Sectional-type main beam and semitrailer underframe with same

A segmented, semi-trailer technology, applied to vehicle components, substructure, transportation and packaging, etc., to improve transportation efficiency and ensure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

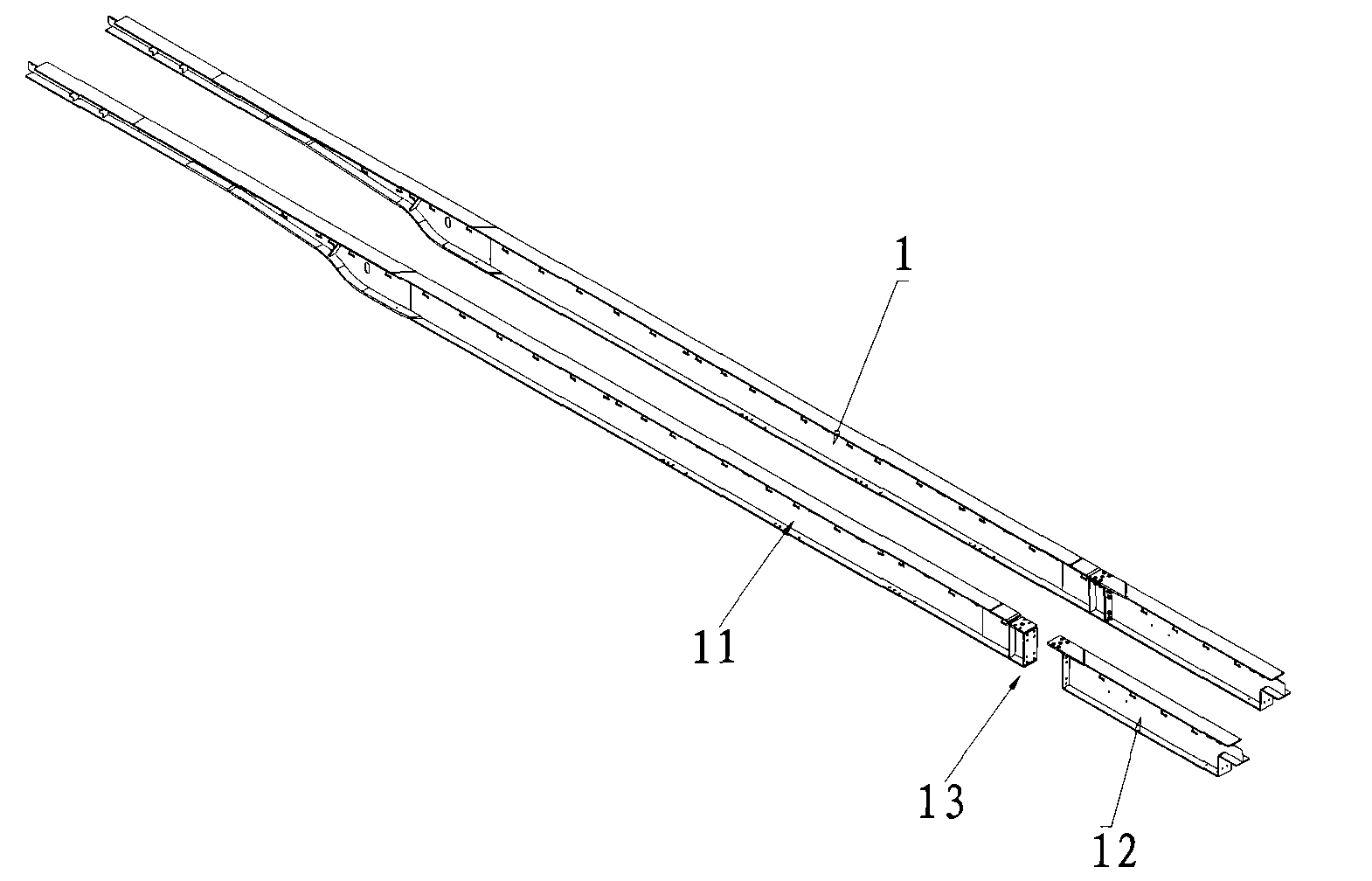

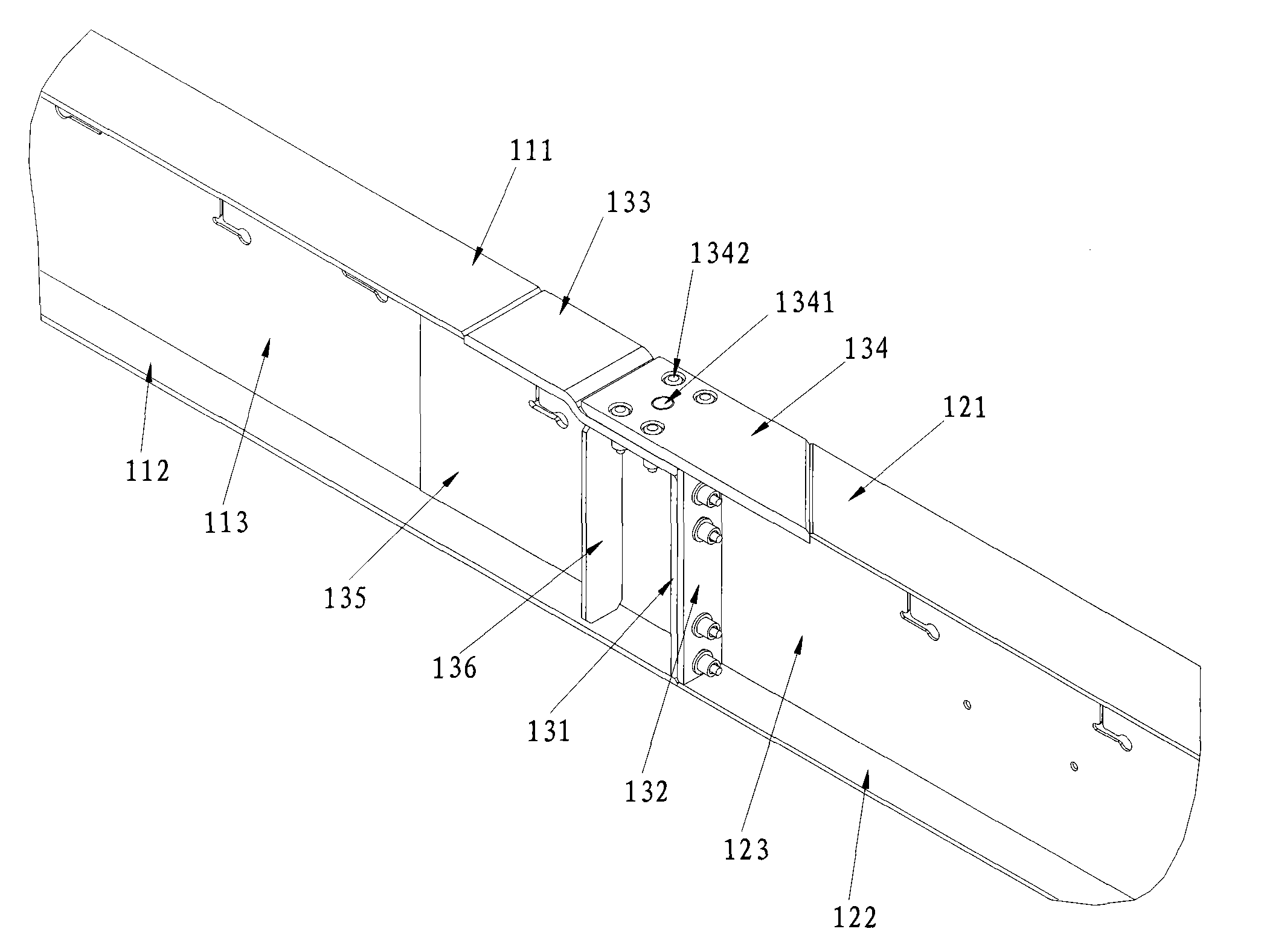

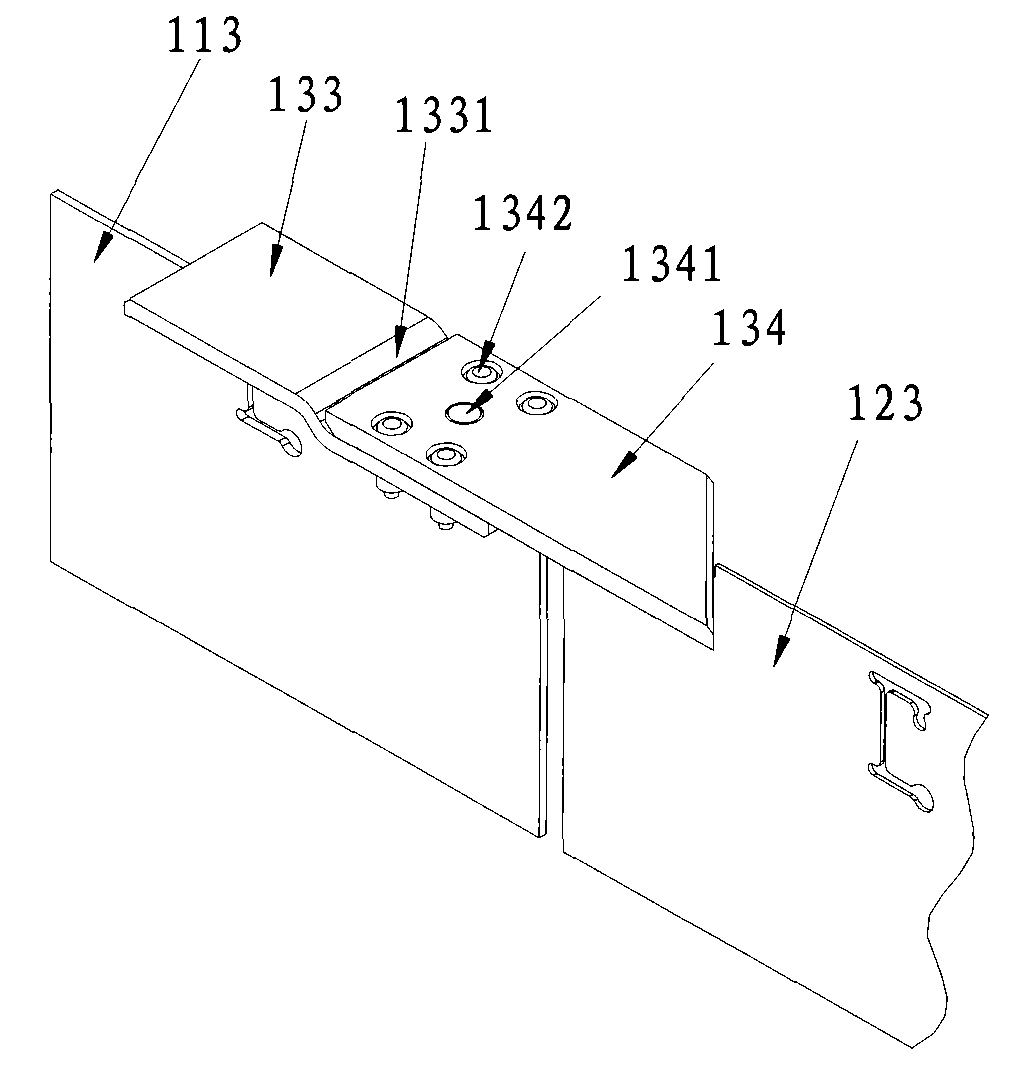

[0023] refer to figure 1 , figure 2 , which is a structural schematic diagram of the first embodiment of the segmented main beam of the present invention. In this embodiment, the segmented main beam 1 is to cut off the existing integrated main beam at a distance of 11000 mm to 12000 mm from the front end of the chassis The two parts are detachably connected by a connecting structure, which includes: a first part 11, a second part 12 and a connecting part 13, and the first and second parts 11 and 12 each include an upper wing Plates 111 , 121 , lower wings 112 , 122 and a web 113 , 123 vertically connected between the upper and lower wings 111 , 121 , 112 , 122 . The connecting part 13 detachably connects the first and second parts 11, 12 together, so that the segmented main girder 1 can be cut into two sections in the length direction and loaded into stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com