Cleaning device for looms

A technology for cleaning equipment and looms, used in auxiliary equipment for weaving, textiles, textiles, and papermaking, etc., and can solve problems such as broken yarns and contaminated fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

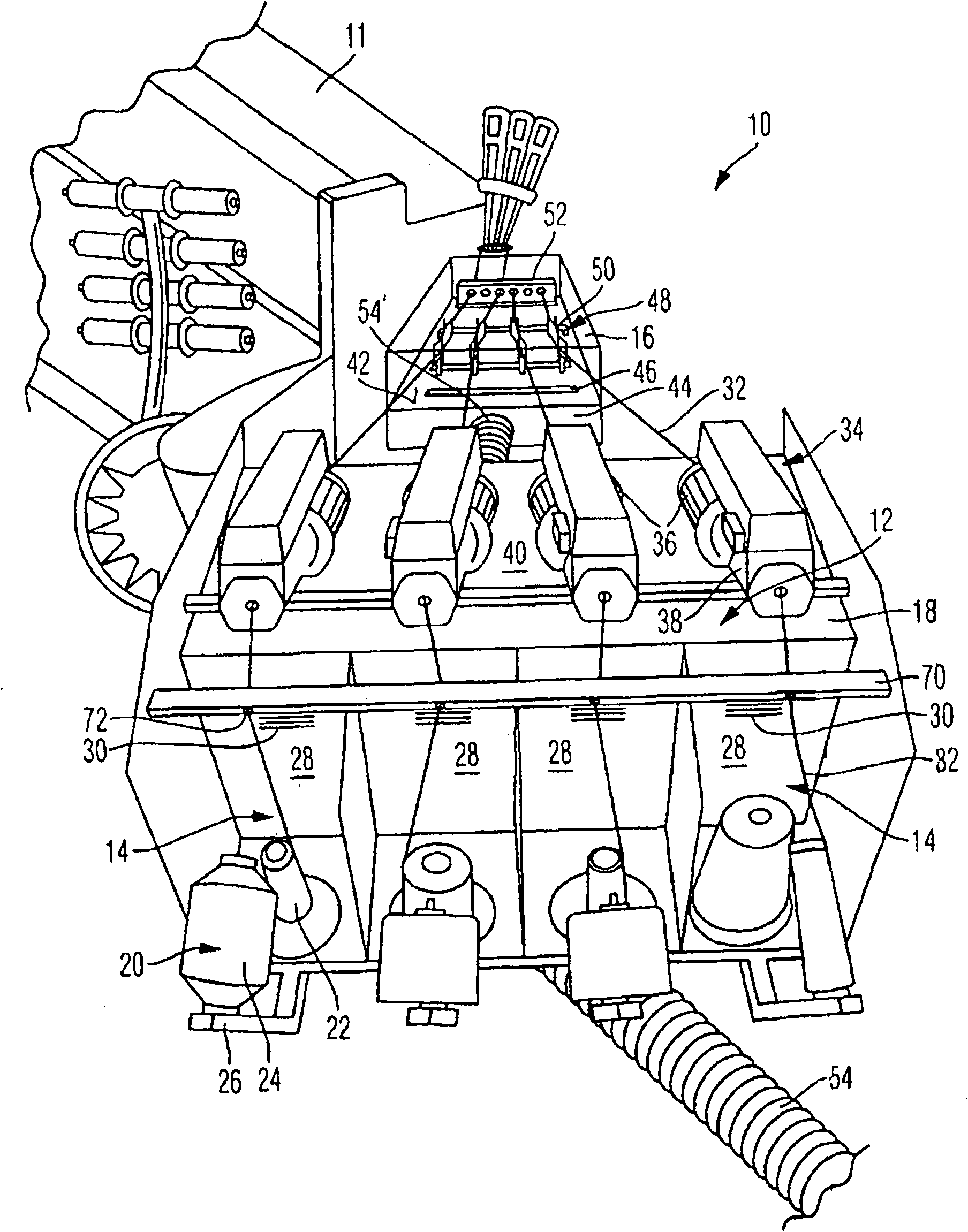

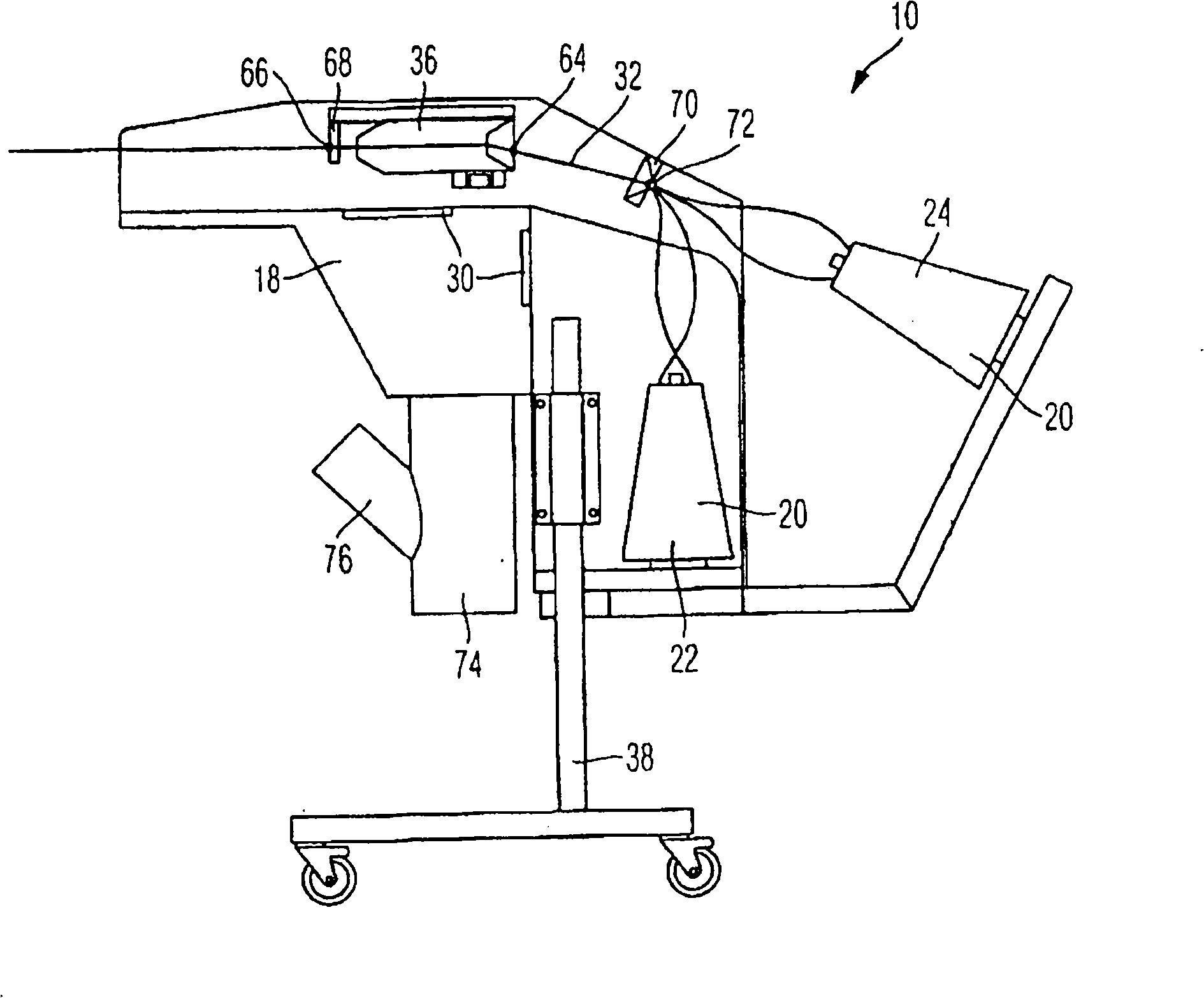

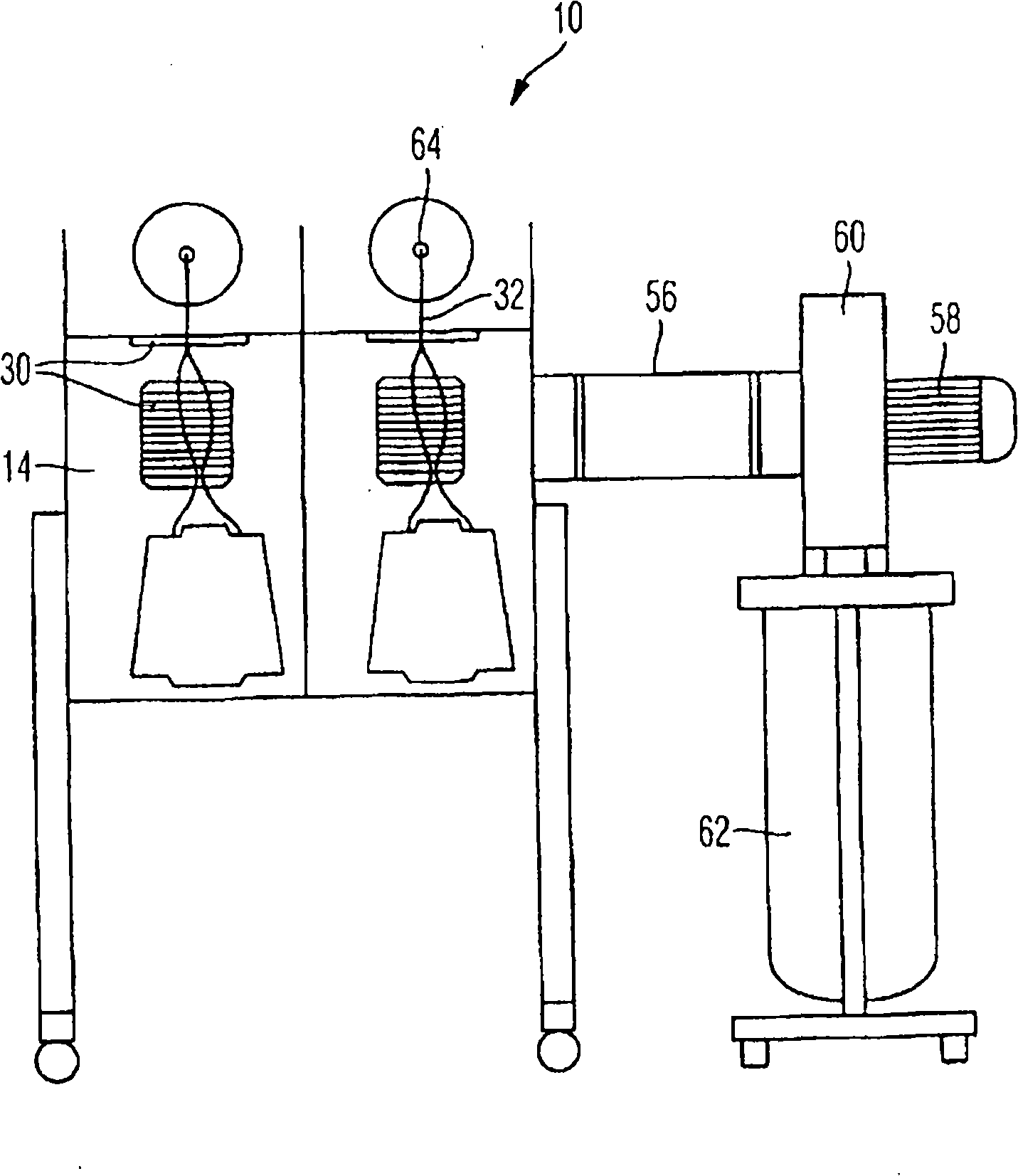

[0028] figure 1A cleaning device 10 according to the invention for a weaving machine 11 is shown, which comprises a discharge or suction device 12 . The discharge or suction device 12 has four open housings 14 which are connected to a common suction connection box 18 . In each housing 14 is accommodated a yarn supply system 20 which each has a first yarn supply reel and a second yarn feed reel, ie a weft reel 22 and a reserve reel 24 . Each housing 14 is designed as an open housing and each has three side walls and a bottom wall on which the weft cylinder 22 is mounted. The storage cylinder 24 is arranged obliquely to the weft cylinder 22 , and the storage cylinder 24 is mounted on a bracket 26 disposed obliquely to the bottom wall of the housing 14 .

[0029] Each of the four housings 14 has a common side wall 28 with the suction connection box 18 , which is provided with a suction opening 30 . The suction openings 30 are formed as slots in the upper part of the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com