Low etching photoresist cleaning agent and its cleaning method

A technology of photoresist and cleaning agent, which is applied in the fields of optics, photomechanical equipment, and photosensitive material processing, etc. It can solve the problems of semiconductor wafer substrate corrosion and other problems, and achieve the effect of obvious corrosion, strong cleaning ability, and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22

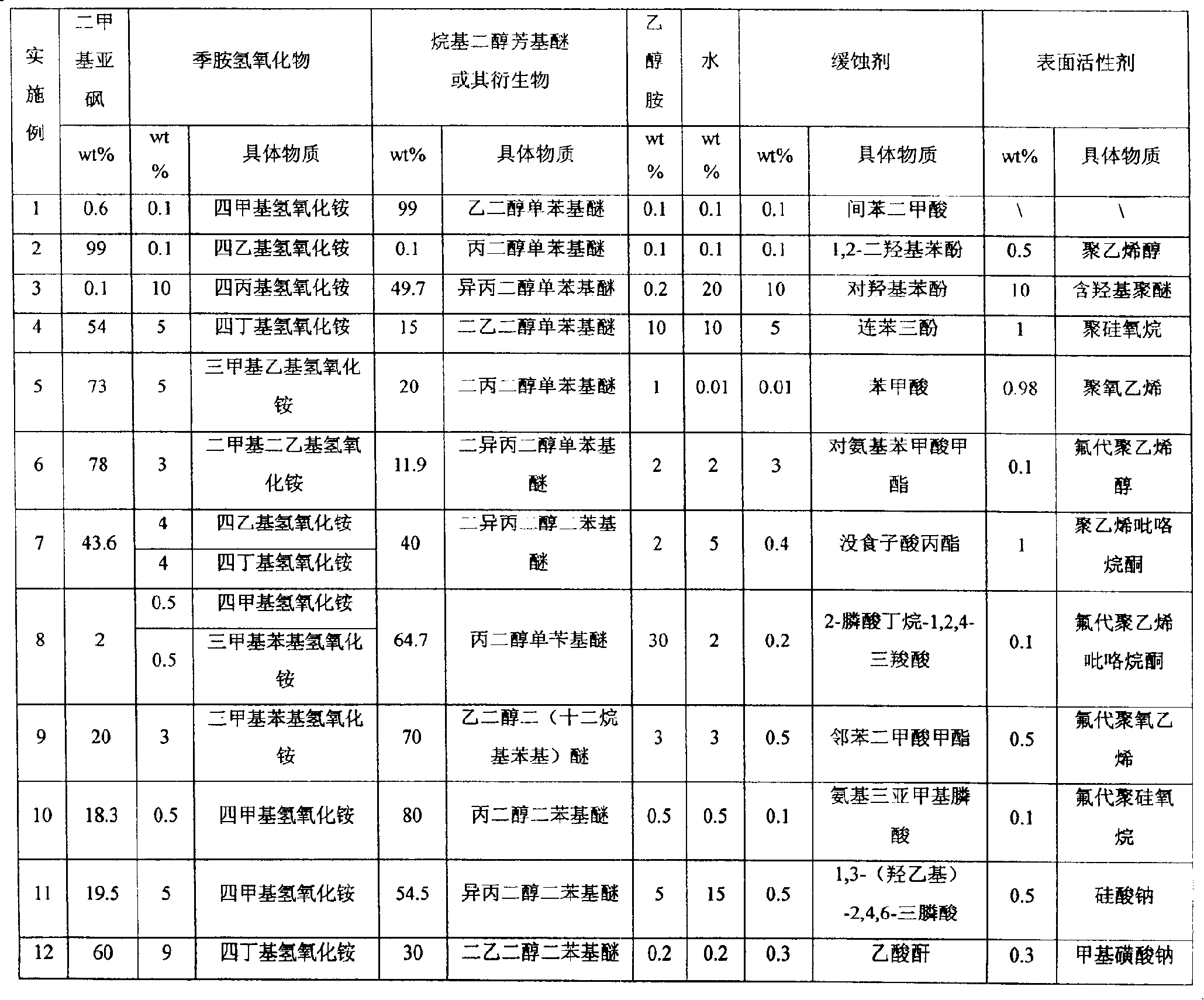

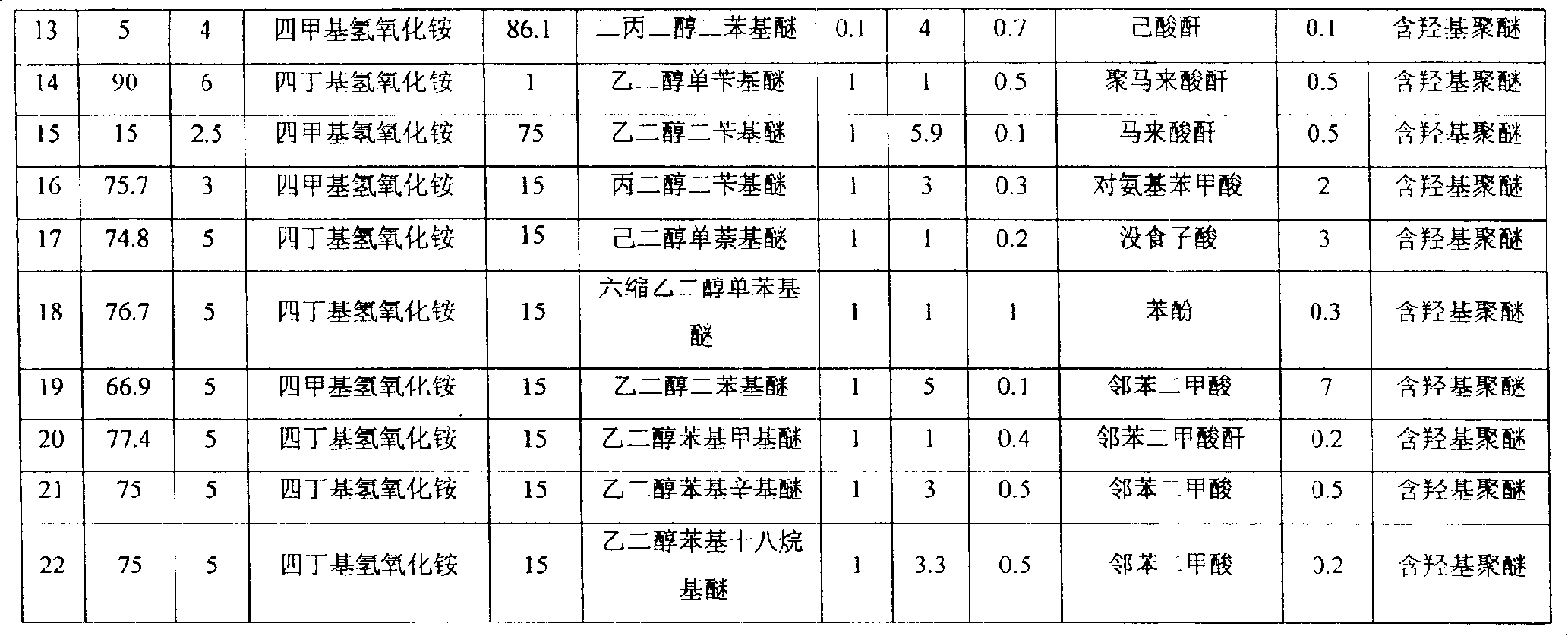

[0023] Embodiment 1~22 low etching property cleaning agent

[0024] Table 1 provides the composition formulations of the low-etching cleaning agent Examples 1-22. According to the formula in Table 1, the cleaning agent can be prepared by simply and uniformly mixing the components.

[0025] Table 1 Low Etching Cleaning Agent Example 1-22 Formula

[0026]

[0027]

Embodiment 1

[0042] Immerse the semiconductor wafer containing photoresist in a low-etching photoresist cleaning agent, wash it in batches at room temperature for 20 minutes, then wash it with deionized water, and then blow it dry with high-purity nitrogen.

Embodiment 2

[0044] Immerse the semiconductor wafer containing photoresist in a low-etching photoresist cleaning agent, clean it in batch rotation at 20°C for 30 minutes, then wash it with deionized water, and then blow it dry with high-purity nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com