Pipe type hydraulic fluid muffler

A technology of hydraulic fluid and muffler, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of hydraulic system noise, etc., and achieve the effect of reducing noise and vibration, novel structure, and reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

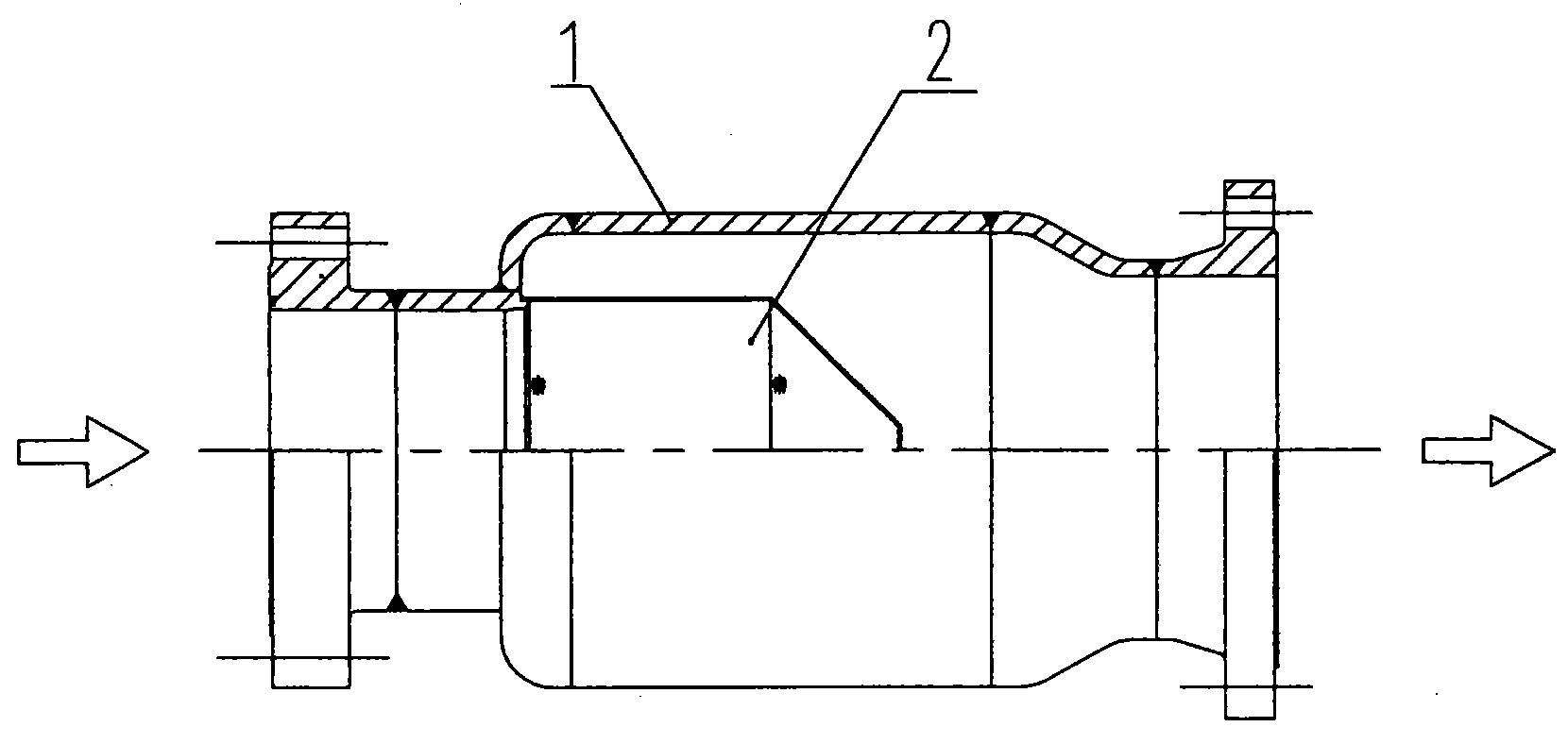

[0017] Such as figure 1 As shown, a pipe-type hydraulic fluid muffler is composed of a muffler shell 1 and a muffler main body 2 , and the muffler main body 2 is welded and installed in the muffler shell 1 . It is worth noting that in the manufacturing process, the muffler main body 2 must be welded to the connecting pipe 4 of the muffler housing 1 before welding other parts of the muffler housing 1 can be completed.

