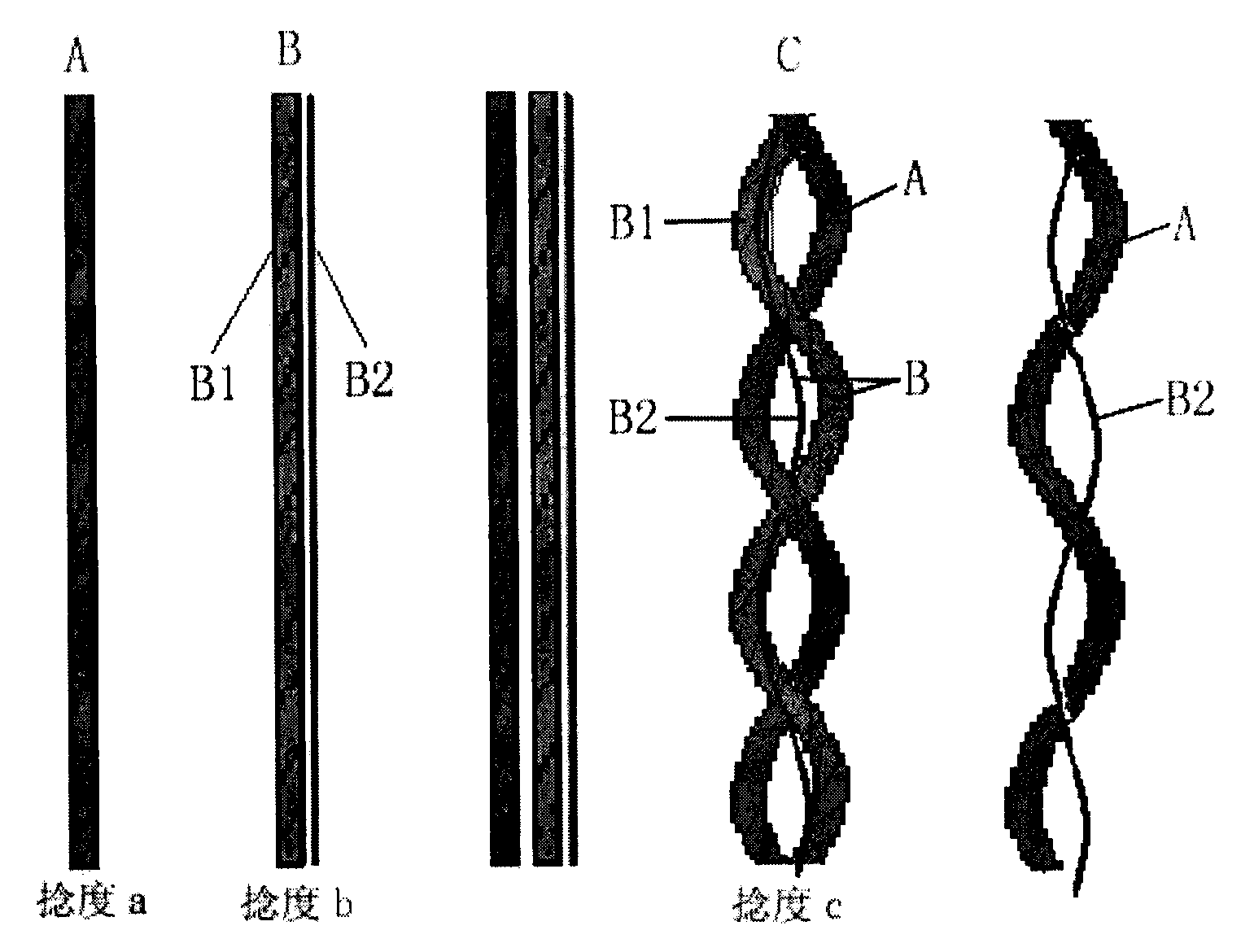

[0034] figure 2 It is a schematic diagram of the preparation method of the cotton fabric of the present invention. As shown in the figure, firstly, the initial twist twist a is applied to the cotton yarn A, and the twist direction can be Z direction or S direction; B can be untwisted, or the twist b of the primary twist is applied, and the twist direction is the same as that of the cotton yarn A; The double-twisted twist applied by the twist is c, thus obtaining the double-twisted cotton yarn C; then using the double-twisted cotton yarn C to make a gray cloth through a weaving process; dyeing and finishing the gray cloth obtained, and in the dyeing and finishing process Set up the fiber removal process; after the water-soluble vinylon B1 in the sliver B is dissolved by the fiber removal process, the fine-denier chemical fiber filament B2 is bundled on the cotton yarn A with a twist c, thereby obtaining a cotton fabric with a bundled structure yarn.

[0035] It should be not...

Embodiment 1

[0037] Example 1: Preparation of untwisted cotton fabric from top roller cotton yarn

[0038] Cotton yarn A is 36s yarn spun by 3-stage top roller cotton with a length of 27mm, 650 twists / m, and the twist direction is Z direction; sliver B is 80s water-soluble vinylon pure spinning (water-soluble temperature is 80°C) (B1) A juxtaposition with a piece of 35D / 24f polyester FDY (B2), untwisted (b=0). Cotton yarn A and sliver B are combined by a doubling machine and wound on an endless metal bobbin, and then 650 twists / m are applied by a two-for-one twister, and the twist direction is S twist. The yarn C thus obtained adopts the general warping, weft winding, and air-jet loom weaving process. After the gray cloth is obtained, it is washed at 90°C for 30 minutes in an overflow dyeing machine with a bath ratio of 1:25. Then clean it, and then enter the conventional dyeing and finishing process, and give sufficient overfeeding and weft shrinkage in the shaping process, and finally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com