Universal orthogonal coupling

A coupling and shaft hole technology, which is applied in the field of universal orthogonal couplings, can solve the problems of small compensation amount, large compensation amount, and inability to compensate for inter-shaft runout, and achieve small shaft end distance, large compensation amount, and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

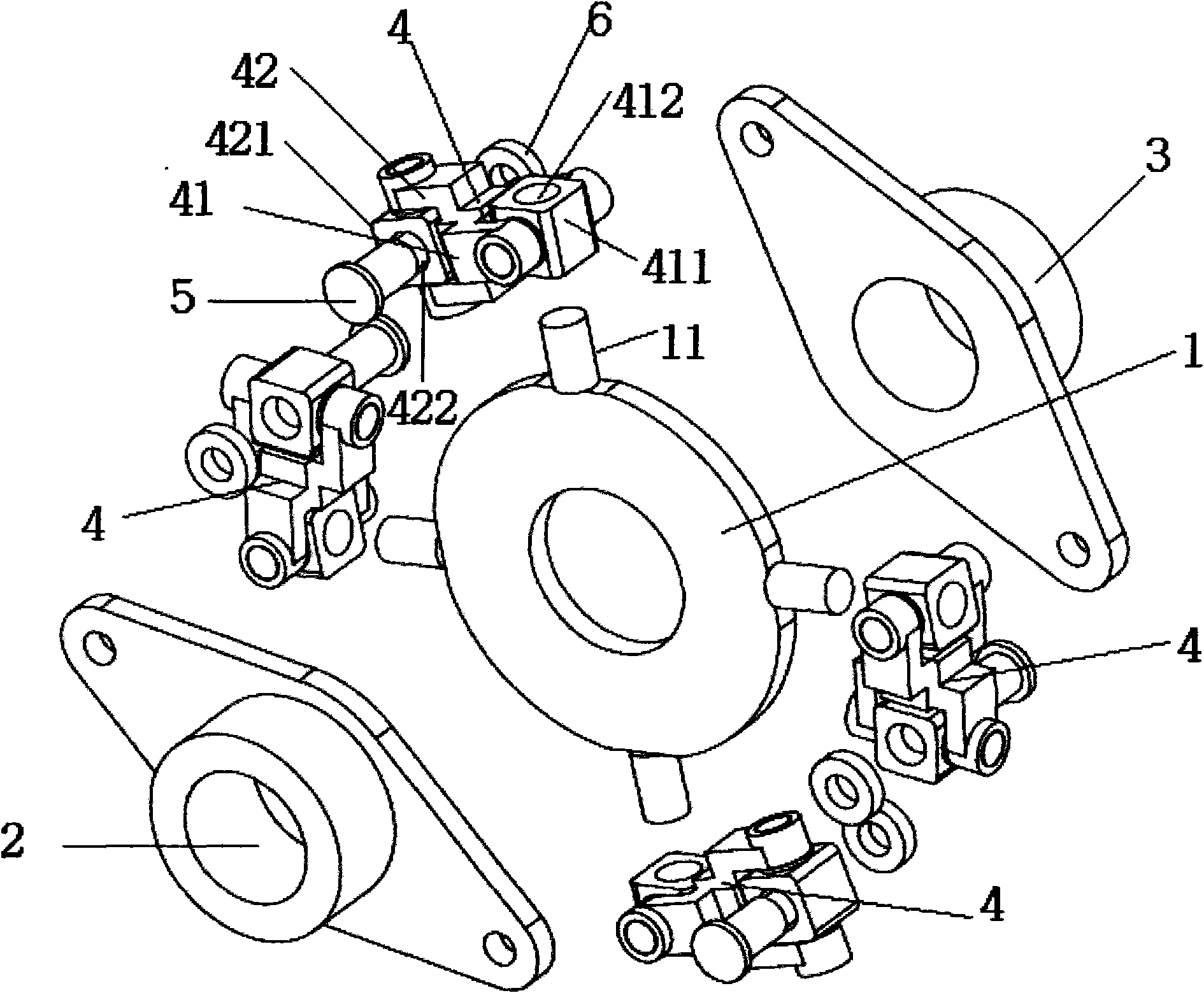

[0034] see figure 1 As shown, a universal orthogonal shaft coupling, a universal orthogonal shaft coupling, includes an intermediate support 1, an input shaft seat 2 and an output shaft seat 3, the input and output shaft seats 2, 3 is a structure with a fixed pin shaft hole at both ends and a shaft hole in the middle;

[0035] The input and output shaft seats 2, 3 are cross-connected to the intermediate support 1 through a movable joint 4;

[0036] The movable joint 4 includes a first (℈)-shaped structure 41 and a second (℈-shaped) structure 42 that are fixedly connected, and the connection mode of the two (℈-shaped) structures 41, 42 is that the opening directions are opposite and the opening surfaces are perpendicular to each other;

[0037] The two arms of the first (℈)-shaped structure 41 are connected with a first joint 411 through a movable shaft, and the first joint 411 has a first connecting shaft hole 412;

[0038] The two arms of the second (℈)-shaped structure 42 ...

