Functionalized graphene/water-borne epoxy resin composite coating with sandwich structure and preparation method thereof

A water-based epoxy resin and composite coating technology, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor anti-corrosion performance, poor hydrophobicity, and low hardness of the paint film, and achieve novel material structure. Integrity, the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

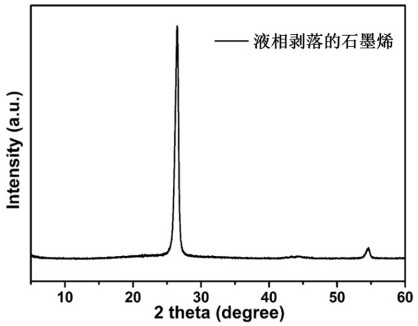

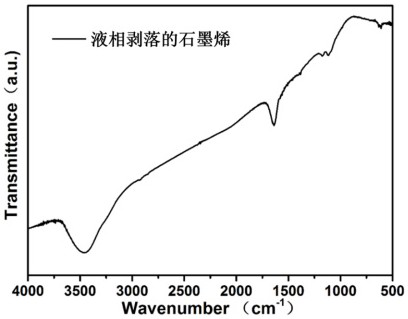

[0038] Preparation of step S1 liquid phase exfoliated graphene:

[0039] Add 200 mg of flake graphite and 200 mL of N-methyl-2-pyrrolidone into a 250 mL beaker, and obtain N-methyl-2-pyrrolidone suspension containing flake graphite after ultrasonication for 30 min. The suspension was then placed in a 60 °C water bath and stirred vigorously for 2 h. After cooling to room temperature, it was ultrasonically treated at a low power of 40 W for 24 h, and then the exfoliated graphene dispersion was centrifuged, washed with methanol, and dried in an oven at 50 °C.

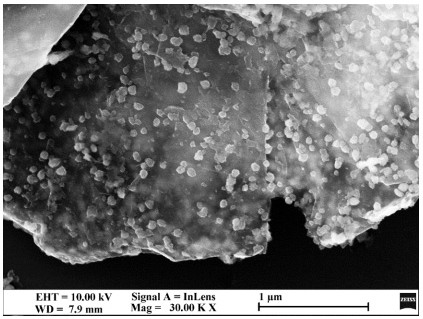

[0040] Preparation of insulating graphene wrapped in step S2 polydopamine:

[0041]Take 100 mg of liquid-phase exfoliated graphene and add it to a beaker containing 200 mL of deionized water, then gradually add tris to adjust the pH to 8.5, and perform ultrasonic treatment for 30 minutes to obtain a liquid-phase exfoliated graphene dispersion. Then add 200 mg of dopamine hydrochloride therein, and continue to sonicate fo...

Embodiment 2

[0047] Preparation of step S1 liquid phase exfoliated graphene:

[0048] Add 200 mg of flake graphite and 200 mL of N-methyl-2-pyrrolidone into a 250 mL beaker, and obtain N-methyl-2-pyrrolidone suspension containing flake graphite after ultrasonication for 30 min. The suspension was then placed in a 60 °C water bath and stirred vigorously for 2 h. Then, after it was cooled to room temperature, it was ultrasonically treated at a low power of 40 W for 24 h, and then the exfoliated graphene dispersion was centrifuged, washed with methanol, and dried in an oven at 50 °C.

[0049] Preparation of insulating graphene wrapped in step S2 polydopamine:

[0050] Take 100 mg of liquid-phase exfoliated graphene and add it to a beaker containing 200 mL of deionized water, then gradually add tris to adjust the pH to 8.5, and perform ultrasonic treatment for 30 minutes to obtain a liquid-phase exfoliated graphene dispersion. Then add 200 mg of dopamine hydrochloride therein, and continue t...

Embodiment 3

[0056] Preparation of step S1 liquid phase exfoliated graphene:

[0057] Add 200 mg of flake graphite and 200 mL of N-methyl-2-pyrrolidone into a 250 mL beaker, and obtain N-methyl-2-pyrrolidone suspension containing flake graphite after ultrasonication for 30 min. The suspension was then placed in a 60 °C water bath and stirred vigorously for 2 h. Then, after it was cooled to room temperature, it was ultrasonically treated at a low power of 40 W for 24 h, and then the exfoliated graphene dispersion was centrifuged, washed with methanol, and dried in an oven at 50 °C.

[0058] Preparation of insulating graphene wrapped in step S2 polydopamine:

[0059] Take 100 mg of liquid-phase exfoliated graphene and add it to a beaker containing 200 mL of deionized water, then gradually add tris to adjust the pH to 8.5, and perform ultrasonic treatment for 30 minutes to obtain a liquid-phase exfoliated graphene dispersion. Then add 200 mg of dopamine hydrochloride therein, and continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com