Cleaning composition for removing resist

A cleaning agent and photoresist technology, applied in the field of cleaning agents, can solve the problems of strong corrosion of wafer substrates and insufficient cleaning ability

Inactive Publication Date: 2013-02-13

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The technical problem to be solved by the present invention is to provide a cleaning agent with strong cleaning ability, which can effectively remove thick films, in order to overcome the problem of insufficient cleaning ability of photoresist cleaning agents in the prior art, or strong corrosion to wafer substrates. Photoresists, photoresist cleaners that are less corrosive to wafer substrates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

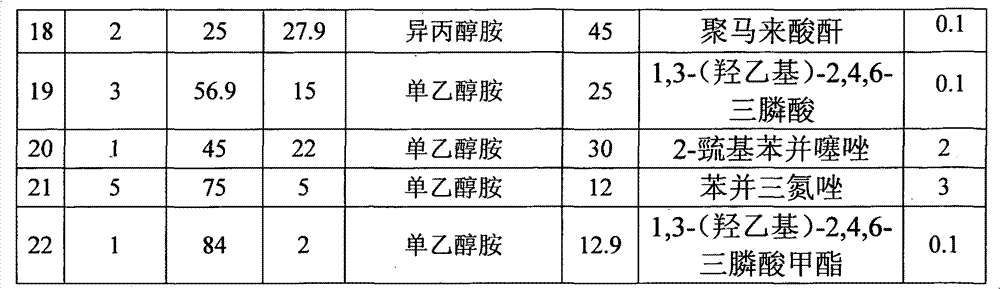

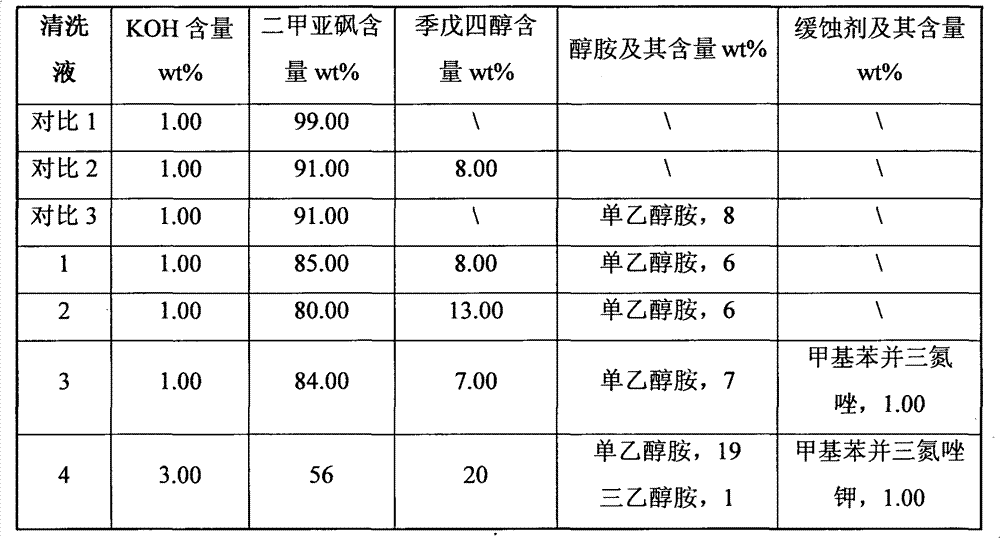

Embodiment 1~22

[0020] Table 1 shows the formulations of Examples 1 to 22. According to the formulations in Table 1, simply mix the ingredients uniformly to prepare the photoresist cleaning solution of each example.

[0021] The photoresist cleaning solution formula of table 1 embodiment 1~22

[0022]

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A cleaning composition for removing resist includes potassium hydroxide, dimethylsulfoxide, pentaerythritol, and alcohol amine. The cleaning composition may clean resist and other residue from a metal, metal alloy and dielectric substrate, and has low etch rate for a metal, such as Cu and the like.

Description

technical field [0001] The invention relates to a cleaning agent in a semiconductor manufacturing process, in particular to a photoresist cleaning agent. technical background [0002] In the usual semiconductor manufacturing process, a photoresist mask is formed on the surface of metals such as silicon dioxide, Cu (copper), and low-k materials, and pattern transfer is performed by wet or dry etching after exposure. In the wafer microsphere implantation process (bumping technology), a photoresist material (photoresist) is also required to form a mask, which also needs to be removed after the microspheres are successfully implanted, but due to the thicker photoresist , is often difficult to remove completely. The more common methods to improve the removal effect are to extend the soaking time, increase the soaking temperature and use more aggressive solutions, but this often causes corrosion of the wafer substrate and microspheres, resulting in a significant decrease in wafer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/42H01L21/02C23G1/06C11D1/83

CPCC11D7/06C11D7/34C11D11/0047G03F7/425G03F7/426C23F1/34C11D7/3218

Inventor 刘兵彭洪修史永涛

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com