Novel food moulding judging method

A new method and food technology, applied in the new field of food mildew evaluation, can solve the problems of single index, lagging control of the measured object, weak fat content, etc., and achieve the effect of expanding the scope of application, comprehensive evaluation and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Early warning of mildew of peanut powder obtained by crushing peanut seeds

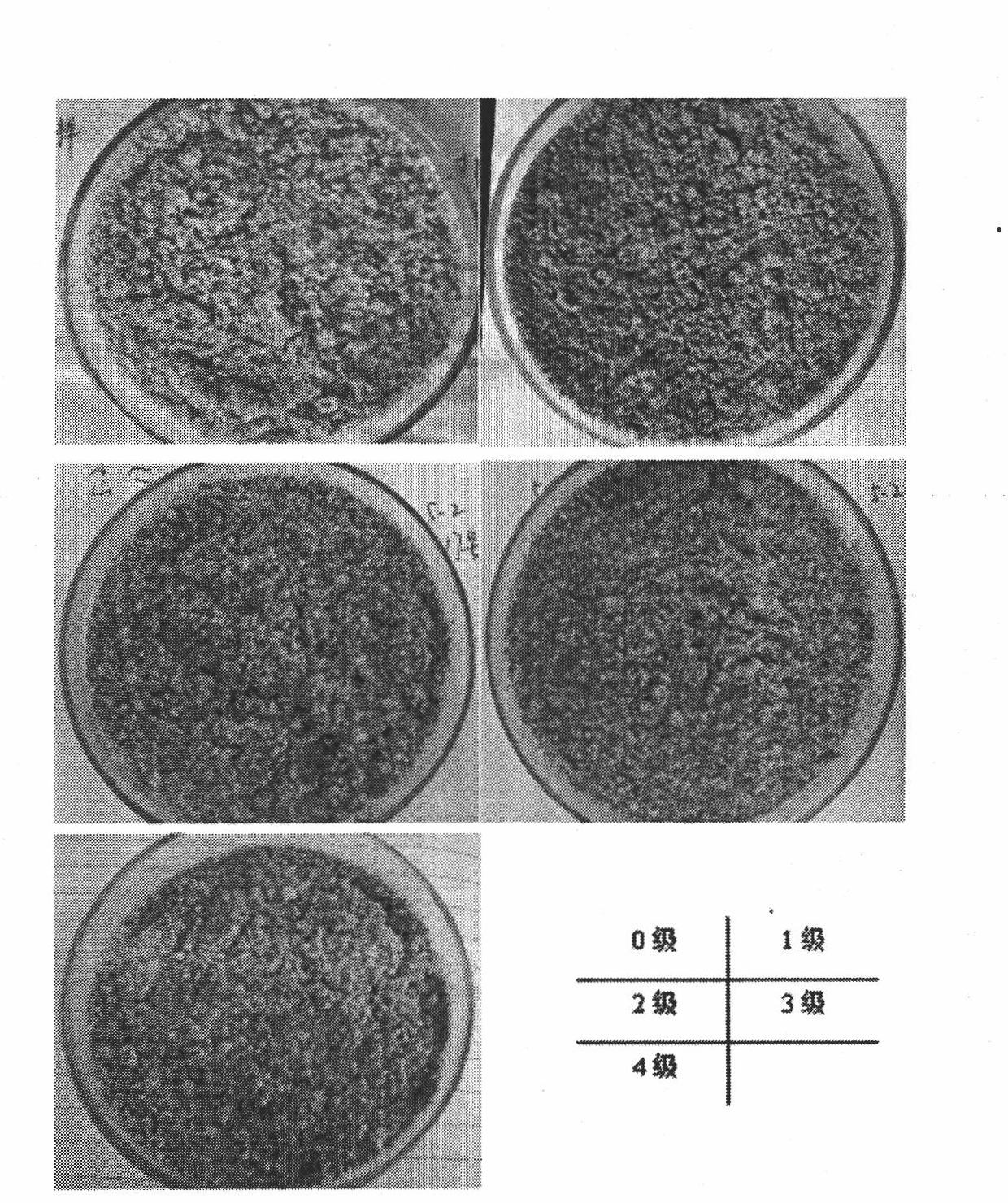

[0032] According to the method of the present invention, the mildew of peanut powder is divided into 5 grades; grade 0 is fresh peanuts with bright color and no mold growth; grade 1 peanuts begin to darken in color, mold growth and reproduction are rare, and dots can be seen on the surface of peanuts The surface of grade 2 peanuts is relatively moist, and the mold is evenly distributed on the surface of peanuts, and no colonies have yet formed; the color of grade 3 peanuts continues to darken, the surface begins to agglomerate, mold grows and reproduces in large numbers, and a large number of colonies appear; grade 4 peanuts deteriorate , the surface becomes dry, the color becomes light, a large number of agglomerates, mold grows and reproduces in large numbers, and the surface of peanuts is completely covered by mold.

[0033] Real-time detection of total flavonoids, proteins, lipid...

