Low-etching photoresist cleaning agent and cleaning method thereof

A photoresist and cleaning agent technology, used in optics, optomechanical equipment, photosensitive material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21

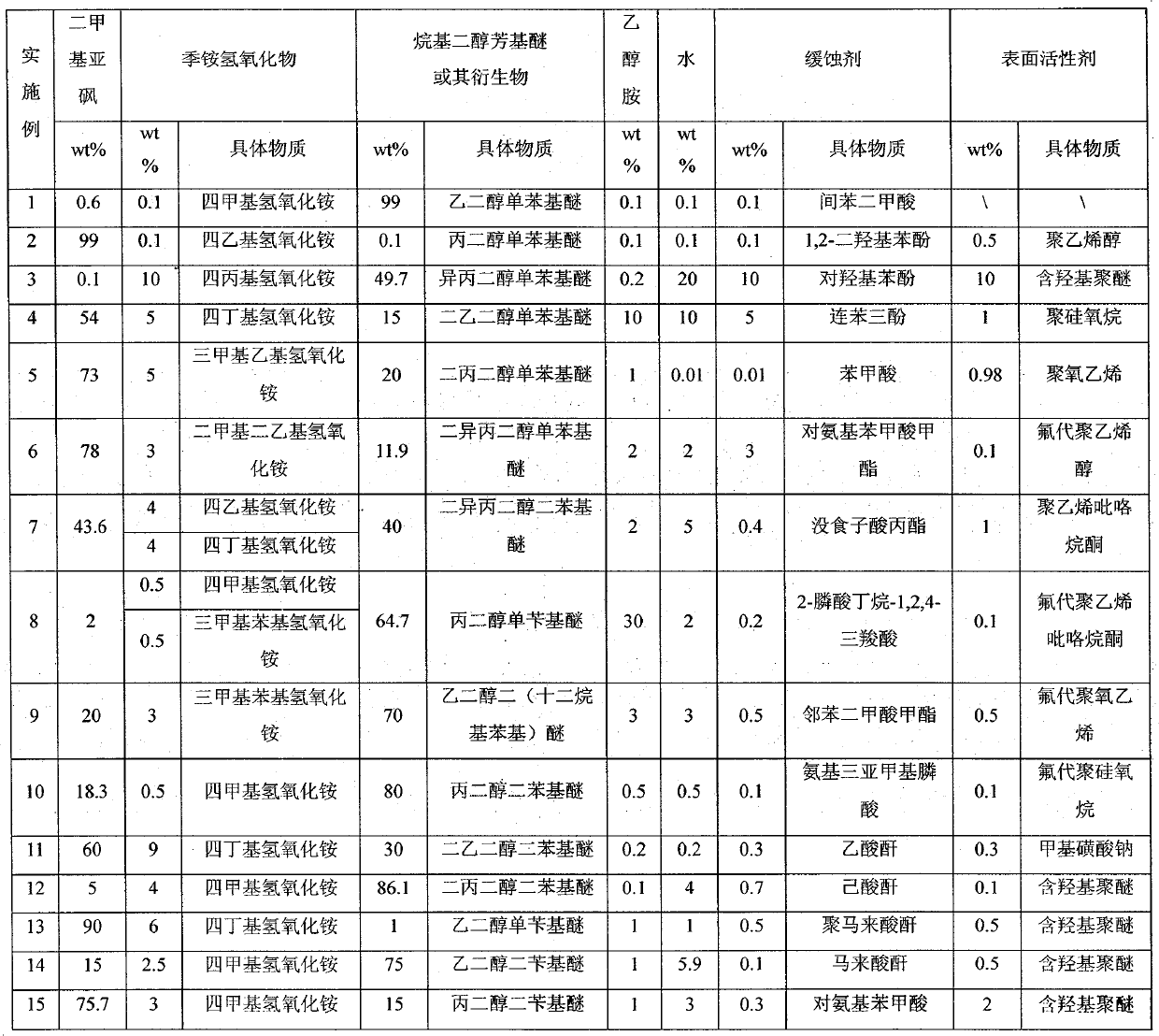

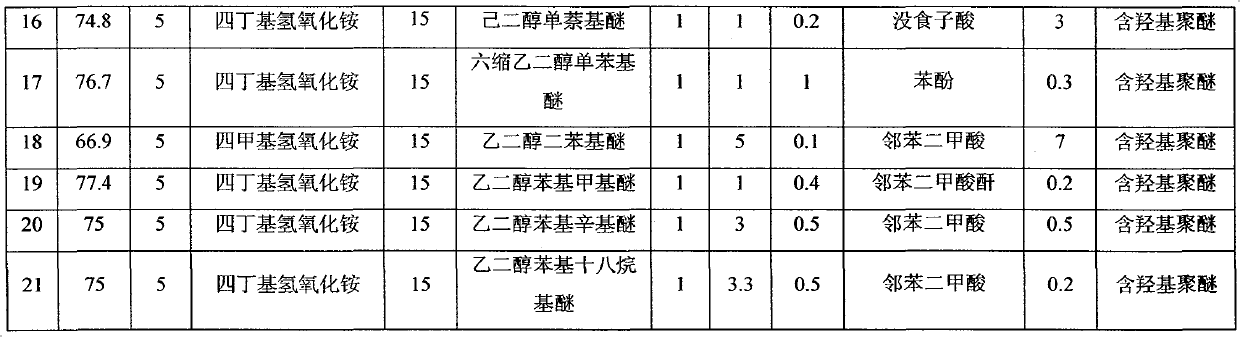

[0024] Embodiment 1~21 low etching property cleaning agent

[0025] Table 1 provides the composition formulations of the low-etch cleaning agent Examples 1-21. According to the formula in Table 1, the cleaning agent can be prepared by simply and uniformly mixing the components.

[0026] Table 1 low etch cleaning agent embodiment 1~21 formula

[0027]

[0028]

Embodiment 1

[0043] Immerse the semiconductor wafer containing photoresist in a low-etching photoresist cleaning agent, wash it in batches at room temperature for 20 minutes, then wash it with deionized water, and then blow it dry with high-purity nitrogen.

Embodiment 2

[0045] Immerse the semiconductor wafer containing photoresist in a low-etching photoresist cleaning agent, clean it in batch rotation at 20°C for 30 minutes, then wash it with deionized water, and then blow it dry with high-purity nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com