Embodiment 2

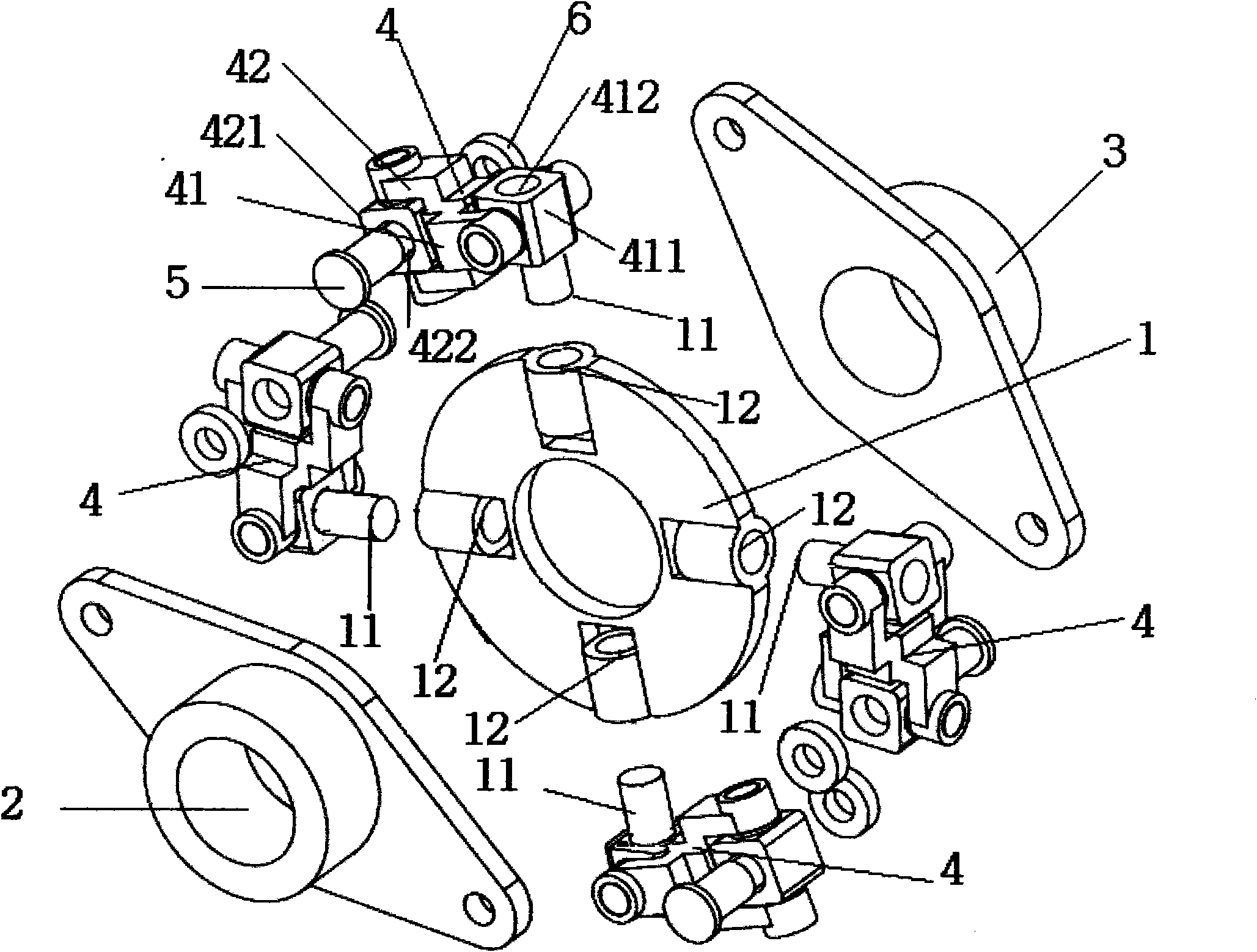

[0043] see figure 2 As shown, the structure of this implementation is basically the same as that of the embodiment, except for the following preferred modes.

[0044] Preferably, the intermediate bracket 1 is an annular cross structure with four connecting shaft holes 12 that are divided into four equal parts along the circumference and are orthogonal to the central axis of the intermediate bracket 1 . The two ends of a connecting shaft 11 The first connecting shaft hole 412 and the connecting shaft hole 12 are connected respectively, so that the first joint 411 and the intermediate bracket 1 are connected to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com