Embodiment 2

[0038] Example 2: Banana mildew warning

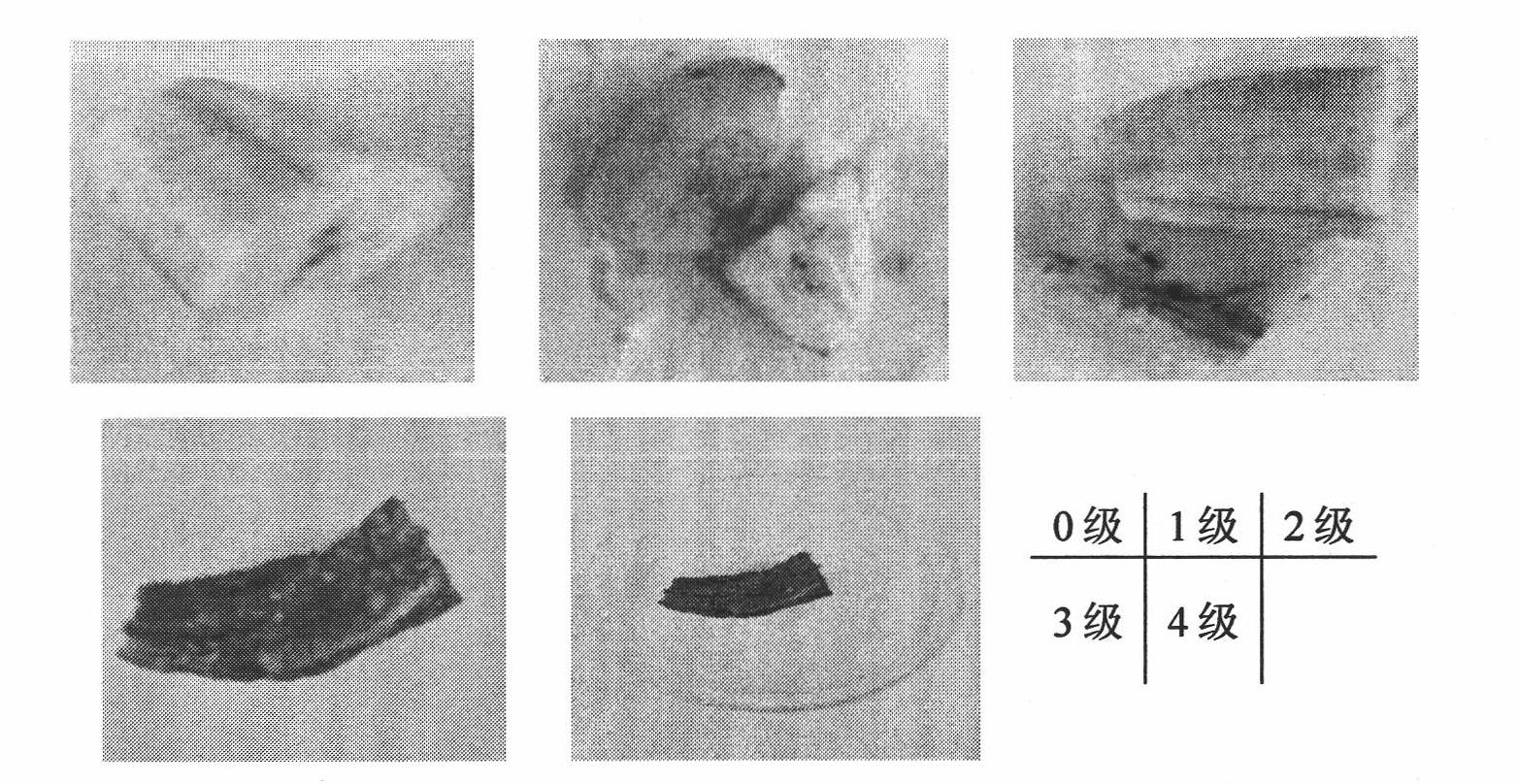

[0039]According to the method of the present invention, the mildew and rot of bananas is divided into 5 grades; grade 0 bananas are not rotten, the fruit is full, the peel is golden yellow, the flesh is firm, and there is no softening phenomenon; the bananas of grade 1 are slightly rotten, the overall color of the peel is dim, and black appears on the surface Spots, softened flesh, part of the flesh began to lighten and become transparent; Grade 2 bananas were moderately rotten, the peel hardened and turned black, the flesh was moderately softened and sticky, the color became dark, and no mold spots; Grade 3 bananas were severely rotten, and the peel hardened , blackened, the pulp is severely softened, blackened, and moldy; grade 4 bananas are severely moldy, at this time, the surface of the banana is dark brown, the inside is yellowish brown, the surface is faintly distributed with green mold spots, and there are white pili around the ...

