Load cabinet system

A technology of load cabinets and containers, applied in the field of shipbuilding, to achieve the effect of ensuring safety and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. All the embodiments are operated according to the above-mentioned method, and each embodiment only records key technical data.

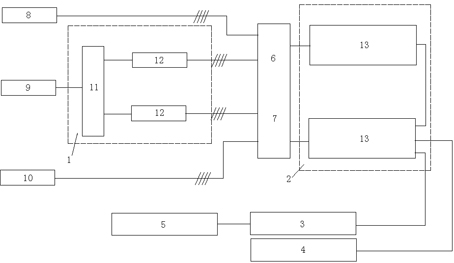

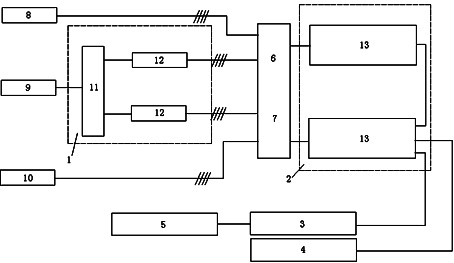

[0023] Such as figure 1 Shown is the structural diagram of the load cabinet system. The system as a whole is composed of a box-type substation container 1 and an integrated resistance-sensing load container 2. connection, the circuit breaker is divided into a first circuit breaker 6 and a second circuit breaker 7, and both the first circuit breaker 6 and the second circuit breaker 7 are high-voltage vacuum circuit breakers.

[0024] The container 1 of the box-type substation is a whole, and the interior is composed of a high-voltage switchgear 11 and two high-voltage transformers 12. The high-voltage swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com