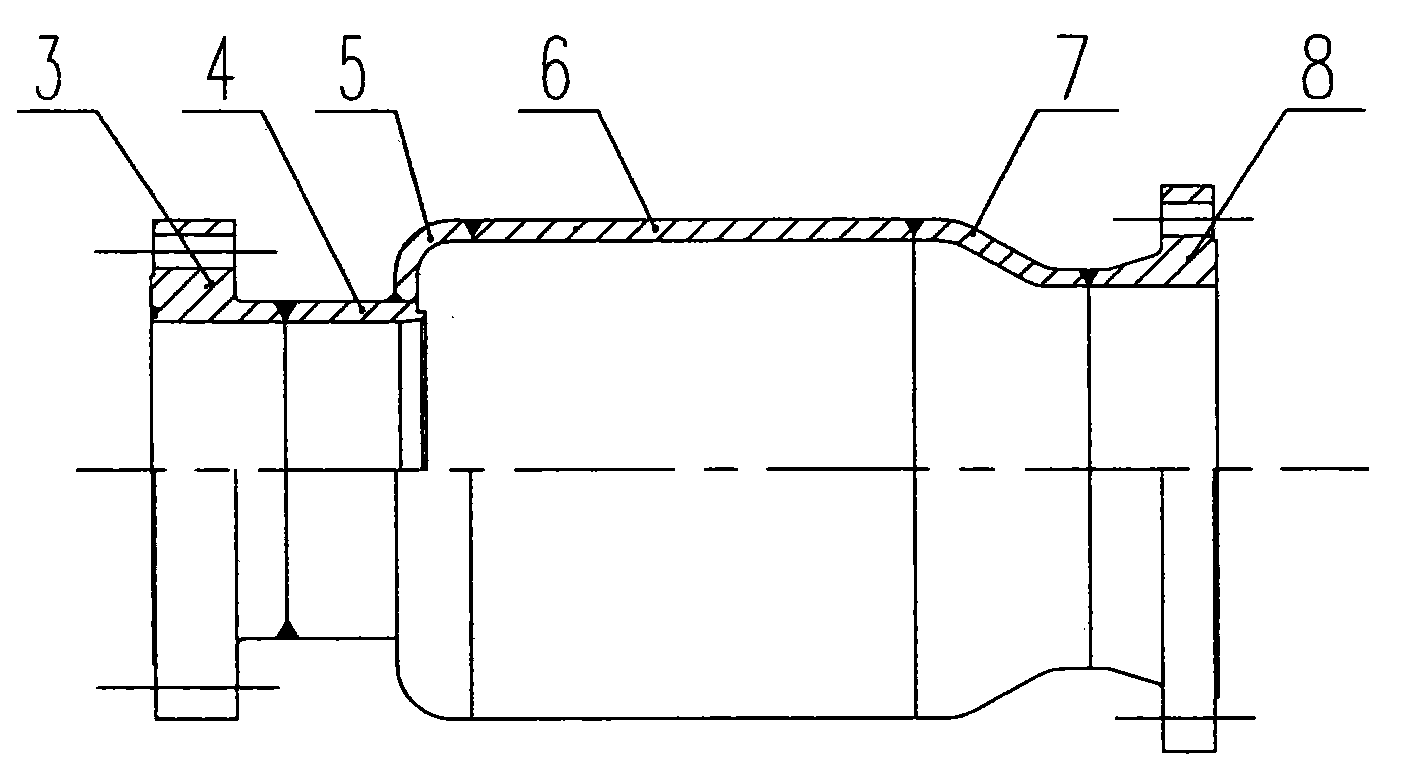

[0018] Such as figure 2 As shown, the muffler shell 1 is composed of an inlet flange 3, a connecting pipe 4, an arc joint 5, a cylinder body 6, a variable diameter joint 7 and an outlet flange 8, and these parts are connected together by welding to form the muffler shell 1 , its inner cavity is a smooth transition without sharp corners, and the inlet flange 3 and outlet flange 8 are used to connect the hydraulic pipes at both ends in series.

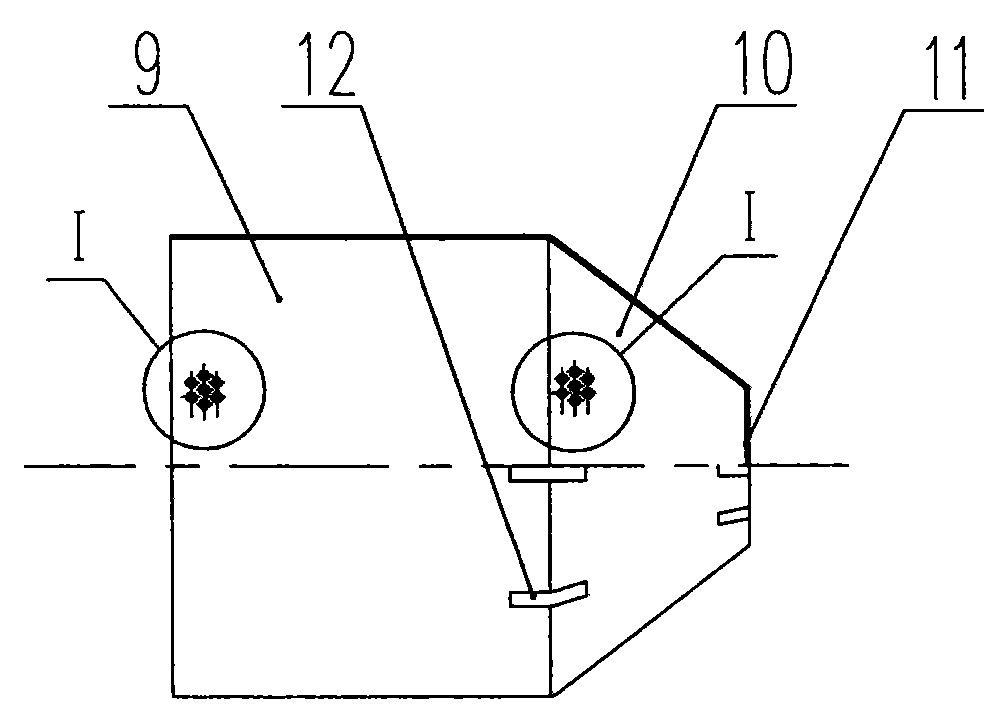

[0019] Such as image 3 As shown, the muffler main body 2 is composed of a porous cylinder 9 , a porous conical cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com