Embodiment 3

[0045] Example 3: Early warning of spinach mildew

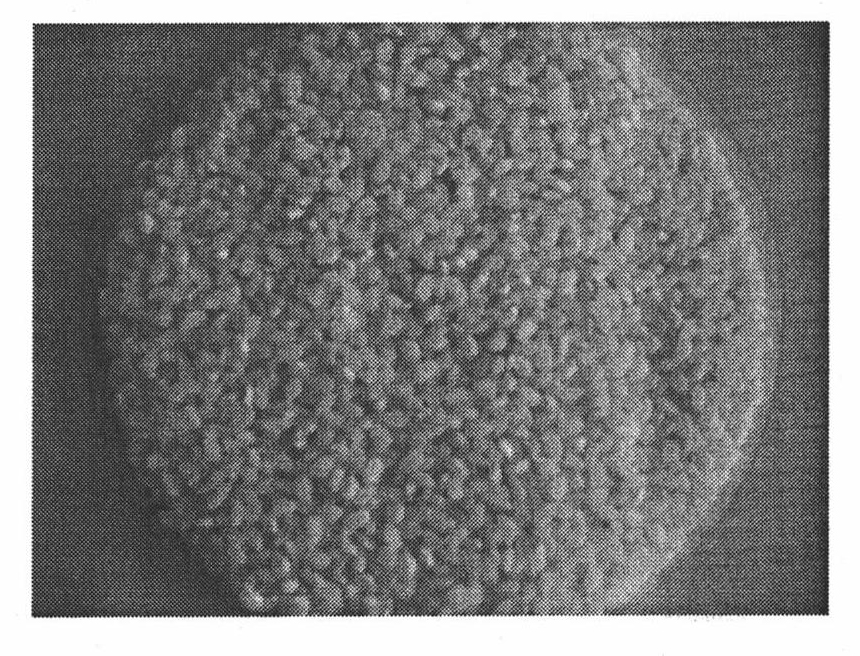

[0046] According to the method of the present invention, the mildew and rot of spinach is divided into 5 grades; the spinach of grade 0 is plump, hard, bright green, and shiny; Yellowing, shrinking, mild rot; Grade 3 moderate rot, mildew; Grade 4 spinach severe rot, severe mildew.

[0047] The content of reducing sugar, vitamin C, and amino acid in spinach was detected in real time, and the early warning indicators of spinach mildew were obtained according to the change trend and change process of the detected components, as shown in Table 4.

[0048] Table 4 Changes and early warning indicators of chemical components related to spinach mildew process

[0049]

[0050] It can be seen from Table 4 that when all the detection indicators are near the early warning indicators or limit values, the spinach mildew early warning signal can be issued.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap